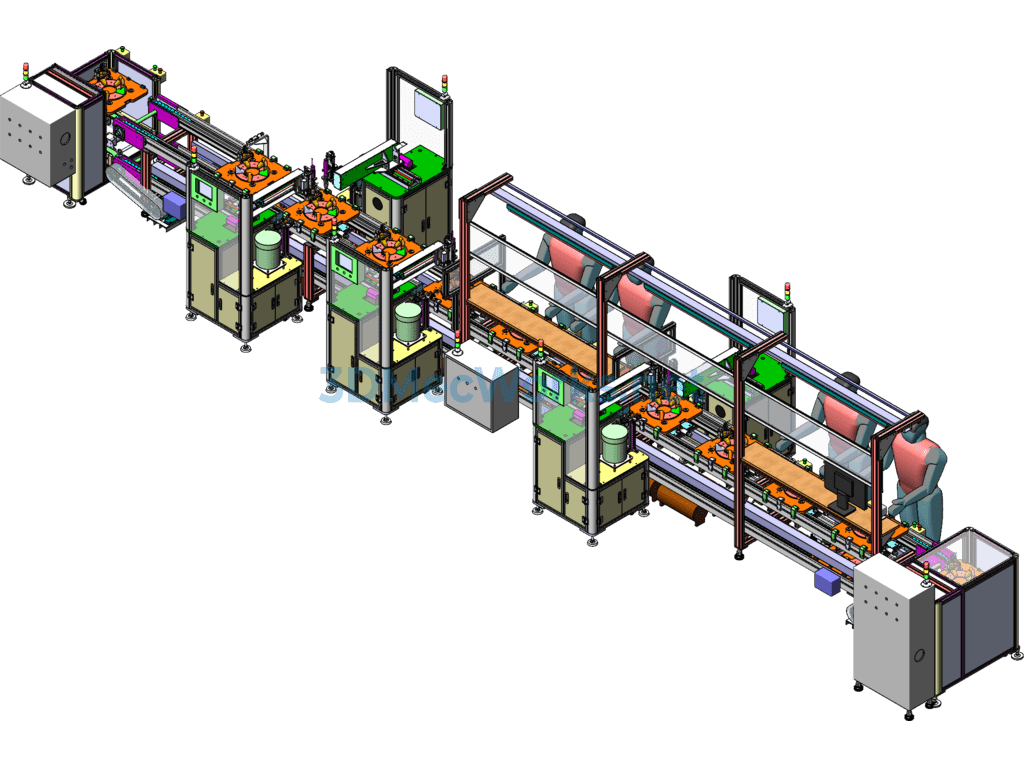

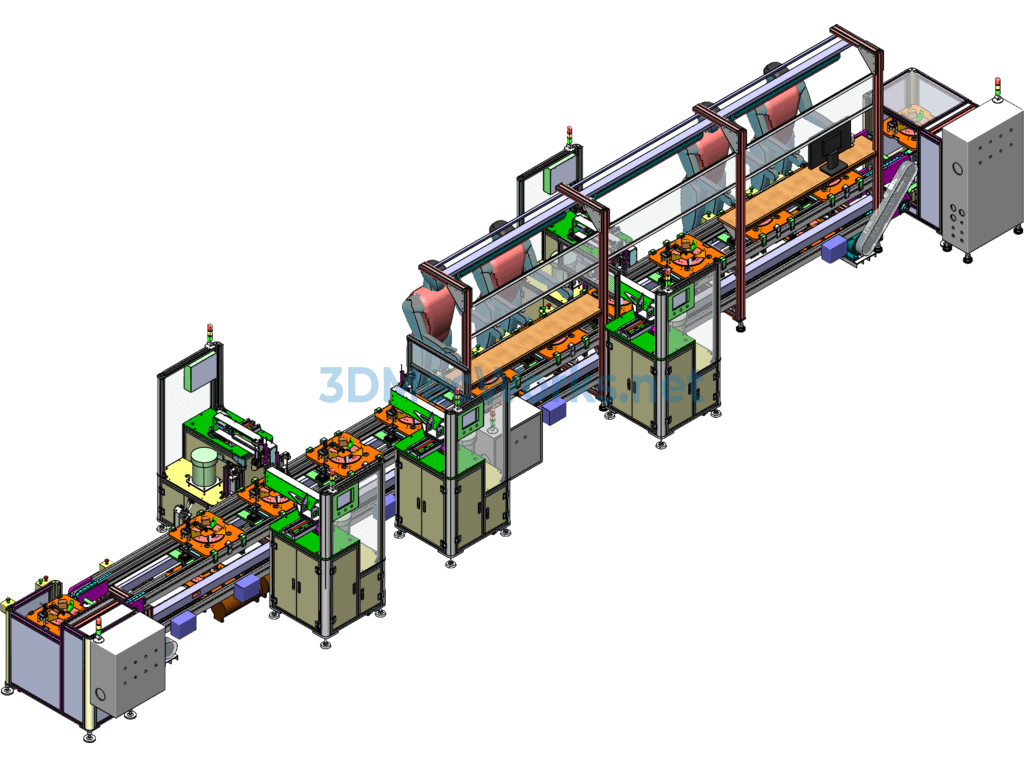

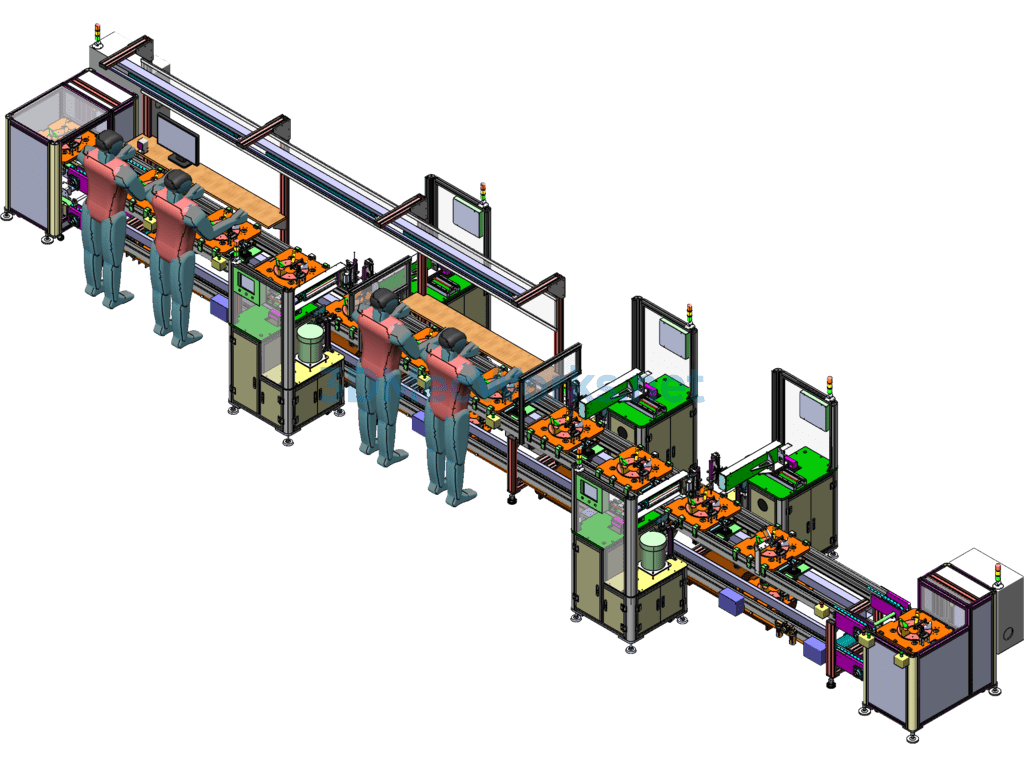

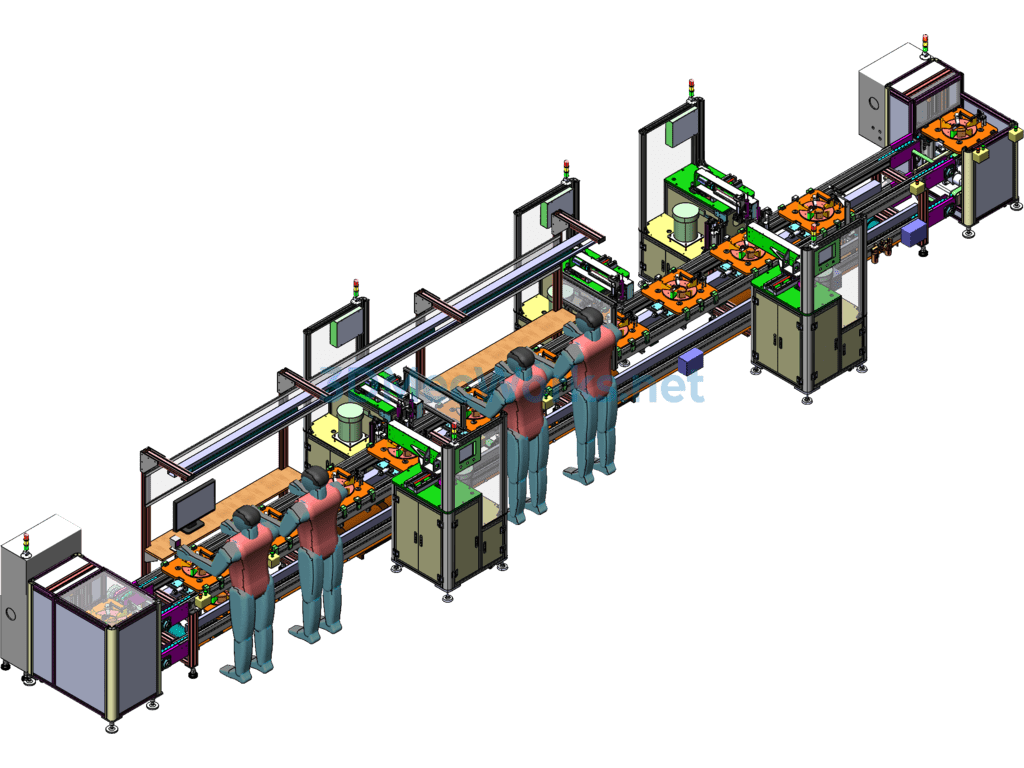

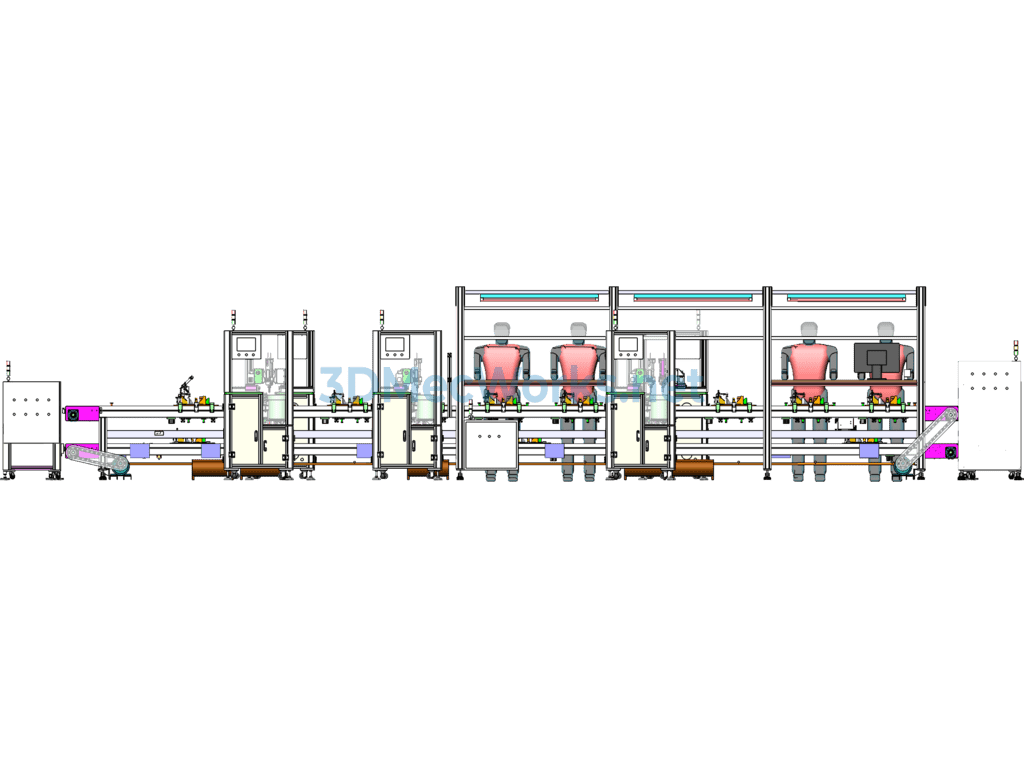

Speaker assembly automatic production line, includes a base, with a conveying device and an assembly rotary table on the base. The conveying device comprises a conveyor belt mounting rack and a conveyor belt. The conveyor belt is mounted inside the conveyor belt mounting rack. The assembly rotary table is equipped with a positioning device and an assembly device. An upper feeding manipulator and a lower feeding manipulator are set between the conveying device and the assembly rotary table. The positioning device includes a positioning platform and a positioning cylinder group. The positioning cylinder group is located on the positioning platform. It includes a first positioning cylinder, a second positioning cylinder, and a third positioning cylinder. The