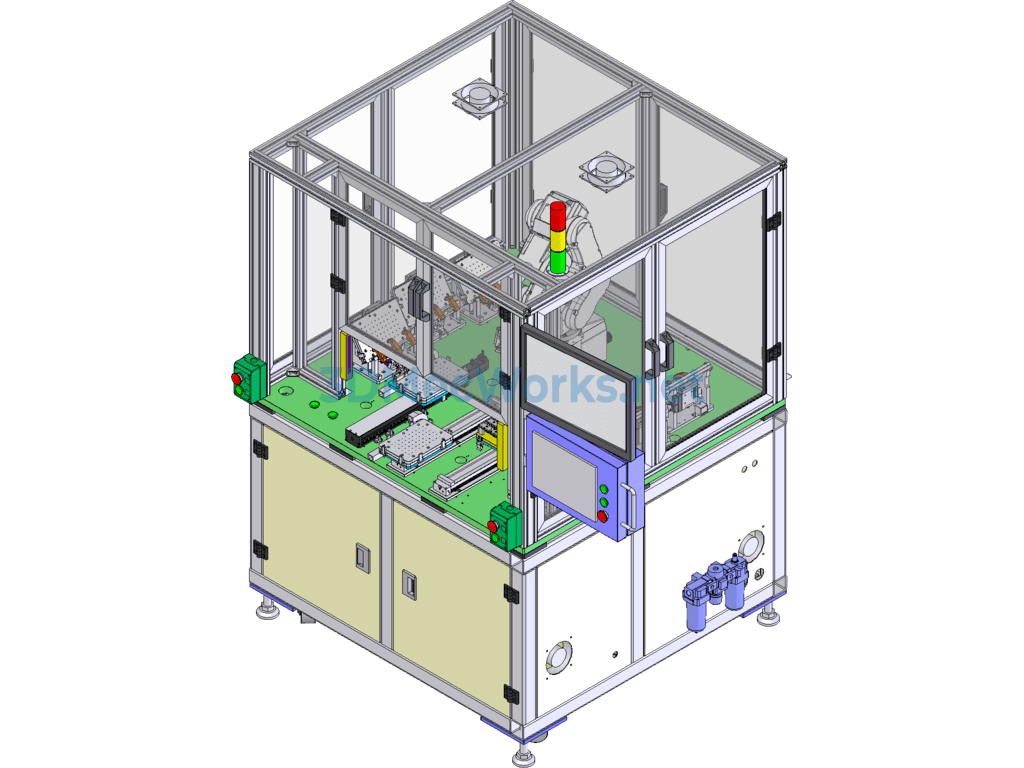

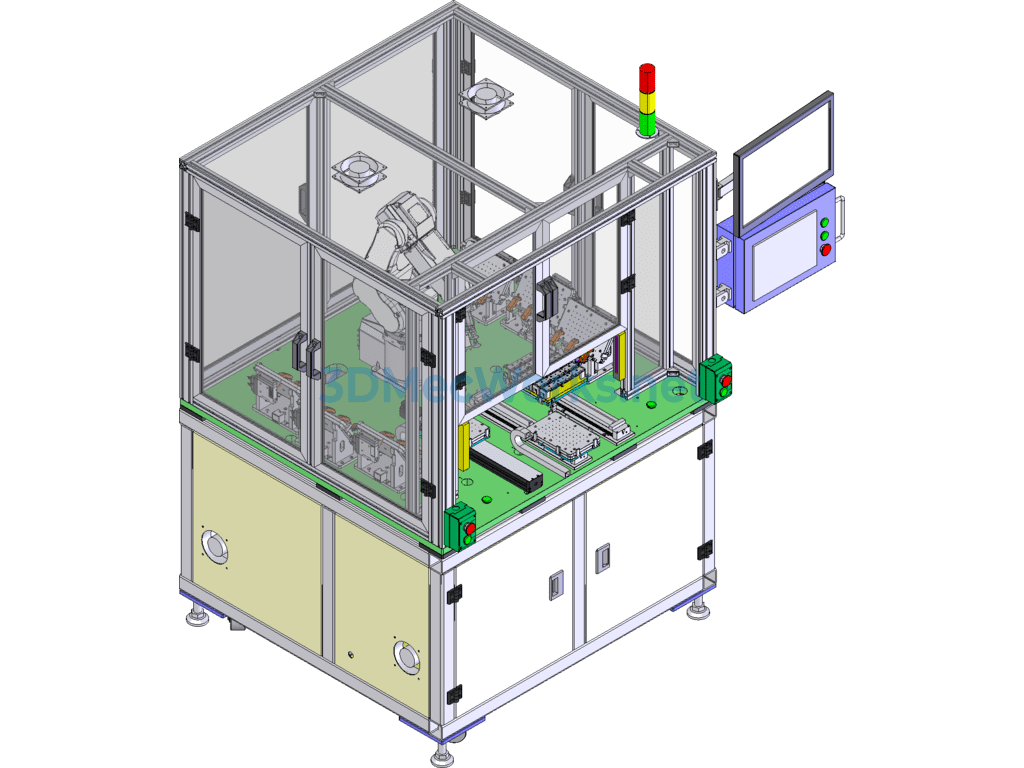

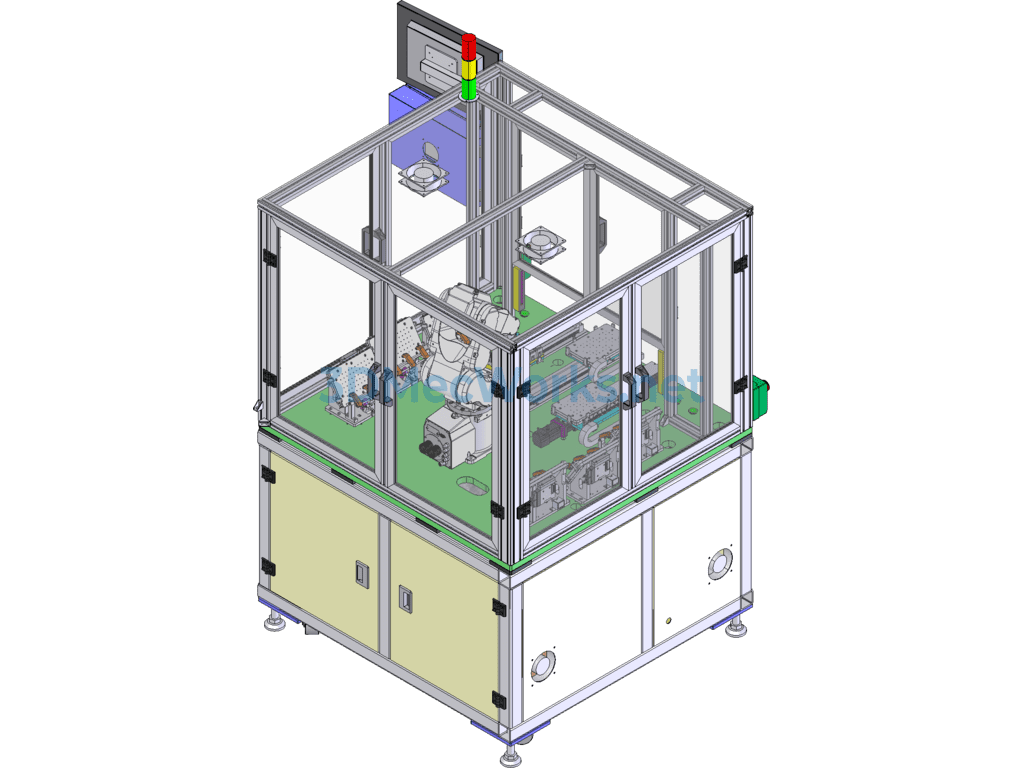

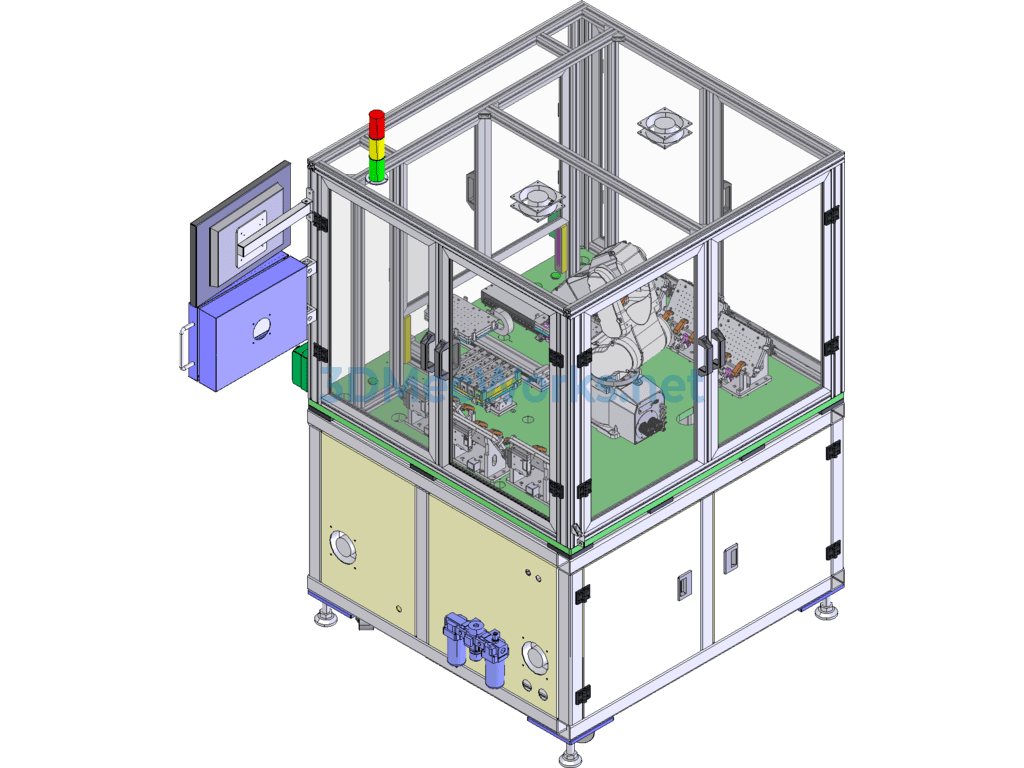

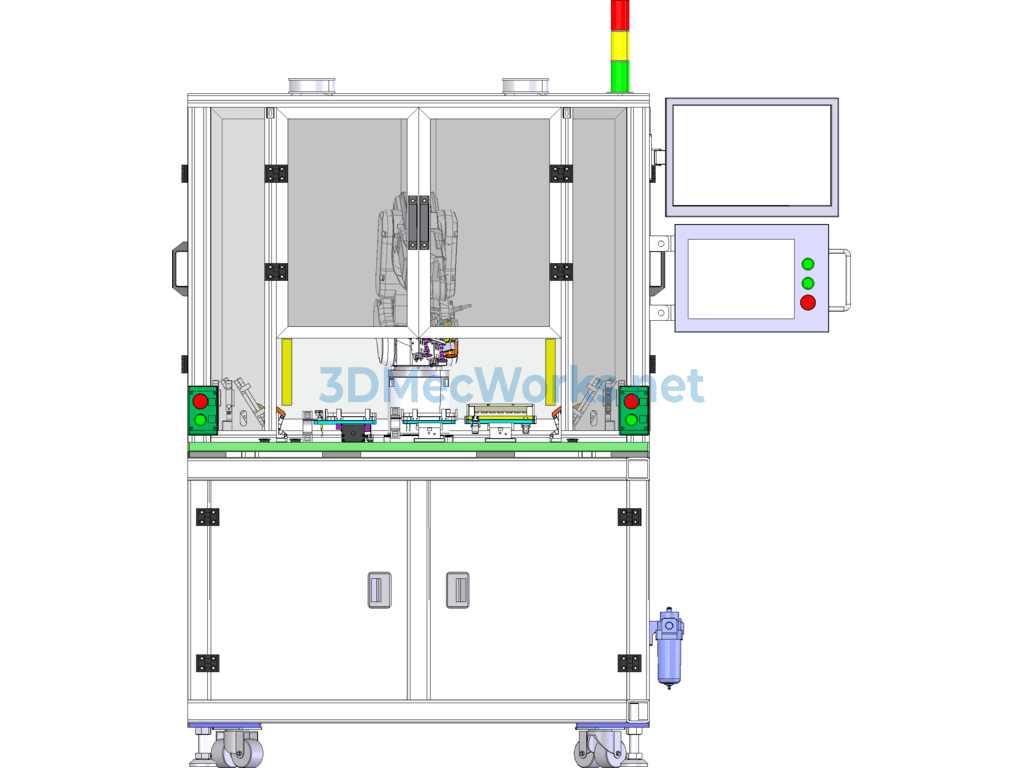

Automated Magnet Assembly Heat Pressure Retention Equipment Process:

1. Manually place the magnet fixture into the equipment;

2. Manually load the flat shell to the shell loading station;

3. The robotic arm adsorbs the shell and magnet fixture to prevent the visual positioning for assembly at the pressure retention workstation;

4. Heat and apply pressure to the magnet;

5. Upon completion, the robotic arm unloads to the shell unloading area;

Specification: Automated Magnet Assembly Heat Pressure Holding Equipment (produced Equipment Includes Dfm)

|

User Reviews

Be the first to review “Automated Magnet Assembly Heat Pressure Holding Equipment (produced Equipment Includes Dfm)”

You must be logged in to post a review.

There are no reviews yet.