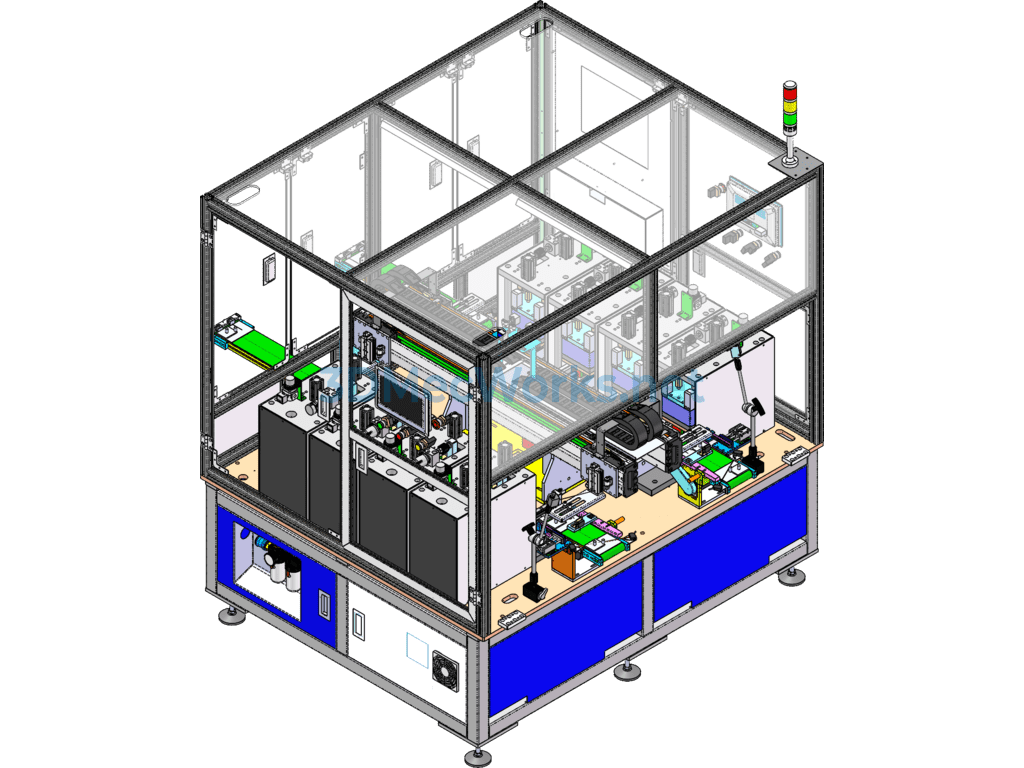

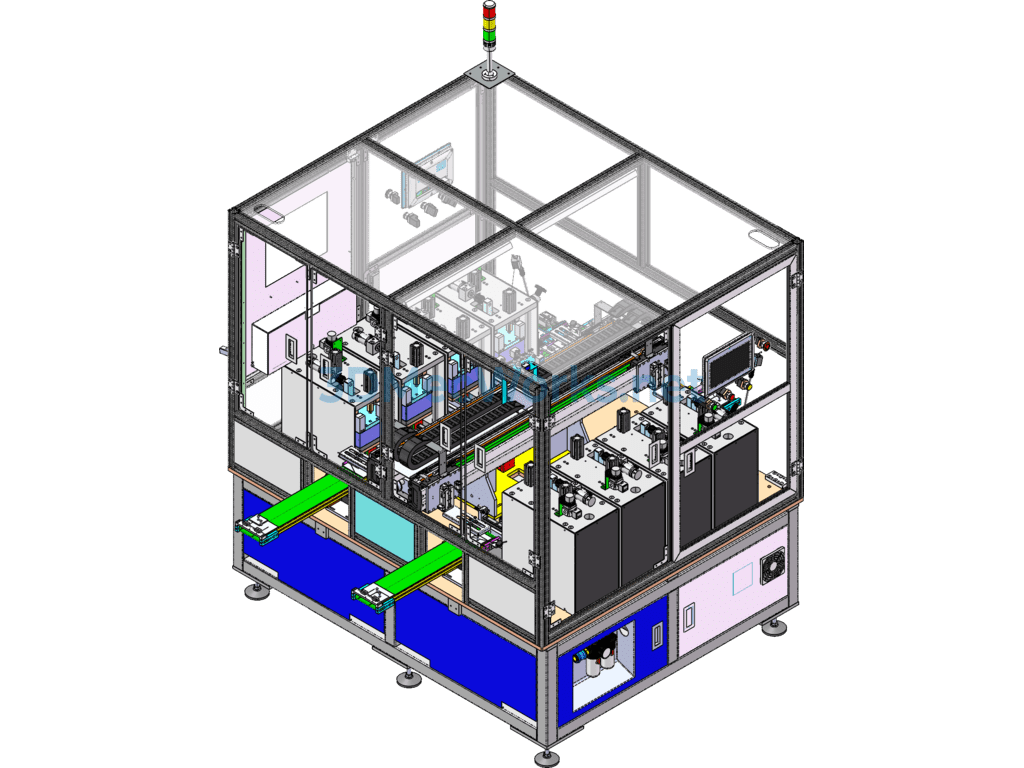

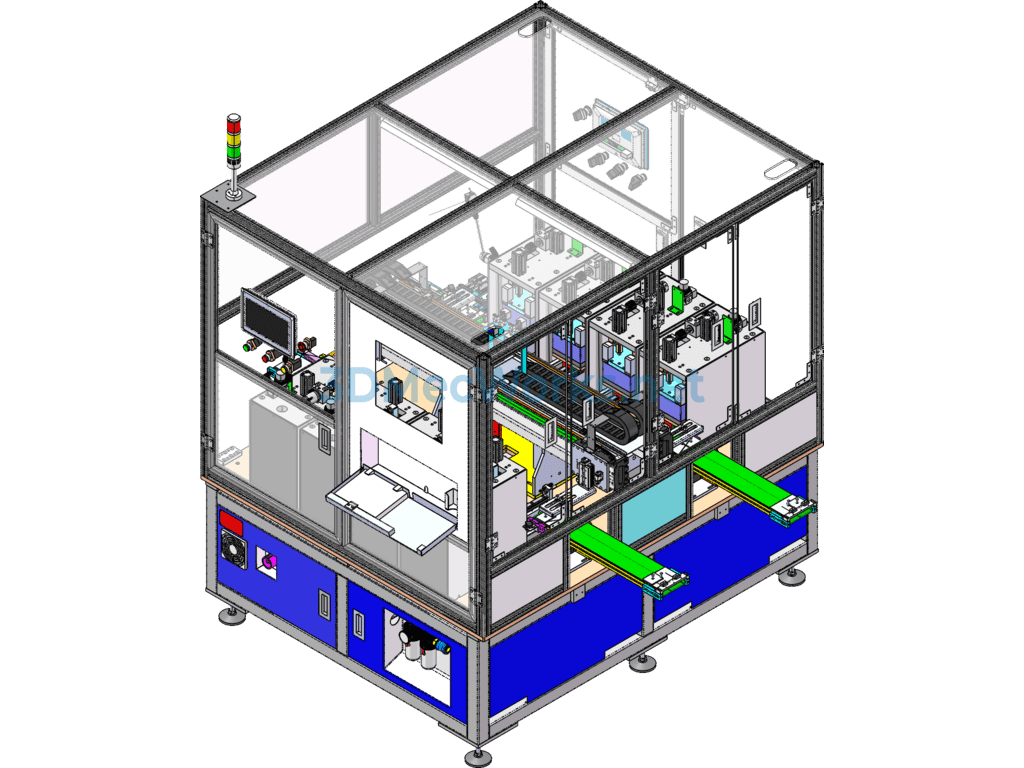

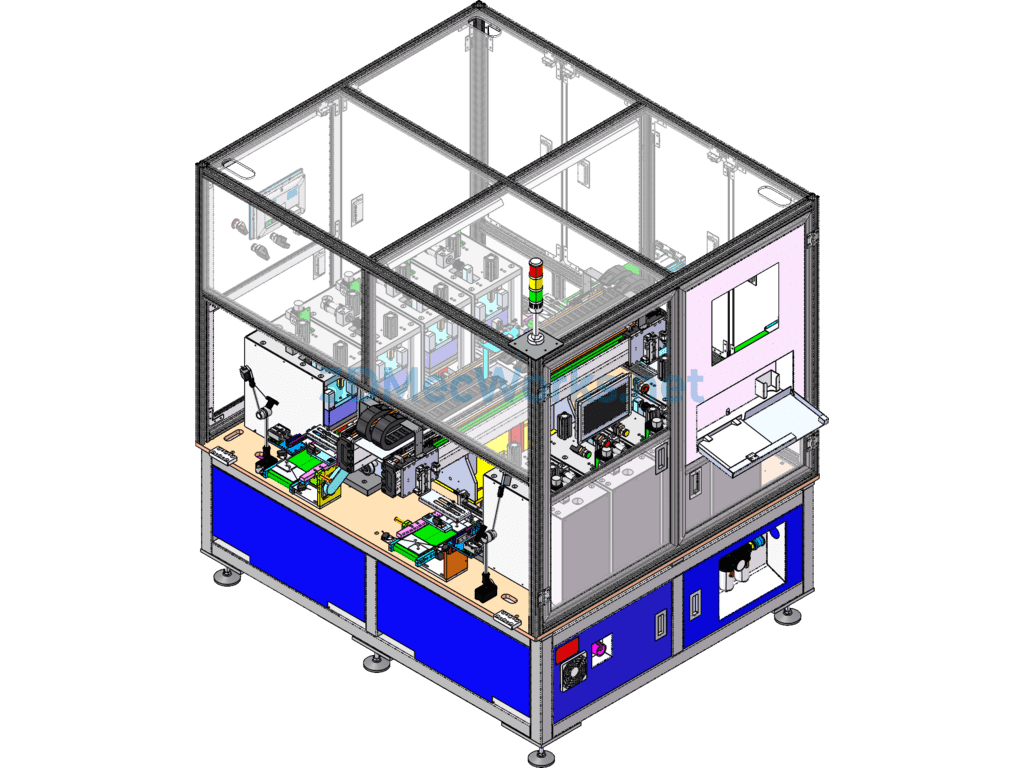

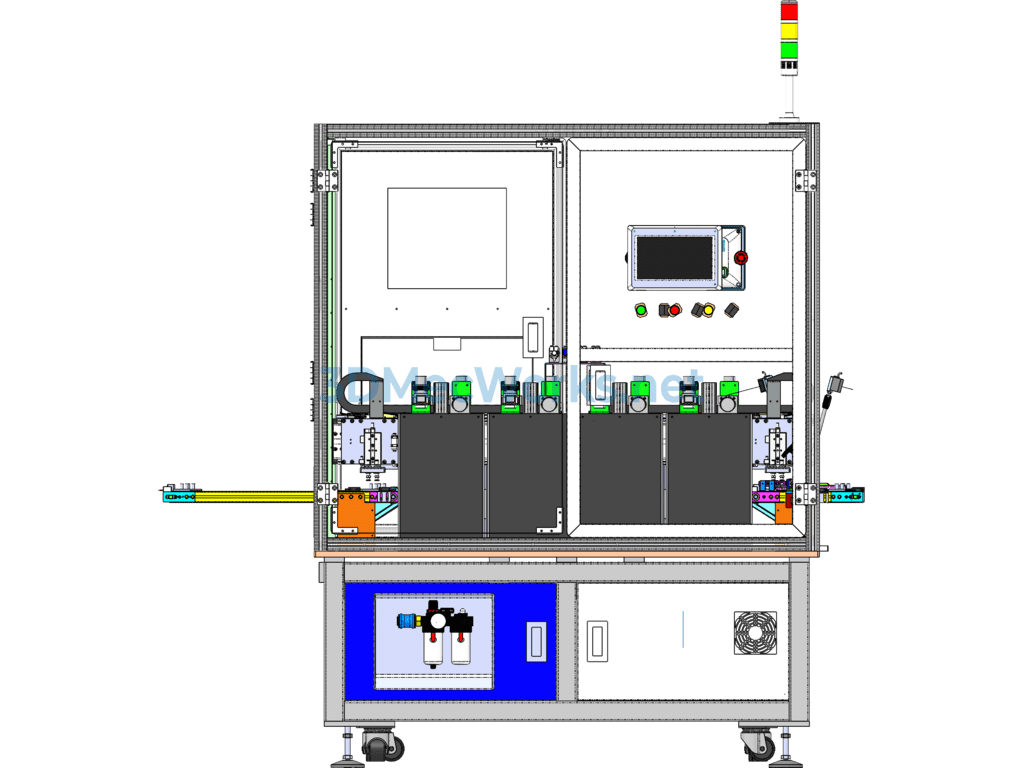

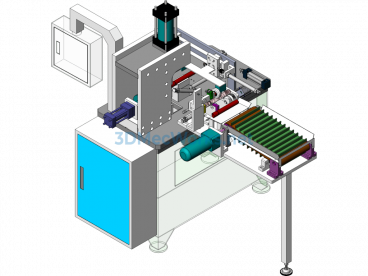

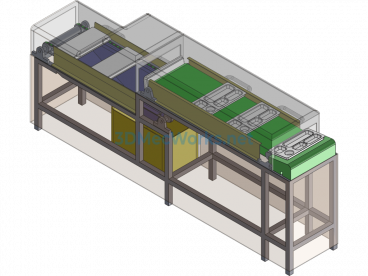

This device is used in the liquid leakage detection procedure on a mobile phone battery production line. The working principle is to use negative pressure to test the airtightness of soft packaged cells. If the airtightness is insufficient, under negative pressure conditions, the inside of the cell will inflate, causing the suction cup in contact with the cell to pull it out, creating an impression. Cells with good airtightness remain unaffected. After the material flows through, manual inspection is conducted to determine whether there is leakage. The design features a high-capacity dual-station setup, with a design capacity of 2000 PCS/h. The equipment dimensions are 1450X1800X1900mm. Detailed structural information is clear and provided for reference in planning.

There are no reviews yet.