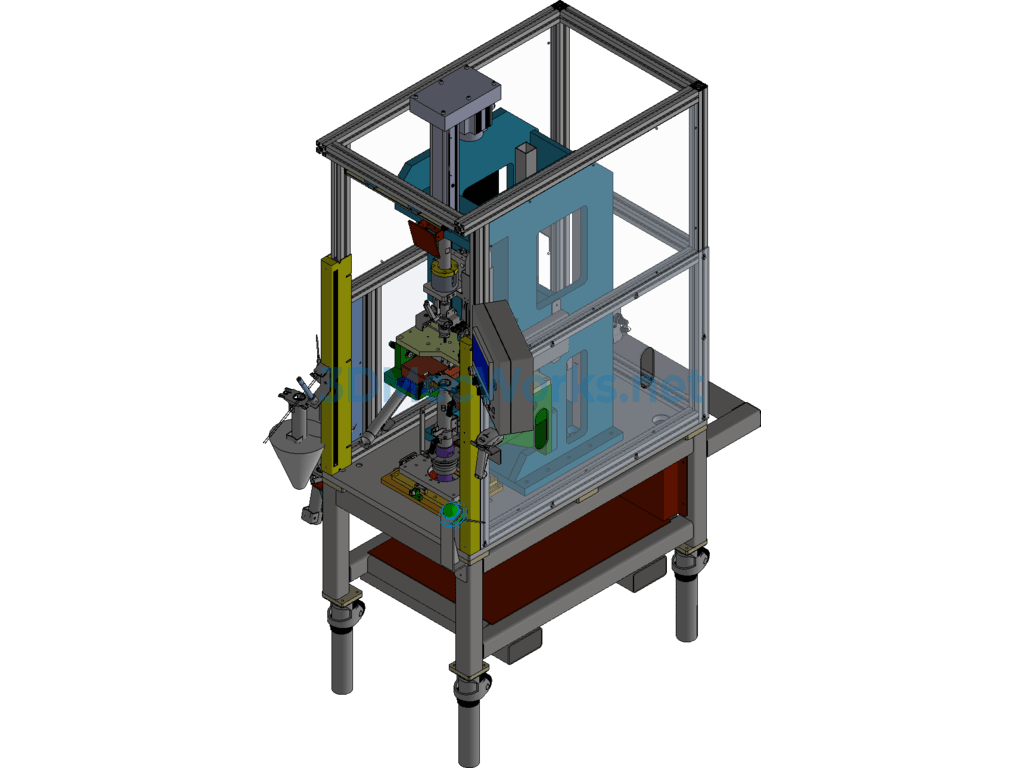

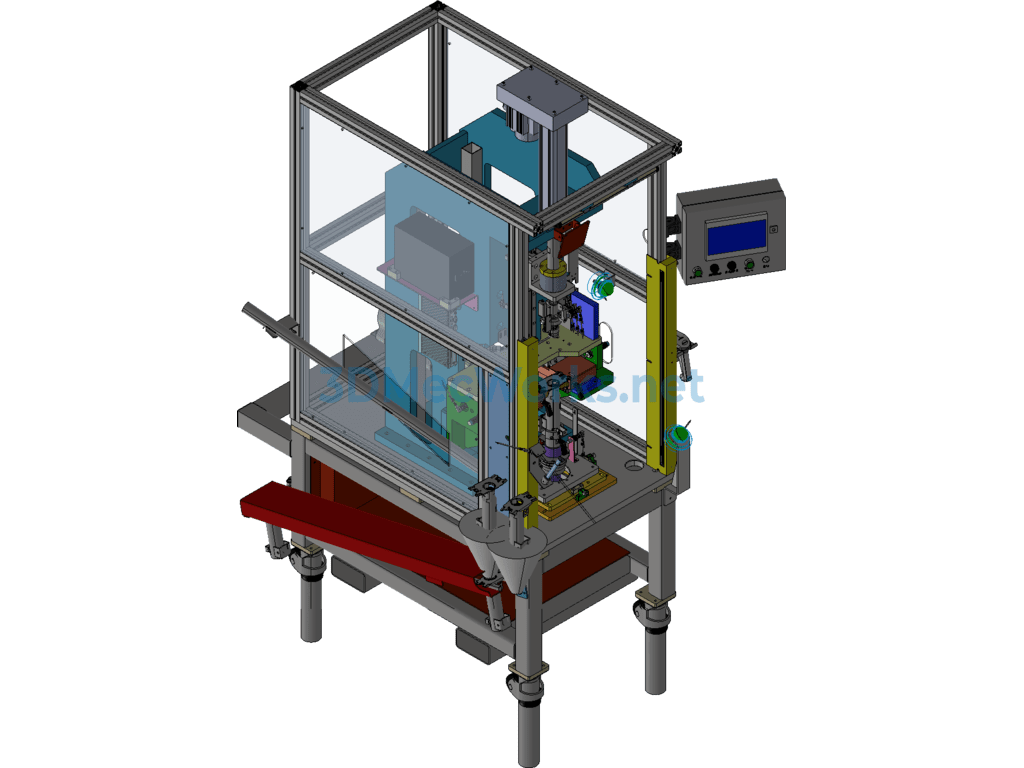

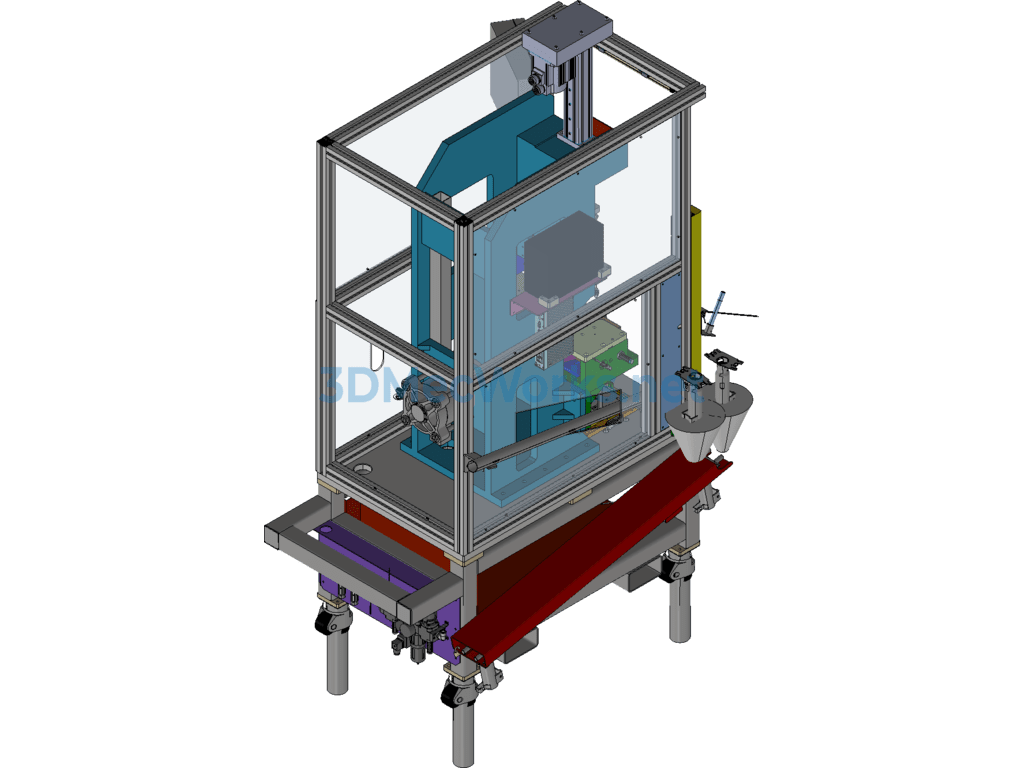

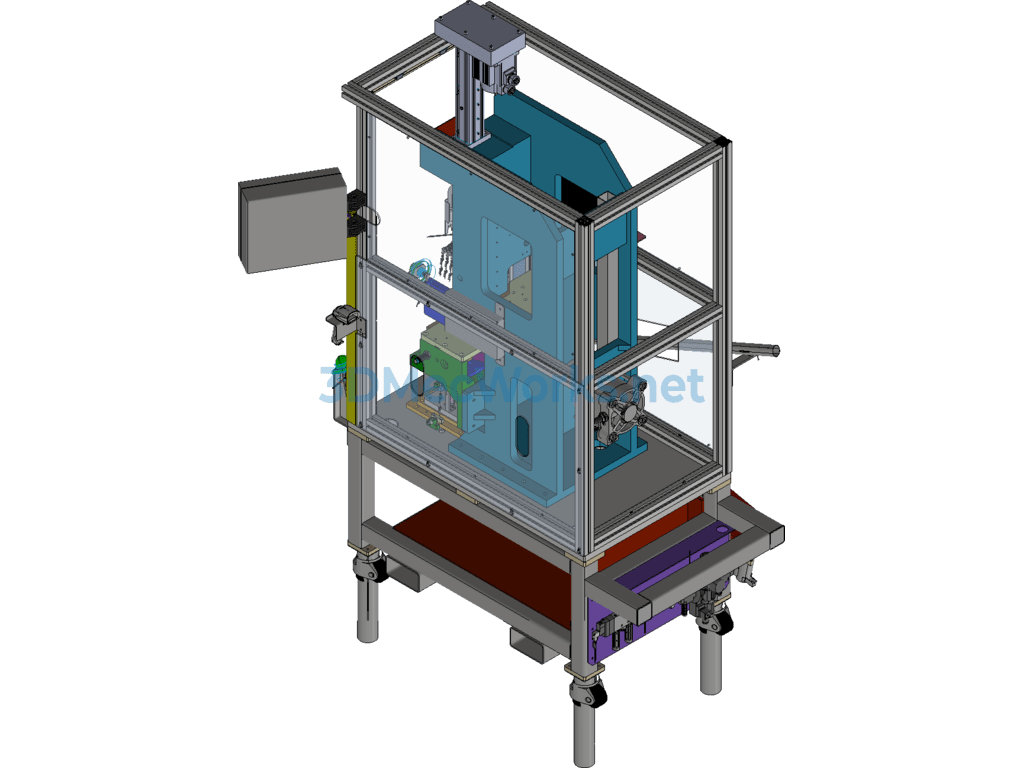

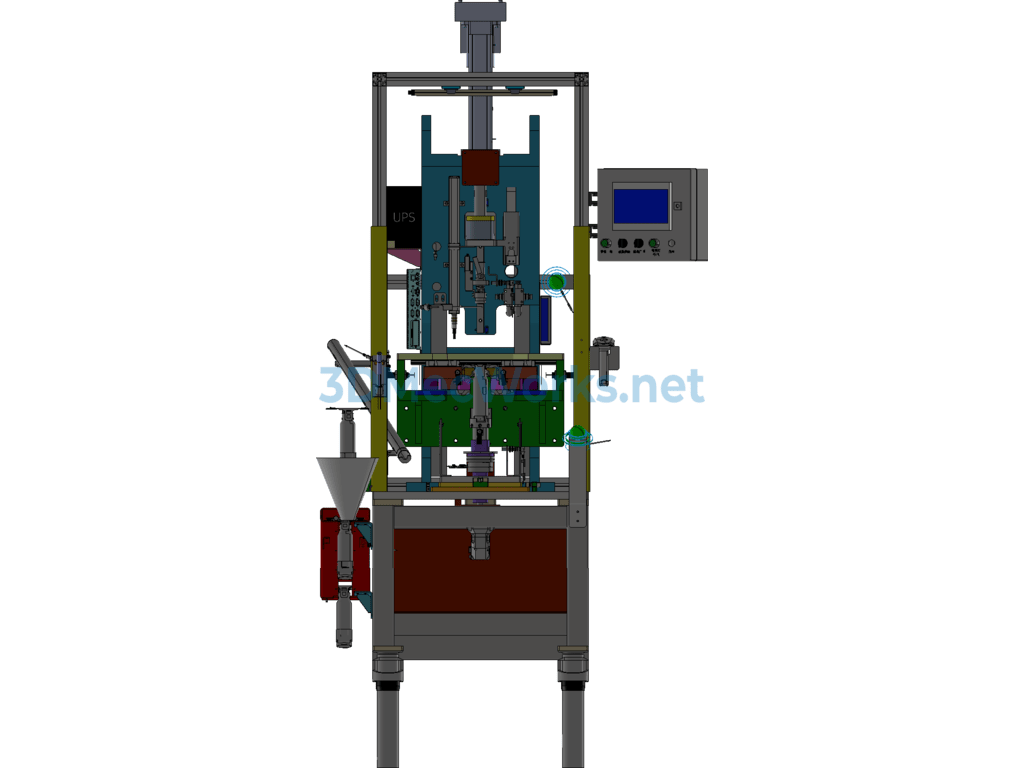

OP180B Tube Column Bearing Pressing and Radial Riveting

1. Purpose: To press the bearing into the upper tube column and perform multi-point radial riveting on the tube column cylinder;

2. Equipment Operation Process (Riveting 4 Points)

1) Take the upper tube column cylinder, visually inspect it for qualification, and then place it into the lower positioning fixture. Sensor senses in position (4s)

2) Take the bearing, visually inspect it for qualification, and then place it into the upper press head. Sensor senses in position (3s)

3) Press the start button (1s)

4) The servo press drives the bearing downward, pressing the bearing into the tube column (7s)

5) Pressing completed, the riveting cylinder extends, driving the riveting fixture to extend and rivet 2 points (3s)

6) Riveting qualified, riveting head retracts, servo press retracts (2s)

7) Rotate the motor by 90 degrees (rotation angle can be set) (1s)

8) Riveting cylinder extends, driving the riveting fixture to extend and rivet the other 2 points (3s)

9) Reset all components (2s)

10) Manually remove the completed part, bearing rotates flexibly without jamming, transfer to temporary storage position (in case of disqualification, manually remove the disqualified part, place it in NG box, trigger NG photoelectric, and reset the system) (2s)

Production cycle: ≤28s

3. Compatible product: JLFC3C

User Reviews

Be the first to review “OP180B Pipe Column Bearing Press-Fit And Radial Riveting”

There are no reviews yet.