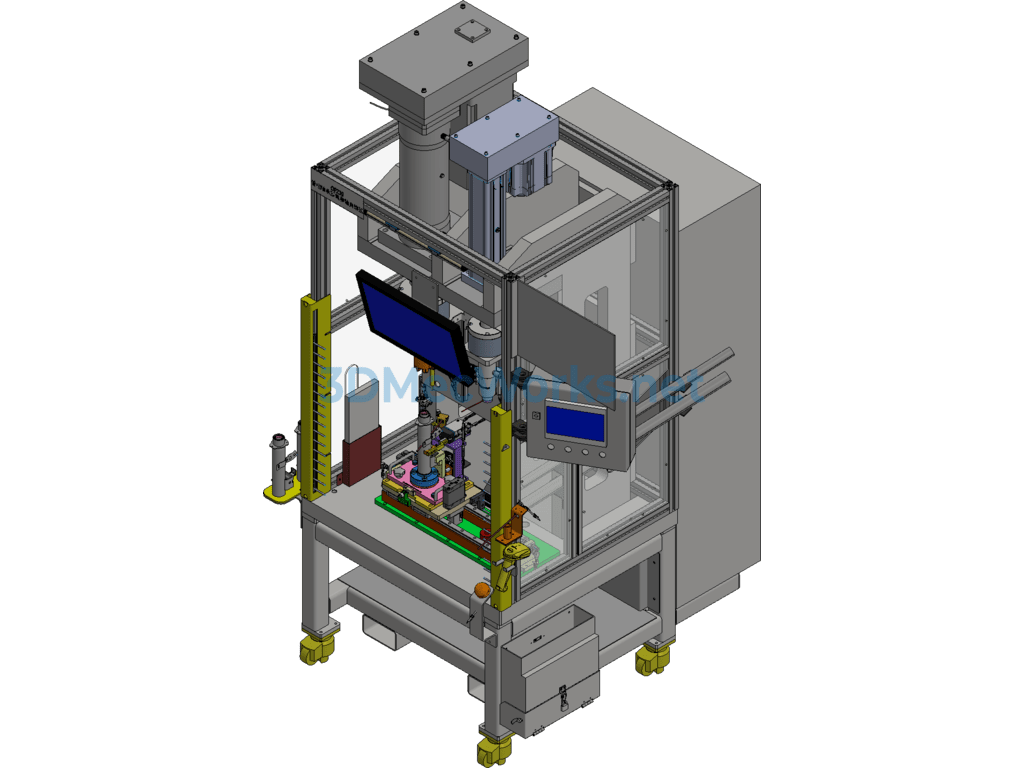

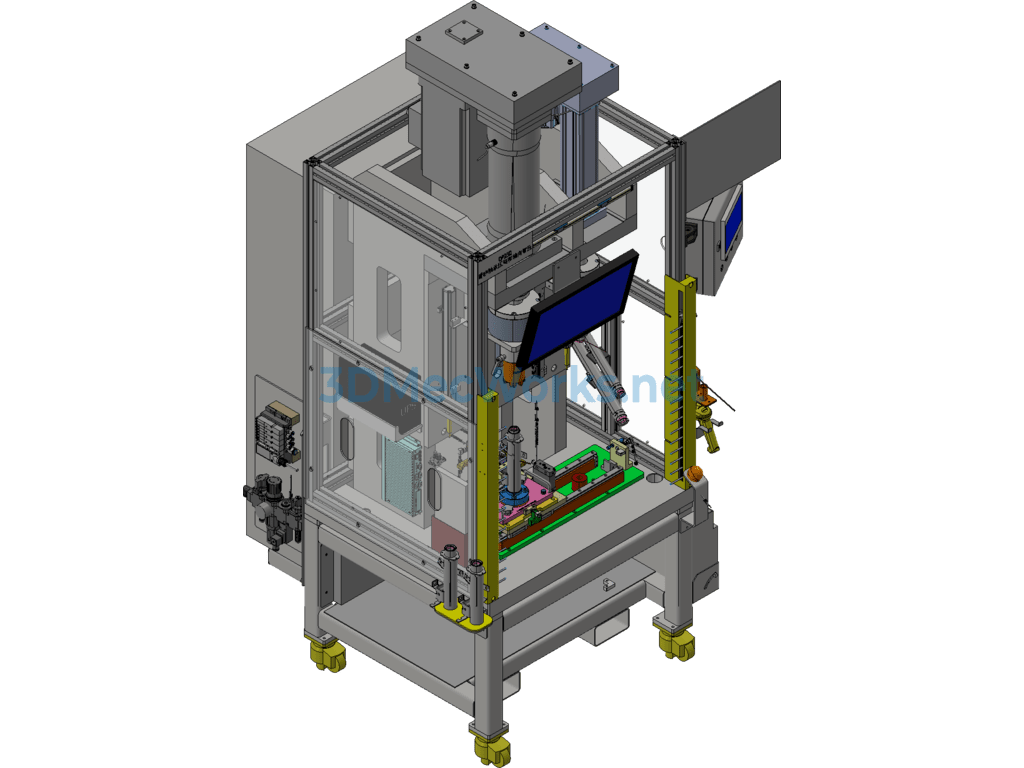

