Working Principle of Diesel Engine

A diesel engine that completes one working cycle with two strokes of the piston is called a two-stroke diesel engine. In a two-stroke diesel engine, the crankshaft completes only one revolution per working cycle. Compared to a four-stroke diesel engine, it enhances operational efficiency and exhibits significant differences in specific structure and working principle.

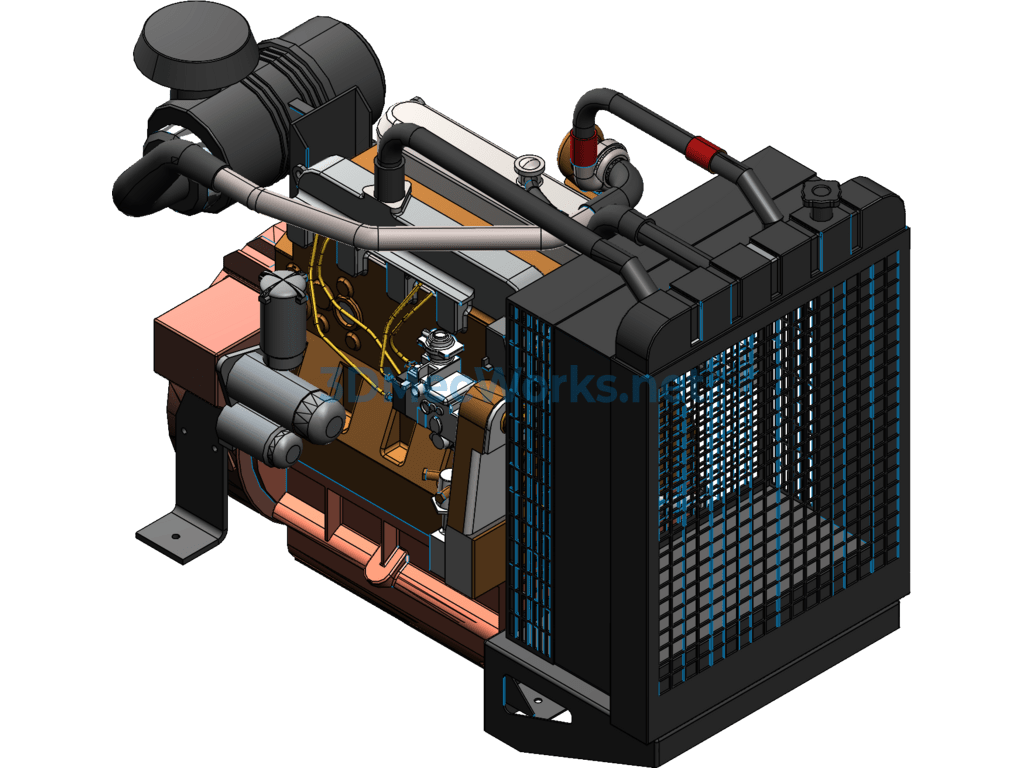

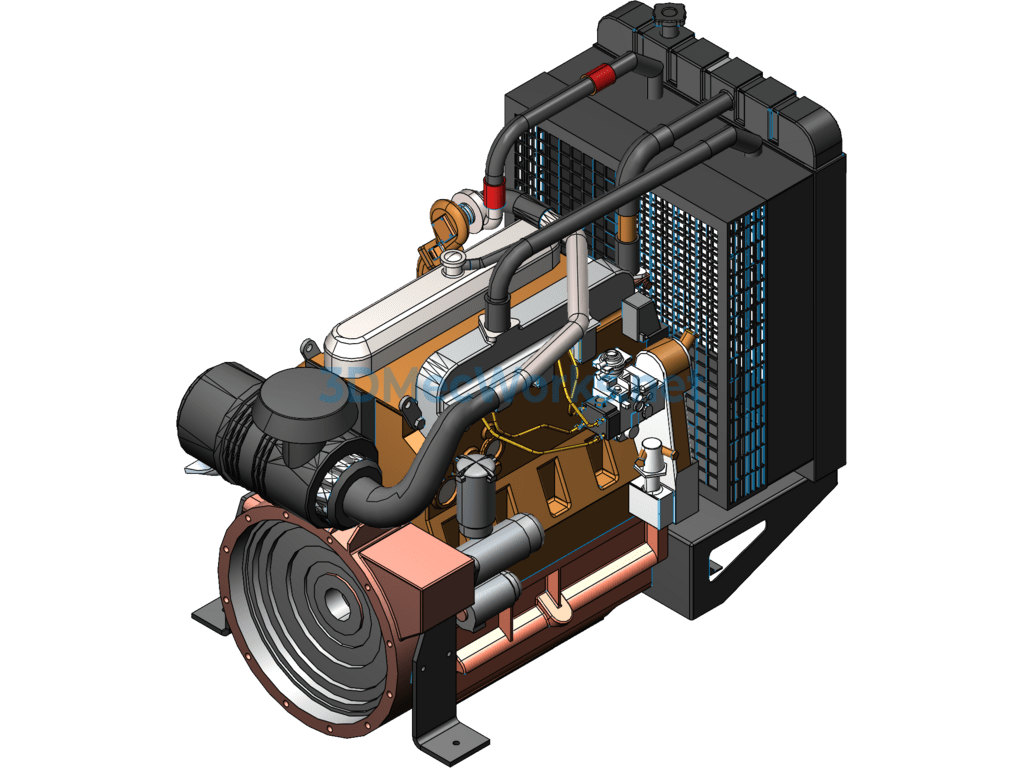

The basic structure of a two-stroke diesel engine is similar to that of a four-stroke diesel engine, with the main differences lying in the valve mechanism. A two-stroke diesel engine does not have an intake valve, and some may not even have an exhaust valve. Instead, intake and exhaust ports are opened at the lower part of the cylinder, or an intake port and exhaust valve mechanism is set up. It also specifically sets up a scavenging pump powered by moving parts and a scavenging box for storing pressurized air, utilizing the coordination between the piston and ports to manage air distribution, thereby simplifying the diesel engine’s structure.

