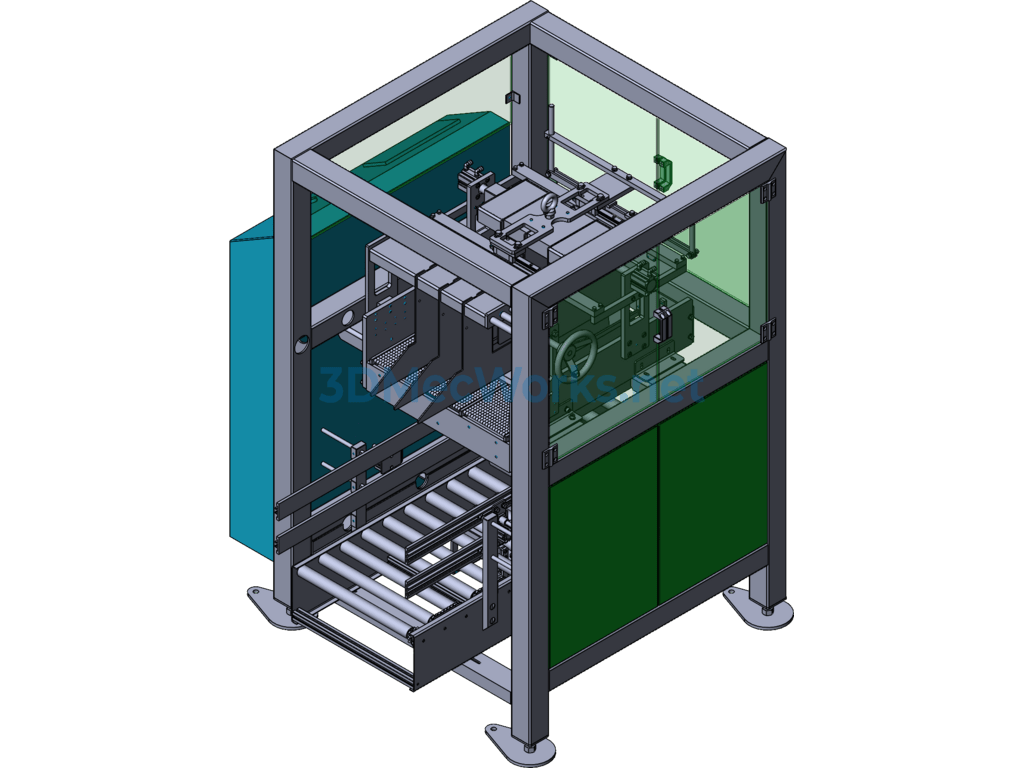

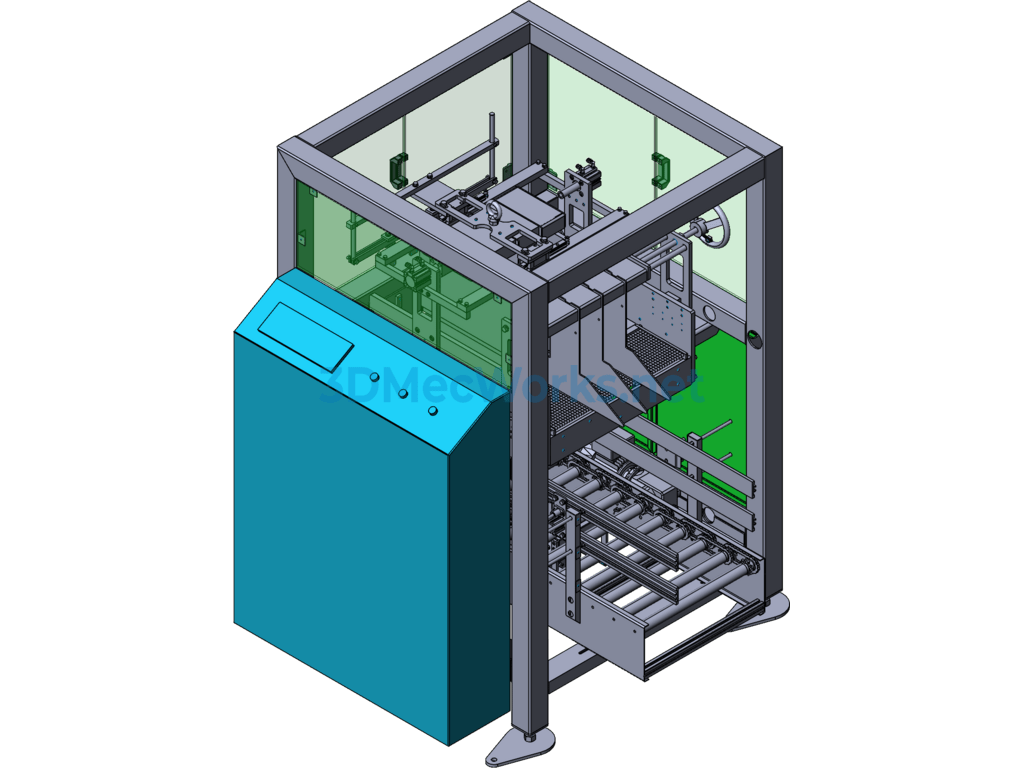

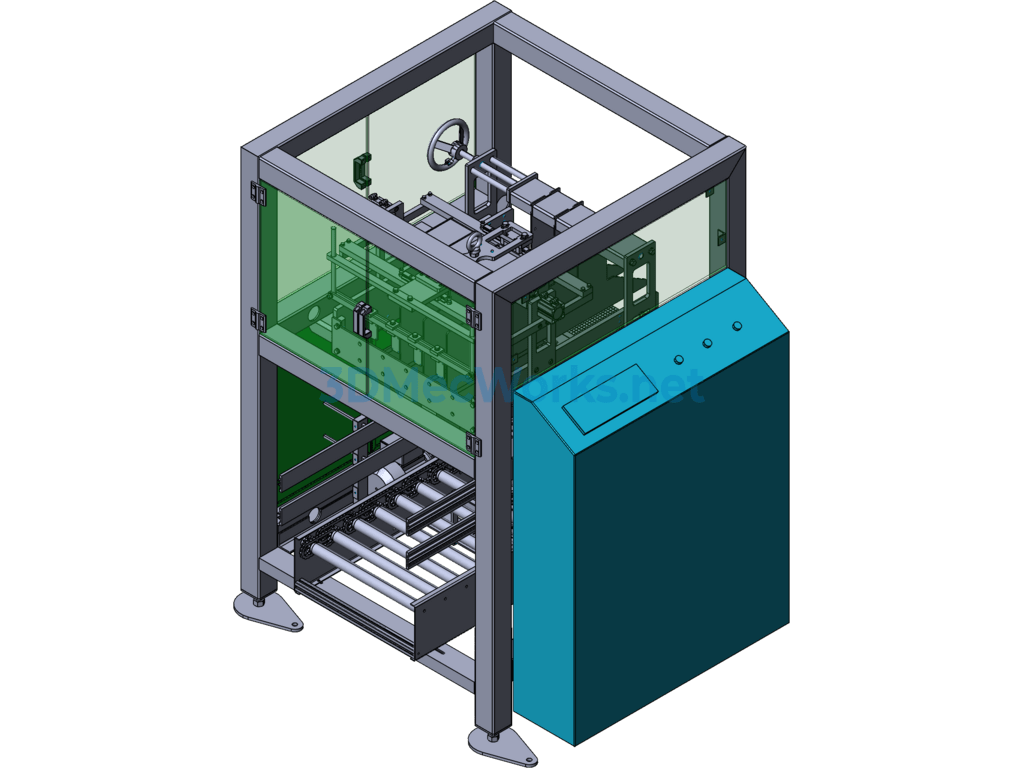

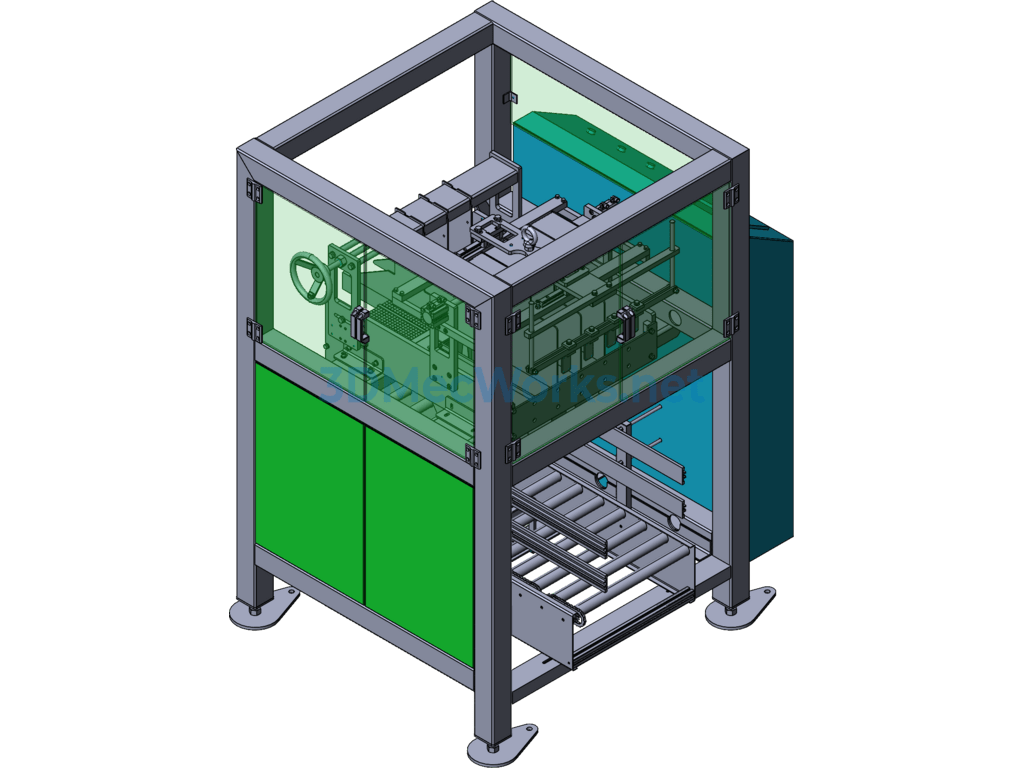

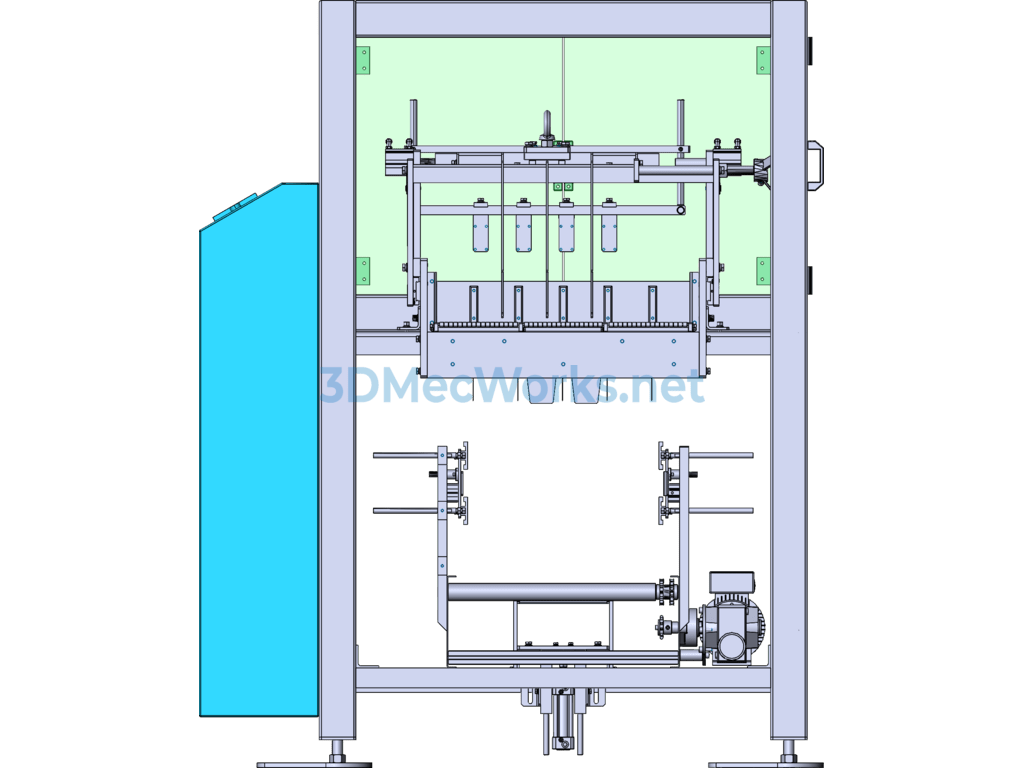

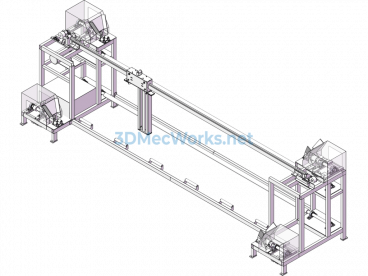

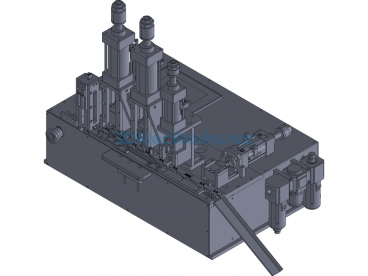

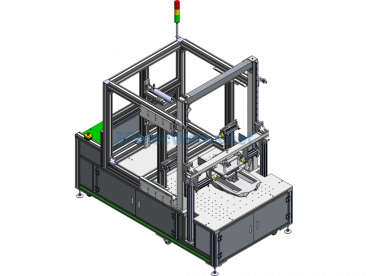

Suitable for various bottled beverages and water, the fully automatic drop-type case packer is developed based on the features of various domestic and international case packers to suit the characteristics of