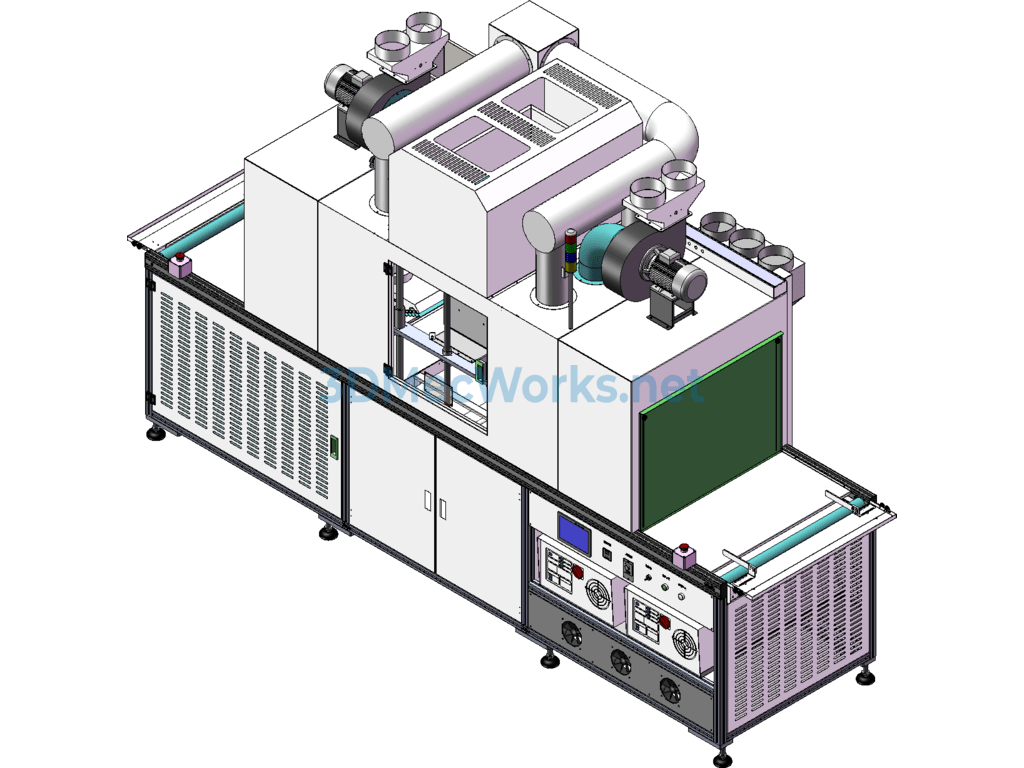

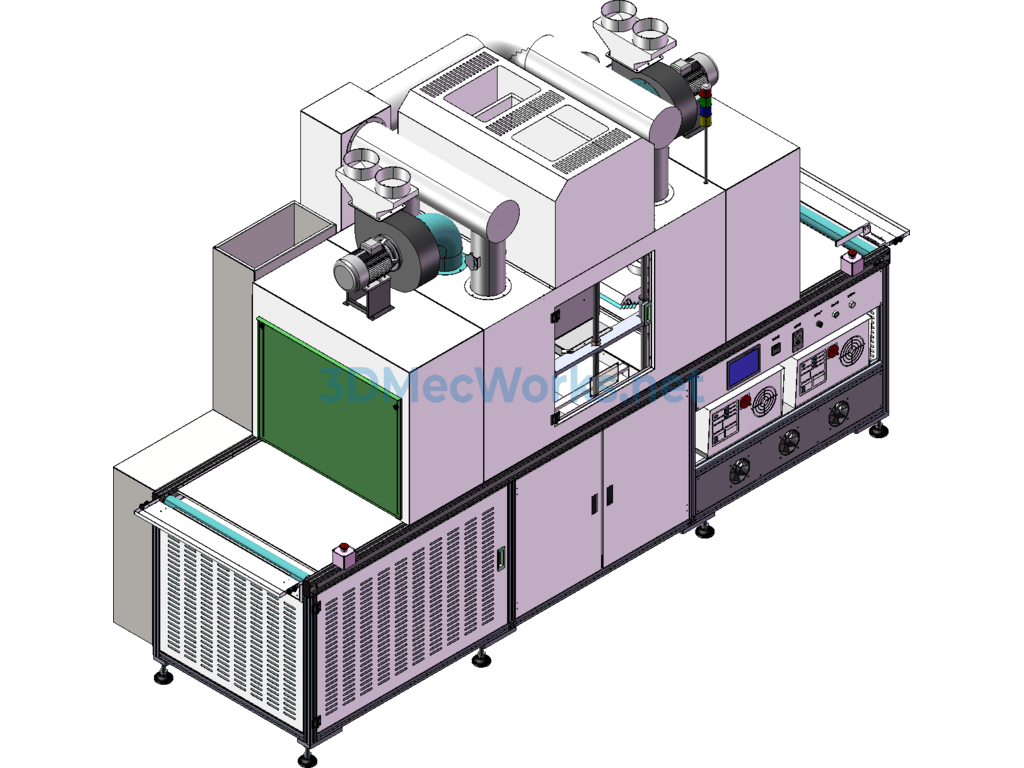

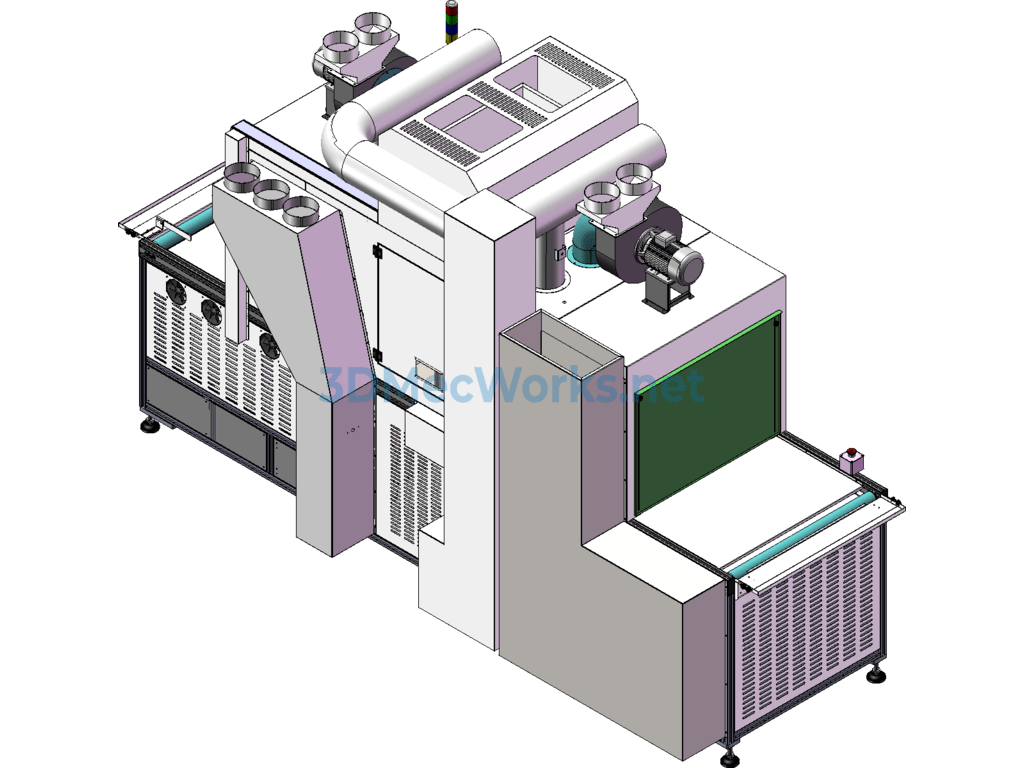

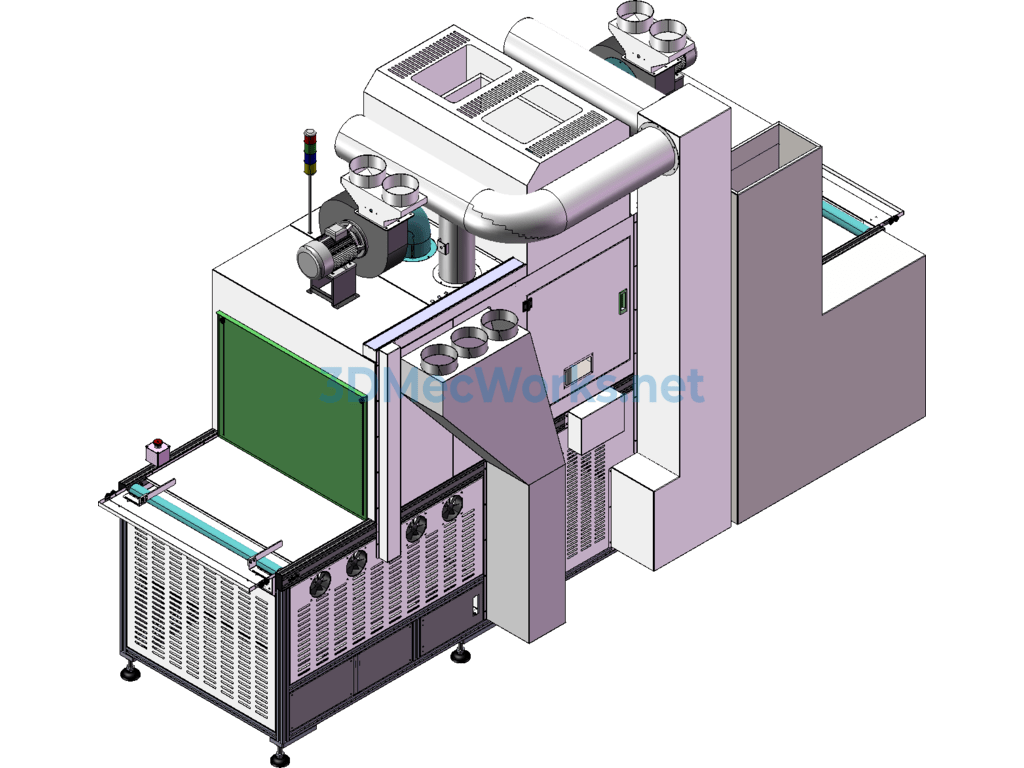

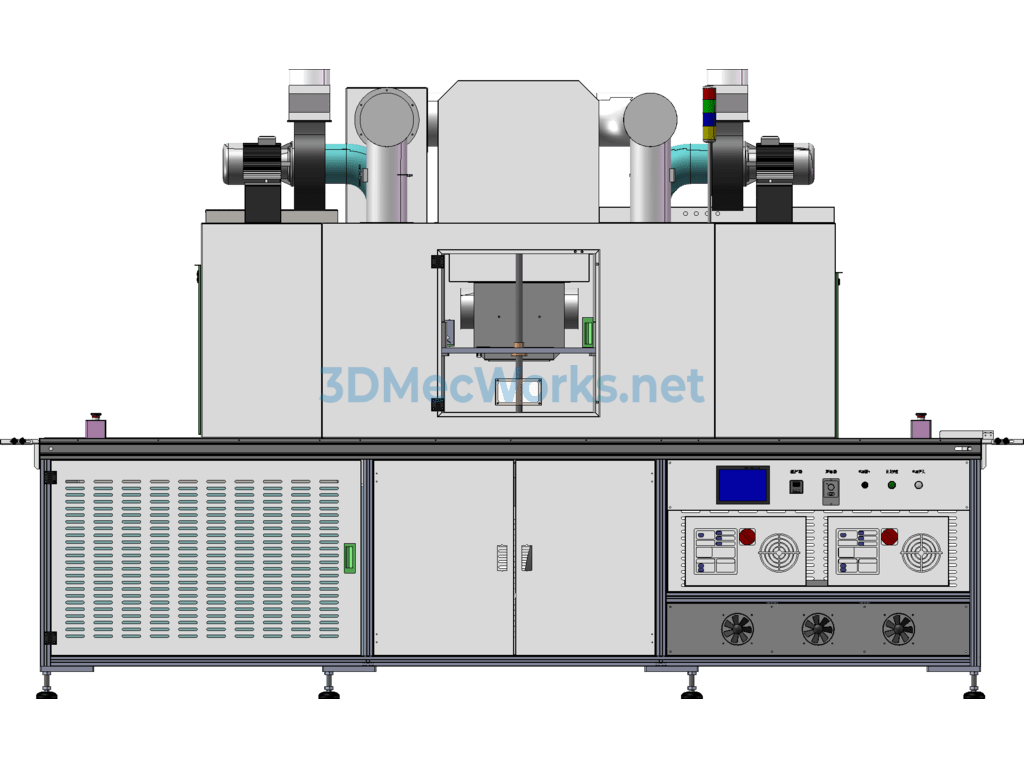

Mobile Phone Screen Automatic UV Exposure Dispensing Machine, Brief Description of Action Process

1. Start the system, adjust the guiding conveyor speed, adjust the material width, and select the corresponding program.

2. The employee manually places the glass workpiece onto the material position conveying trough on the conveyor belt.

3. After UV curing, the glass fixture flows out along the conveyor belt.

4. The leveled workpiece flows into the UV component for UV curing operation.

