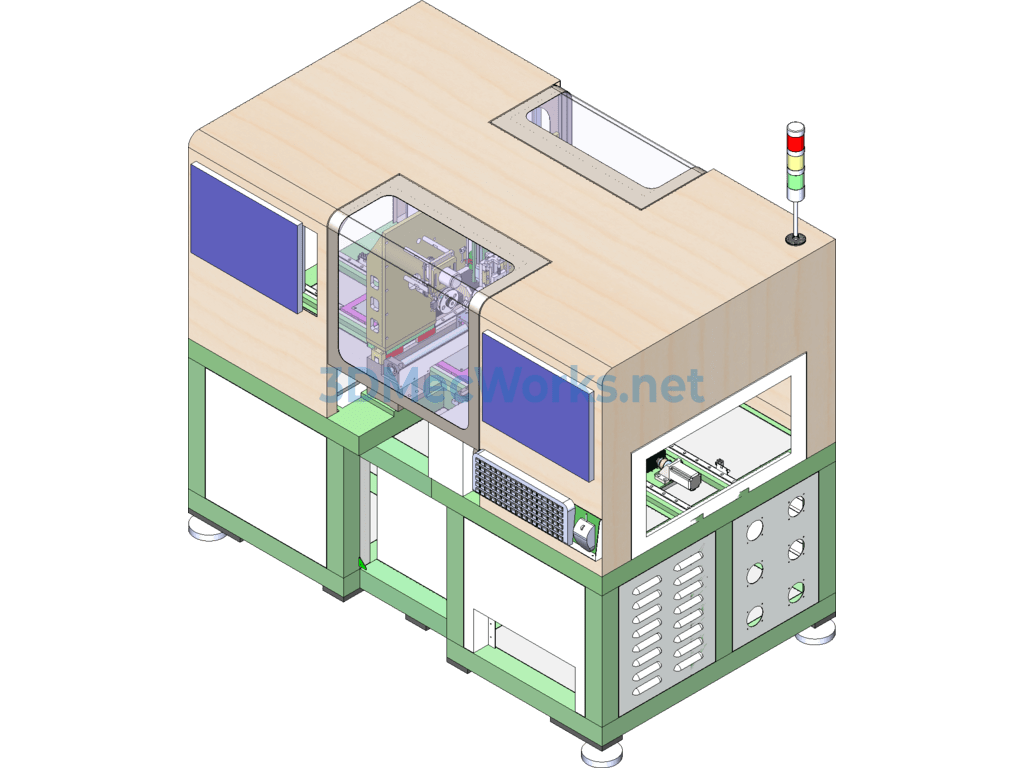

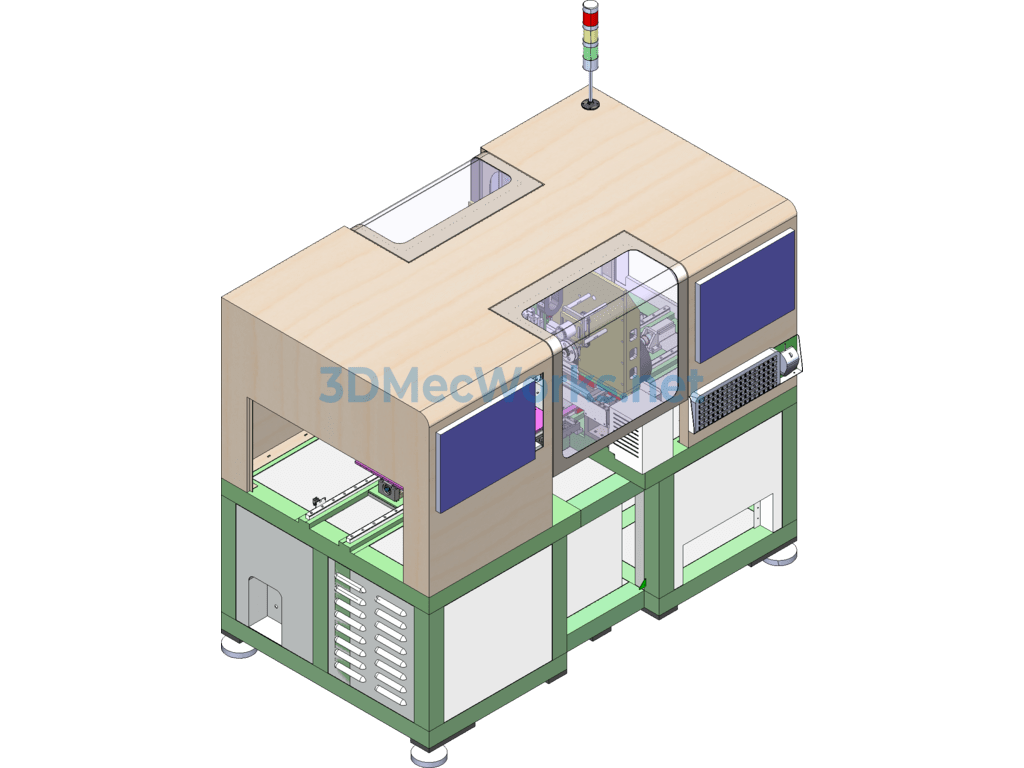

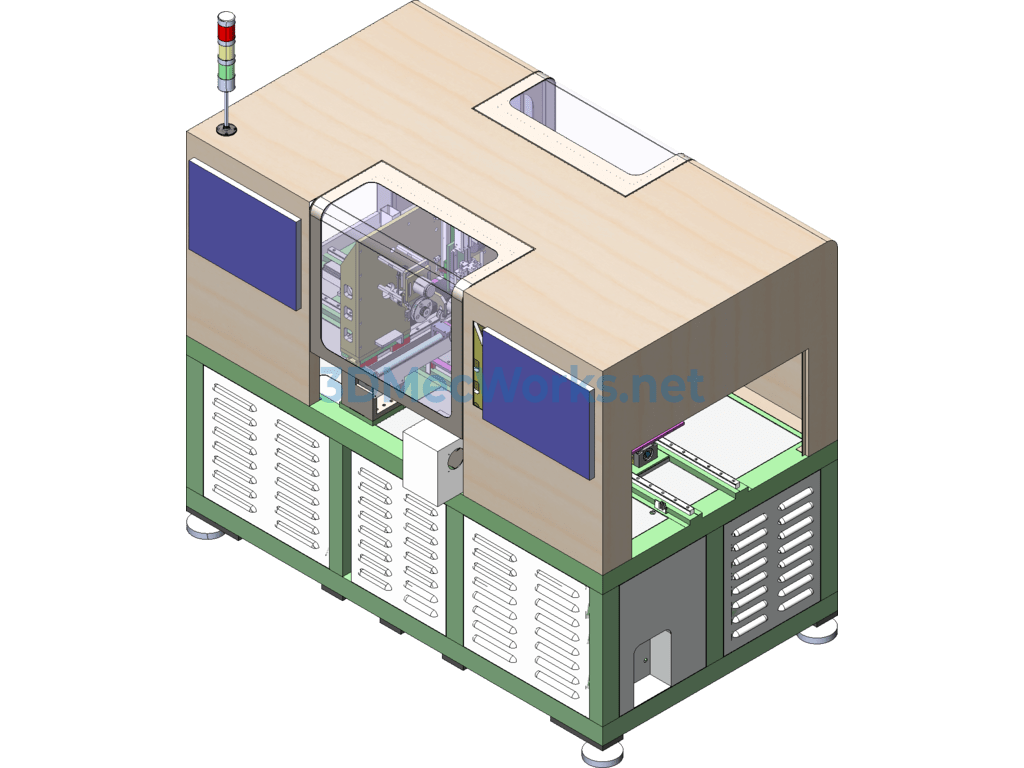

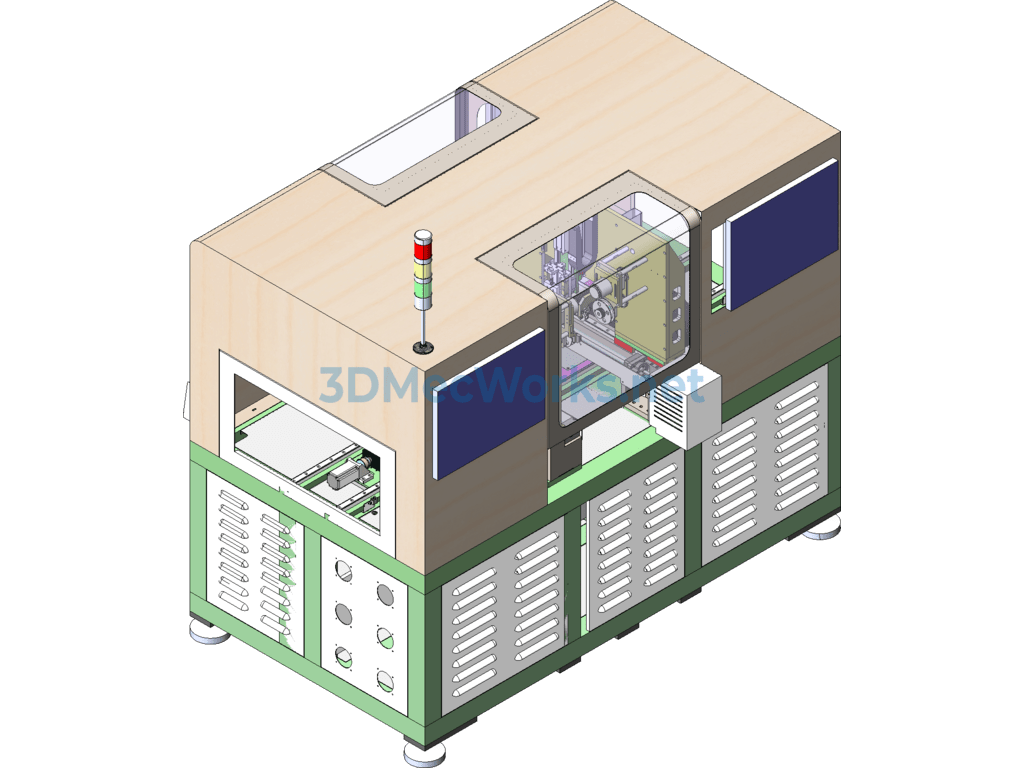

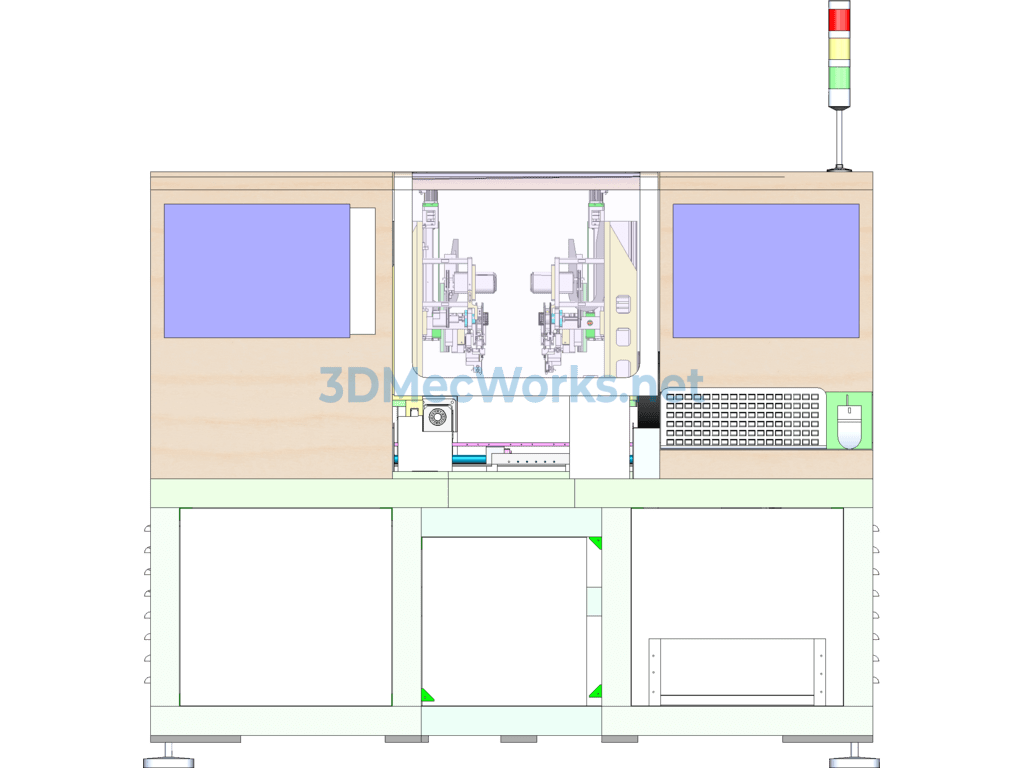

The mechanism of this equipment is designed with SW2016 and includes editable part features. The equipment can be equipped with magnetic ring installation and dispensing functions to achieve the installation of magnetic rings and dispensing on the pins of thyristors (crystals). This saves labor and reduces repetitive equipment investments for enterprises, resulting in more stable product processing, with efficiency 4-5 times that of manual work. It features a Japanese Mitsubishi PLC control system and a Japanese fiber optic controller that is quick and responsive. The operation interface uses a Taiwanese WeLUN touchscreen for convenient operation and fault reflection, allowing operators and engineers to promptly address and resolve issues. It employs pneumatic controls from Taiwanese AIRTAC and Japanese SMC, paired with Taiwanese HIWIN sliders and bearings, which are precise, stable, and durable. The brushless electric screwdriver is durable with precise torque adjustment. The screw feeding part supplies fast without backflow, and it operates completely differently from ordinary screw feeders. This new screw feeding mechanism features backflow prevention and reverse feeding functions. The thyristor feeding part uses Taiwanese technology to create linear vibration with low noise and stable feeding without backflow. The screw fastening is stable, and it can simultaneously detect defects, such as no heat sink on the fixture, a heat sink without holes, a heat sink with holes but no screws, reversed screw feeding, incomplete fastening, and screws without a crosshead. It includes editable formats common to STP and UG.

There are no reviews yet.