Actuators are an indispensable and important component of automatic control systems. Their function is to receive control signals from the controller and change the size of the controlled medium, thereby maintaining the controlled variable at the required value or within a certain range. Actuators can be divided into three major categories based on their energy forms: pneumatic, hydraulic, and electric.

Pneumatic actuators use compressed air as their energy source. Their characteristics include simple structure, reliable operation, smooth movement, high output thrust, easy maintenance, fireproof, explosion-proof, and relatively low cost. As a result, they are widely used in the production processes of industries such as chemical, paper, and refining. They can easily be used in conjunction with passive instruments. Even when using electric instruments or computer control, pneumatic actuators can still be employed, provided that the electrical signals are converted into standard pneumatic signals of 20-100 kPa using electropneumatic converters or electropneumatic valve positioners.

Electric actuators have the advantage of convenient access to energy and rapid signal transmission, but they have complex structures and poor explosion-proof performance. Hydraulic actuators are rarely used in chemical, refining, and similar production processes, mainly due to their substantial output thrust.

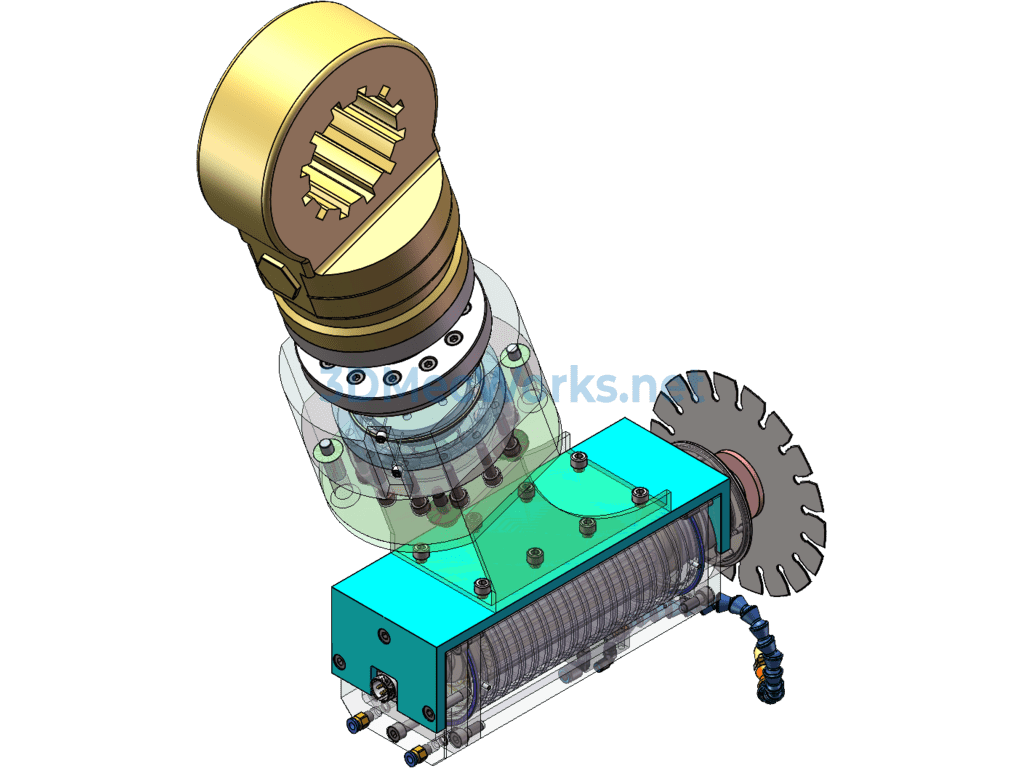

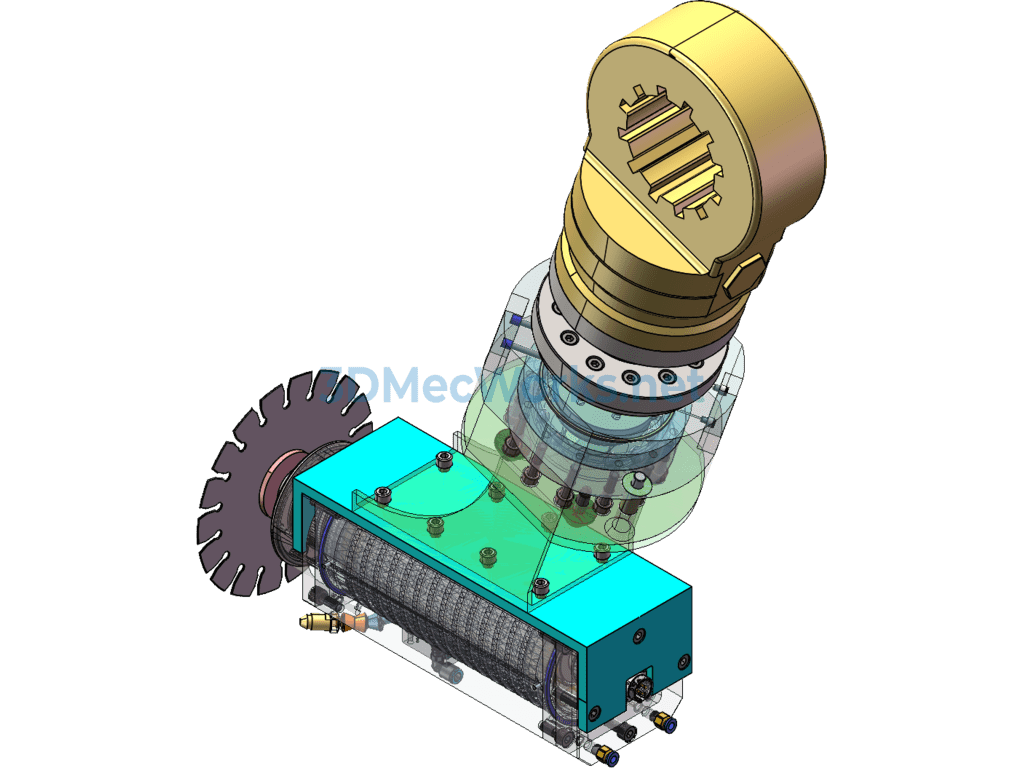

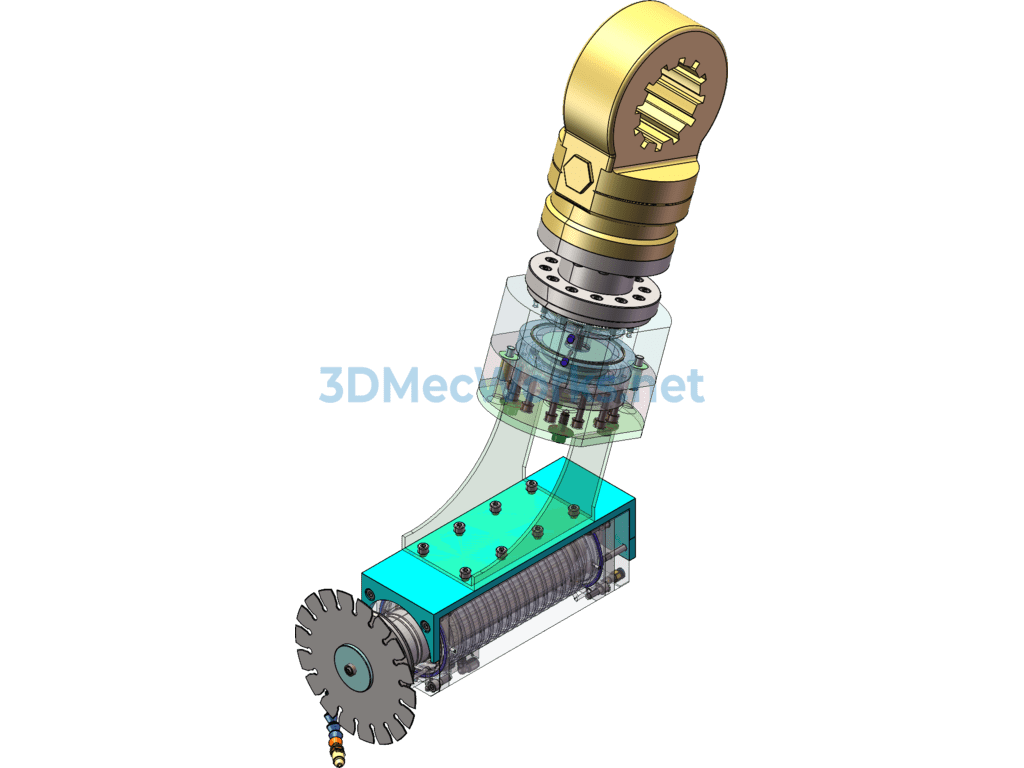

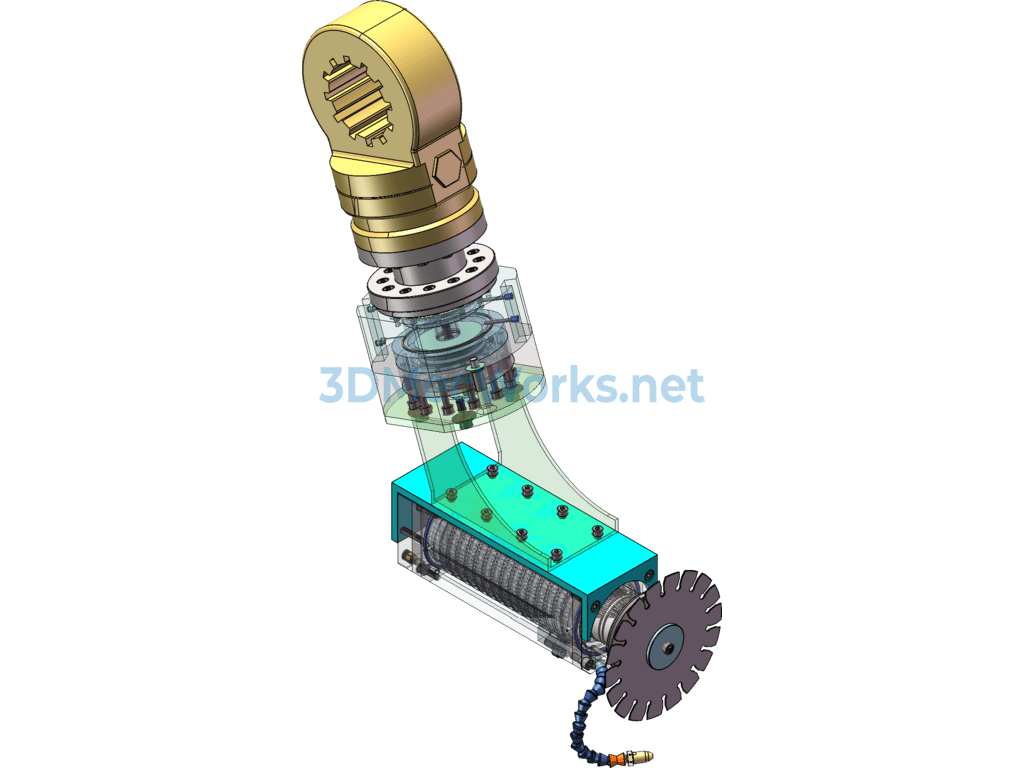

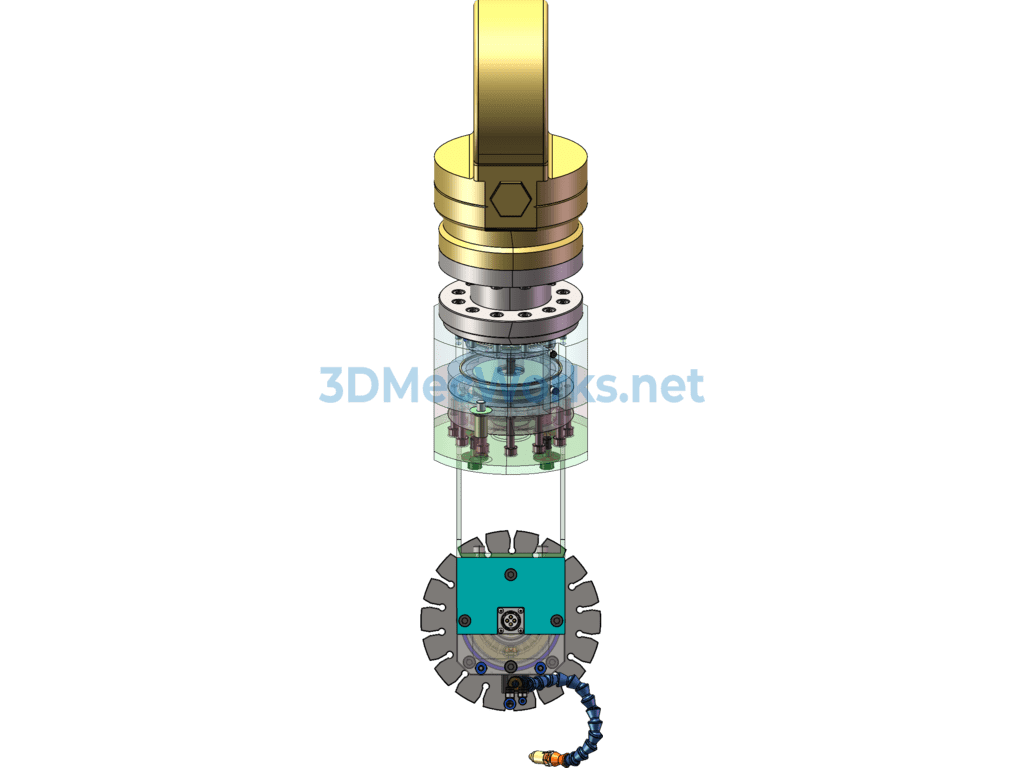

Specification: End Effector Model

|

There are no reviews yet.