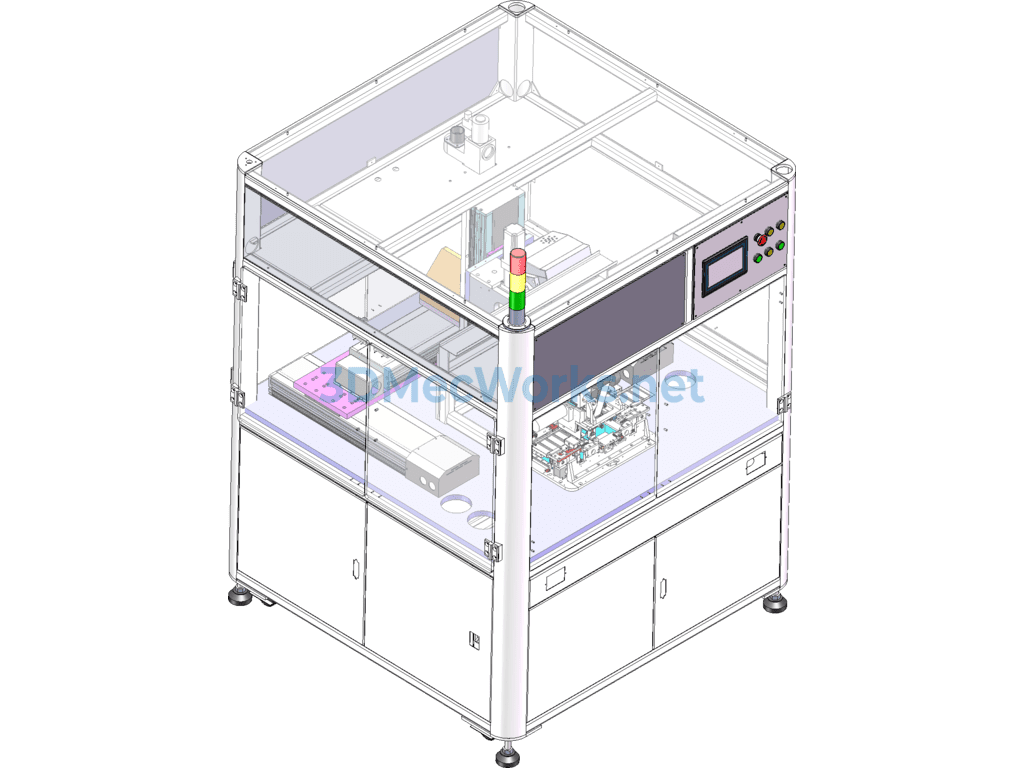

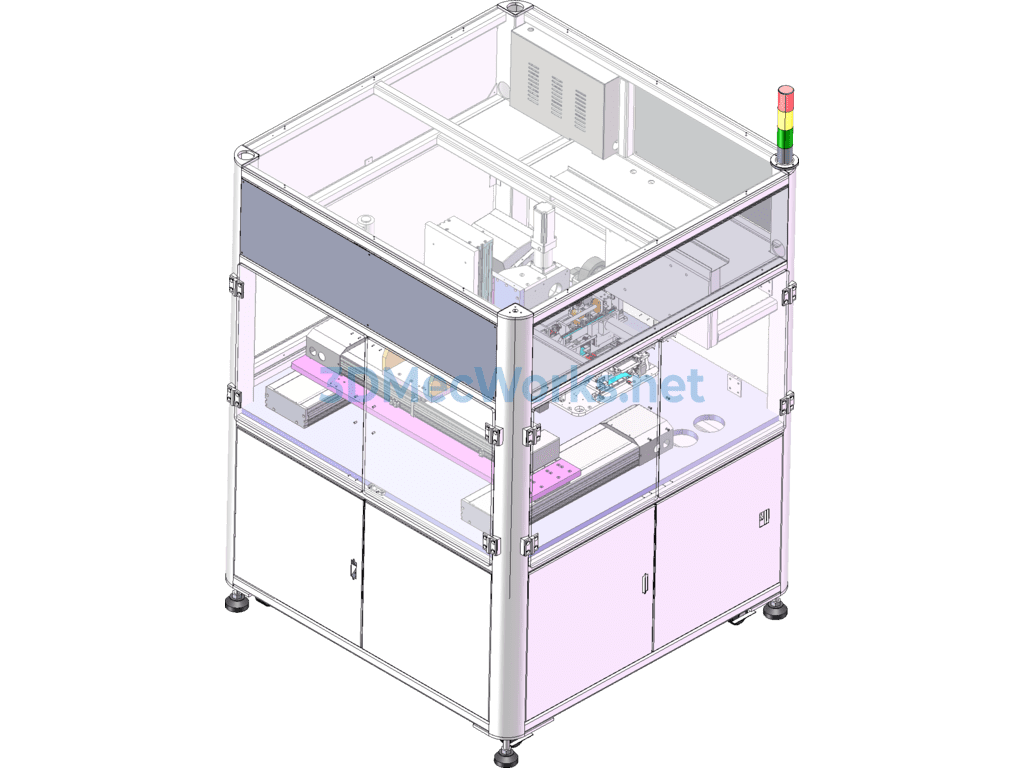

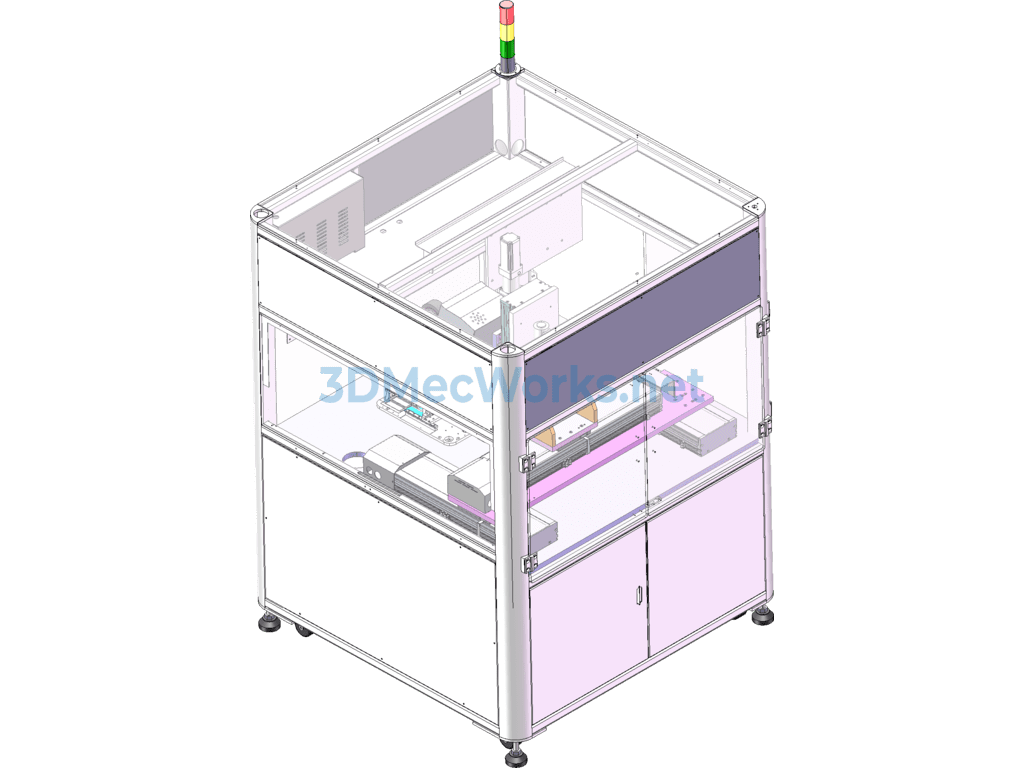

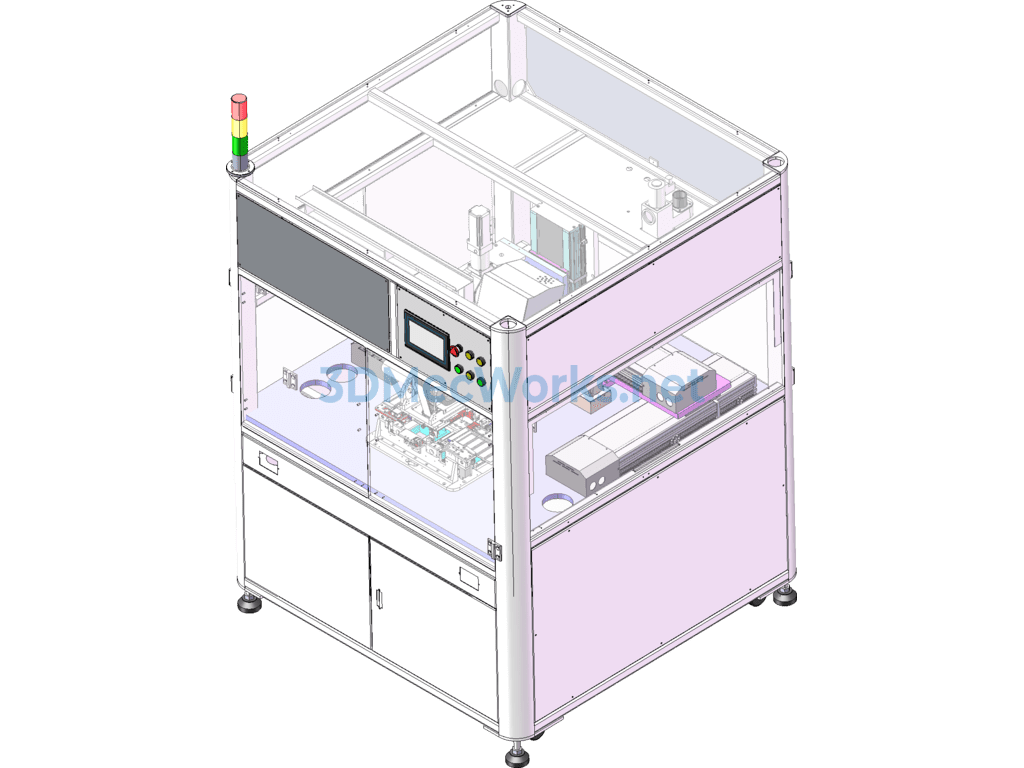

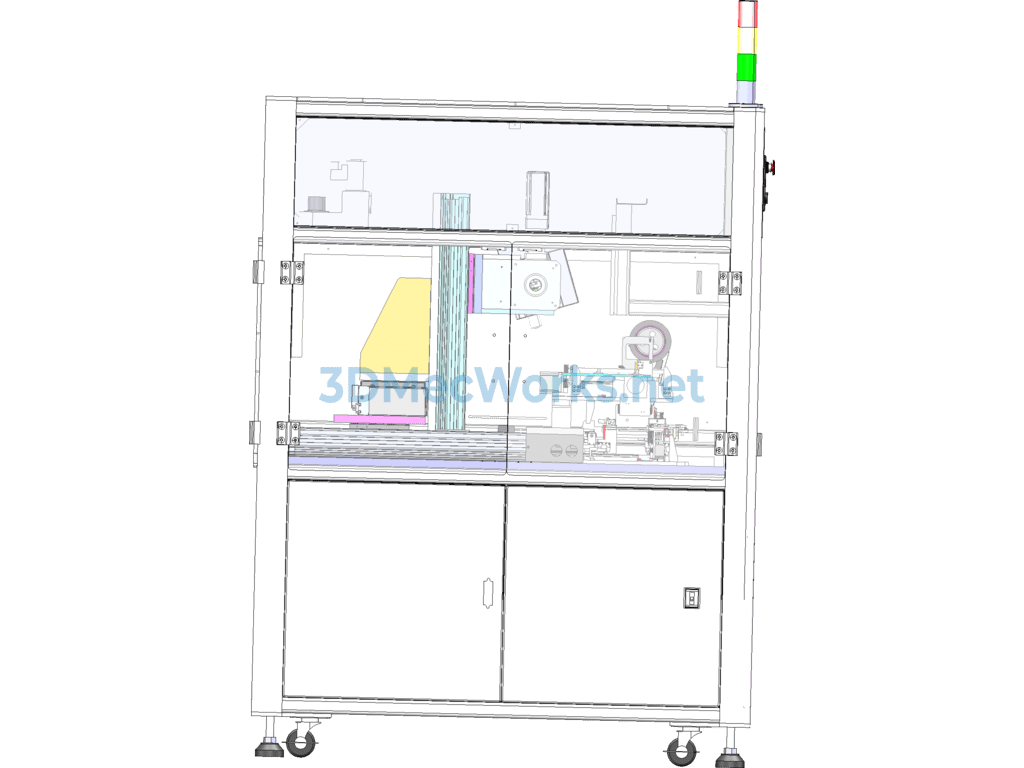

This equipment mechanism, designed with SW2016, includes editable part features. It is suitable for the semiconductor integrated circuit manufacturing process (back-end packaging) for the mounting of chip components, achieving functions like dispensing, gluing, die bonding, die attach, wafer die bonding, flip-chip packaging, and GaAs bonding. The bonding pressure is controllable, with high precision. It uses a precision magnetic levitation motion platform, and the main system X and Y axes employ a contactless, frictionless magnetic levitation system with high-resolution linear encoders. The encoder scale achieves a precision of 0.02μm, capable of high-speed, precise, sub-micron-level positioning. Rotation Angle: The equipment has a 360-degree rotation capability, with a rotational resolution precision of 0.01 degrees, allowing chip mounting at any angle during the assembly process. Includes STP and UG generic editable formats.

There are no reviews yet.