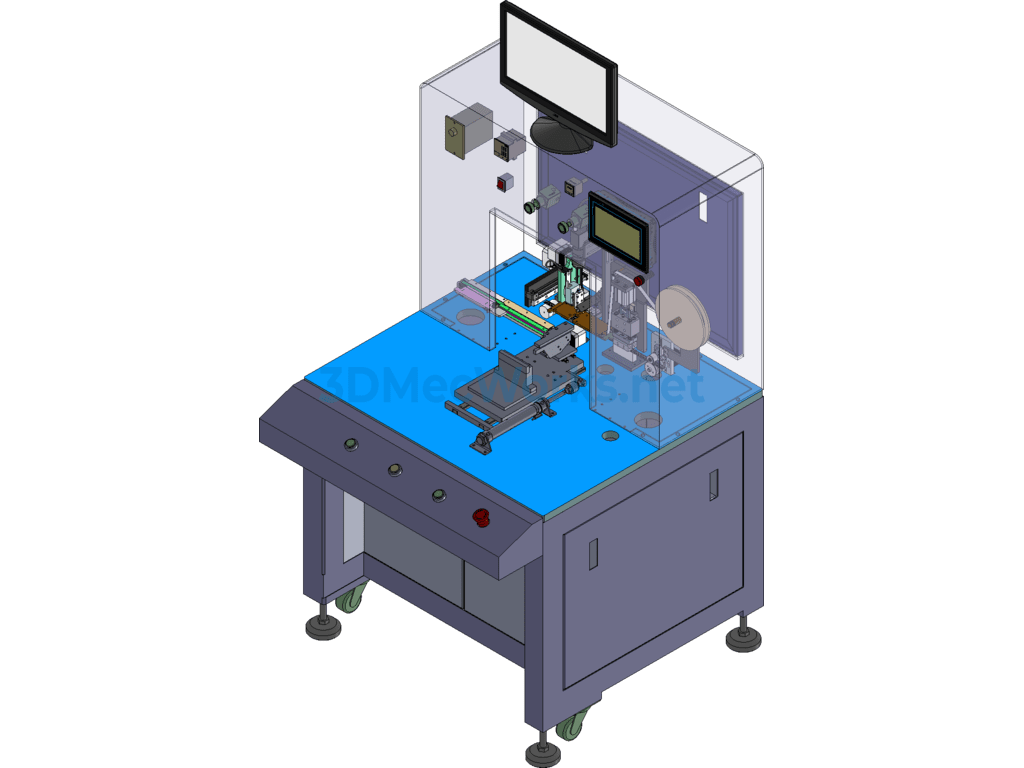

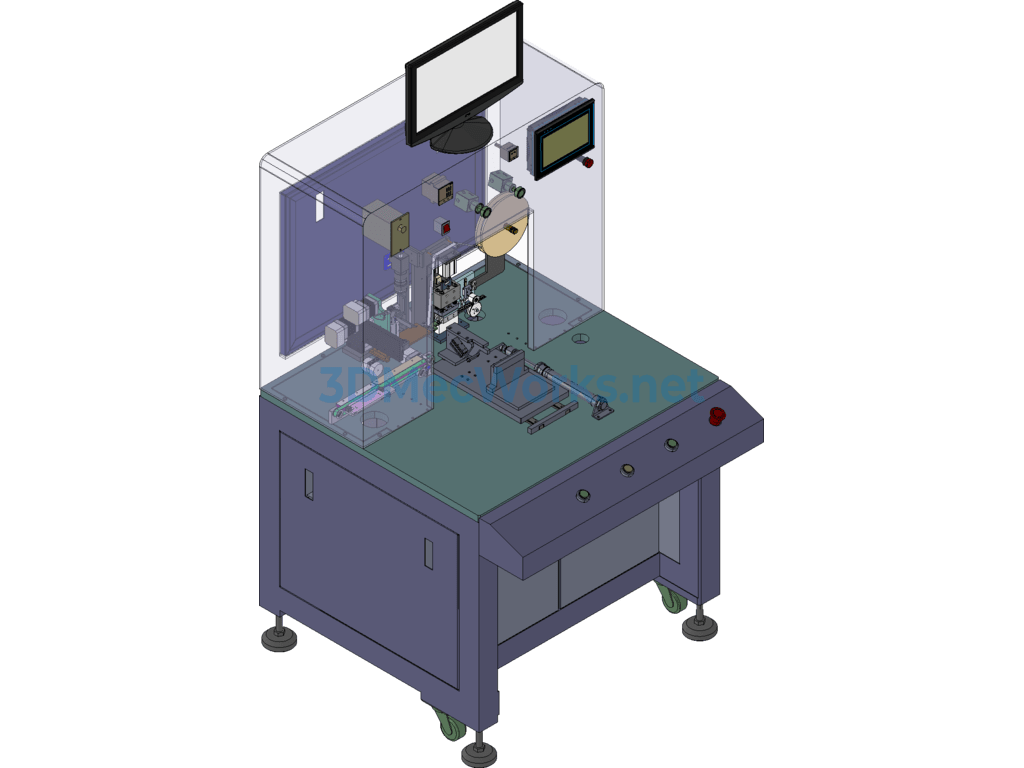

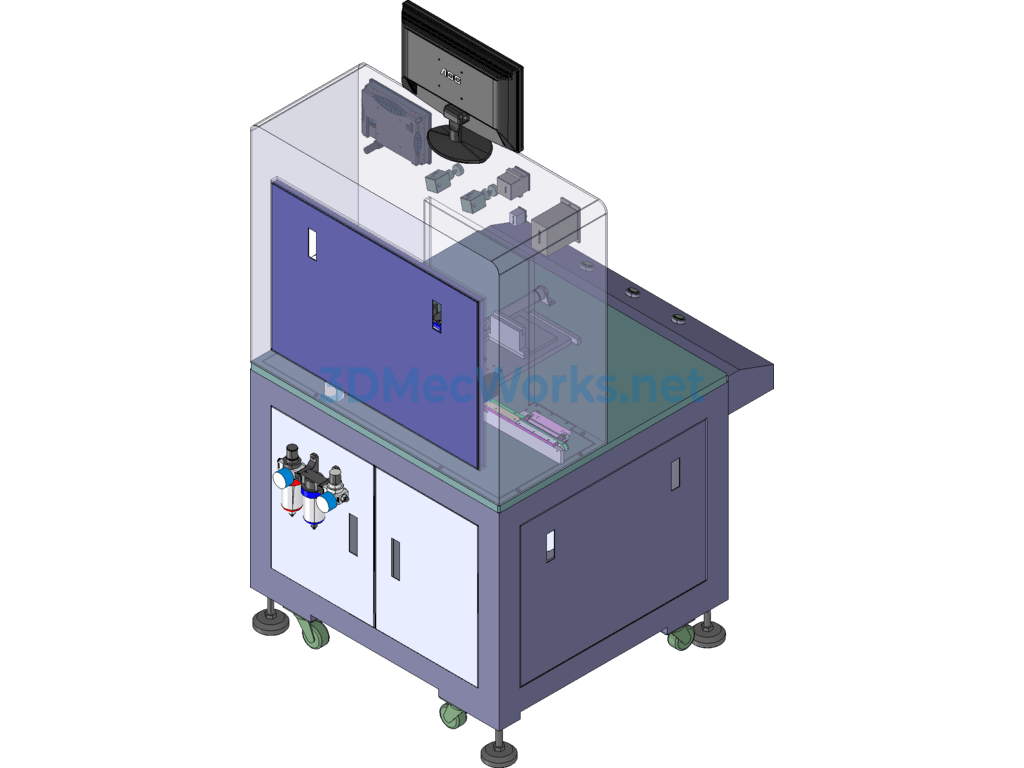

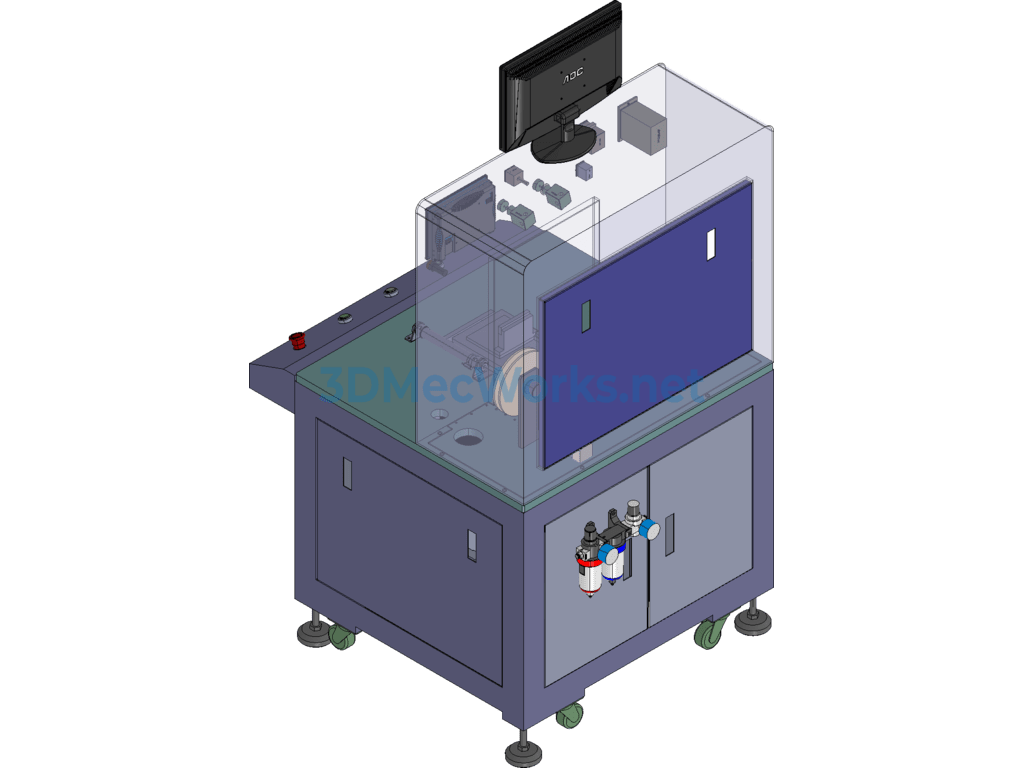

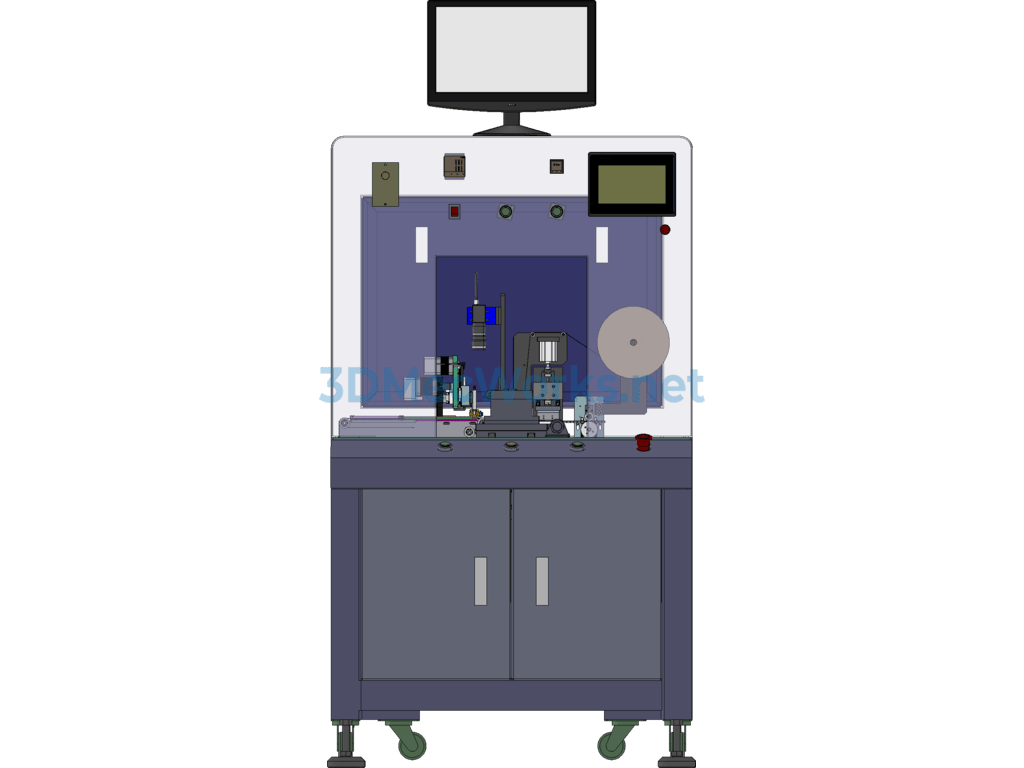

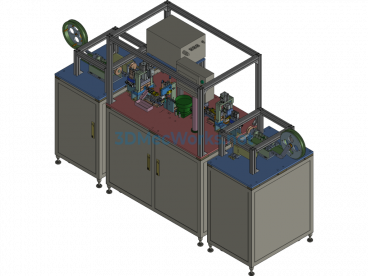

The mechanism of this equipment, designed with SW2016, includes editable part features. The concept of flexibility and high speed features a double cycloidal belt pulley, achieving higher speeds and transmission without jitter. The intelligent imaging system with special light source design is more effective for character detection and has a wide range of applications. It is suitable for inspecting SMD, IC, and products after taping. It is compatible with carrier tape specifications. The entire machine control system is PC-based with automatic material collection control, and the machine automatically alarms when there is a fault. The machine’s capacity ranges from 2000-6000 pcs/h for material trays with specifications of 7″, 13″, 15″ reels. It has a repeat positioning accuracy of ±0.02. The entire machine is controlled by a closed-loop stepper motor. It uses high-precision imaging software to detect characters, orientation, pins, polarity, batch, and missing components, among others. Includes STP and UG universal editable formats.

There are no reviews yet.