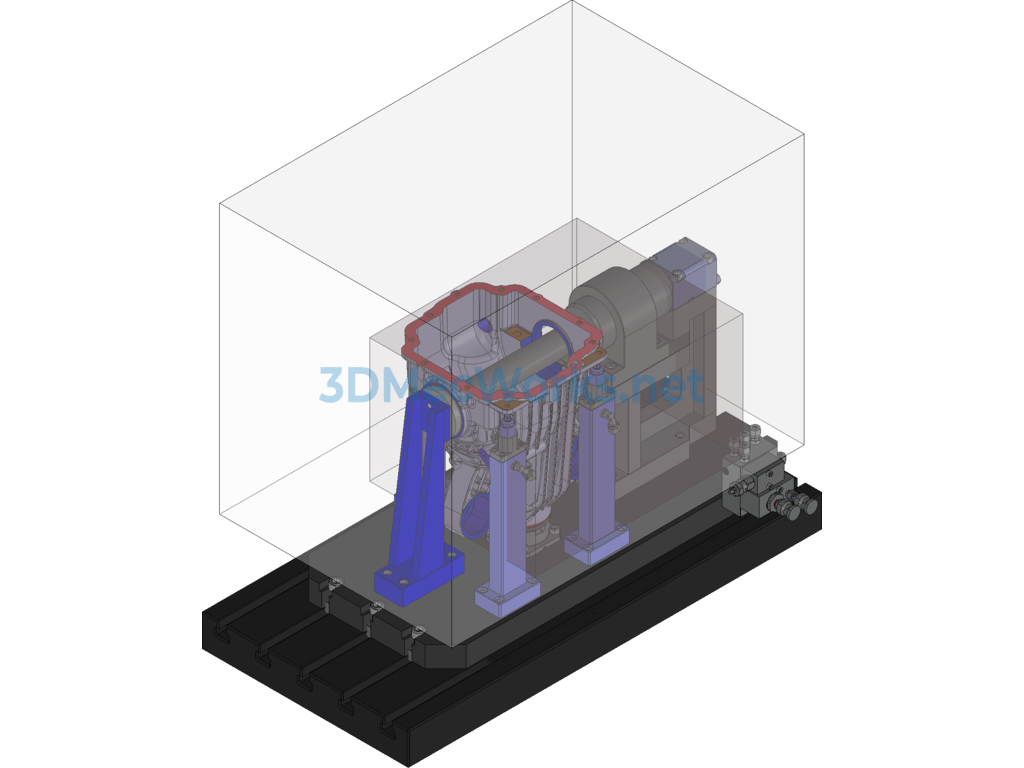

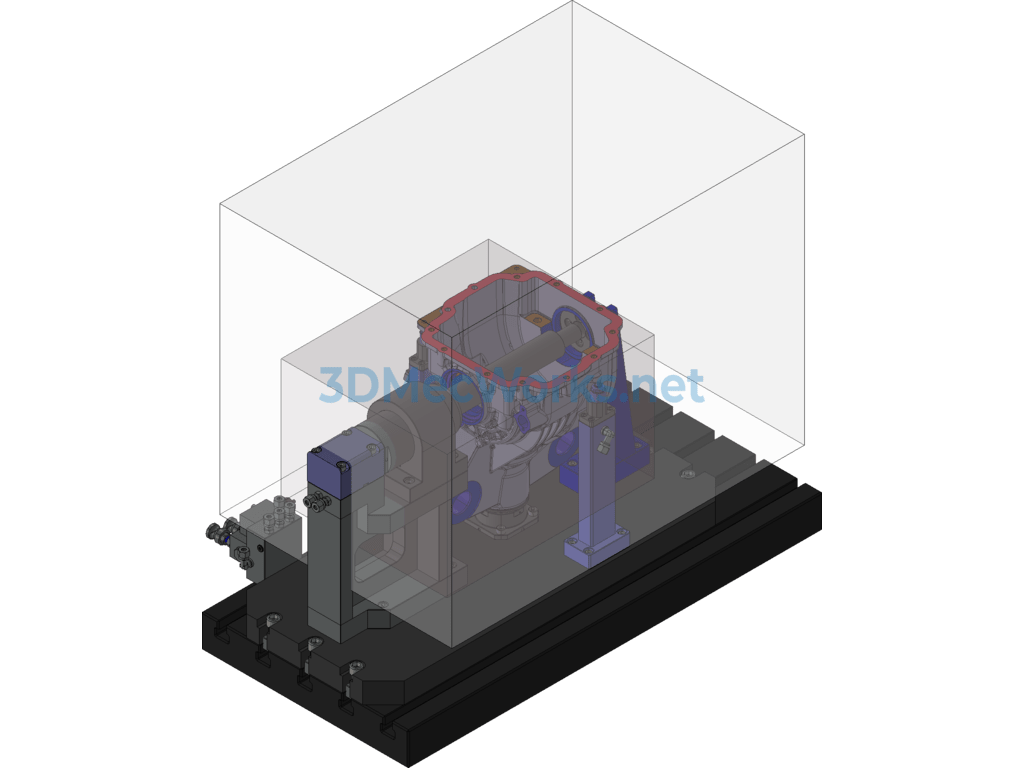

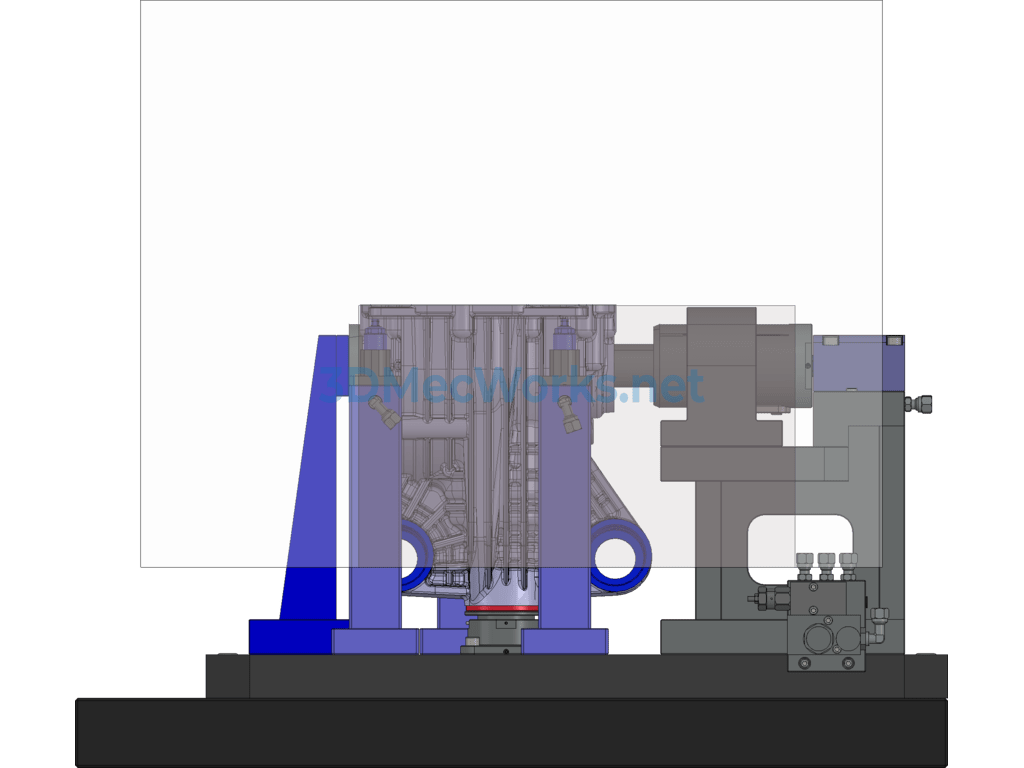

First Sequence: Use device VMC850 X travel 800, Y travel 450, maximum distance from spindle nose to worktable 700

Machining Parts:

1. Red mounting surface, and threaded holes on the surface 12-M10 tap 27 depth 30;

2. E datum, and threaded holes on the surface 4-M15×1.5 tap 35 depth 40;

3. F-F end face, holes on the surface 2-φ8 holes (precision reaming) — process holes of the part;

Clamping Principle:

Use C and D datum for rough centering of the blank (long mandrel principle), restrict four degrees of freedom; C datum end face for axial positioning; A datum end face for angular positioning; the rest with auxiliary supports added according to clamping conditions;

Specification: A Rear Shell Fixture (first Sequence)

|

User Reviews

Be the first to review “A Rear Shell Fixture (first Sequence)”

You must be logged in to post a review.

There are no reviews yet.