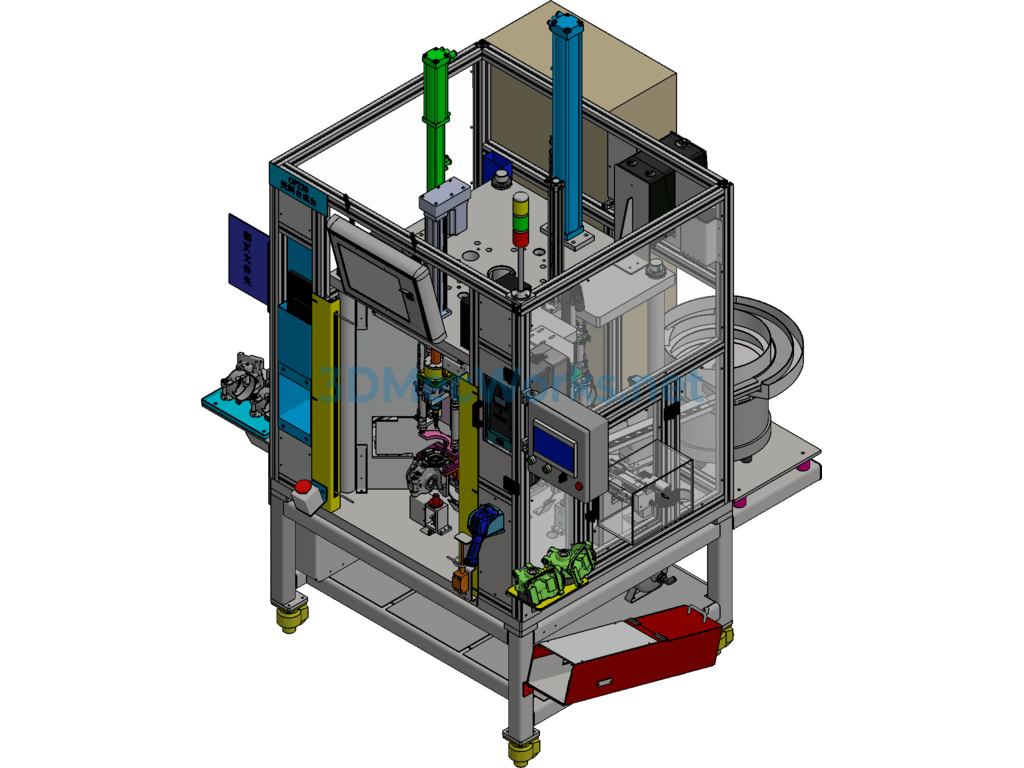

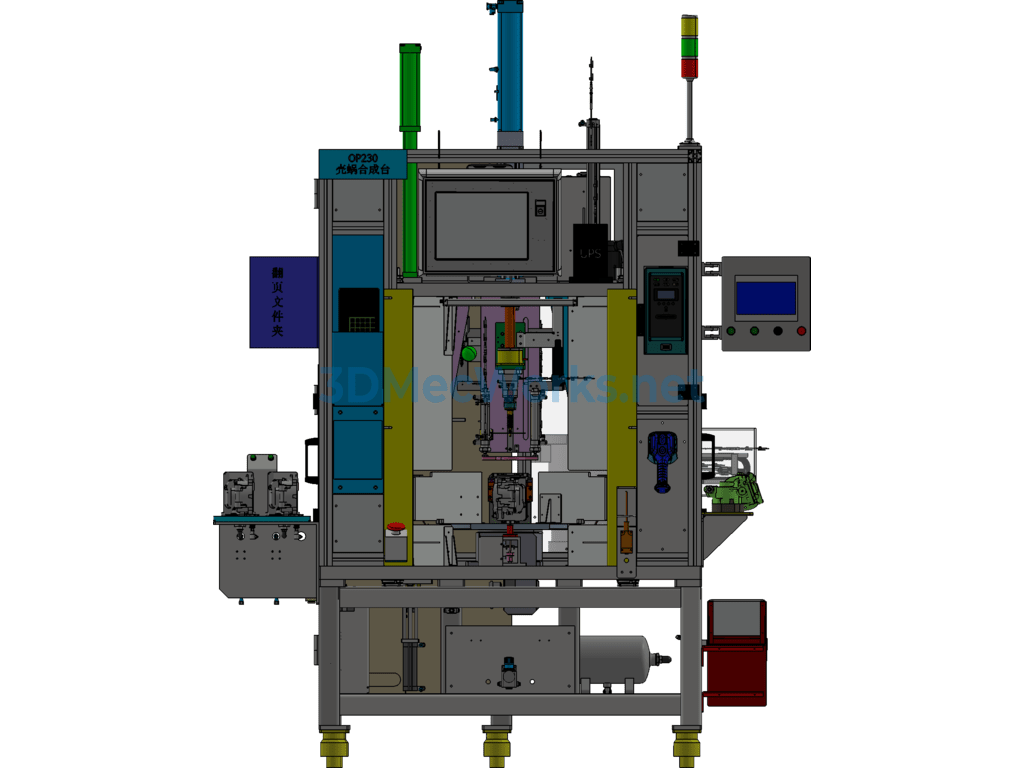

OP230 Shell Worm Synthesis Platform

1. Purpose: Install the worm gear assembly into the housing, tighten the lock nut, rivet the lock nut, press the steel ball into the housing

