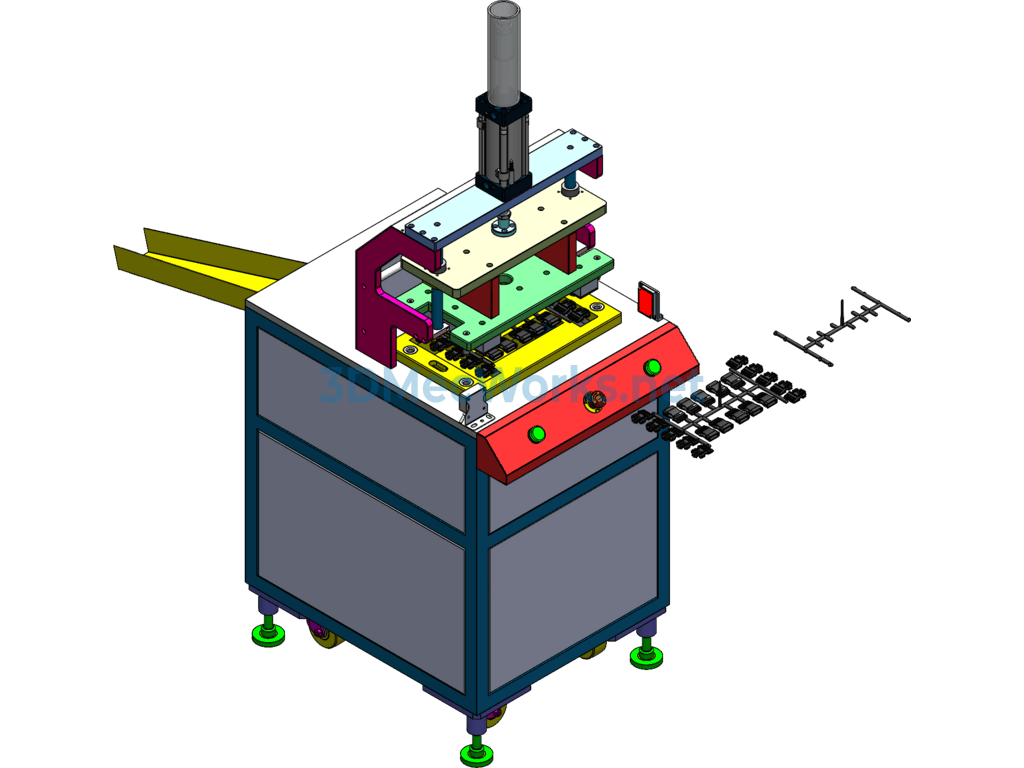

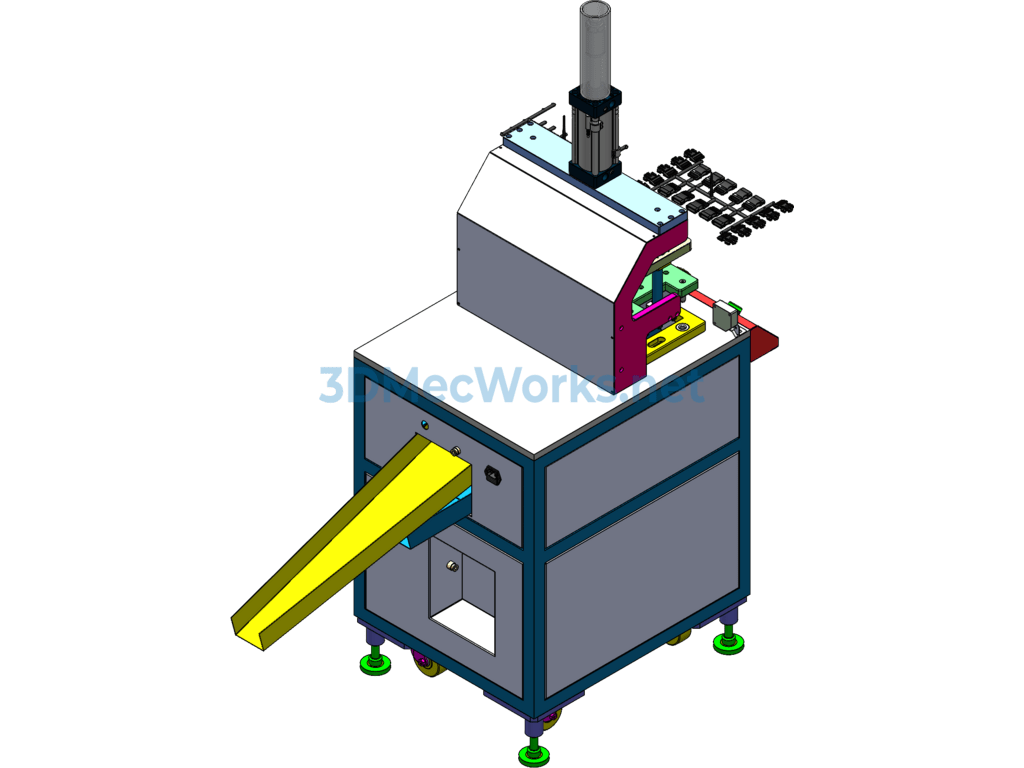

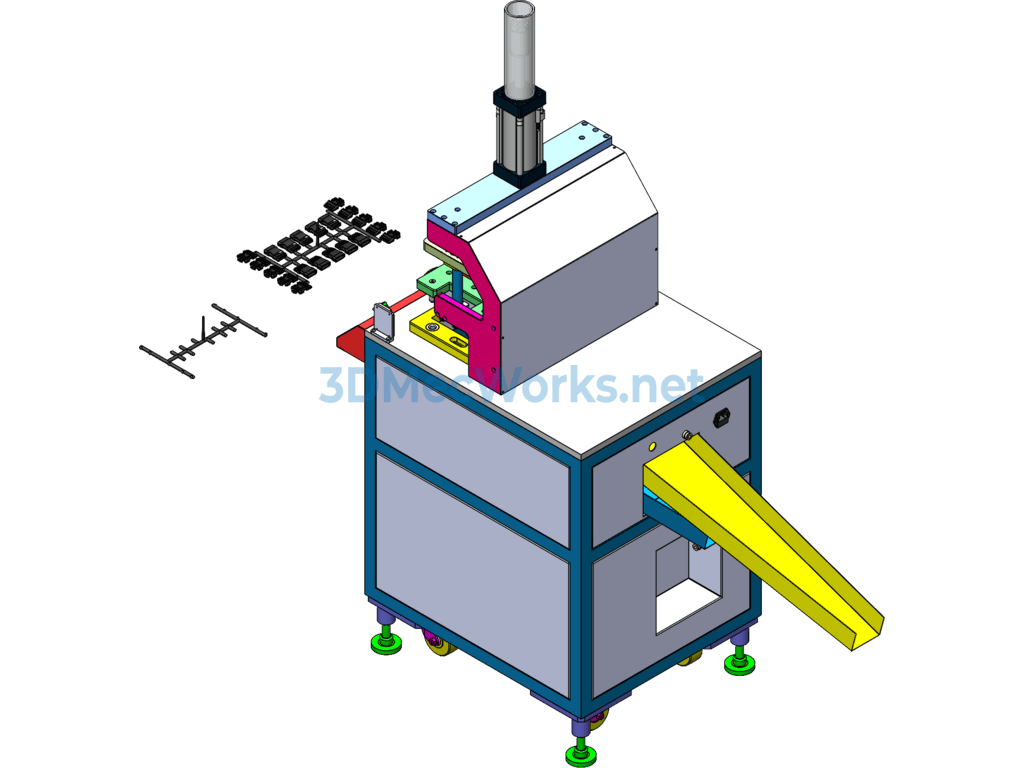

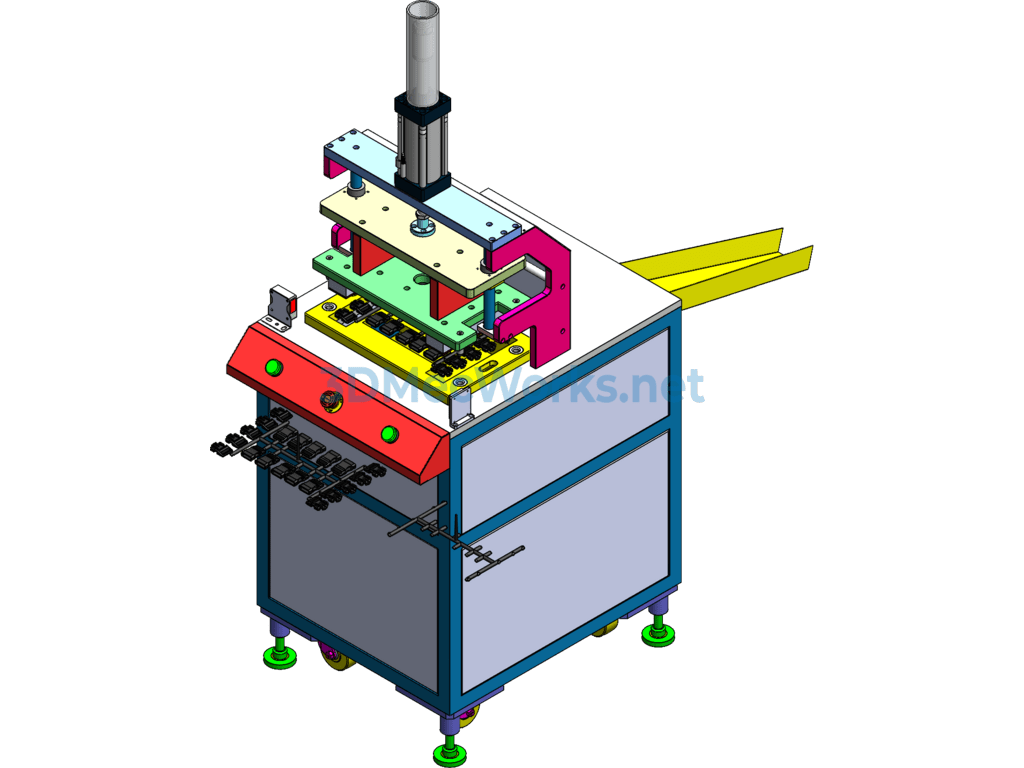

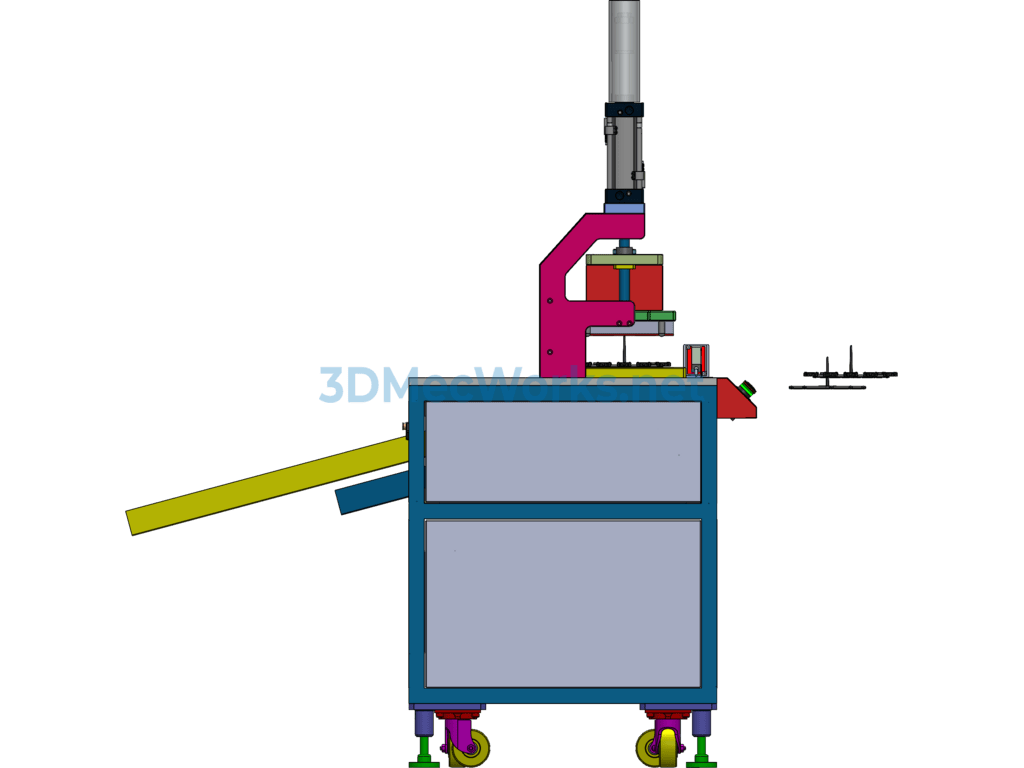

Plastic Runner Cutting Machine 3D Model

SolidWorks Source File

Parametrically Editable, Can Be Used as a Reference for Planning

1. Purpose: Replaces manual removal of runners.

2. Features: High efficiency, stable quality, safe and reliable, easy operation.

3. Application Scenarios: Where runner cutting is needed.

4. Four major advantages of the machine operation compared to manual work:

A. Efficiency: Over 100% improvement

B. Quality: Reliable

C. Cost: Varies according to customer requirements

D. Safety: Reliable protection for operators

5. Power: Single-phase AC220V power supply; Clean compressed air above 5KG/cm²

6. Dimensions: L*W*H=650*700*750mm

A runner refers to the junction between the framework and parts formed during mold casting in a factory. Also known as a “pouring gate” (runner), it refers to the inlet and outlet for the flow of molten plastic. This is a specialized term in injection molding, where melted plastic flows into the mold cavity through the runner. To create a model, the parts are cut from the framework by clipping the runners that connect the parts to the framework. The goal here is to use diagonal cutters to neatly cut the runners at the edges of the parts. This is where the plastic runner cutting machine comes into play.

Specification: Automated Plastic Water Gate Cutting Machine

|

User Reviews

Be the first to review “Automated Plastic Water Gate Cutting Machine”

You must be logged in to post a review.

There are no reviews yet.