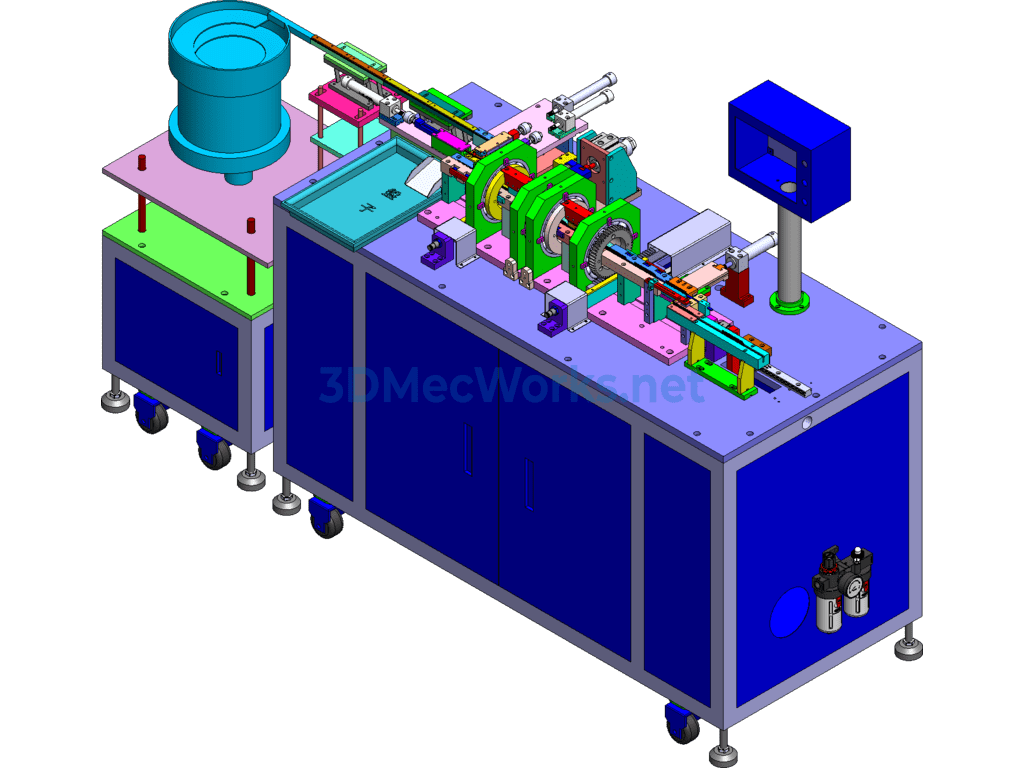

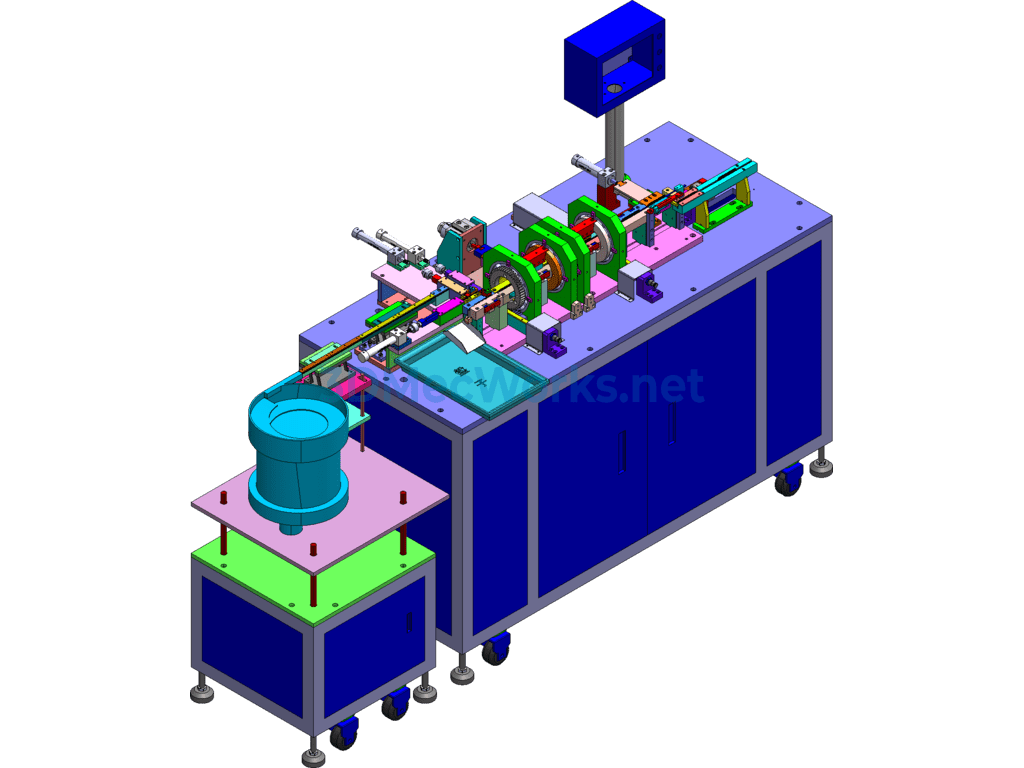

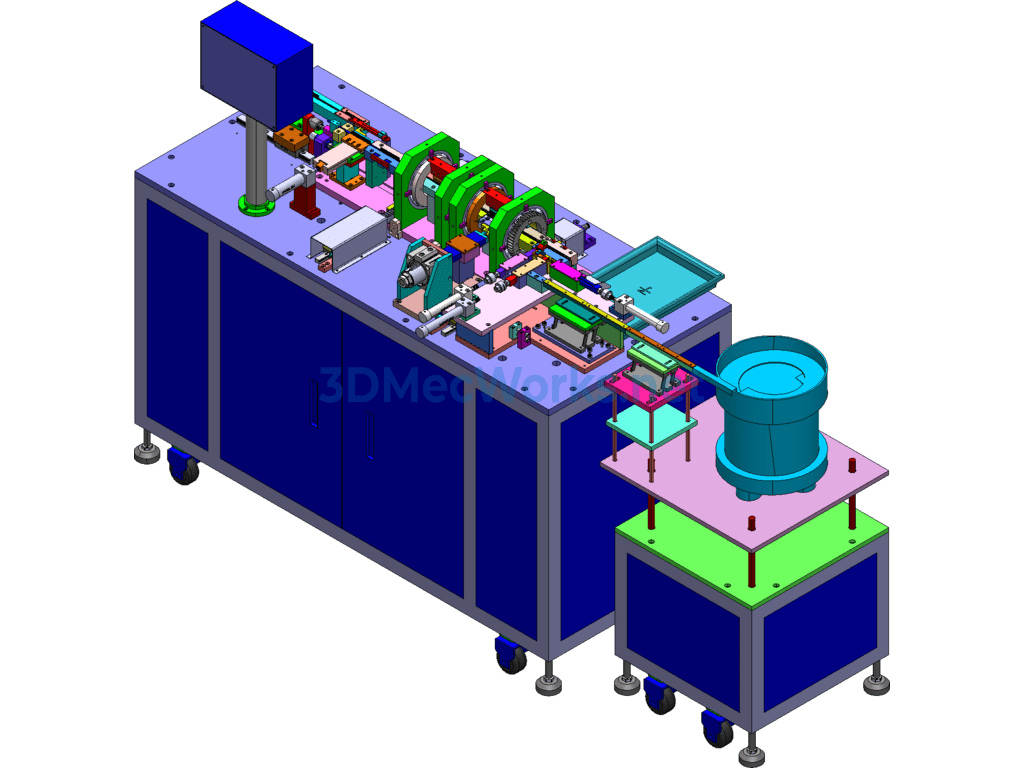

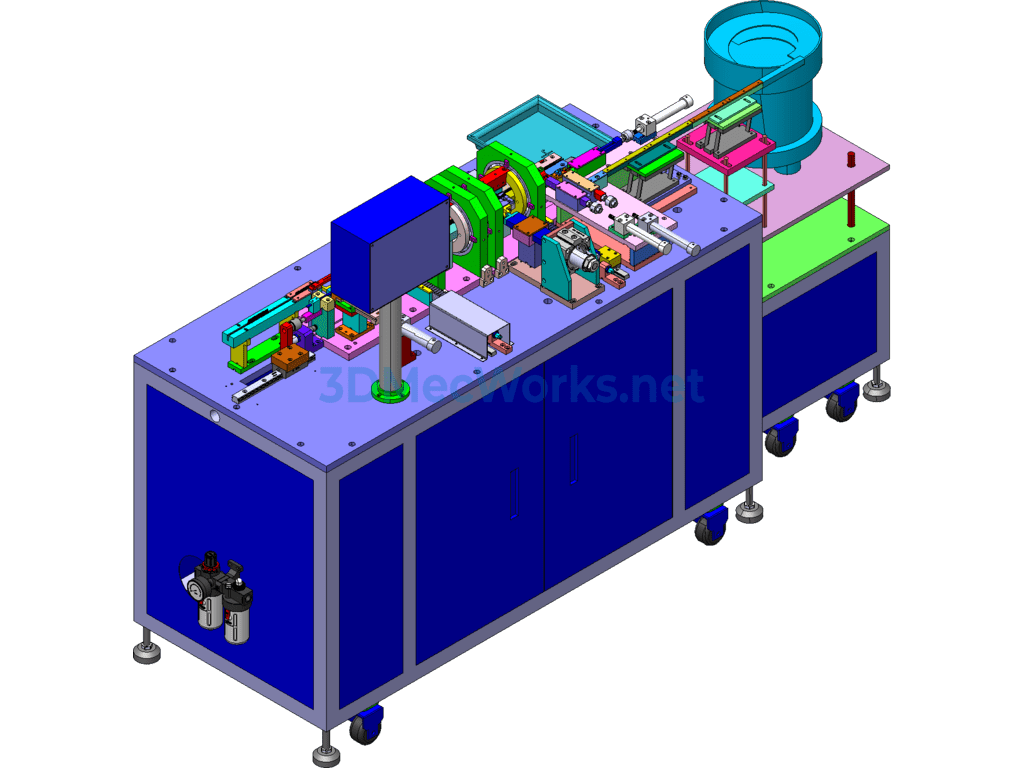

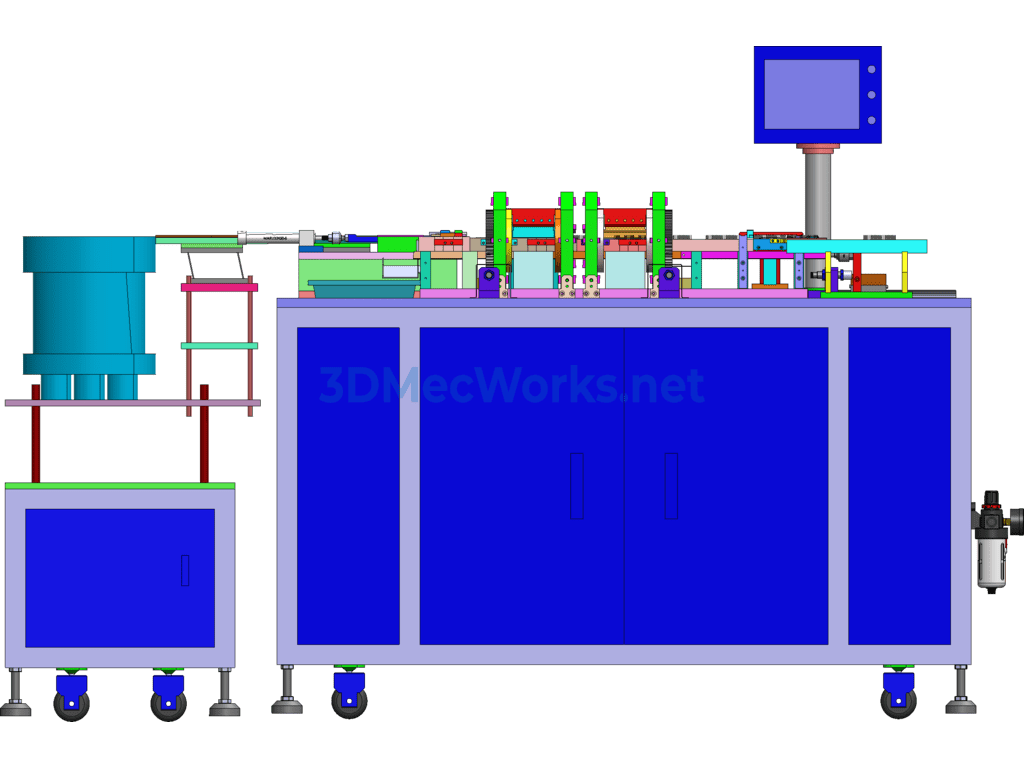

A connector bending forming machine, the loose pin terminals have been assembled. This machine is used to bend terminals at a 90-degree angle, bending two rows of terminals. After bending, a small plastic component is added, which is fed by a vibration plate. The product is manually placed at the front section, and fiber optics are used to sense material movement. After feeding, the bending is done, driven by a rack to bend around the center. The finished product has extremely high stability and the angle can be freely adjusted. The structure for adding the small plastic is compact and is a classic original creation. Drawn in SolidWorks 2012, the machine’s parts include parameters that can be freely edited for reference by everyone!

Specification: Automated Terminal Connector Bending and Forming Plastic Machine

|

User Reviews

Be the first to review “Automated Terminal Connector Bending and Forming Plastic Machine”

You must be logged in to post a review.

There are no reviews yet.