Process Description

This process uses a one-to-two control method, where a single camera control system simultaneously recognizes and controls both the left and right recognition cameras. The camera reads the material to identify products of levels 1 to 4, and the system feedback is given to the PLC controller to differentiate and exclude products of levels 1 to 4. The left and right conveyors are each divided into 22 equal parts, and each part is within the camera recognition area. The camera reads the good and bad materials, and the data analyzed by the system is fed back to the PLC, which controls the products of each level. At designated positions, the products are excluded to exits 1-2-3-4 on the conveyor. When level 1 material is recognized, it directly exits without intervention from valves 2-3-4. Products identified at levels 2-3-4 will be excluded at positions 2-3-4 and must not exit with level 1 products.

Functional Process Description Process Description

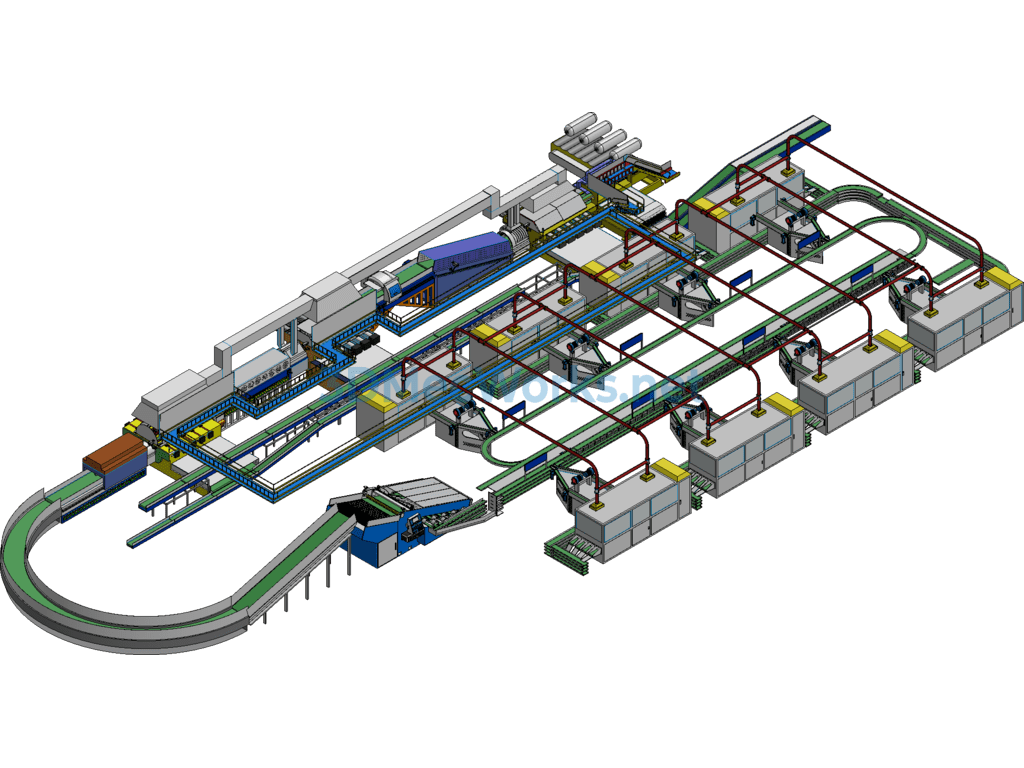

1.1.1.1. This program is designed according to the raw material recognition sorting process. Raw materials are manually placed into the feeding machine, which is then started. The raw materials enter the automatic cleaning area for washing. The cleaning equipment uses S-shaped conveyor belts for cleaning, which effectively allow the raw materials to automatically turn over and quickly wash off mud. High-pressure spray washing is used for cleaning, rapidly cleaning the raw material surfaces. After entering the drying area and undergoing rapid dehydration, excessive moisture is prevented from entering the visual equipment. The dehydrated raw materials are then conveyed to the rapid separation machine, which quickly spreads the raw materials apart at a certain distance, smoothly transporting them to the inspection area. Dust collectors are installed within the inspection equipment to ensure that the cameras and processing mechanisms remain clean. With the cooperation of high-resolution cameras and lighting, images are quickly captured and fed back to the image processor, which provides accurate signals to the PLC. The PLC control system will quickly process the different levels. The equipment is equipped with two rapid conveyors, automatically conveying sorted materials to primary and secondary channels, and transporting them to designated boxes. This includes images from the vision camera used.

Specification: Automated Crystal Vision Recognition Sorting

|

User Reviews

Be the first to review “Automated Crystal Vision Recognition Sorting”

You must be logged in to post a review.

There are no reviews yet.