assembly device includes an assembly manipulator and a dispensing machine. The assembly manipulator comprises an assembly seat and assembly fingers. The assembly seat is equipped with an X-direction assembly screw rod module, a Y-direction assembly screw rod module, and a Z-direction assembly screw rod module. The Y-direction assembly screw rod module is mounted on the assembly seat. The upper end of the Y-direction assembly screw rod module is connected to the X-direction assembly screw rod module, which is connected to the Z-direction assembly screw rod module. The lower end of the Z-direction assembly screw rod module is connected to the assembly fingers. The dispensing machine includes a dispensing mounting seat and a dispensing head. The dispensing mounting seat is equipped with an X-direction dispensing screw rod module. At the lower end of the X-direction dispensing screw rod module is a dispensing cylinder mounting seat, which is equipped with a dispensing cylinder. The conveying device, through the conveyor belt mounting rack and the conveyor belt, smoothly places the speaker parts onto the assembly rotary table for assembly work. Once assembly is completed, the assembled speakers are transported via the conveyor belt to the storage point (not shown in the diagram) by the lower feeding manipulator. The positioning device through the first, second, and third positioning cylinders positions the speaker parts, in preparation for the assembly device to work on assembling the speaker parts. The assembly manipulator uses the X, Y, and Z direction assembly screw rod modules to allow the assembly fingers to move freely, working together with the dispensing machine to complete the speaker assembly work.

Specification: Air Speaker Line Automatic Assembly Line

|

User Reviews

Be the first to review “Air Speaker Line Automatic Assembly Line”

You must be logged in to post a review.

There are no reviews yet.