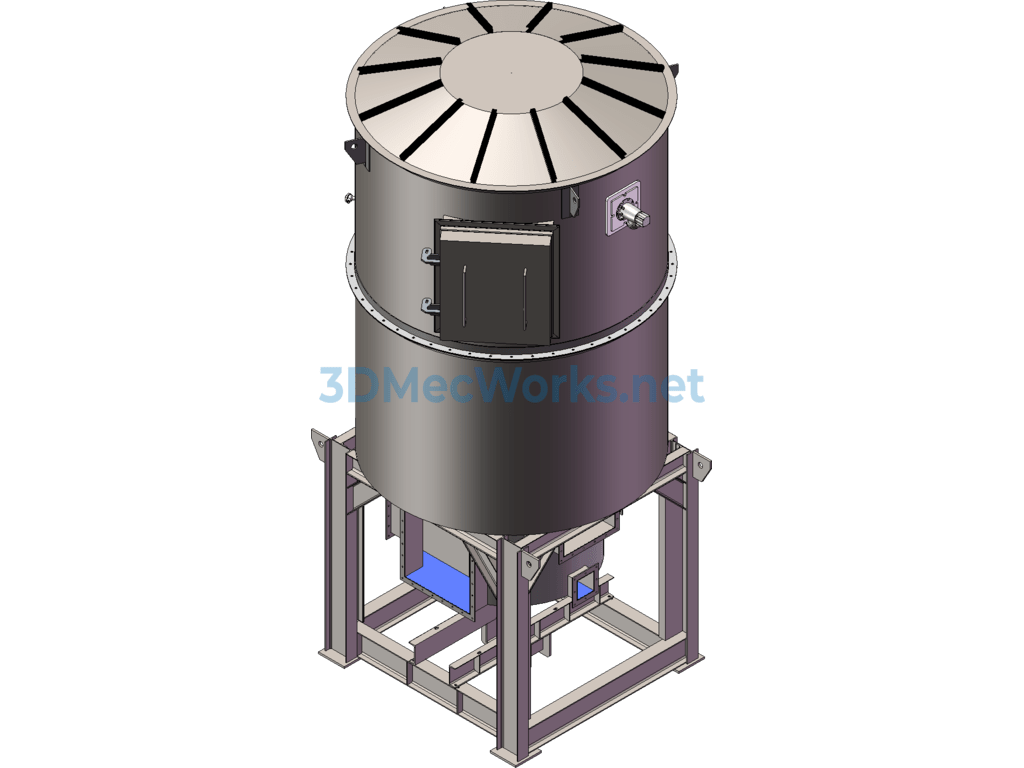

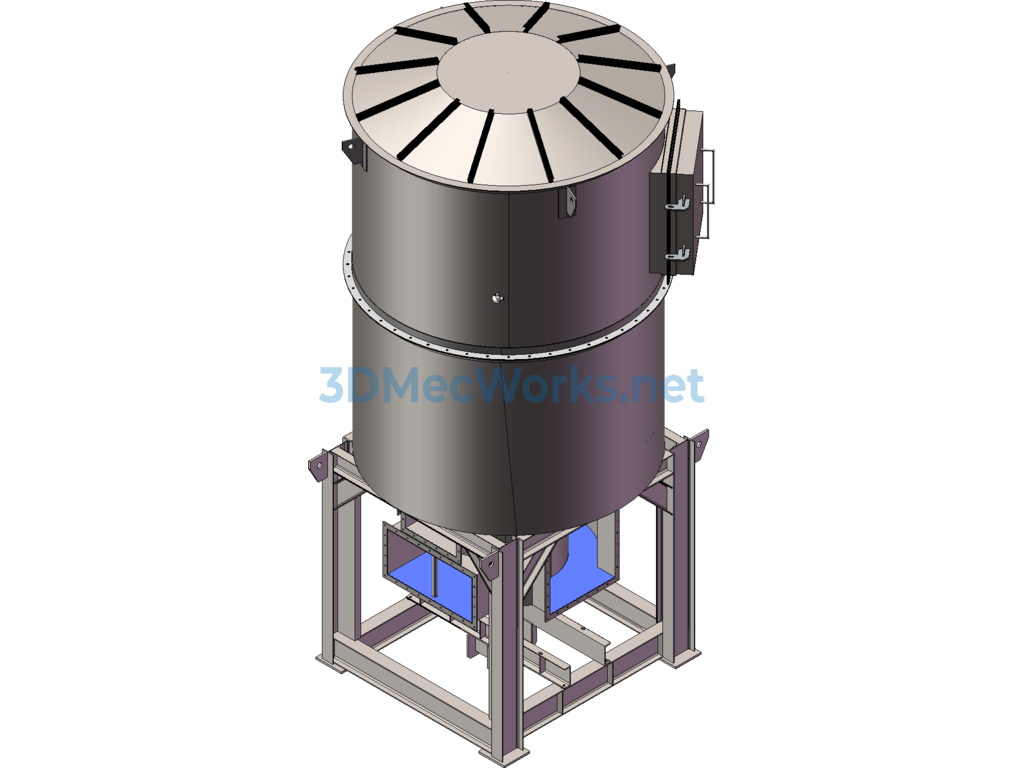

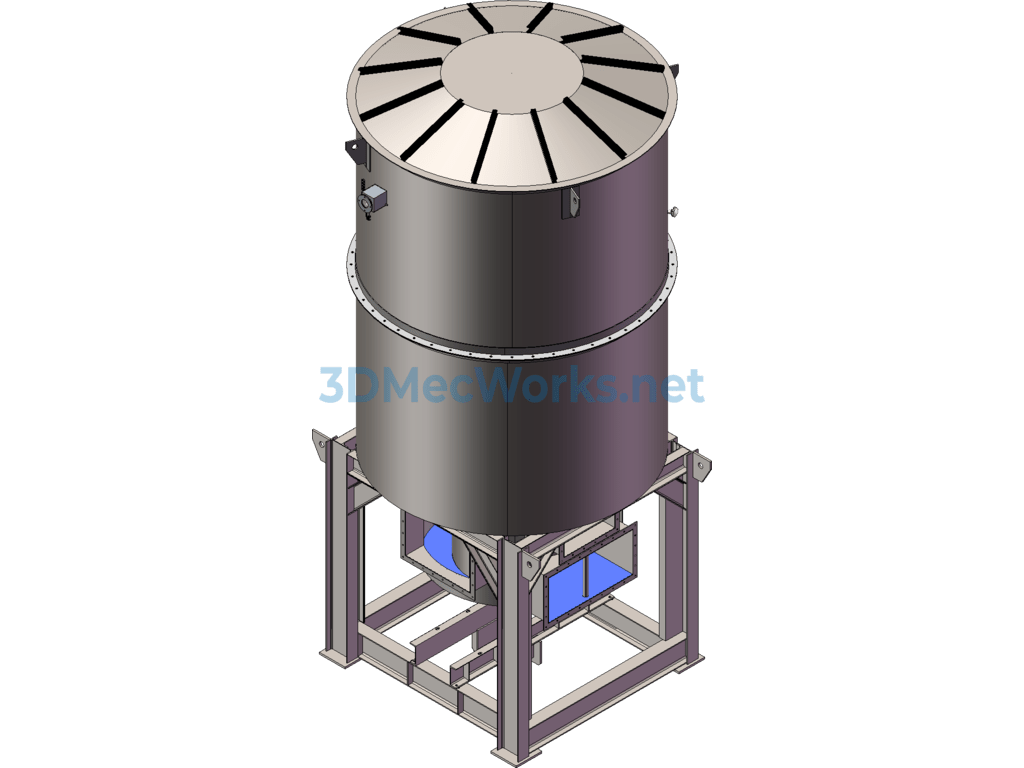

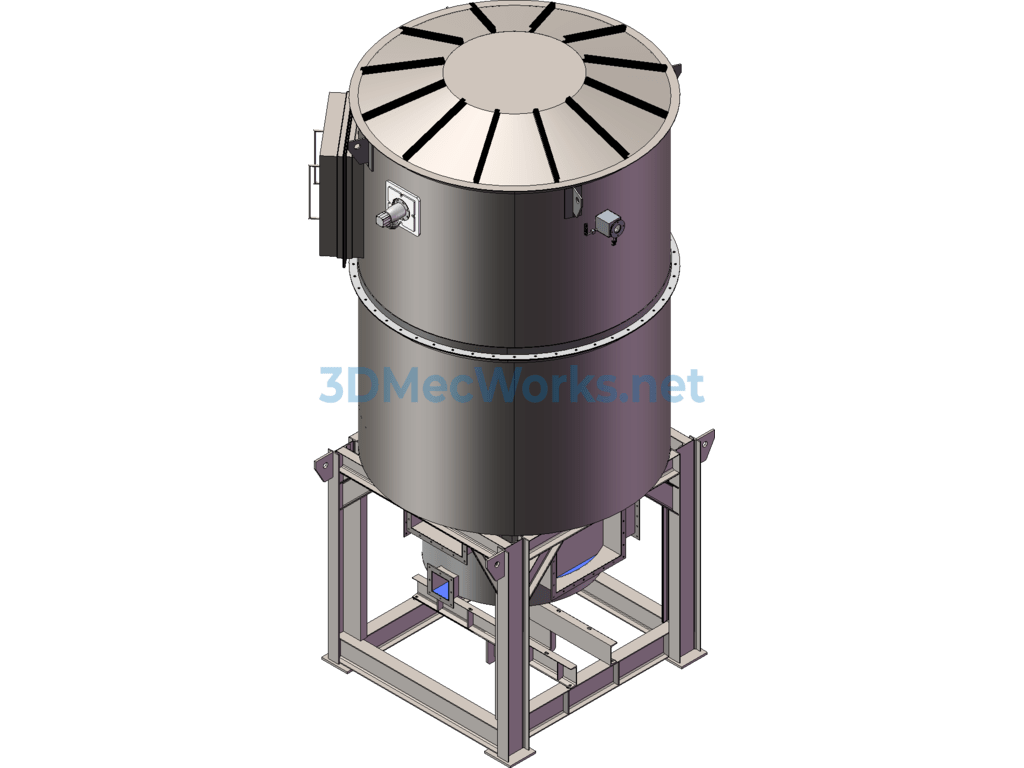

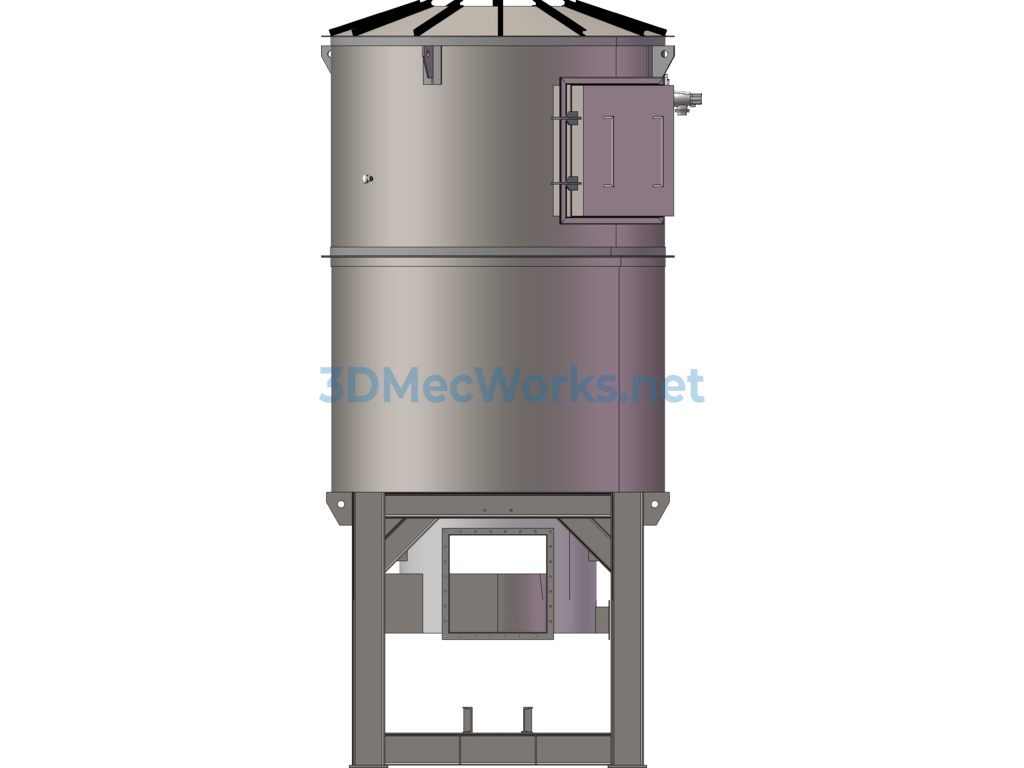

5000 Air Volume Rotary RTO Furnace Catalytic Combustion Regenerative Equipment

Rotary RTO Incinerator, VOCs Organic Waste Gas Treatment

With the continuous advancement of industrialization, the pollution of VOCs shows a trend of further expansion. As environmental protection policies have become increasingly stringent recently, controlling emissions of organic polluted gases has become more important. The rotary RTO furnace utilizes twelve (numbered 1~12#) fixed heat exchange media beds, using regenerative ceramics as the heat exchange medium. The exhaust gas from the production line is heated after passing through five (1~5# as the intake area) thermal ceramic media beds; the high-temperature gas burned in the furnace chamber heats the other five (7~11# as the exhaust area) heat exchange media beds, with 6# corresponding to the purge area, and 12# as the transition area. Under the function of the rotary switch valve, the two groups of numbers of the ceramic media beds cycle alternately (e.g., 2~6# as the intake area, 8~12# as the exhaust area, 7# as the purge area, and 1# as the transition area, cycling accordingly), thus the two groups of heat exchange media beds switch with each other, regenerating heat to warm the low-temperature exhaust gas. Since only 1/6 of the ceramic media changes airflow direction each time it switches, it effectively reduces the wind pressure fluctuation at the RTO inlet and outlet, having minimal impact on the air pressure of the front-end production line. This set model is a 5000 air volume rotary RTO.

Specification: 5000 Airflow Rotary Rto Furnace, Catalytic Combustion Regenerative Equipment

|

User Reviews

Be the first to review “5000 Airflow Rotary Rto Furnace, Catalytic Combustion Regenerative Equipment”

You must be logged in to post a review.

There are no reviews yet.