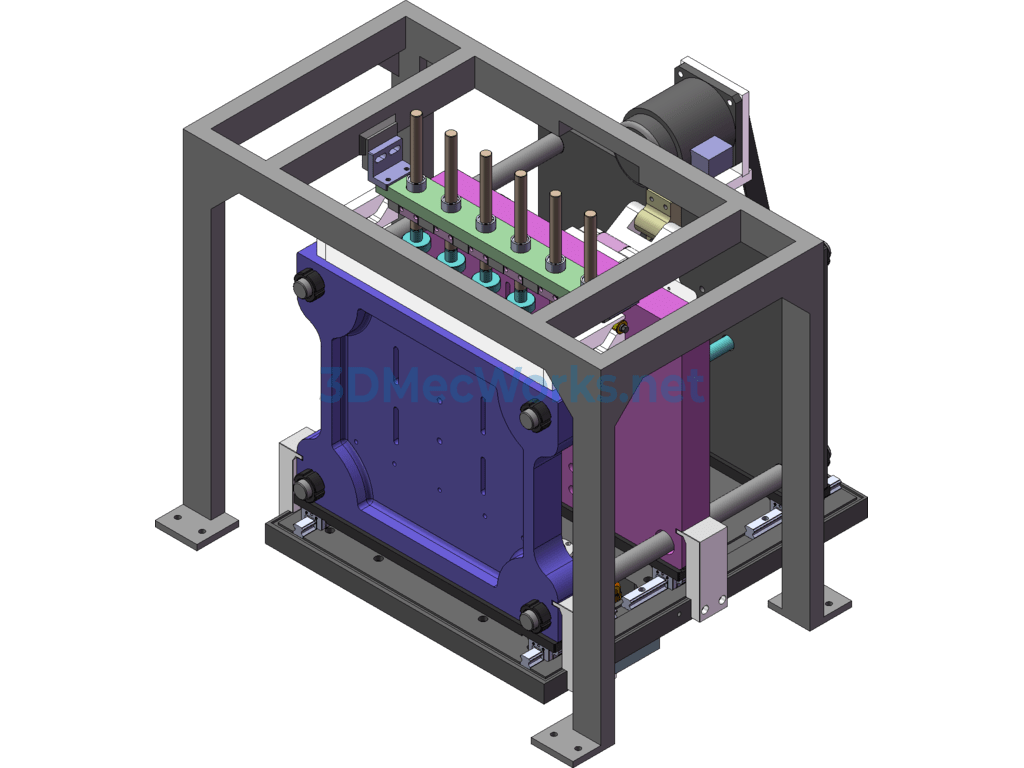

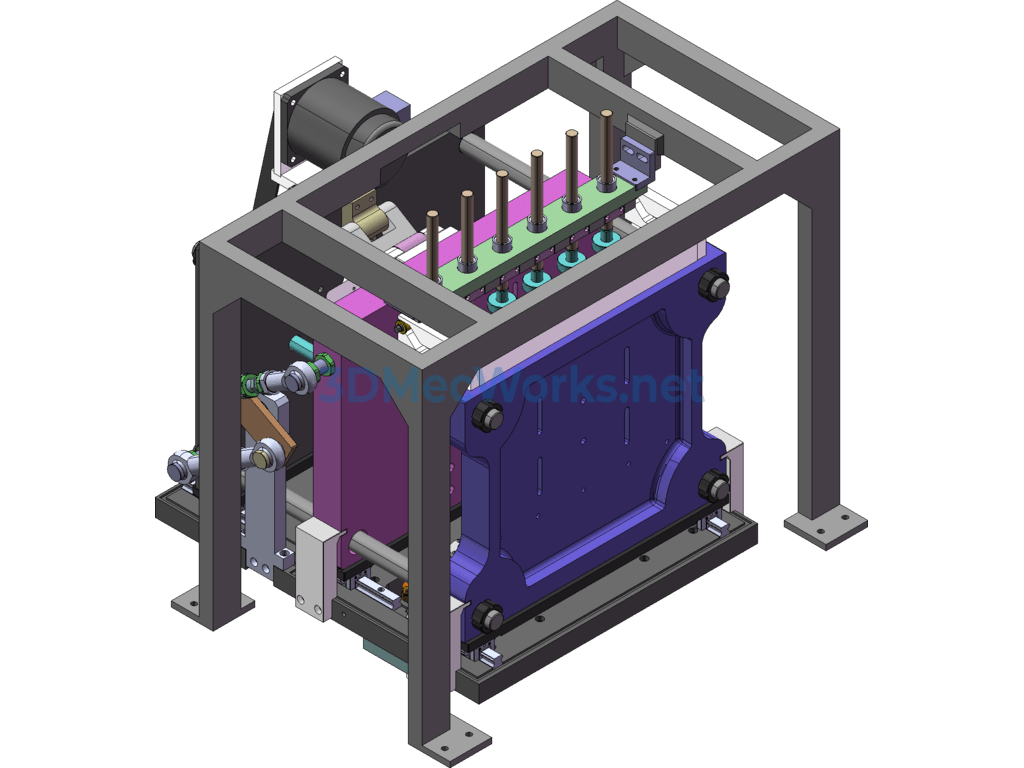

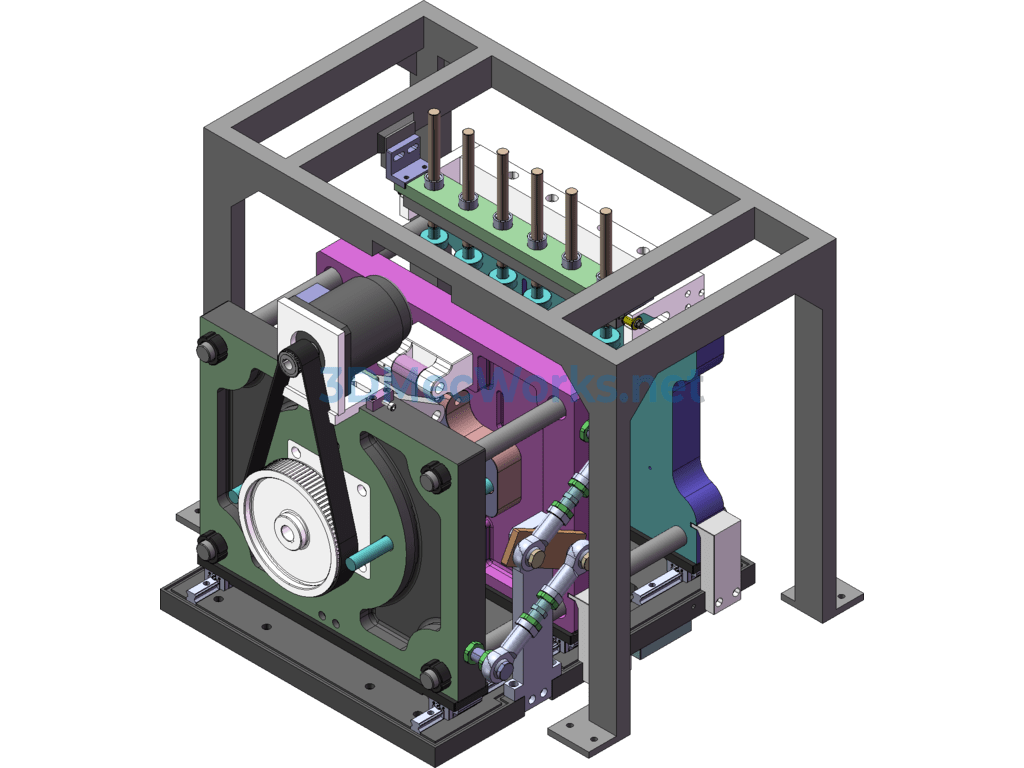

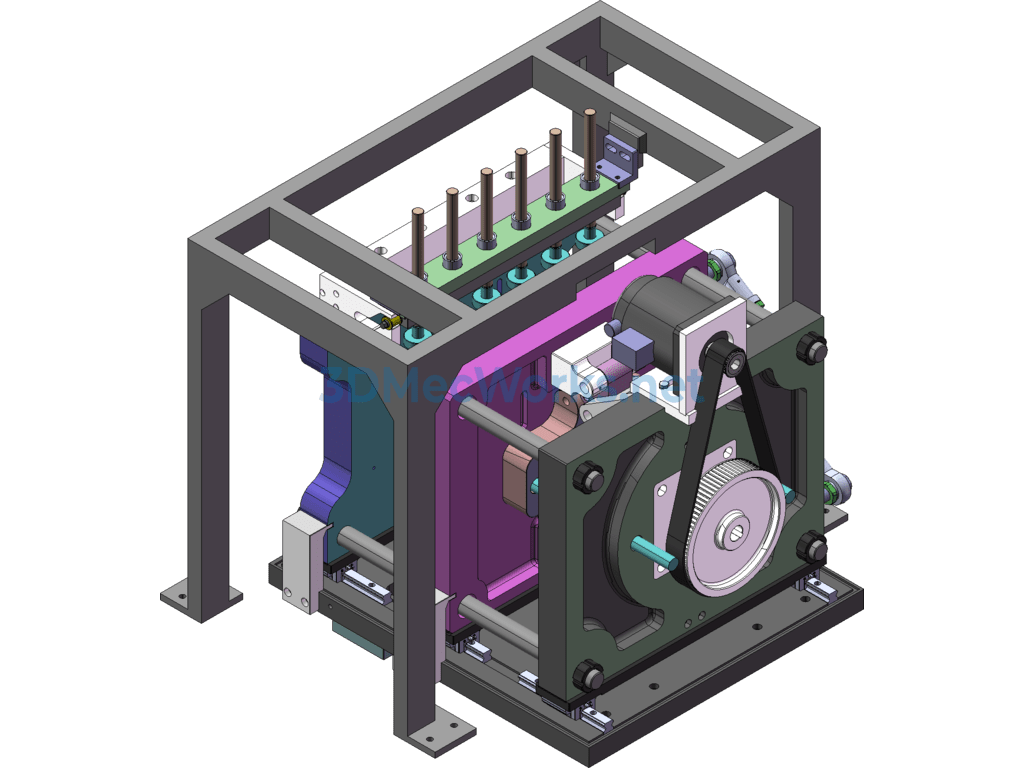

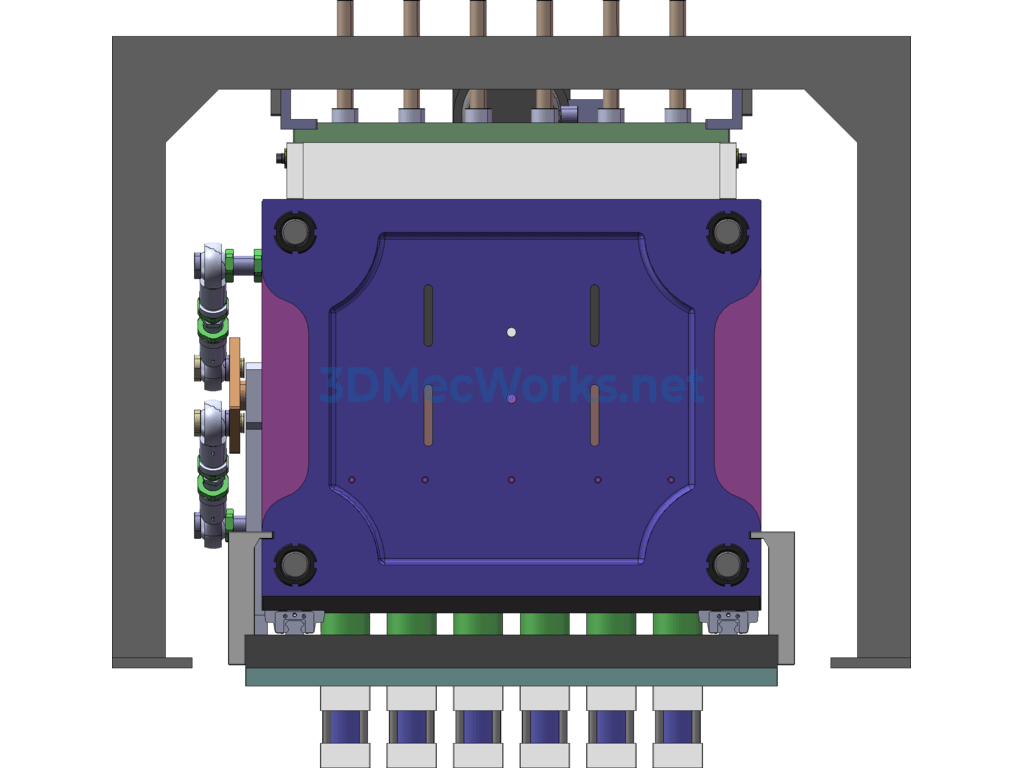

Electric clamping of blow molding machine

Injection molding machine clamping mechanism

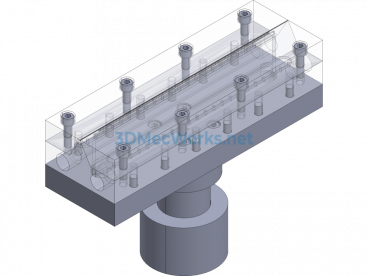

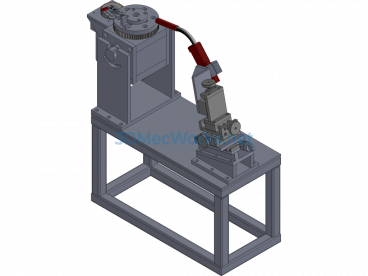

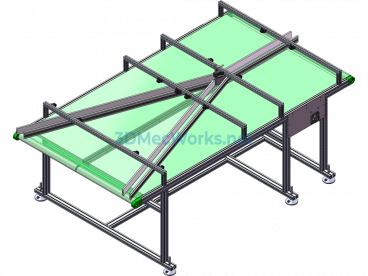

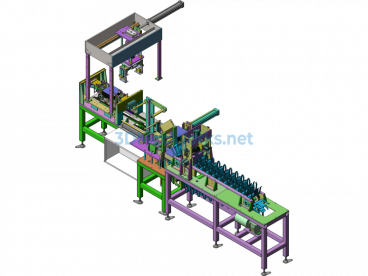

The clamping machine is a specialized mold fitting and testing equipment, mainly used in the later stages of mold manufacturing to fit the upper and lower molds with the required pressure. It adopts various reliable devices, equipped with a mobile worktable clamping positioning device, upper movement locking device, mechanical flipping device, hydraulic ejector, mold slider control, safety drop prevention device, etc.

The clamping device refers to the injection molding machine composed of the injection device, clamping device, hydraulic control system, etc. The injection device injects a quantitative amount of melt into the mold cavity at a certain pressure and speed; the clamping device enables mold opening and closing, ensures reliable mold closure and product ejection; the hydraulic control system ensures the preset pressure, speed, temperature, time, and action sequence.

There are no reviews yet.