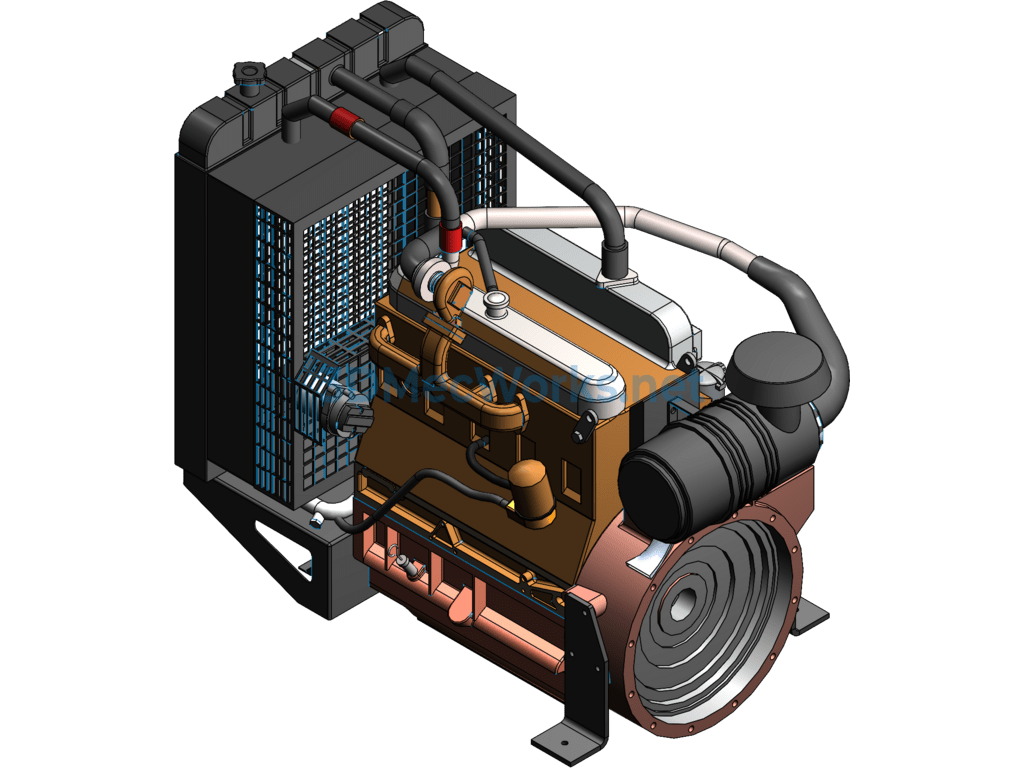

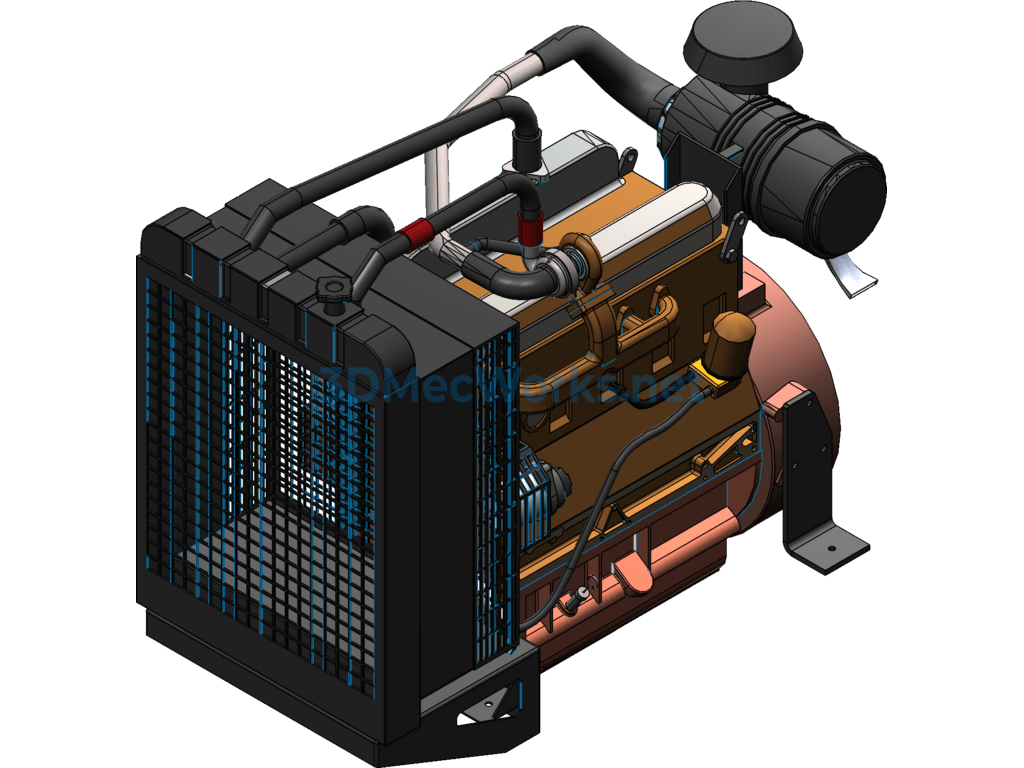

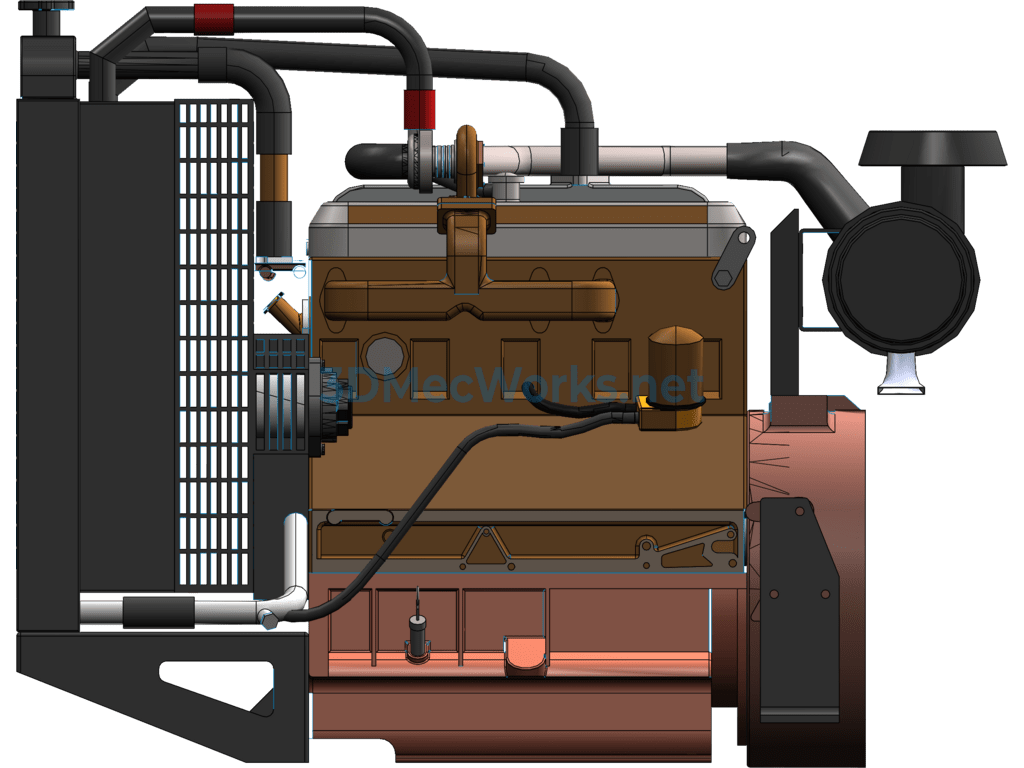

The diagram illustrates the working principle of a two-stroke diesel engine. The scavenging pump is attached to one side of the diesel engine, with its rotor driven by the engine. Air is drawn into the pump, compressed, and then discharged into a scavenging box with a relatively large volume, where it is maintained at a certain pressure.

Specification: Diesel Engine Sw Model

|

User Reviews

Be the first to review “Diesel Engine Sw Model”

You must be logged in to post a review.

There are no reviews yet.