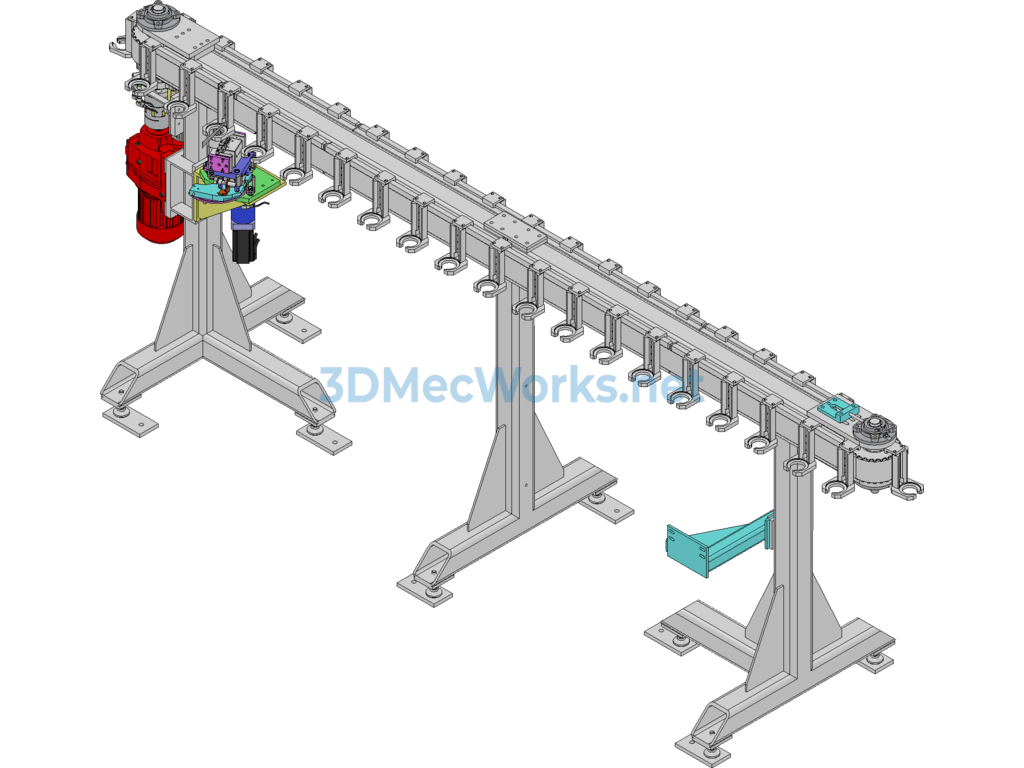

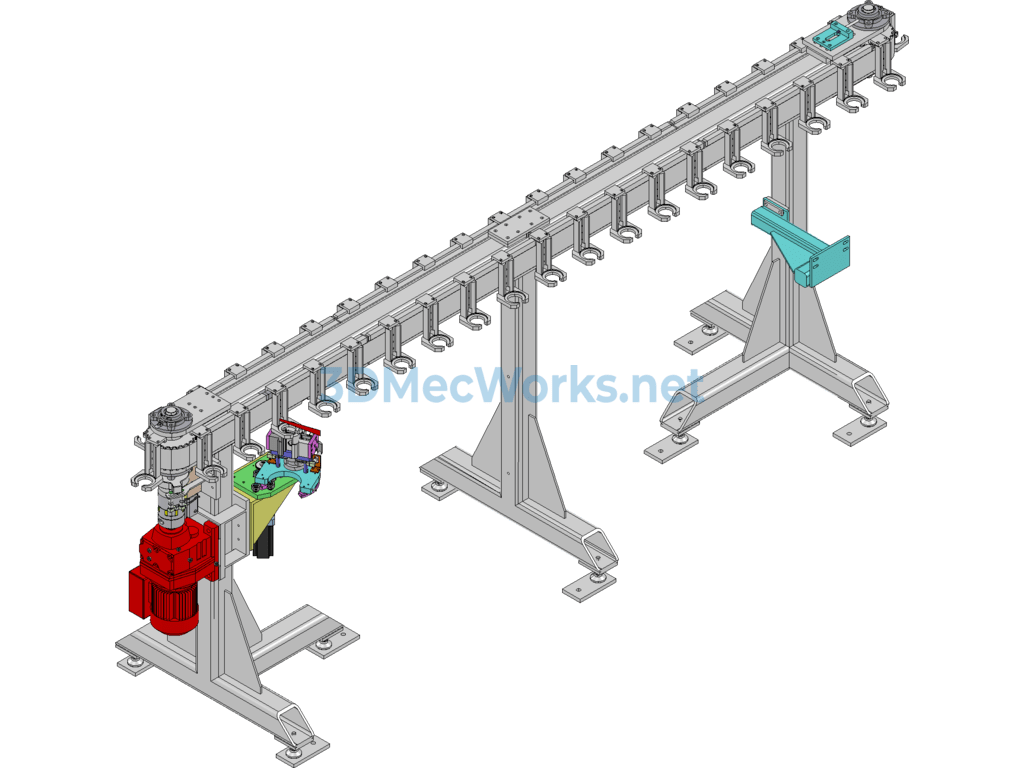

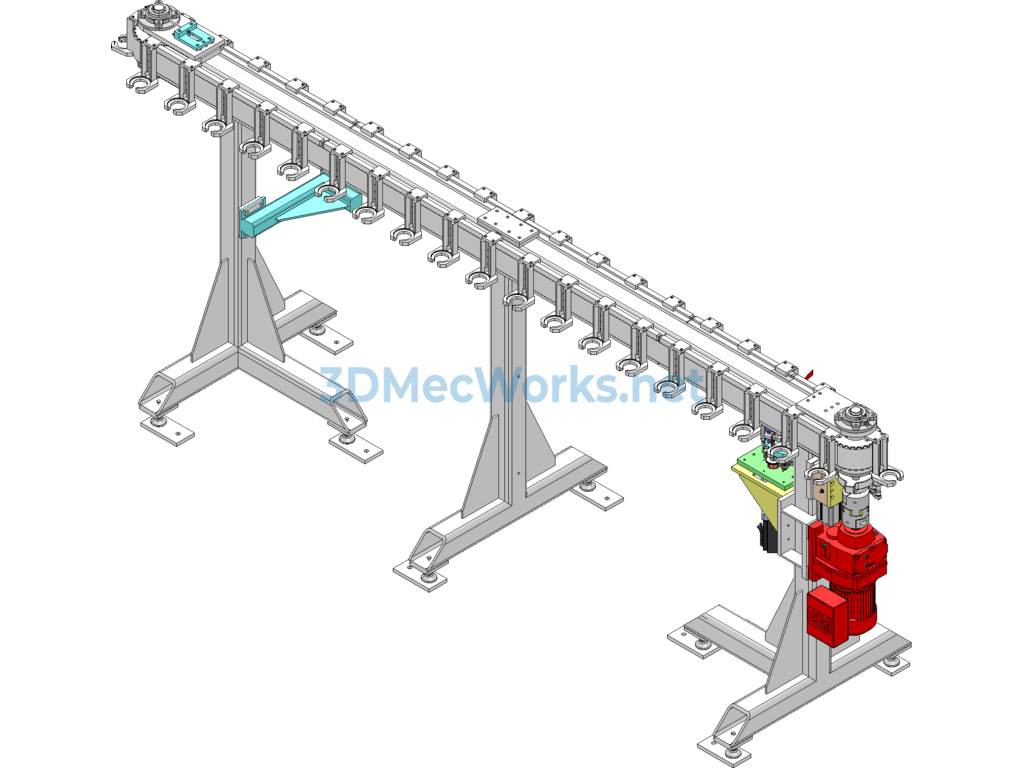

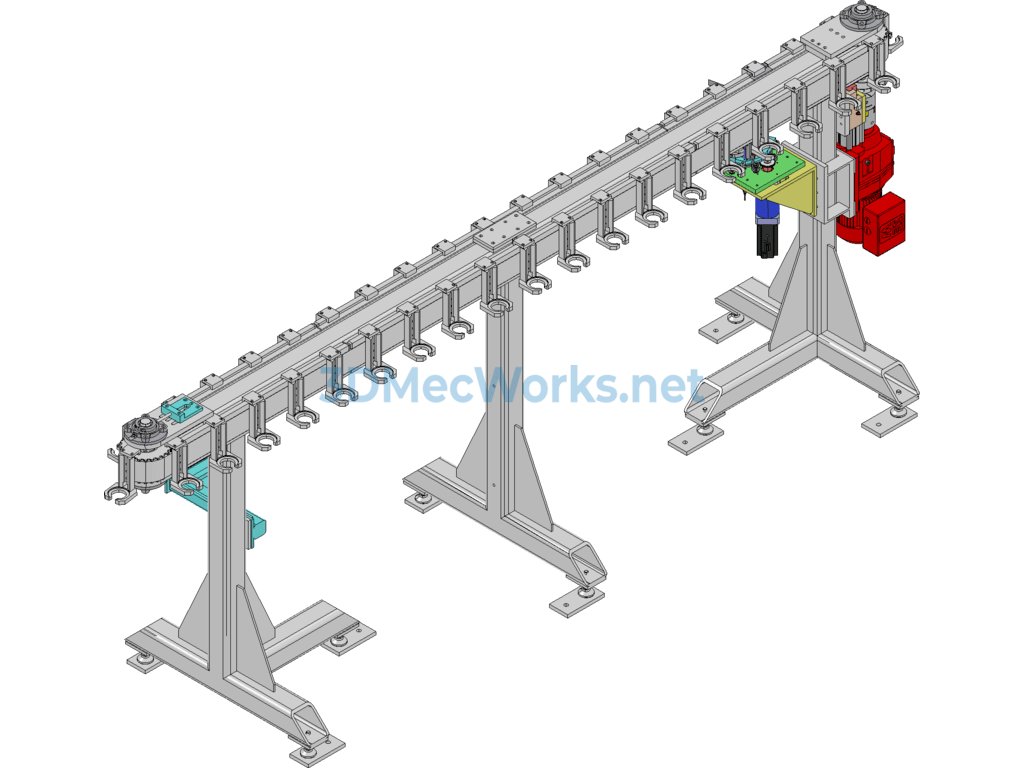

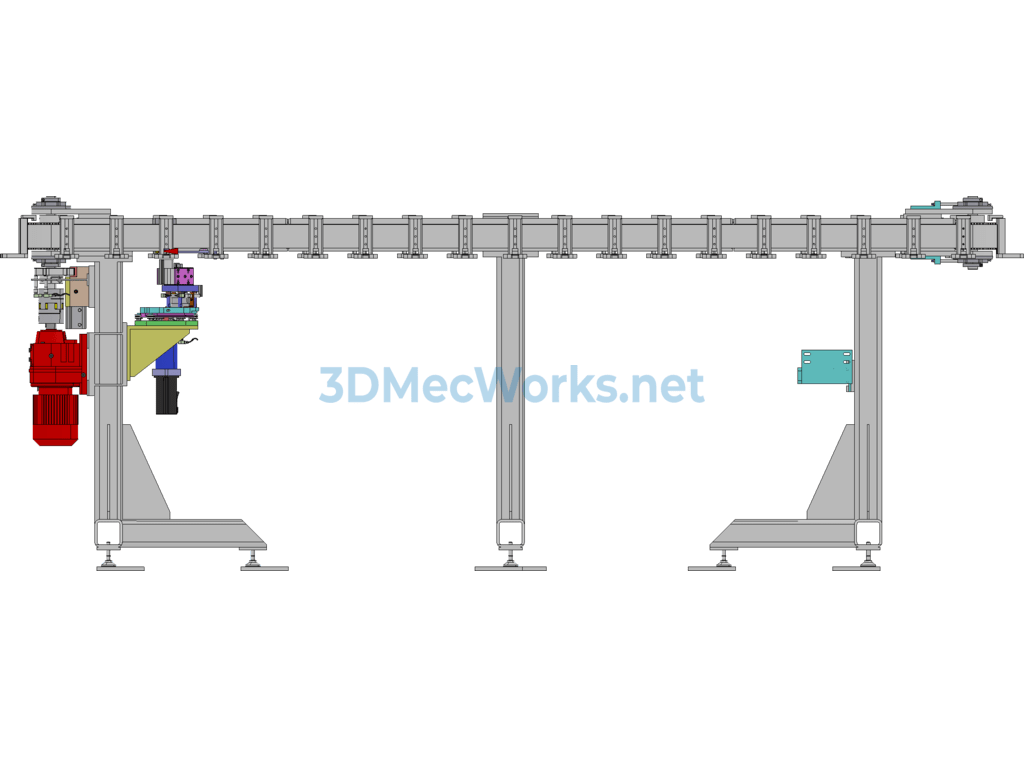

This is an assembly equipment used for electric motor assembly, mainly employing a rotary conveyor station. This design allows for multiple stations to work continuously at the same time. The rotary assembly station can effectively detect the positioning of the workpieces, ensuring accurate assembly. The model creation is realistic, but it does not include parameters. You are welcome to download it. The model structure includes: traction components, bearing components, driving devices, tensioning devices, redirecting devices, and supporting components. Traction components are used to transmit traction force, which can be a conveyor belt, traction chain, or wire rope; bearing components are used to carry materials, such as hoppers, brackets, or hoists; the driving device provides power to the conveyor, generally consisting of an electric motor, reducer, and brake (stopper); tensioning devices are generally of two types: screw and counterweight, which allow the traction components to maintain a certain tension and sag to ensure the normal operation of the conveyor belt; supporting components are used to support traction or bearing components, and can be rollers, idlers, etc. It does not include parameters but can be edited and opened with SOLIDWORKS2010.

Specification: Assembly of Electric Motor With Rotating Overhead Conveyor System

|

User Reviews

Be the first to review “Assembly of Electric Motor With Rotating Overhead Conveyor System”

You must be logged in to post a review.

There are no reviews yet.