Mobile Phone Screen Automatic UV Exposure Machine uses UV irradiation to cure the mobile glass. Currently, Ofilm, a listed company in the mobile screen panel industry, is using this device. Equipment related to curing furnaces can be downloaded and used as components:

1. Frame (Dimensions: 4000x800x1820, aluminum profile frame & painted sheet metal)

2. Belt conveyor (UV-resistant Teflon round belt & flat belt)

3. Conveyor chain and conveyor belt (ultra-quiet, high-speed jig transmission sprocket)

4. Adjustable position LED UV light component (provided by SSI, USA)

5. Material width adjustment mechanism (stepper motor, leadscrew up and down adjustment, automatic width adjustment)

6. Electrical control components (including alarm, counting, etc.)

7. UV lamp control system (using imported system from the USA)

UV exposure machine, mobile screen UV curing machine dispensing machine (including the complete set of engineering drawings) please use Solidworks 2011 or higher version to open.

Specification: Uv Exposure Machine, Mobile Screen Uv Curing Machine, Dispensing Machine (including a Complete Set of Engineering Drawings)

|

User Reviews

Be the first to review “Uv Exposure Machine, Mobile Screen Uv Curing Machine, Dispensing Machine (including a Complete Set of Engineering Drawings)”

You must be logged in to post a review.

There are no reviews yet.