domestic production enterprises. It is newly developed and successfully launched, with a wide range of applications, small footprint, and can be used as a single machine or integrated with front-end shrink wrap machines and cellophane wrapping machines to complete the back-end packaging production line. According to the required number of products to be packed, the machine stacks rectangular products such as boxes or packs and pushes them into the case. The filled case is then automatically flipped to the conveyor rollers for seamless integration into an unmanned production line. This machine is widely used in the pharmaceutical, food, daily chemical, and other light industries.

The automatic case packer is designed with advanced technology, compact structure, ease of use, and reliable operation, effectively ensuring product quality. It improves production efficiency and reduces labor intensity. The machine uses the Omron PLC programmable controller from Japan, all pneumatic components from CKD Corporation of Japan, and electronic components from Omron of Japan. Through optical monitoring, the actions are coordinated to ensure stable, reliable, and safe operation. It is suitable for cartons with dimensions: L250-500mm, W200-400mm, H180-450mm. Packing efficiency is 6-10 boxes/minute (Type A machine) and 10-15 boxes/minute (Type B machine). Power supply/power: 220V 50Hz (can also be customized according to customer requirements). Air source: 5-6kg/cm², 150Ne/Min. Machine dimensions: L2000*W1500*H1350mm.

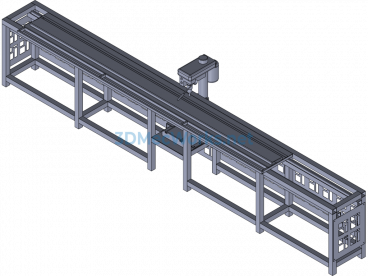

Specification: Drop-Type Case Packer

|

There are no reviews yet.