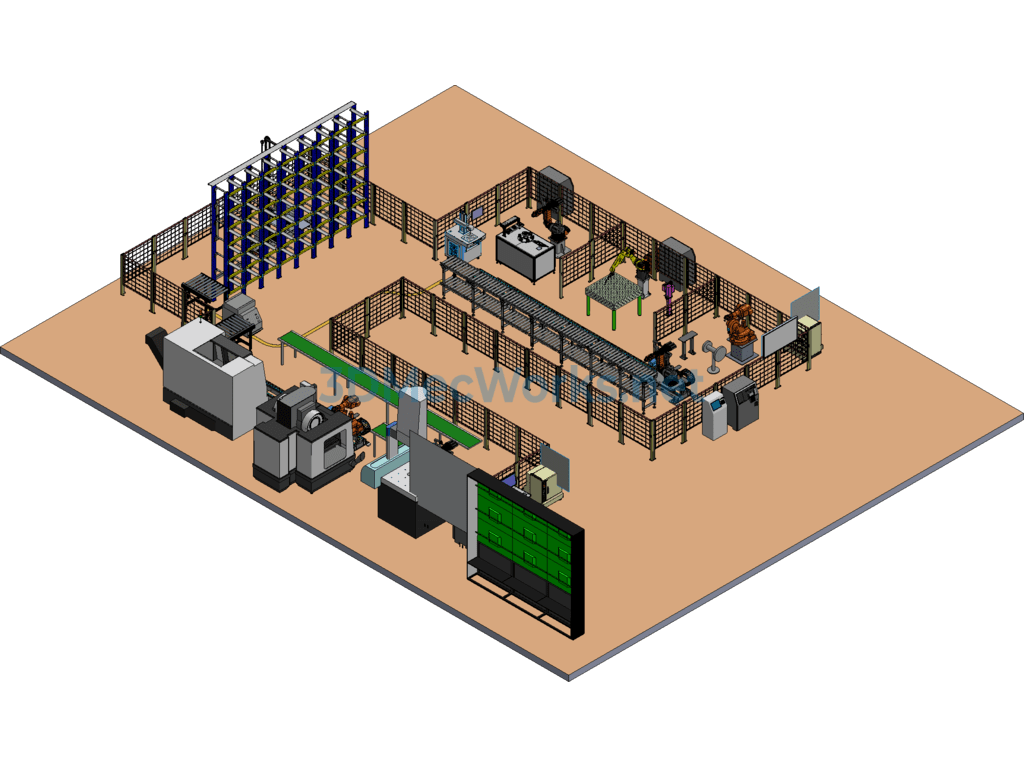

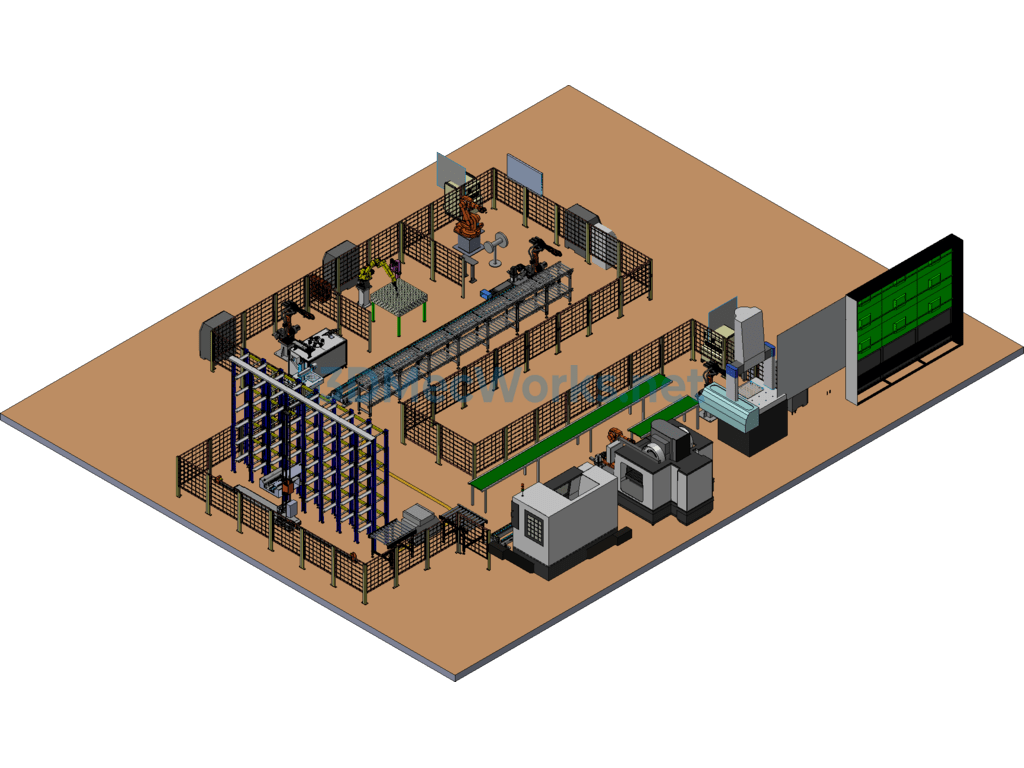

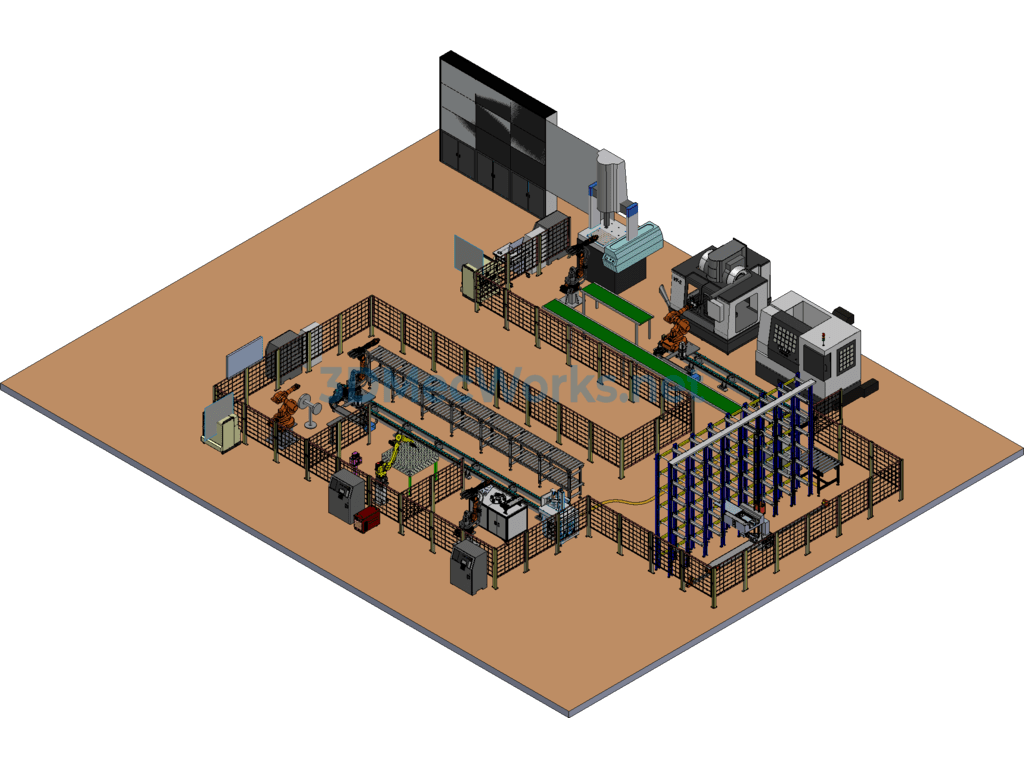

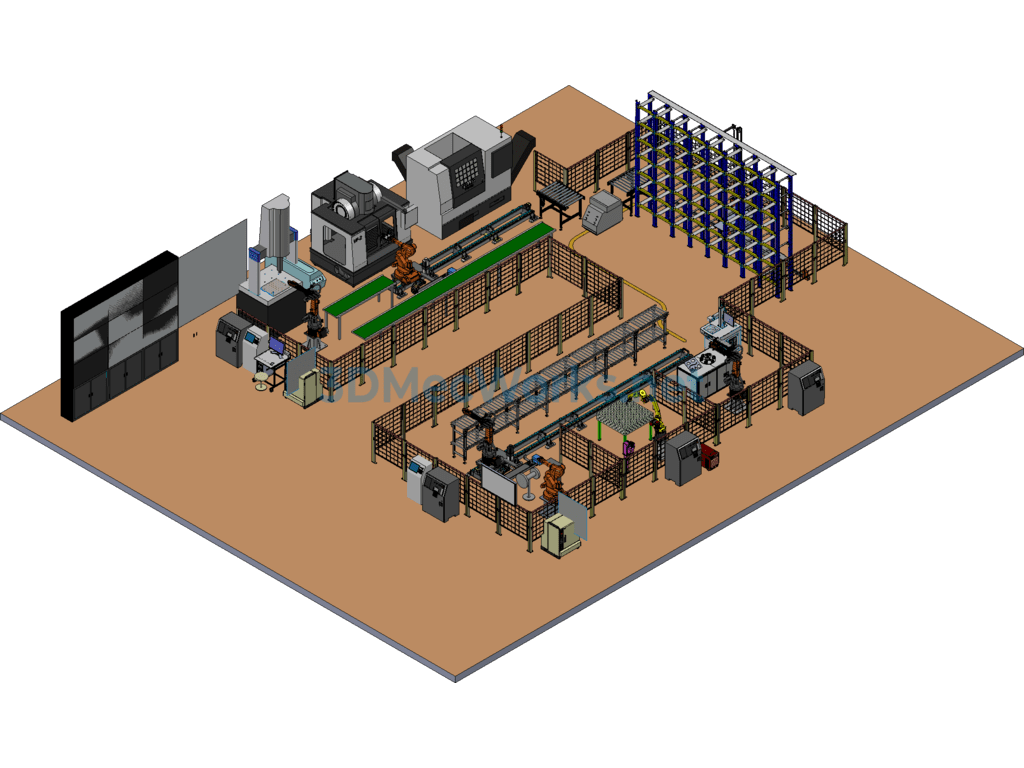

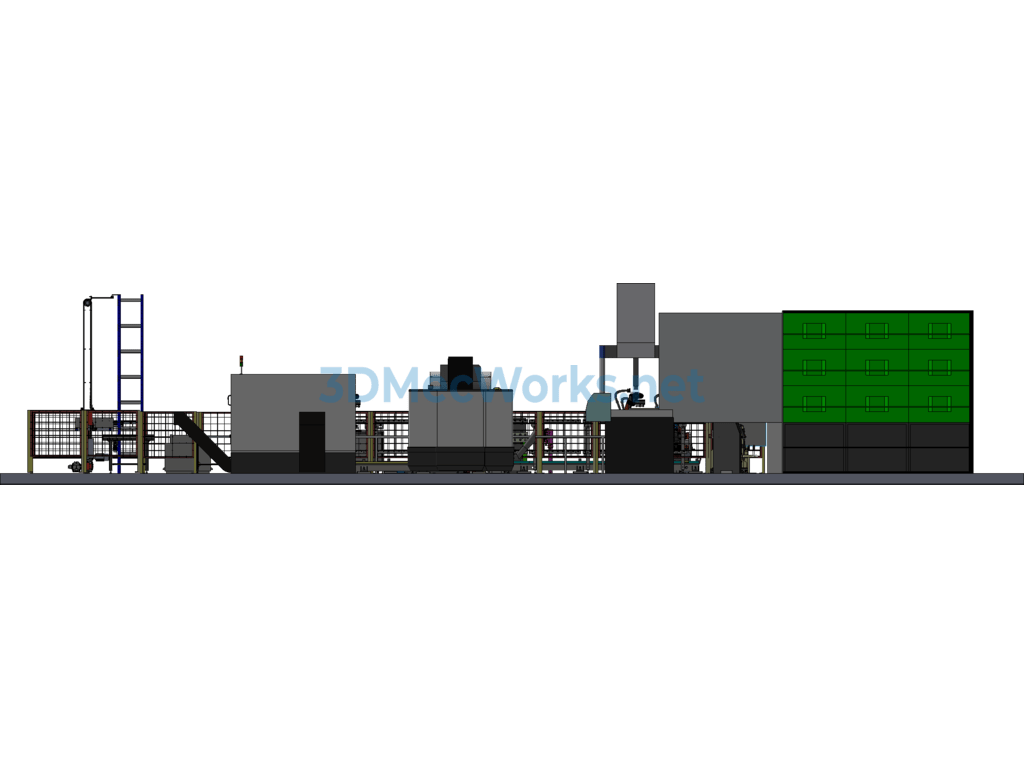

The intelligent manufacturing training base consists of a set of flexible intelligent manufacturing production line systems composed of CNC lathes, vertical high-speed machining centers, automated storage and retrieval systems, and robots for grinding, welding, assembly loading and unloading, coordinate measurement, conveying devices, laser marking, etc. This system achieves automated material and finished product storage in the automated storage and retrieval system, with materials and finished products transported via conveyor lines. The robot machine tool loading and unloading system connects the conveyor device with the CNC lathe or vertical high-speed machining center. After undergoing processes such as turning, milling, drilling, grinding, and welding, materials are turned into finished products. The machine tool loading and unloading robot places the processed finished products onto the conveyor line, which then uses the AGV machine to send them into the automated storage and retrieval system.

There are no reviews yet.