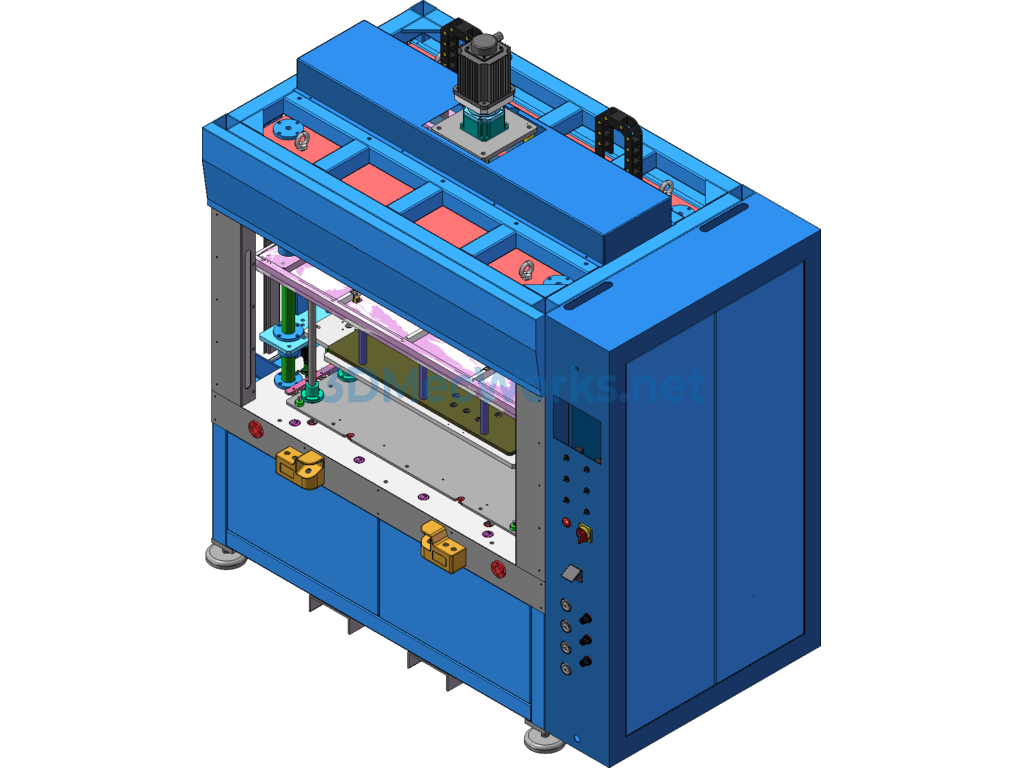

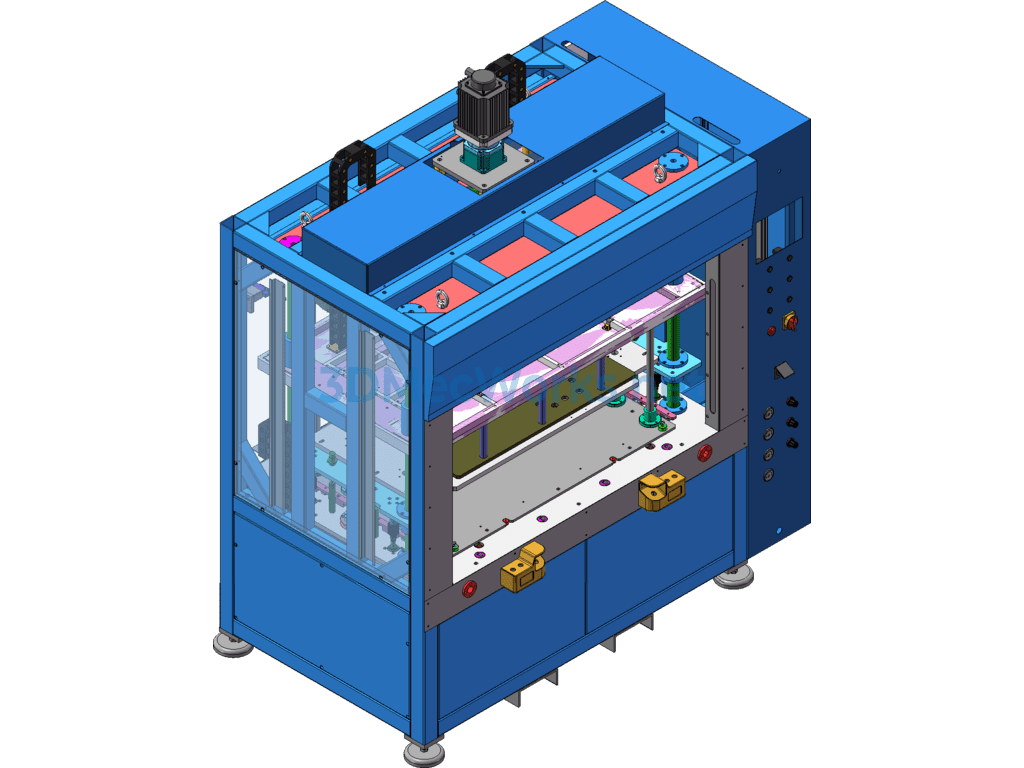

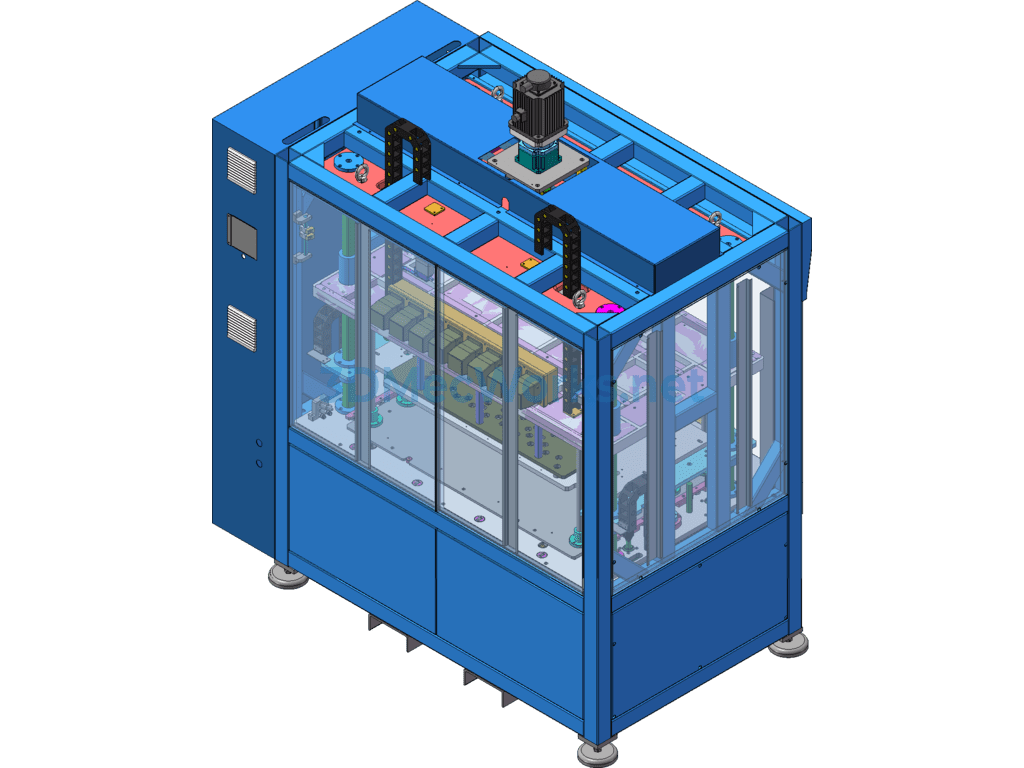

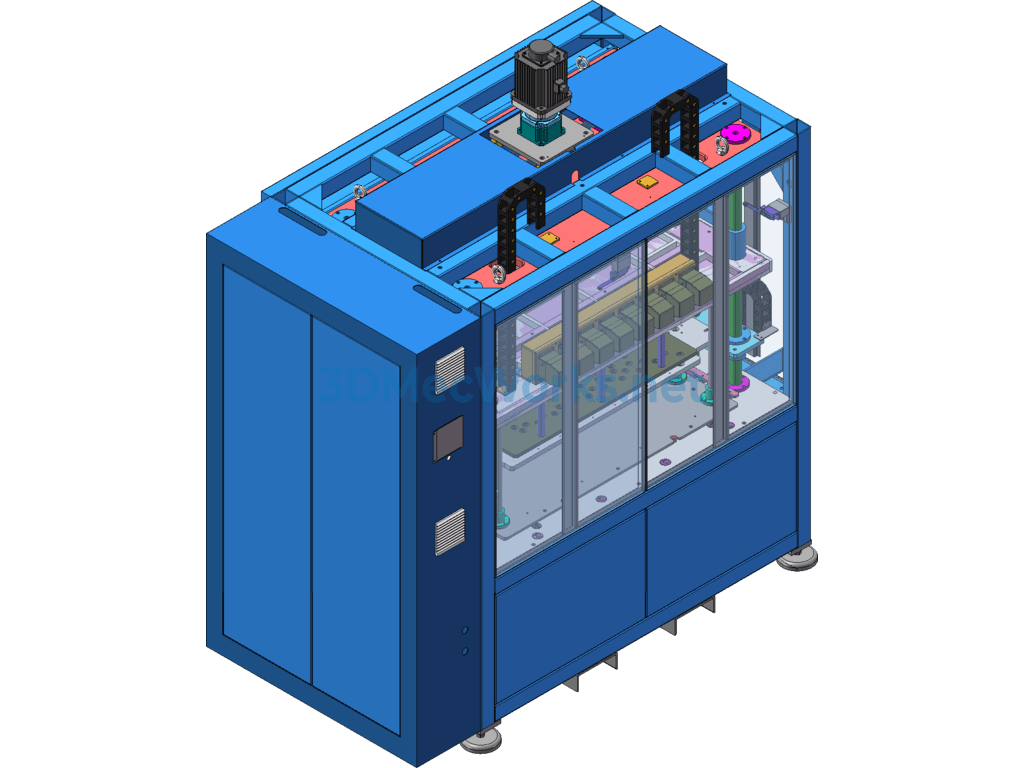

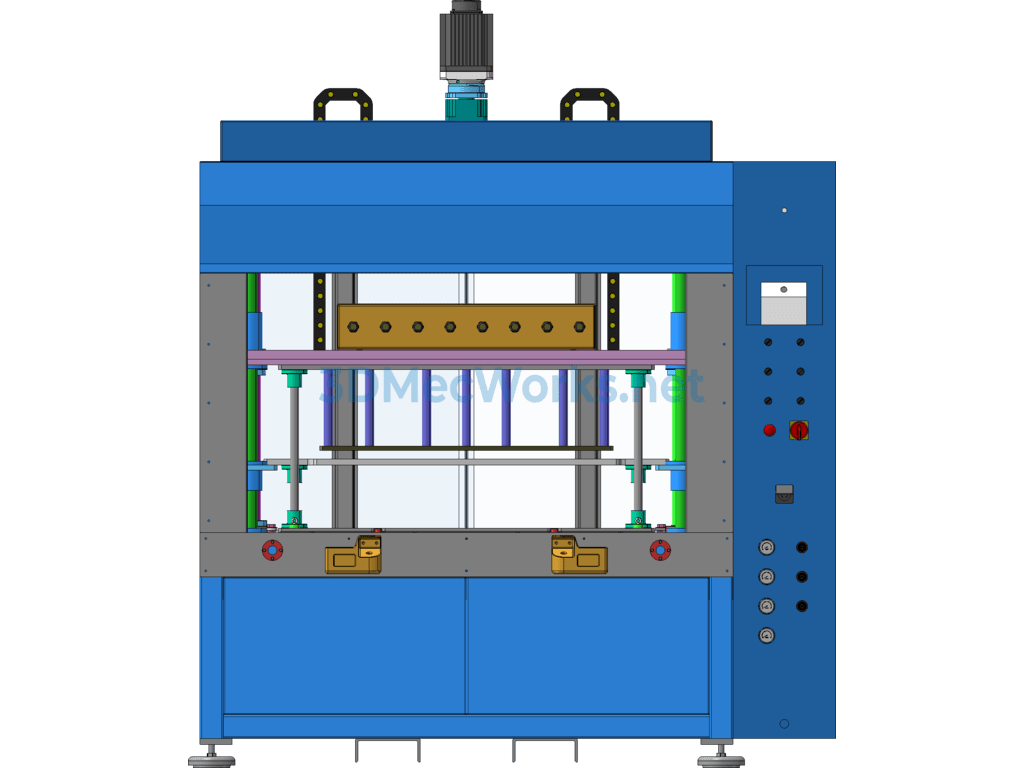

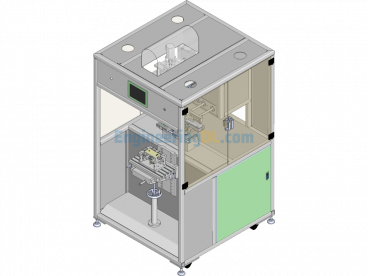

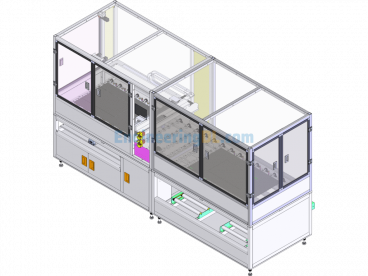

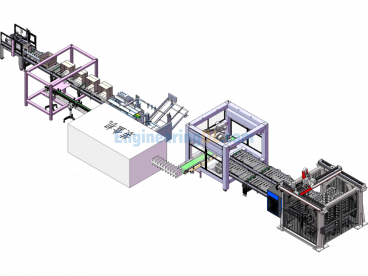

Dual Screw Rod Servo Thermal Riveting Welding Equipment 3D Model SW Design, commonly used in electronic industry equipment, the equipment is already in production, can be directly copied and used, dual screw rod transmission, classic equipment