2. Equipment Specifications: 1400mm(W)x1500mm(L)x2260mm(H), including control panel.

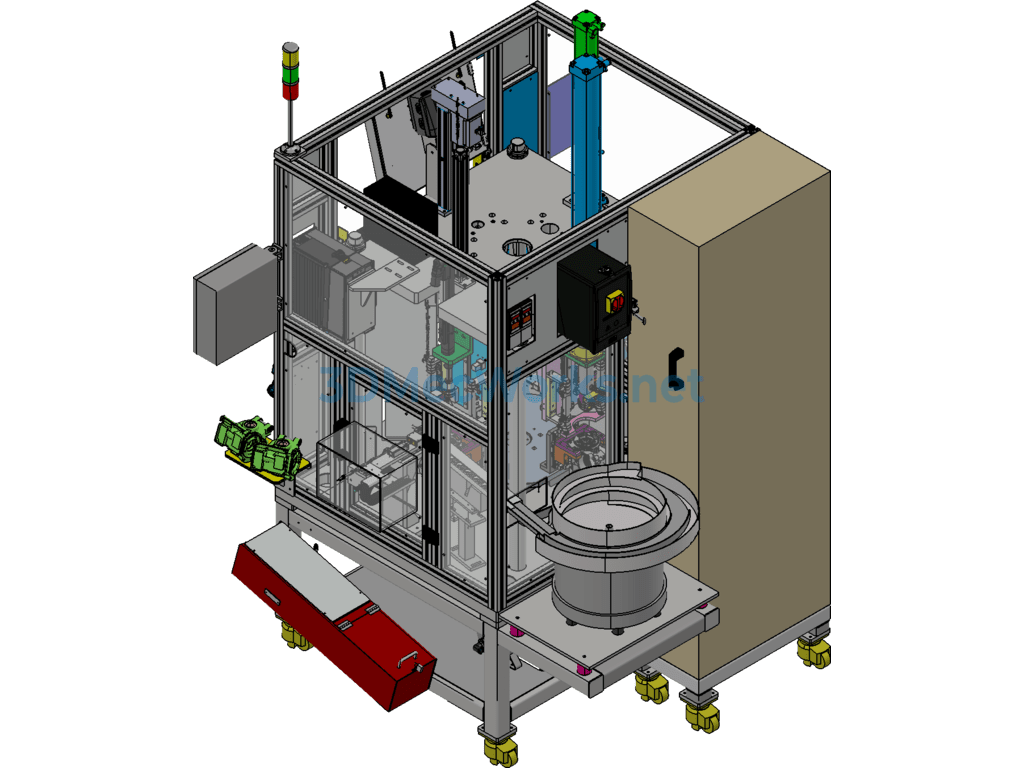

3. Production Cycle: ≤36s

4. Equipment Technical Parameters

4.1 Equipment Power: 15kw;

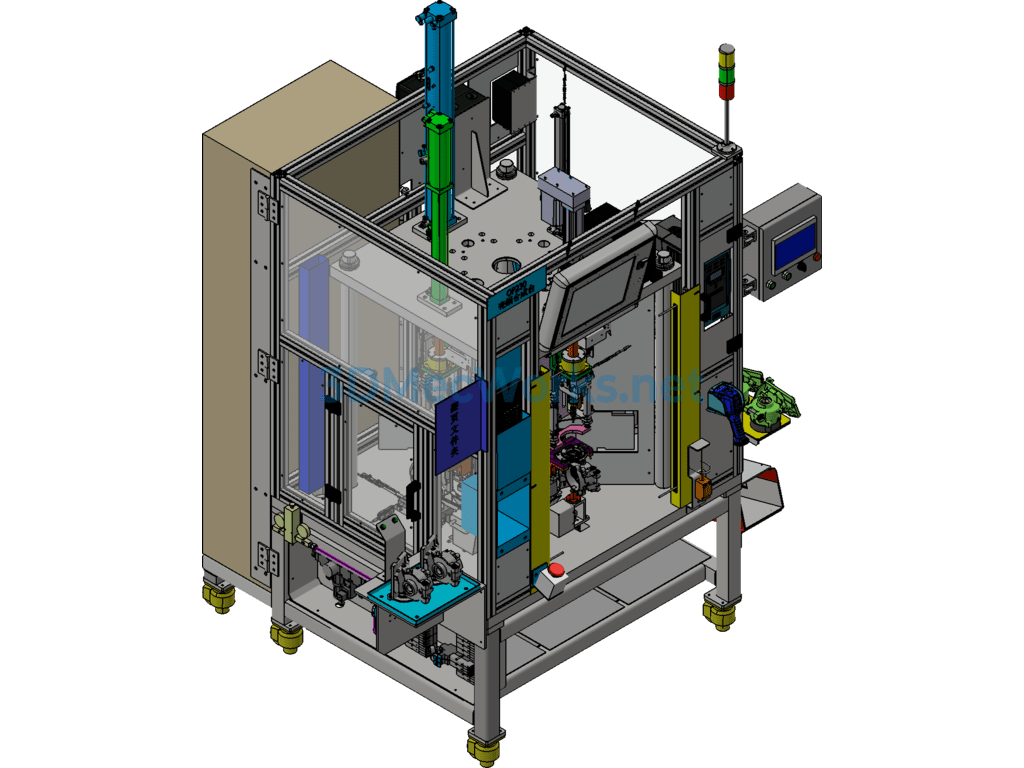

4.2 Equipment Operation Mode: Loading/unloading is performed by the operator (manual), tightening and riveting work is automatically completed by the equipment

4.3 Equipment Requirements: The pressure head adopts a floating mechanism to ensure rigidity; the pressure head and fixture are equipped with identifiable sensors, and the equipment can automatically recognize them.

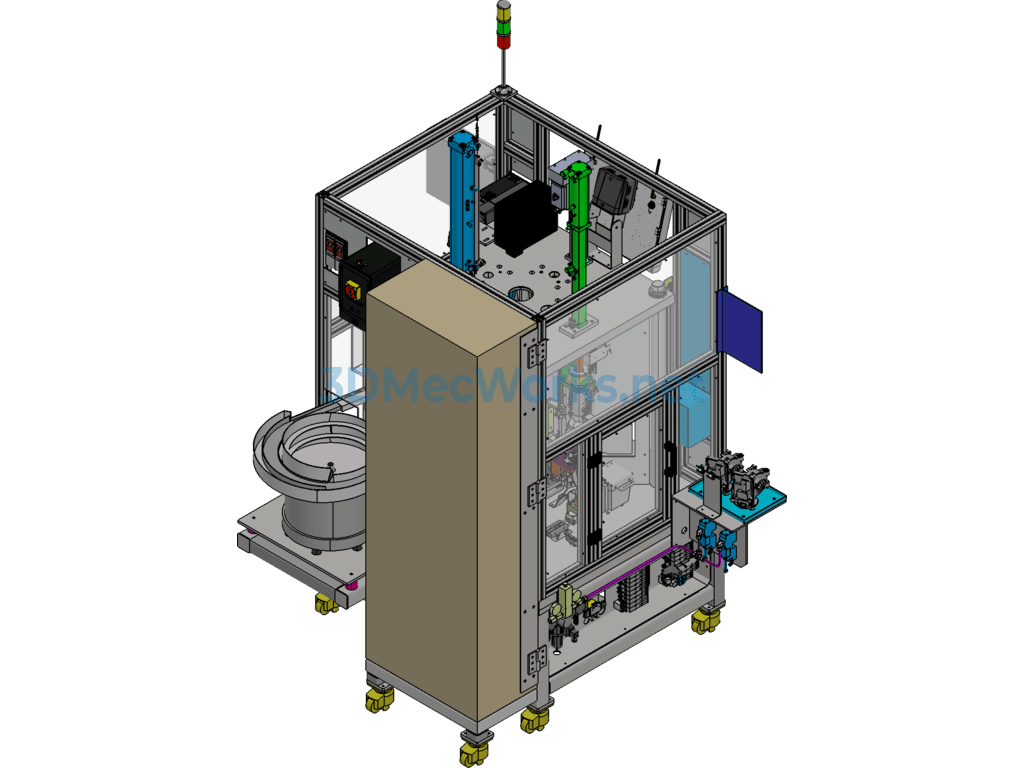

4.4 Pressing Force Monitoring: Pressure sensor range is 10KN, accuracy is 0.3%FS, with self-calibration feature and segmented monitoring curves.

4.5 Press Displacement Monitoring: Stroke of 300mm, accuracy ±0.01mm, full stroke monitoring.

4.6 Press-Fit Judgment: During the pressing process, both force and displacement are within the set tolerance range.

4.7 Equipment Requirements: The pressure head uses a floating mechanism, ensuring rigidity; the pressure head and fixture are equipped with recognizable sensors, and the equipment can automatically identify them.

4.8 Model Change: The tooling fixtures needing replacement are placed below the equipment with a specially made placement tray.

4.9 Equipment CPK Value ≥1.33; the precision of pressed parts and assembly precision are inspected according to the drawing requirements.

5. Compatible Product: D591000

6. Workflow:

STA1 Servo Press Worm Component (36s)

STA2 Tighten Nut (25s)

STA3 Rivet Nut (13s)

STA4 Rivet Steel Ball (14s)

There are no reviews yet.