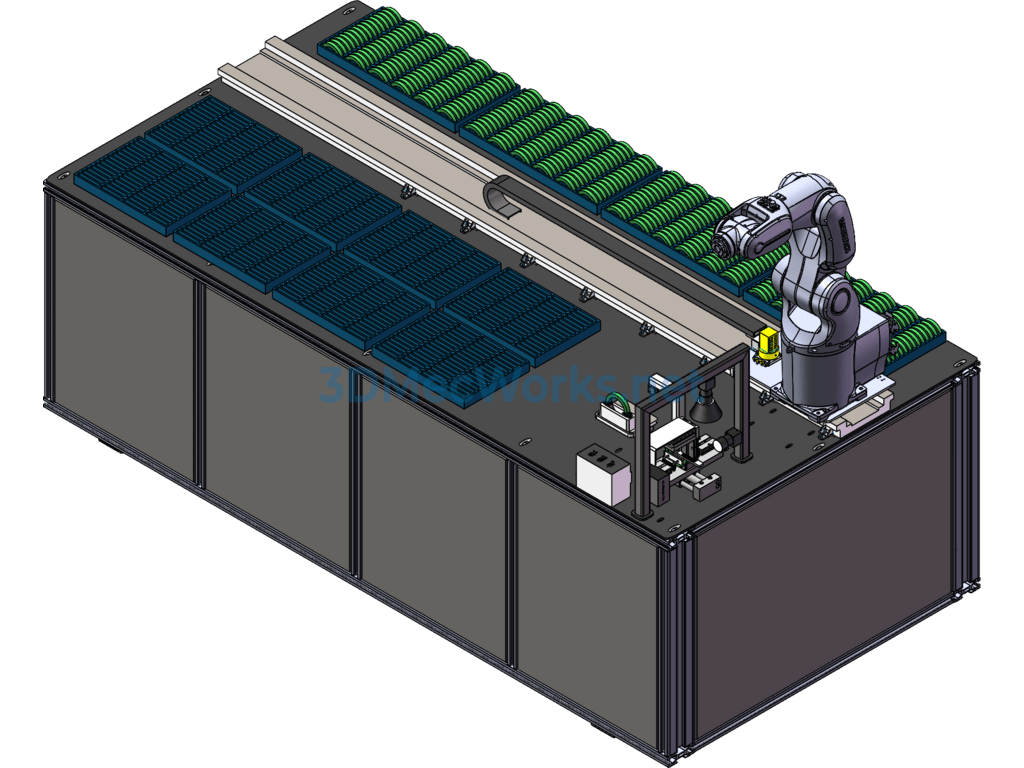

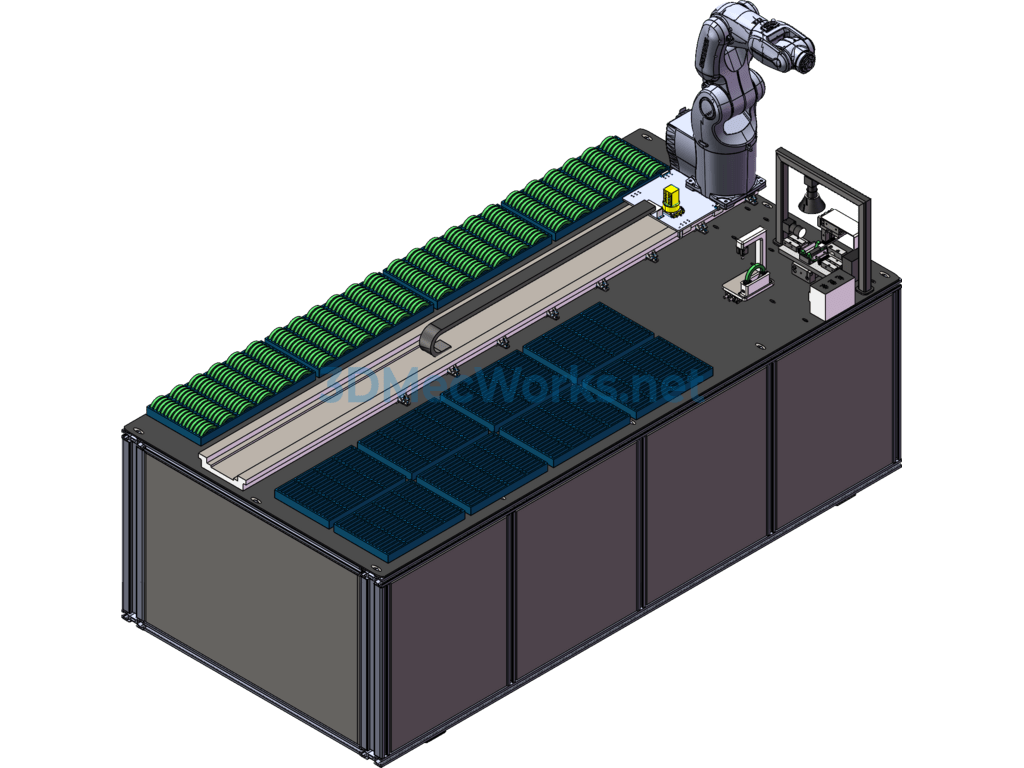

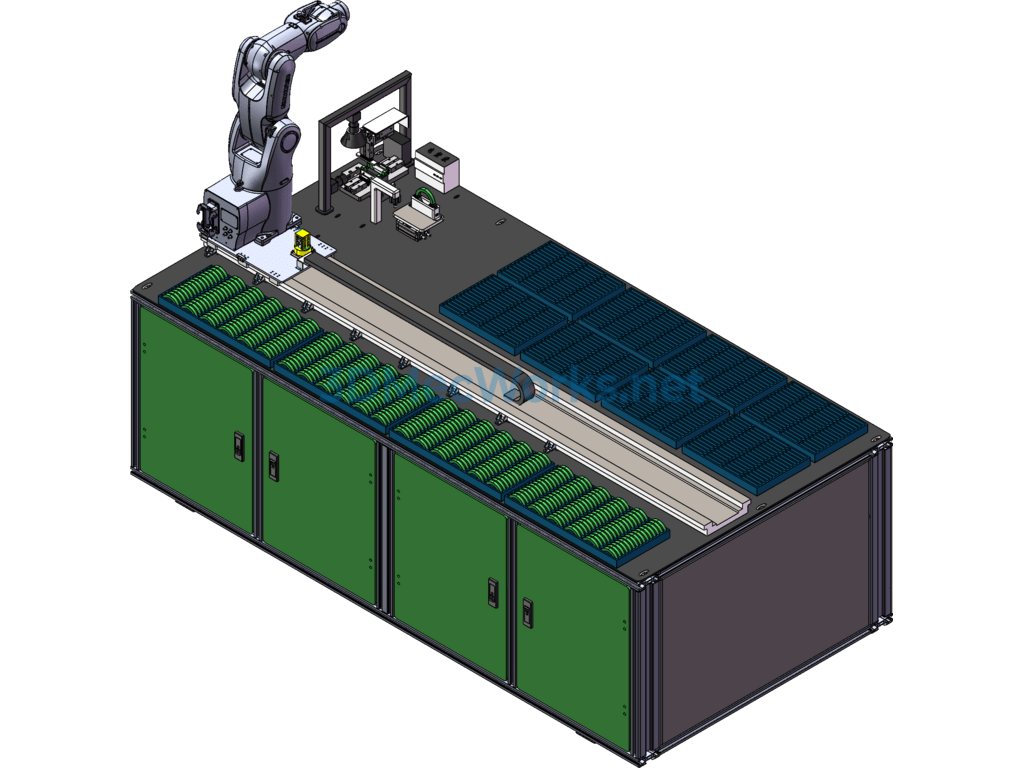

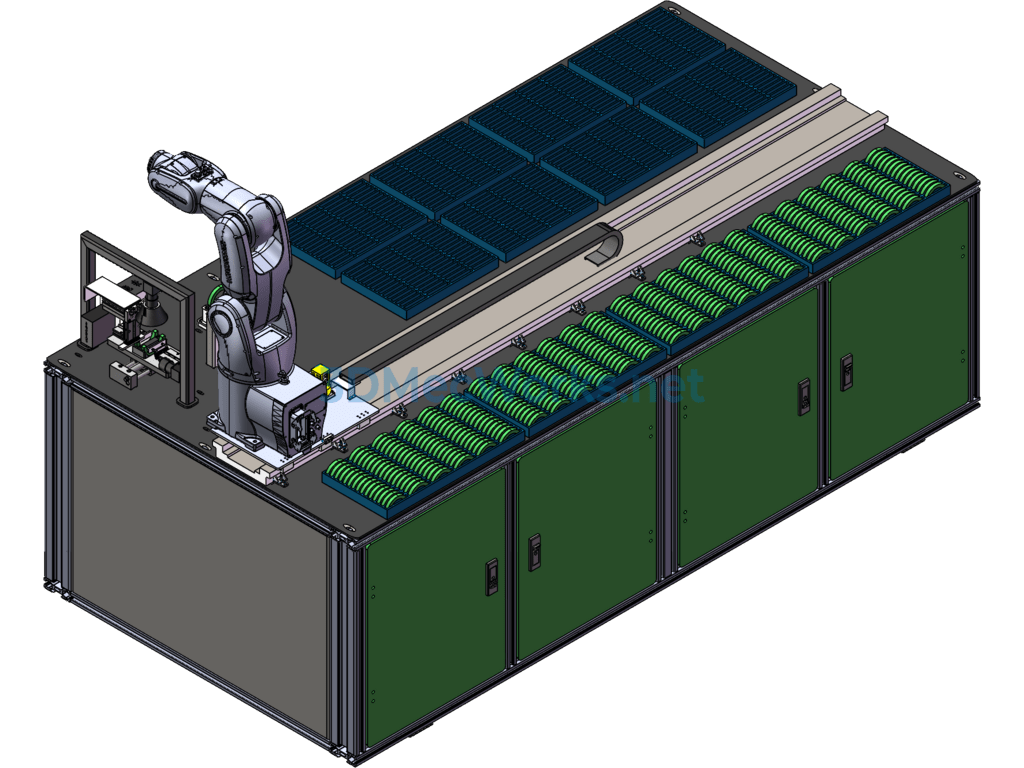

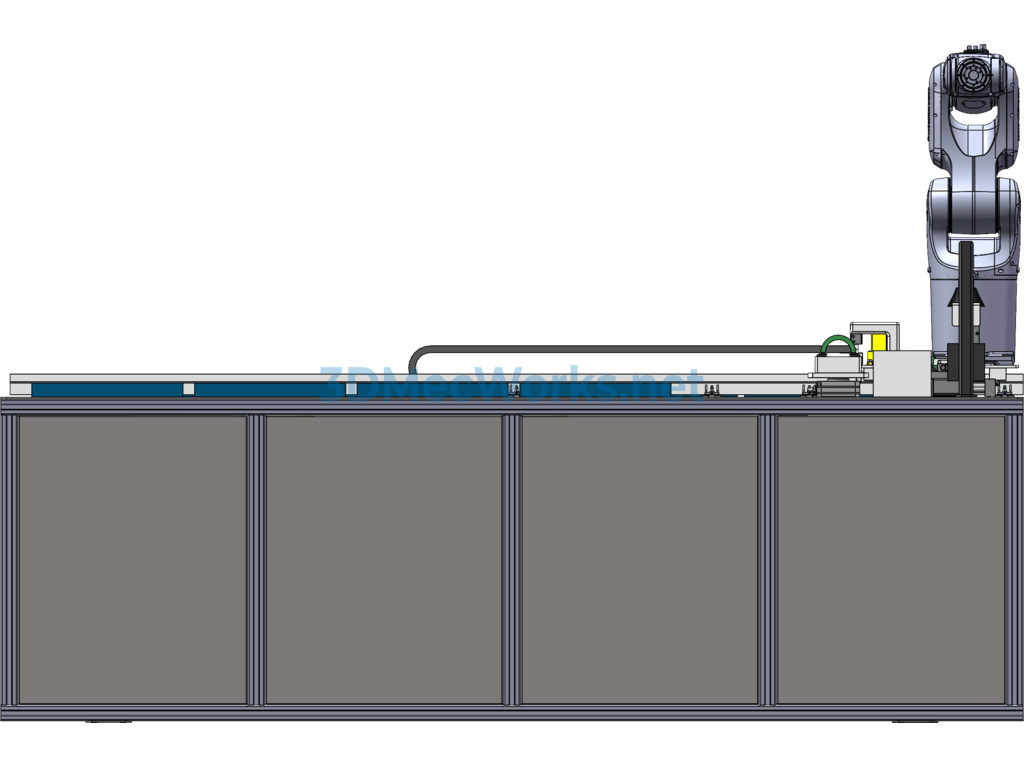

This model is for an automatic detection station for defects in magnetic induction coils. It includes components such as a material handling robot, coil fixture tool, defect detection camera, and an operation table. During operation, the robot picks up materials from the tray, then detects end surface defects and four-axis cracks, stains, and other defects under the camera. Finally, it checks the detected current value in the copper coils. Qualified parts and defective products are placed in their respective trays for further processing.

Specification: Automatic Detection Station for Defects in Magnetic Induction Coils

|

User Reviews

Be the first to review “Automatic Detection Station for Defects in Magnetic Induction Coils”

You must be logged in to post a review.

There are no reviews yet.