mechanism, compact mechanism, beautiful appearance, the equipment contains a total of 569 files, welcome to download, recommended to open with Solidworks 2014!_x000D_

Thermal Riveting Welding Machine (also known as thermal riveting machine or hot melt machine, full name hot melt riveting welding machine) is used to connect parts made from different materials, enabling the interconnection between thermosetting plastics and thermoplastic parts, or connecting plastic parts with metal; it uses the plastic rivet posts, ribs, and standing ribs that are innate to the molded parts, correspondingly passing through pre-drilled holes on the stamped metal plate structure, pressing tightly with metal surface protrusion rivet posts (thermal stakes). After being controlled for heat-melt softening, they are then pressed, cooled, reformed, and clamped again with specially designed metal forming rivet heads. Specific shapes of rivet heads can achieve flush riveting (countersinking), hemispherical riveting, arcuate flanging riveting, ribbed strip riveting, mechanical forging, edge wrapping inlay, etc. It achieves a connection method where different material mechanical riveting assemblies are combined together, with the connection part being not prone to embrittlement, beautiful, firm, and with good sealing properties, thereby realizing optimal structure design and fully utilizing the best combination of various materials’ mechanical properties, greatly enhancing the performance of the entire assembly, and making the overall structure impact-resistant, achieving the most perfect fit, especially suitable for long-term mechanical vibration, wide range of environmental temperature and humidity changes, and extremely harsh natural environments.

There are no reviews yet.