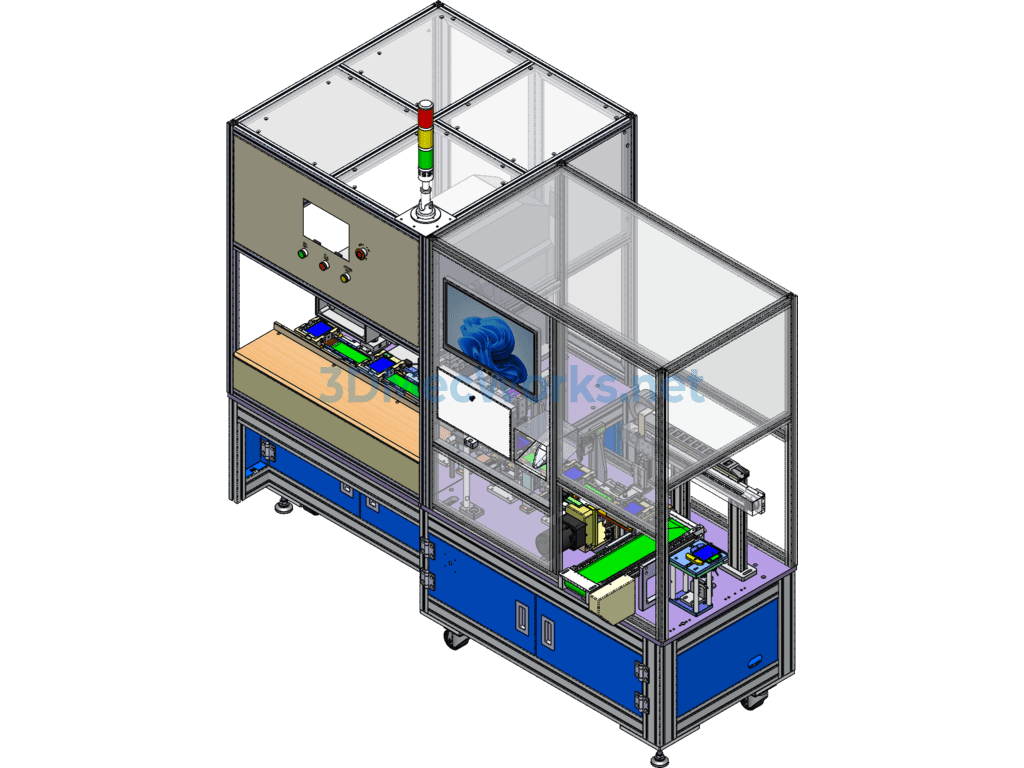

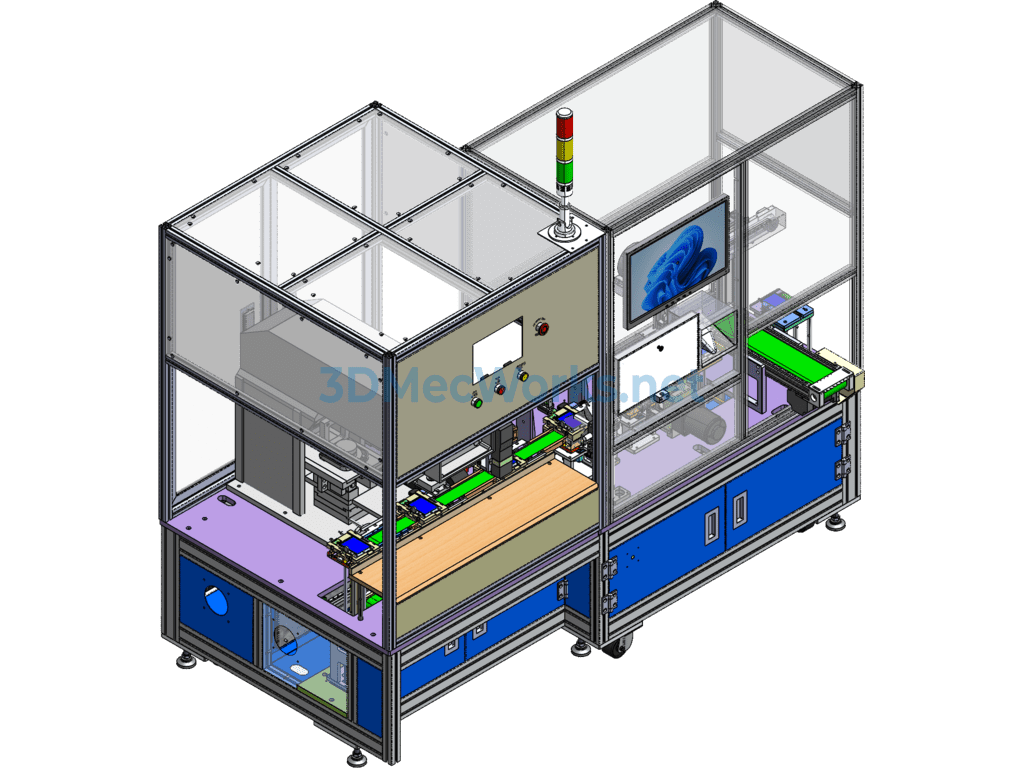

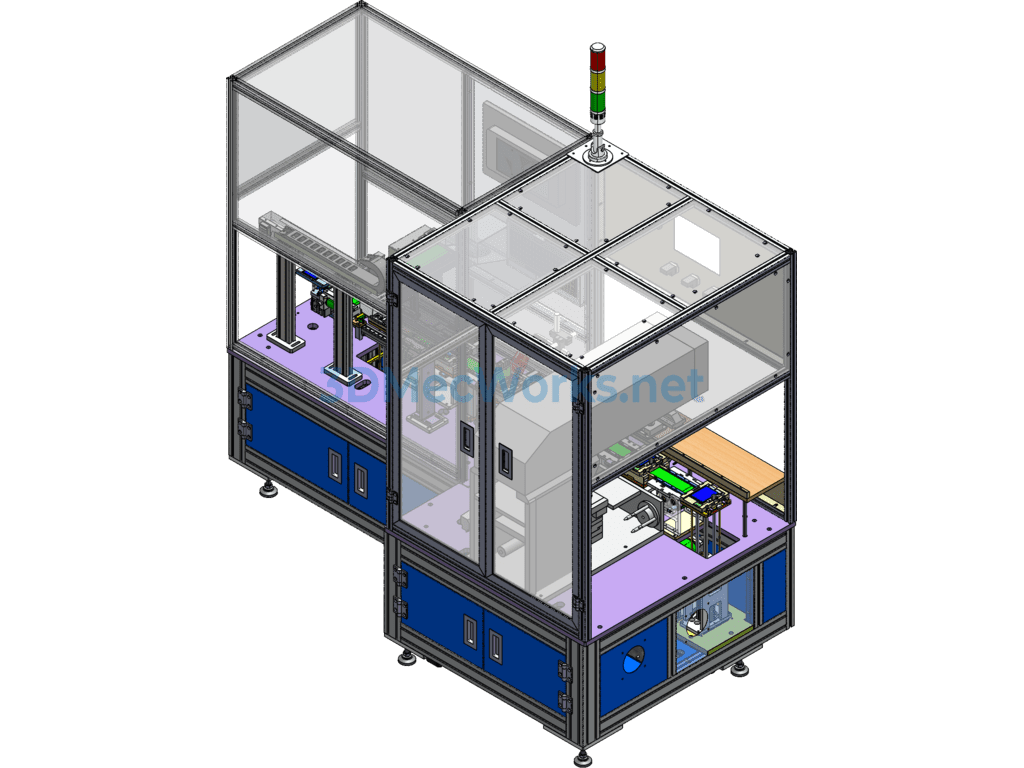

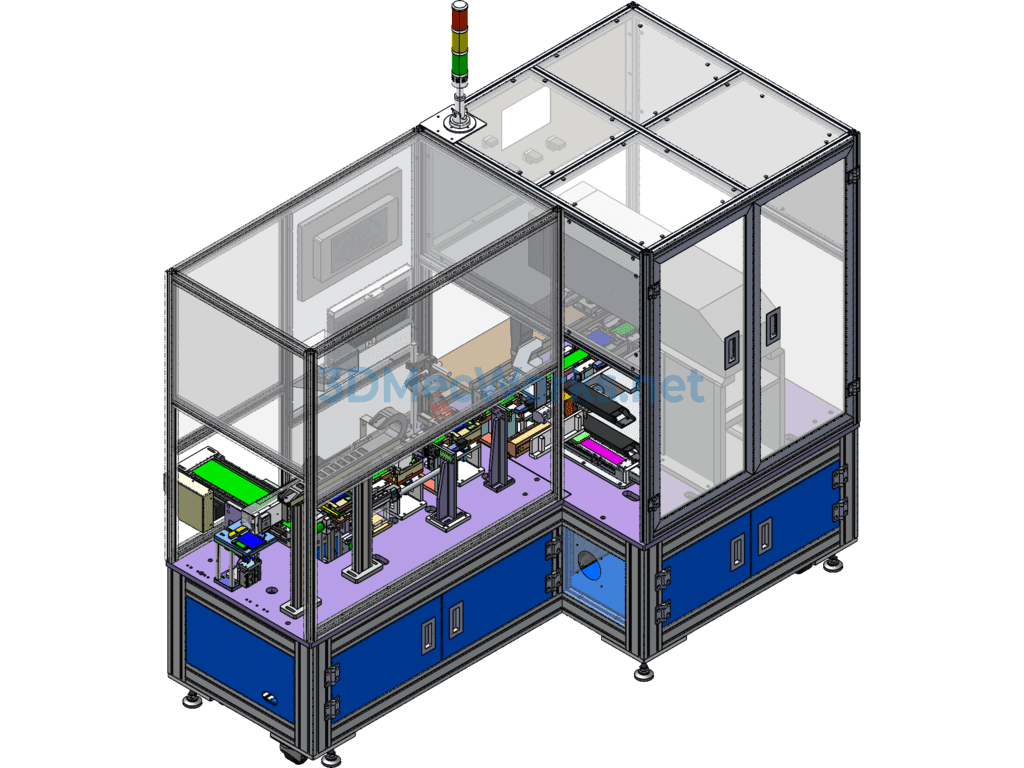

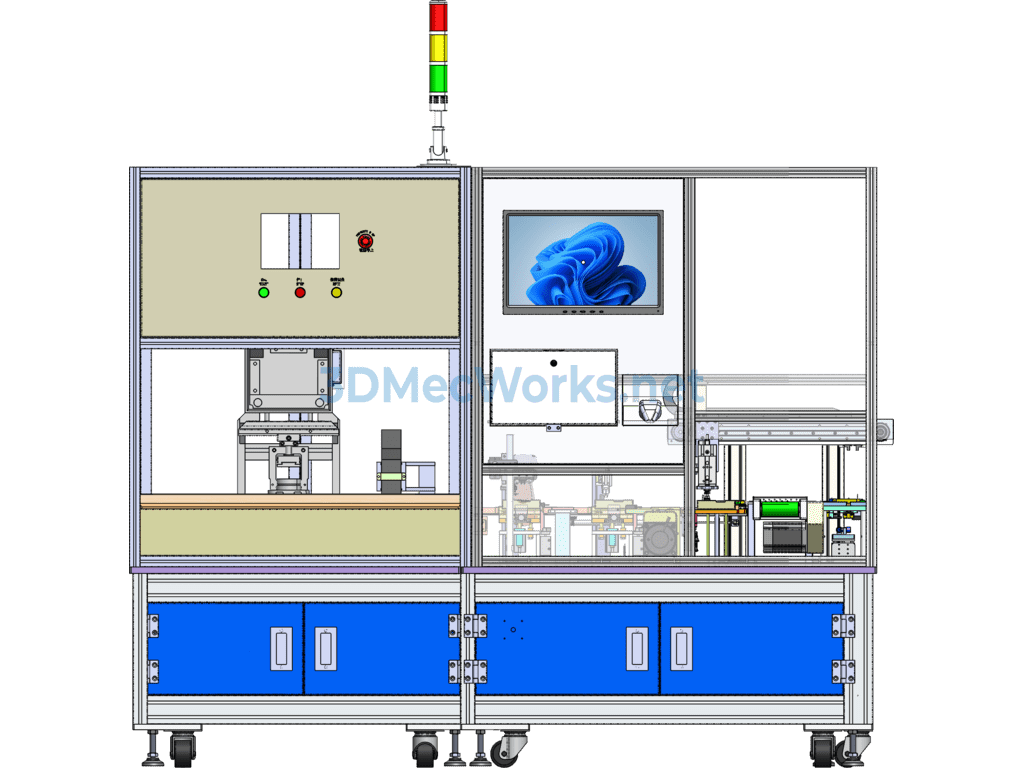

This device is a fully automatic pad printing and coding testing machine for mobile phone batteries. The drawings of the equipment are 350MB, with a total of about 400 parts of various sizes. The 3D model of this device is designed using SolidWorks 2012 software. The complete set of drawings is an original 3D model design blueprint. The quality of these drawings is superior to other members’ drawings, so feel free to download them. The main function of the device is to perform pad printing and coding on the surface of batteries, printing some characters and barcodes. Batteries are positioned and transported to each station through carriers and conveyor belts. First, they are lifted and positioned at the pad printing and coding station, then the pad printing machine performs pad printing. If coding is needed, it is done at the next station. The carrier board transports the battery to the scanning and testing station, where a scanner gun can determine if the printing and coding are defective, and any defects are automatically removed through a manipulator. The batteries then flow into the OCV testing station for voltage and internal resistance testing. Once testing is complete, the batteries exit the conveyor for manual collection. The entire process is divided into two stations to complete all pad printing, coding testing, and other tasks. This device can also be applied to other industries to achieve automation of pad printing and coding functions. After coding, the carrier returns to the lower conveyor belt for continued manual loading and unloading loop operations. Due to the extensive content of the drawings, detailed structures and specifics require downloading the drawings for further understanding. Therefore, friends in need are welcome to download, learn, and understand. Downloading and referencing the drawings is highly beneficial.

Specification: Fully Automatic Battery Pad Printing and Coding Testing Machine

|

User Reviews

Be the first to review “Fully Automatic Battery Pad Printing and Coding Testing Machine”

You must be logged in to post a review.

There are no reviews yet.