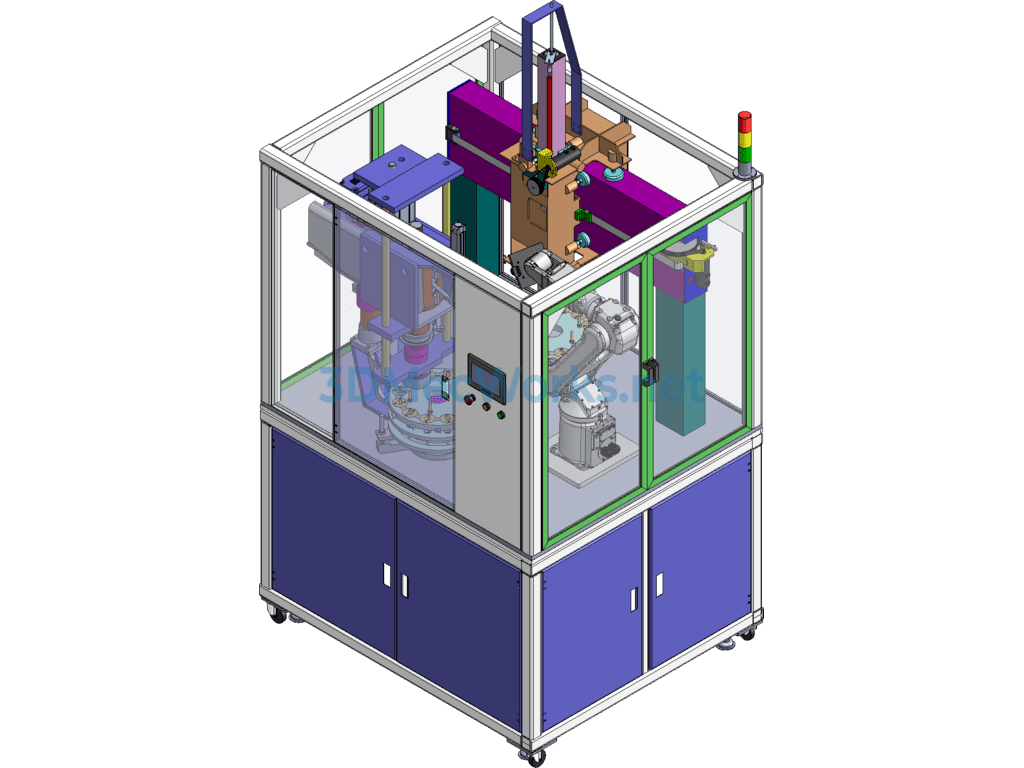

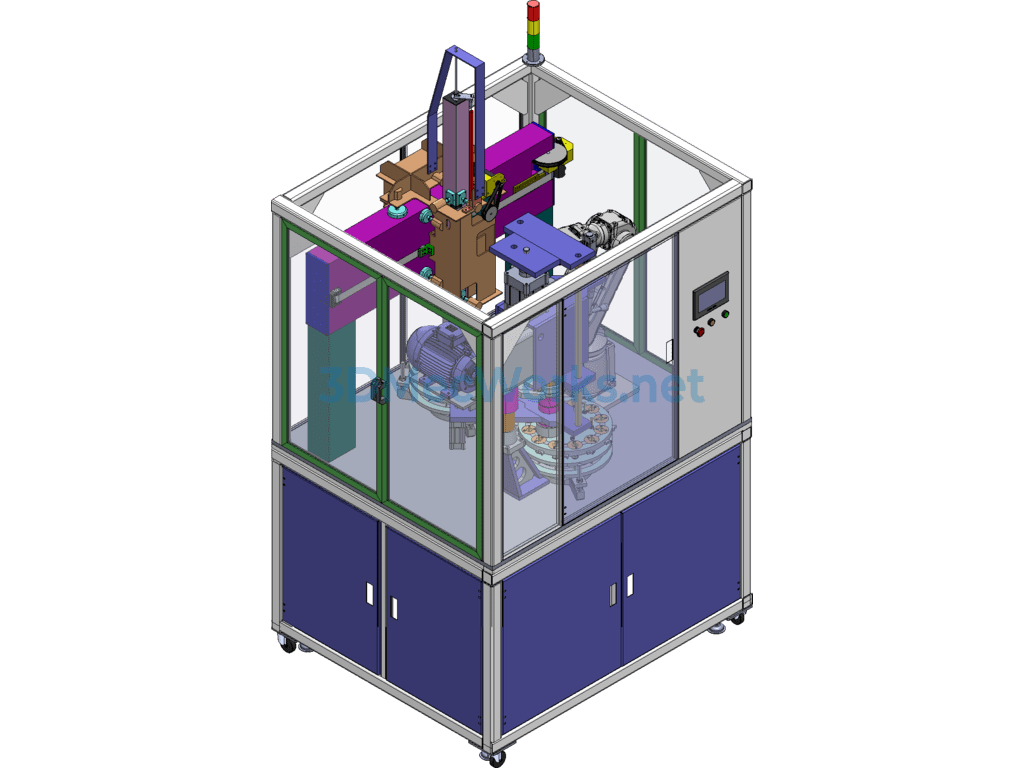

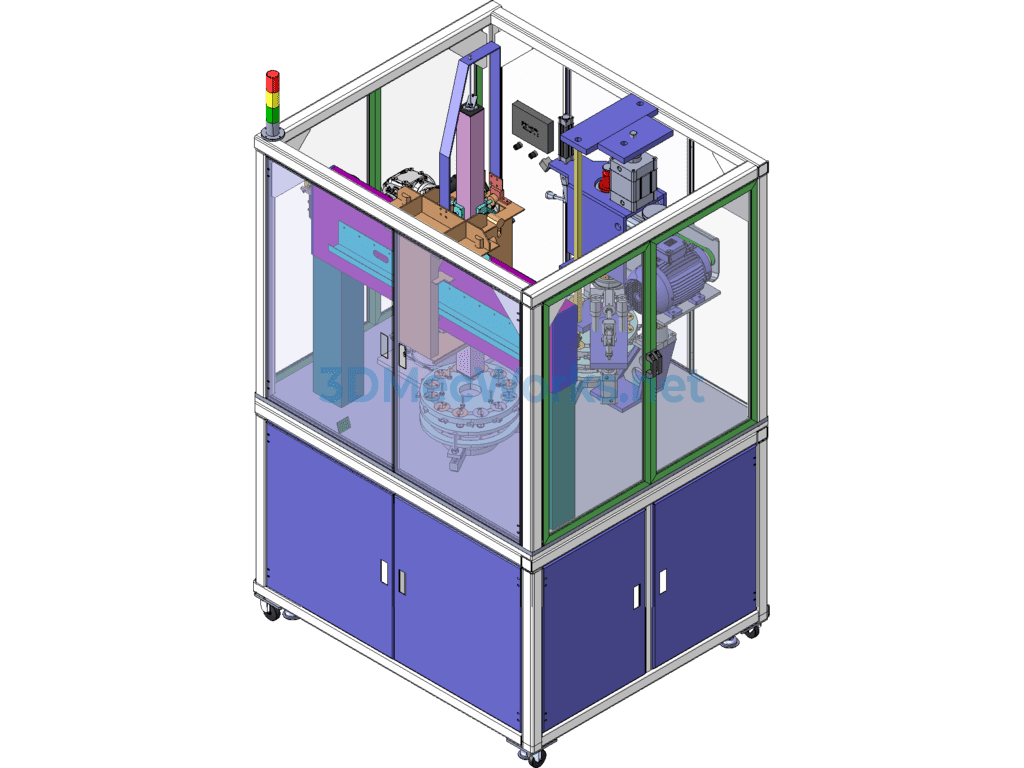

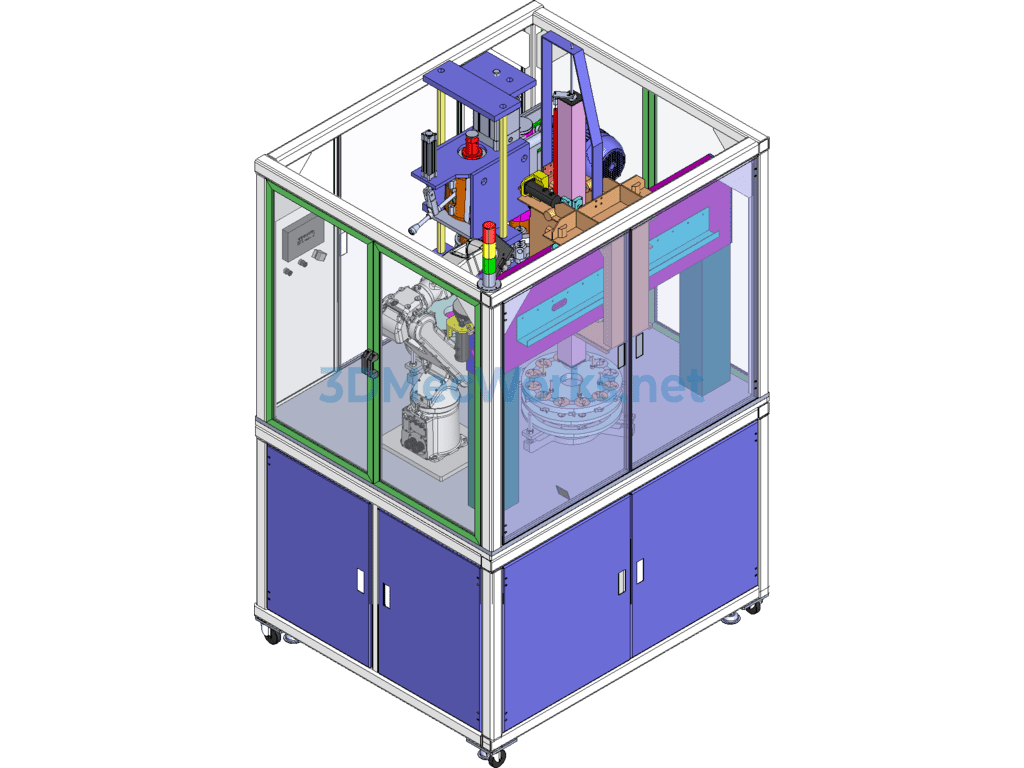

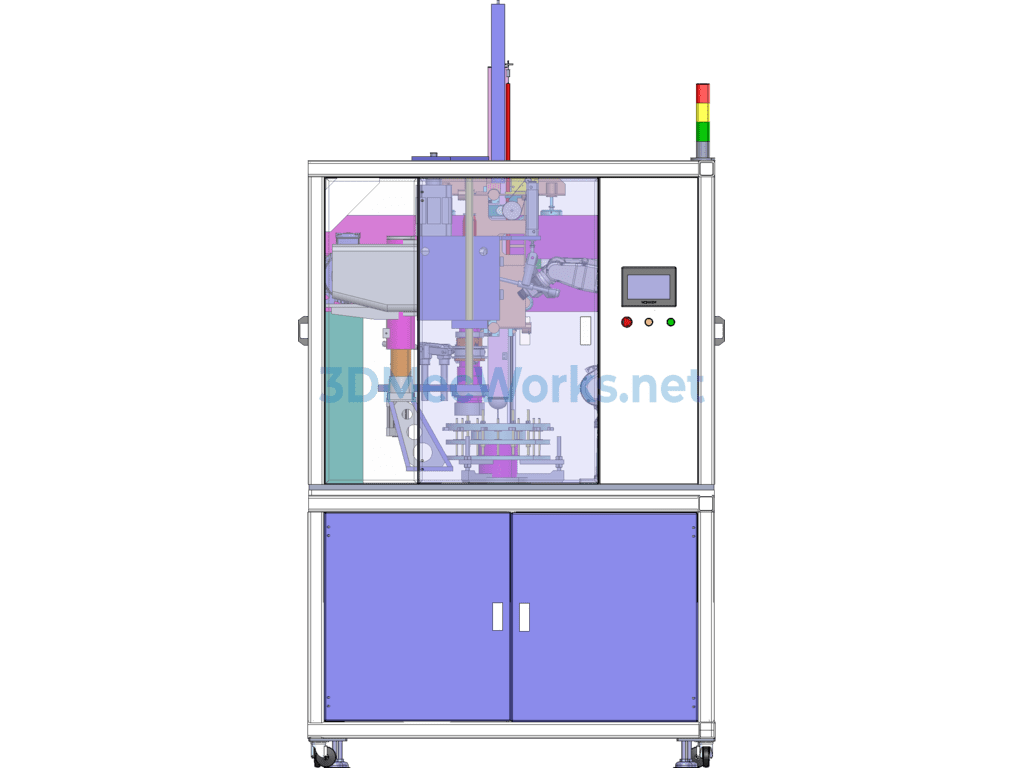

The double-headed rivet assembly equipment mechanism is designed with SW2016 and includes editable part features. The key components of the equipment use new materials and processes to improve the stability of equipment operation; the equipment adopts some new structures, and some debugging positions are visualized to enhance the operability of the equipment; the equipment uses a semi-enclosed structure, with an internal oil mist treatment system, making the equipment safer, more aesthetically pleasing, noise-reducing, and environmentally friendly. Automation control of the equipment is achieved, including material shortage detection, automatic counting, upsetting anomalies detection, separation of nonconforming products (caused by variations in head thickness size and alignment of nail foot with head); shop floor digital production control is realized—where 40 devices form a group, which can be connected through one terminal (host computer) with these 40 devices (slave computers) to issue orders, monitor the order production status of slave machines, equipment status, etc., forming a database. Includes editable formats in STP and UG.

Specification: Double Head Rivet Assembly Equipment

|

User Reviews

Be the first to review “Double Head Rivet Assembly Equipment”

You must be logged in to post a review.

There are no reviews yet.