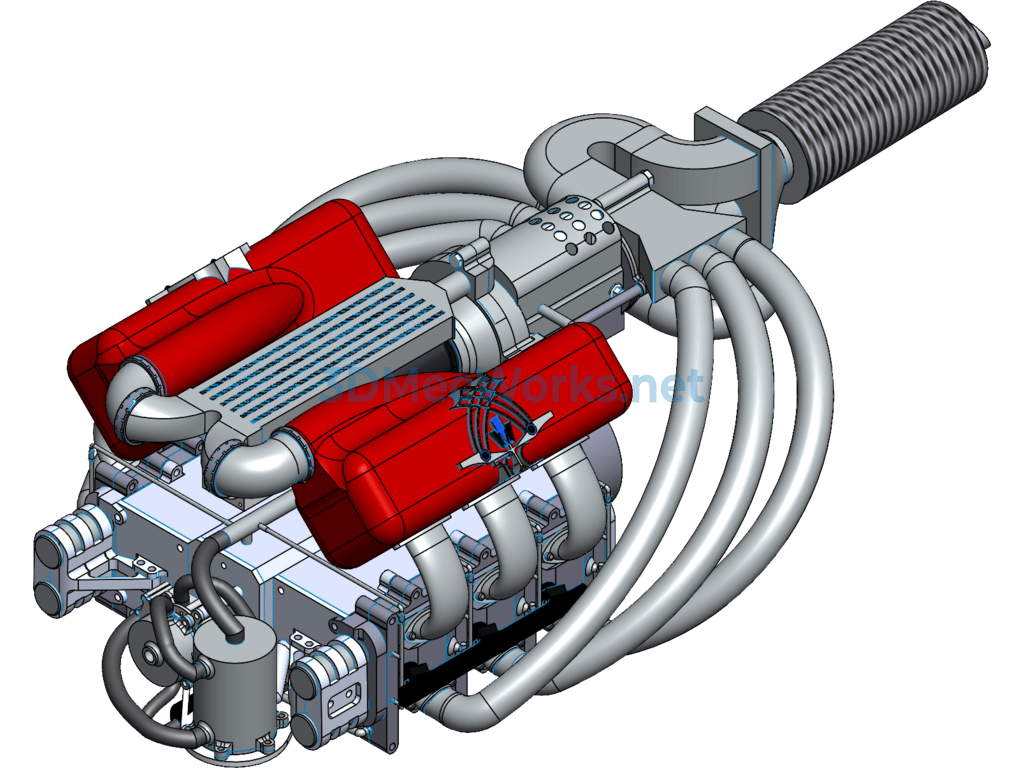

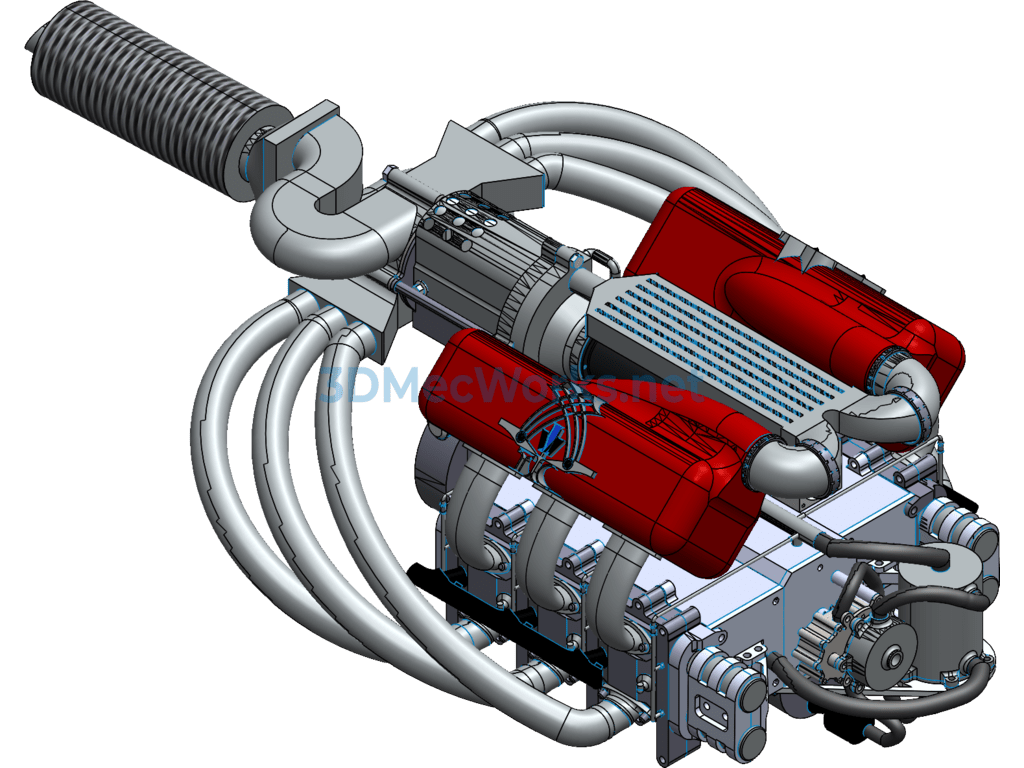

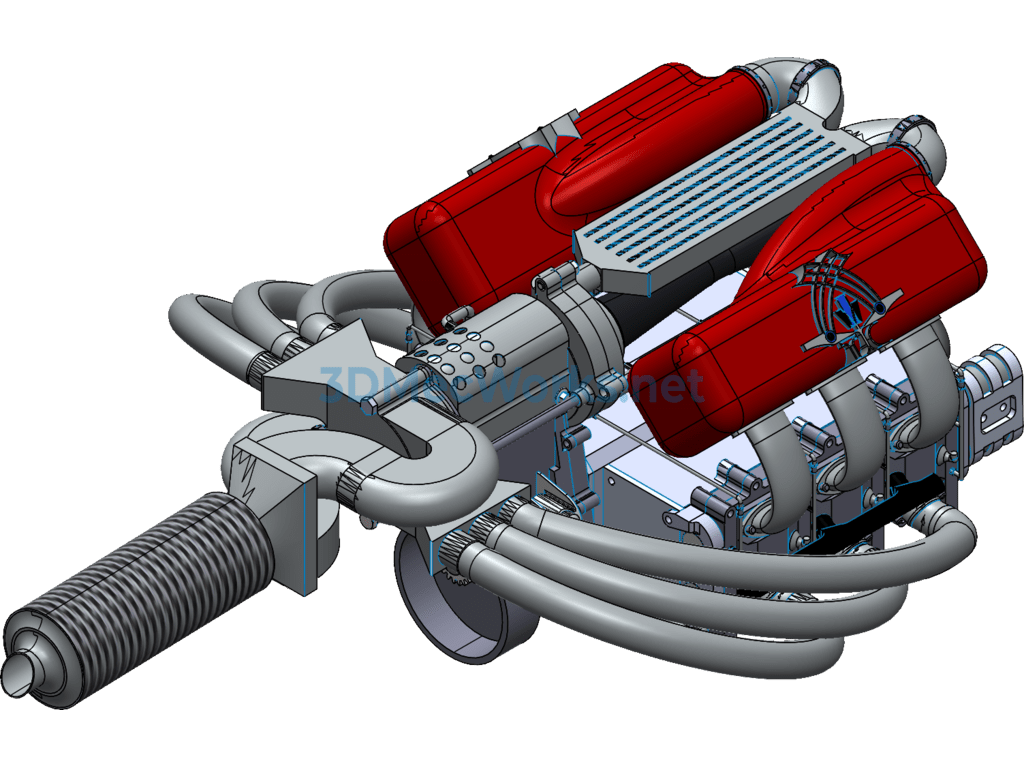

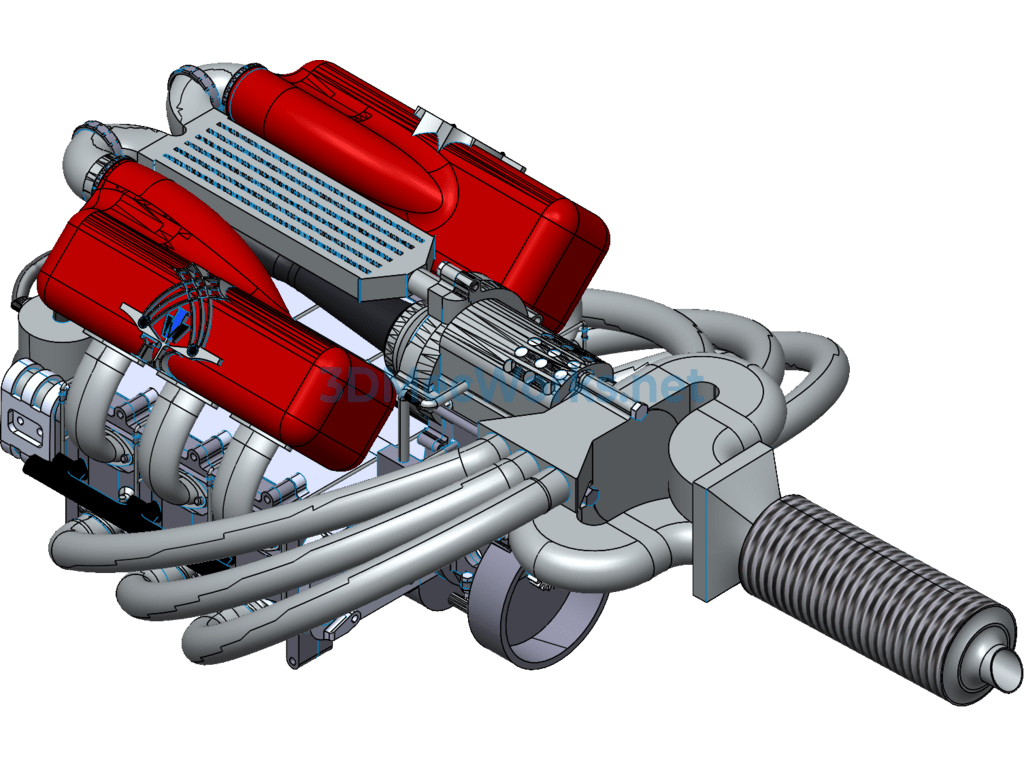

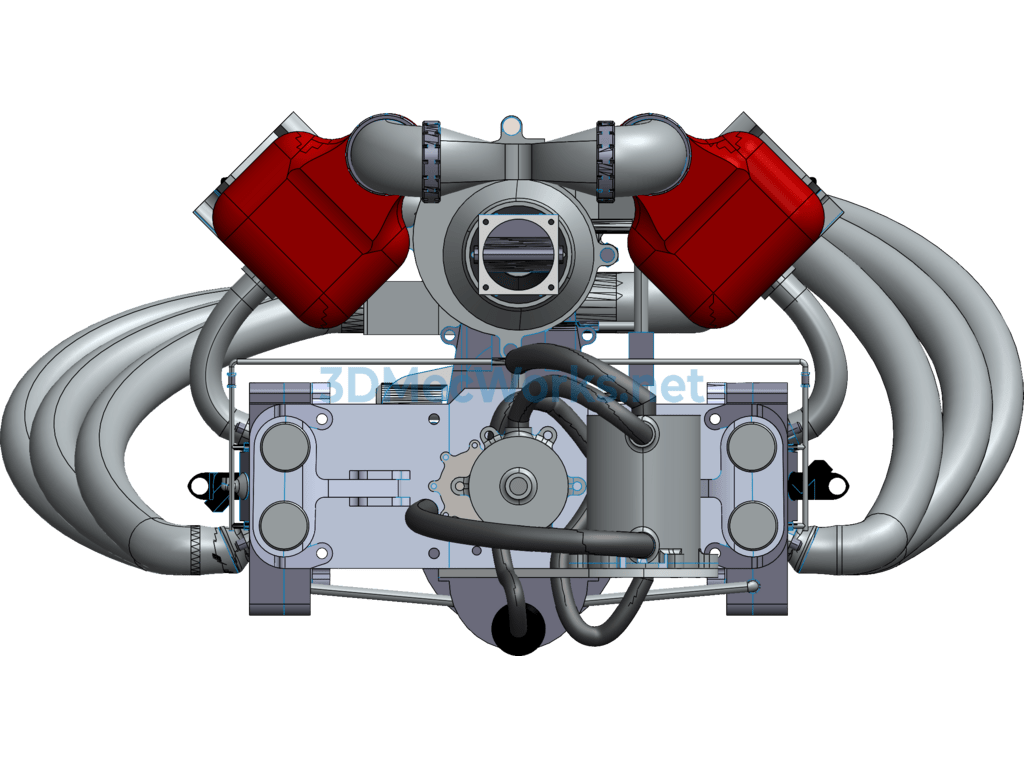

3D Model of a 610cc Turbo Compound Engine SW Design, created using SolidWorks 2012 version, available for download!

All turbo engines consist of three main components: a compressor, a combustion chamber, and a turbine, which are the sources of the name “turbo engine.” The compressor is usually divided into a low-pressure compressor (low-pressure section) and a high-pressure compressor (high-pressure section). The low-pressure section sometimes also functions as an intake fan to increase airflow. The incoming air is compressed by the compressor into a high-density, high-pressure, low-speed airflow to enhance engine efficiency. After the airflow enters the combustion chamber, fuel is injected by supply nozzles and mixed with the airflow for combustion. The high-temperature exhaust gas produced after combustion then drives the turbine, causing it to rotate. Any remaining energy is discharged through a nozzle or exhaust pipe. The amount of energy used to drive the turbine depends on the type and design of the turbo engine. Similar to the compressor, the turbine is divided into high-pressure and low-pressure sections.

Specification: 610cc Turbo Compound Engine

|

User Reviews

Be the first to review “610cc Turbo Compound Engine”

You must be logged in to post a review.

There are no reviews yet.