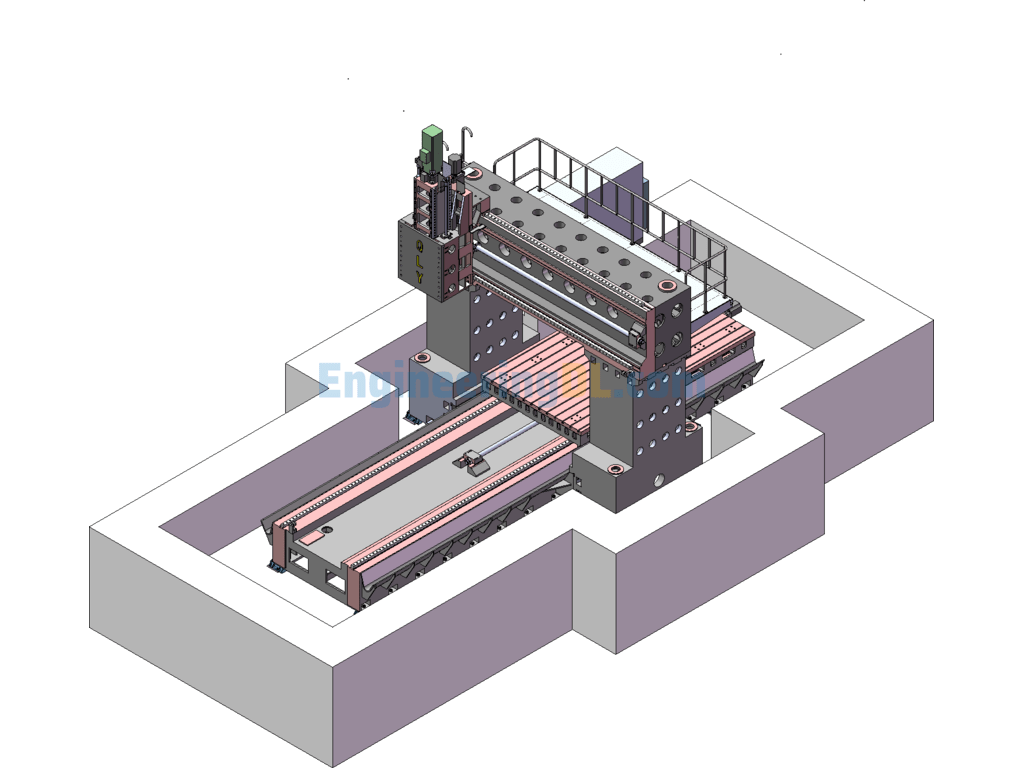

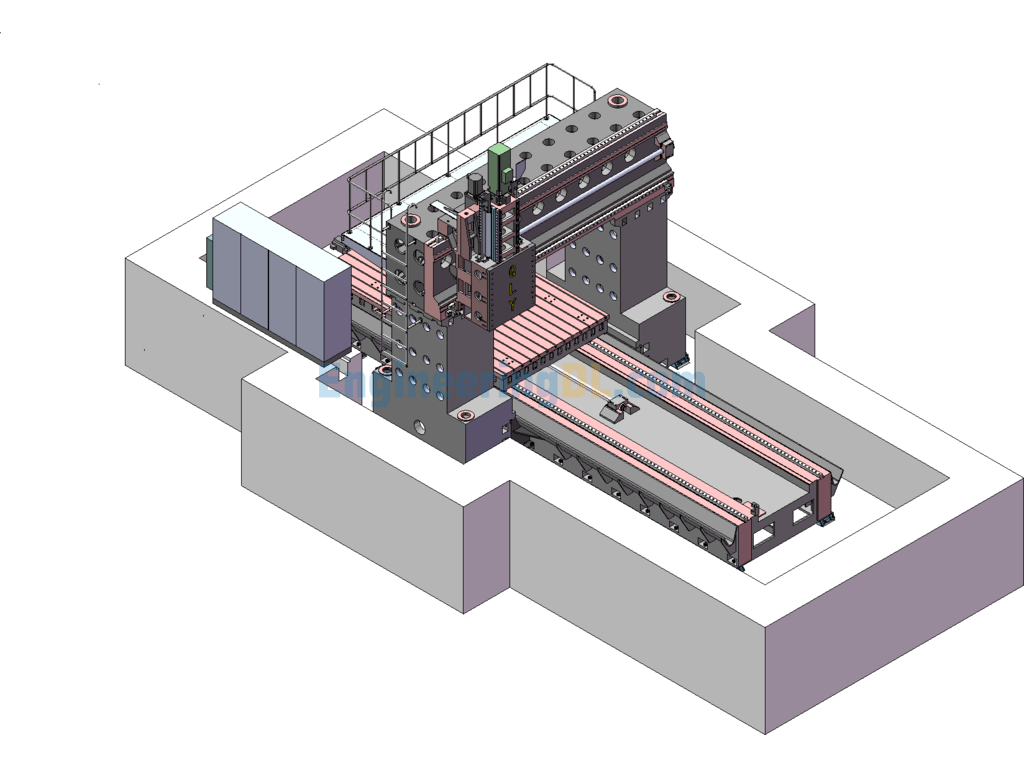

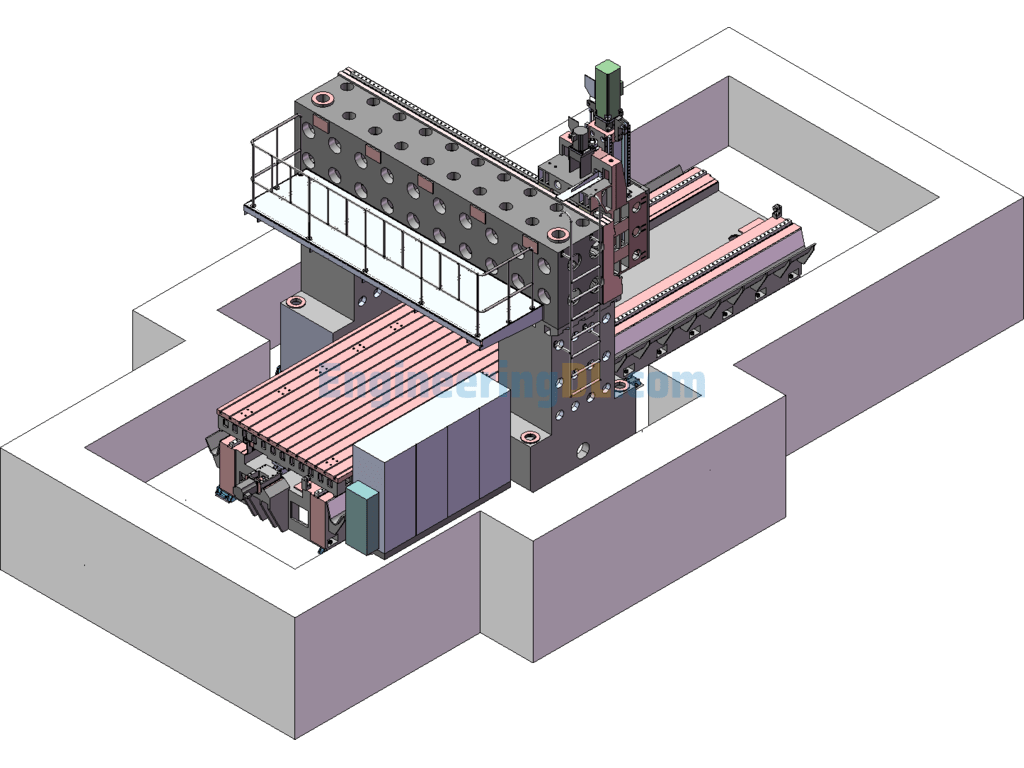

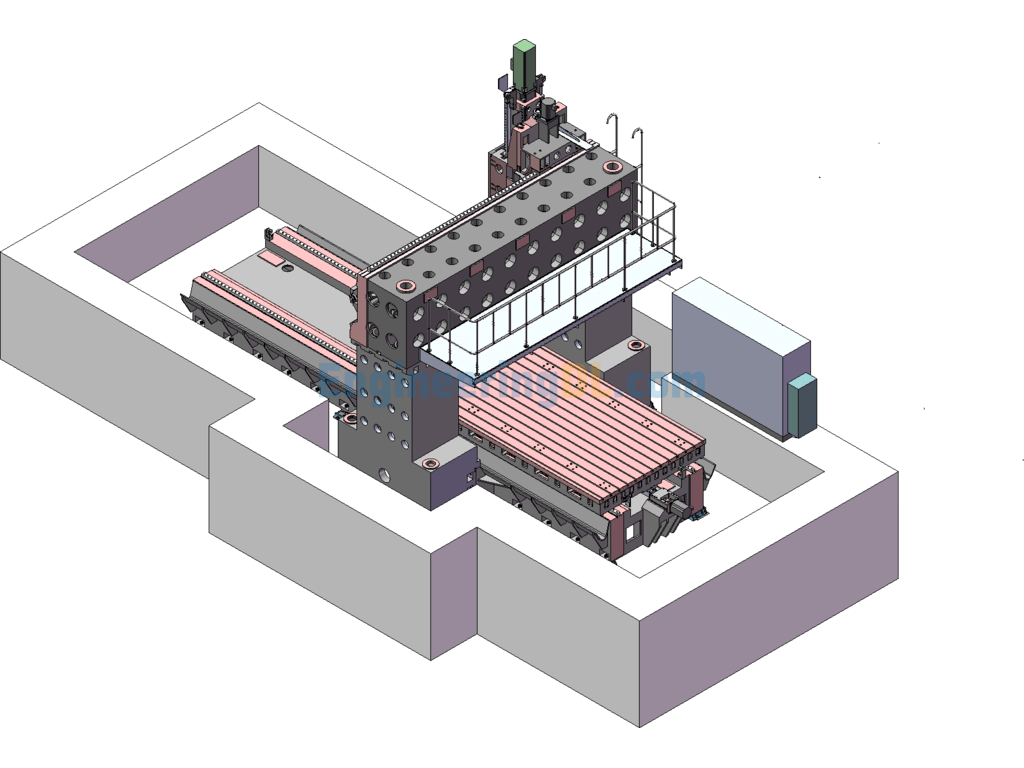

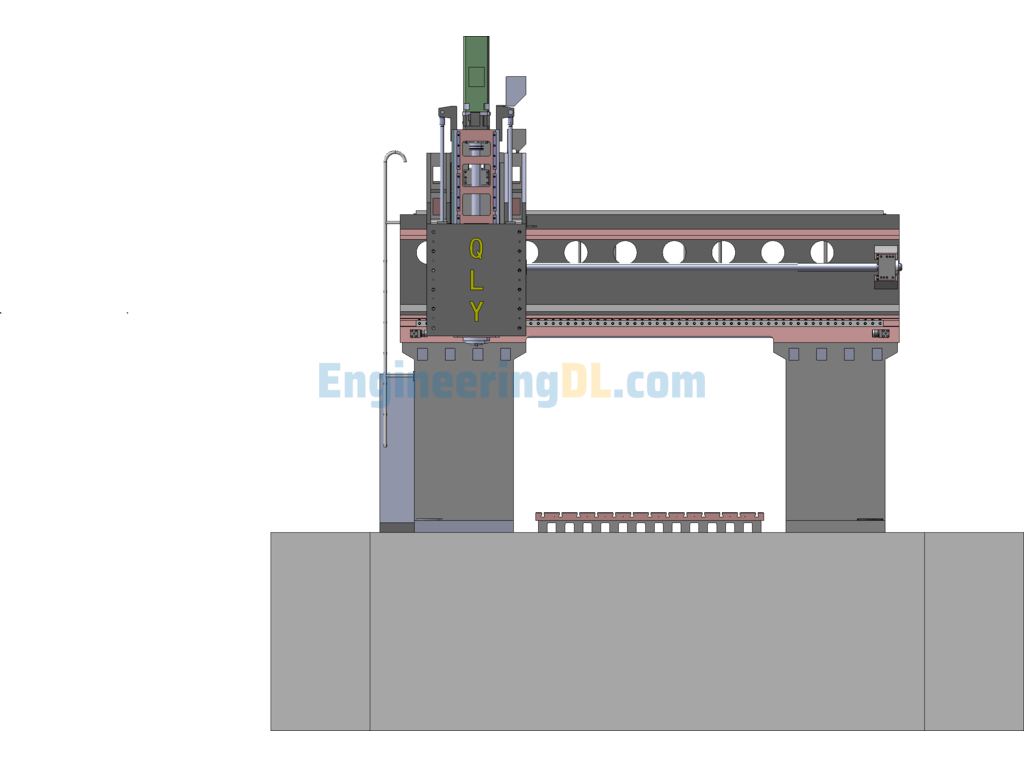

The overall layout of the 2540 gantry milling machine adopts a high-rigidity structure. Both the worktable surface and rail surfaces are precisely ground, providing good precision retention. The Z-axis uses a reinforced spindle structure, significantly improving the geometric precision and radial rigidity of the spindle. (This item only applies to Morse No. 4 and BT50 spindles.) If the BT50 structure is selected for the spindle, pneumatic tool change can be achieved, which also facilitates functions like drilling and light milling. It can complete procedures like drilling, milling slots, milling protrusions, chamfering workpieces, and milling sprockets. The X and Y axes movement employs high-precision ball screws for rotation and high-precision rolling linear guides for control. Feed is smooth without crawling, and the sensitivity is high, supporting and meeting requirements for micro-feeding and compensation functions. Under heavy load, it maintains smooth sliding, stable movement, and accurate positioning.

Specification: 2540 Gantry Milling Machine

|

User Reviews

Be the first to review “2540 Gantry Milling Machine”

You must be logged in to post a review.

There are no reviews yet.