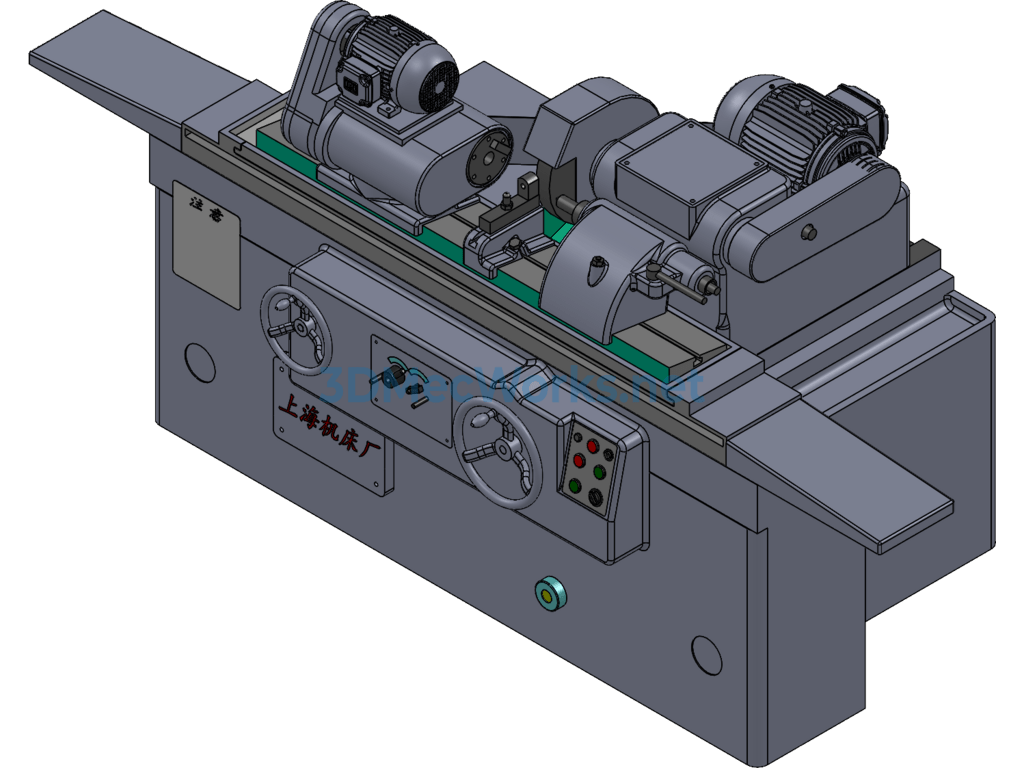

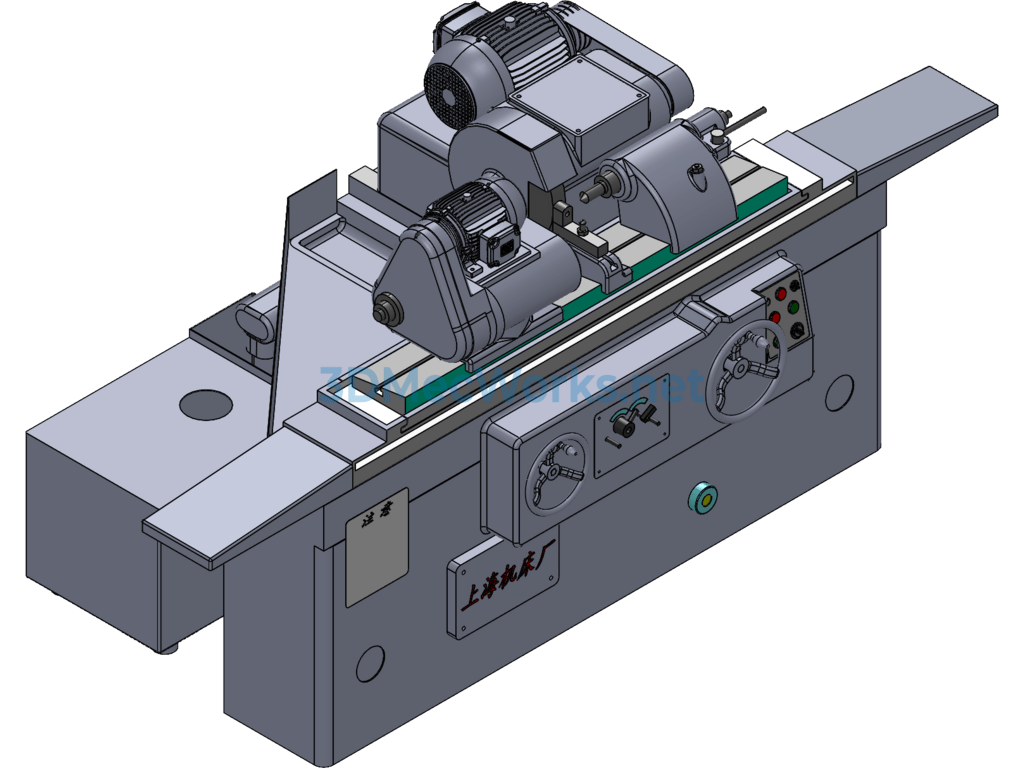

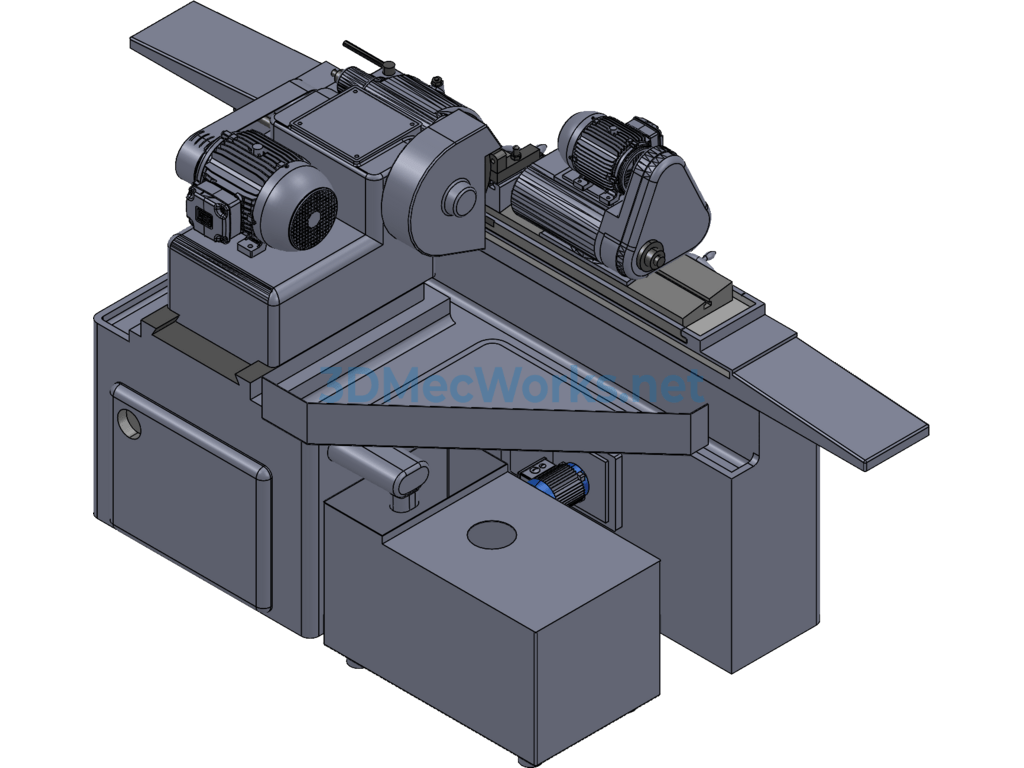

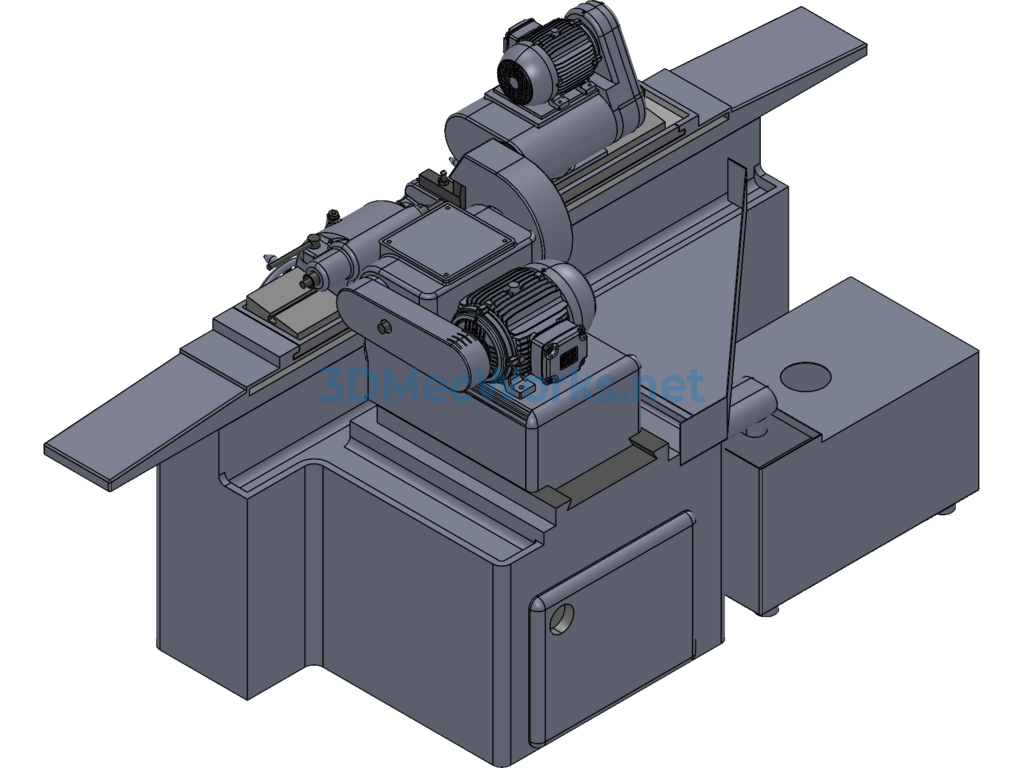

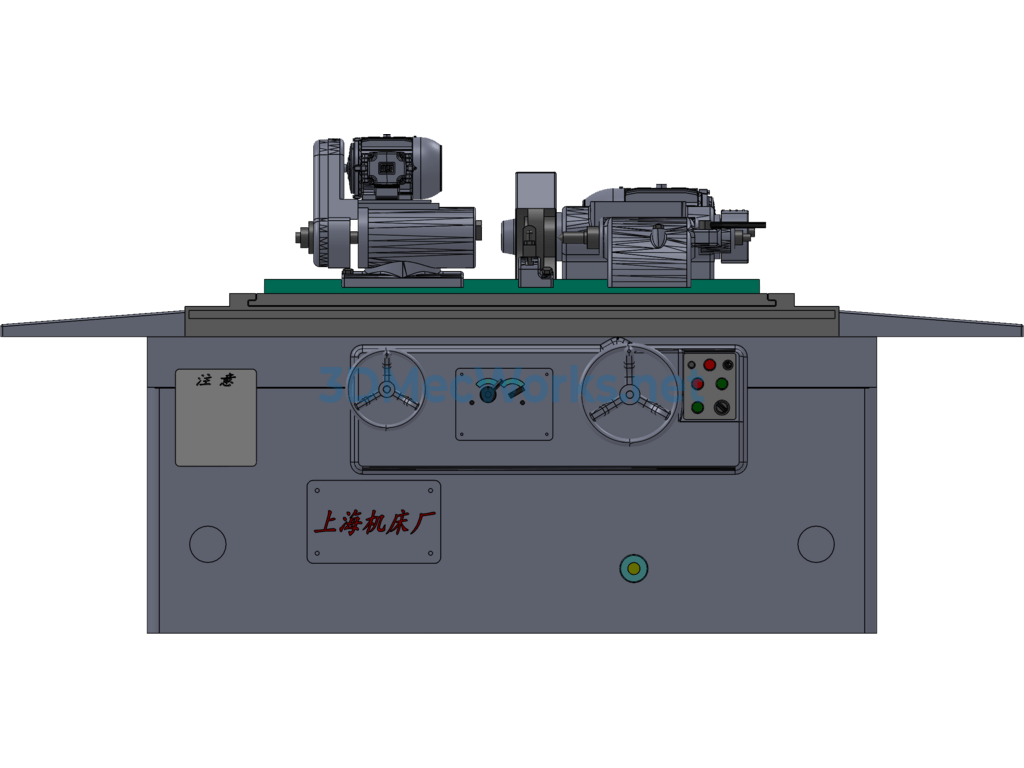

SOLIDWORKS 2010 designed a universal cylindrical grinding machine with complete part and assembly drawings, including feature data. The universal cylindrical grinding machine is used for grinding external surfaces and shaft shoulder end faces that are cylindrical, conical, or formed by generating lines of other shapes. The workpiece is supported between the centers of the headstock and the tailstock, and is rotated for circumferential feeding by the driving disc of the headstock. The headstock and tailstock are mounted on the worktable, which can perform longitudinal reciprocating feed motion (see machine tool). The worktable is divided into upper and lower layers, with the upper table adjustable to a small angle to grind conical surfaces.

Universal cylindrical grinding machine: The wheelhead is equipped with an internal grinding attachment, and both the wheelhead and the headstock can be adjusted to a certain angle around the vertical axis. In addition to the driving disc’s rotation, the spindle on the headstock can also rotate. The grinder can expand the processing range and is capable of grinding internal holes and both large internal and external tapered surfaces, making it suitable for small to medium batch and single-piece production.

Specification: Universal Cylindrical Grinding Machine

|

User Reviews

Be the first to review “Universal Cylindrical Grinding Machine”

You must be logged in to post a review.

There are no reviews yet.