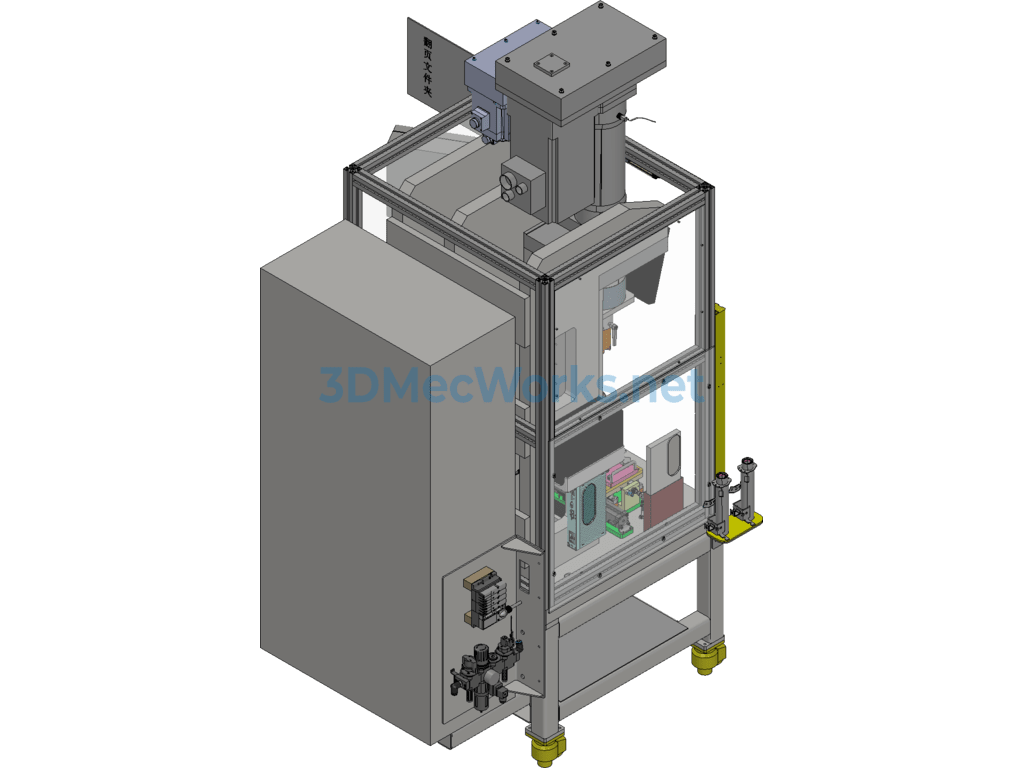

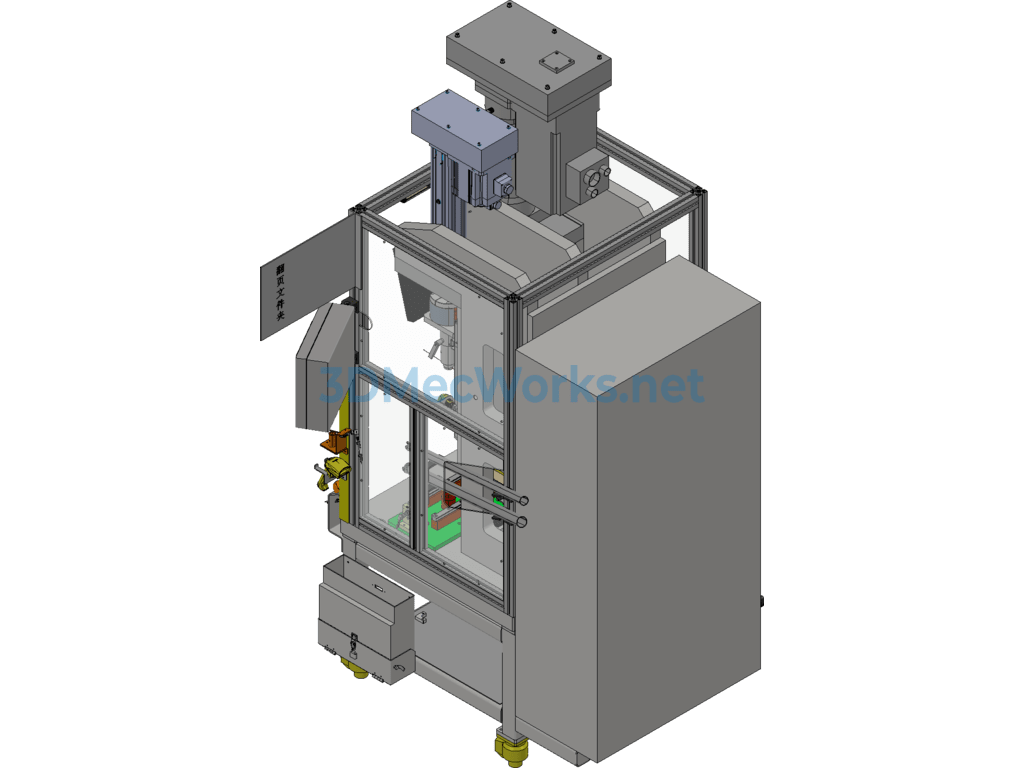

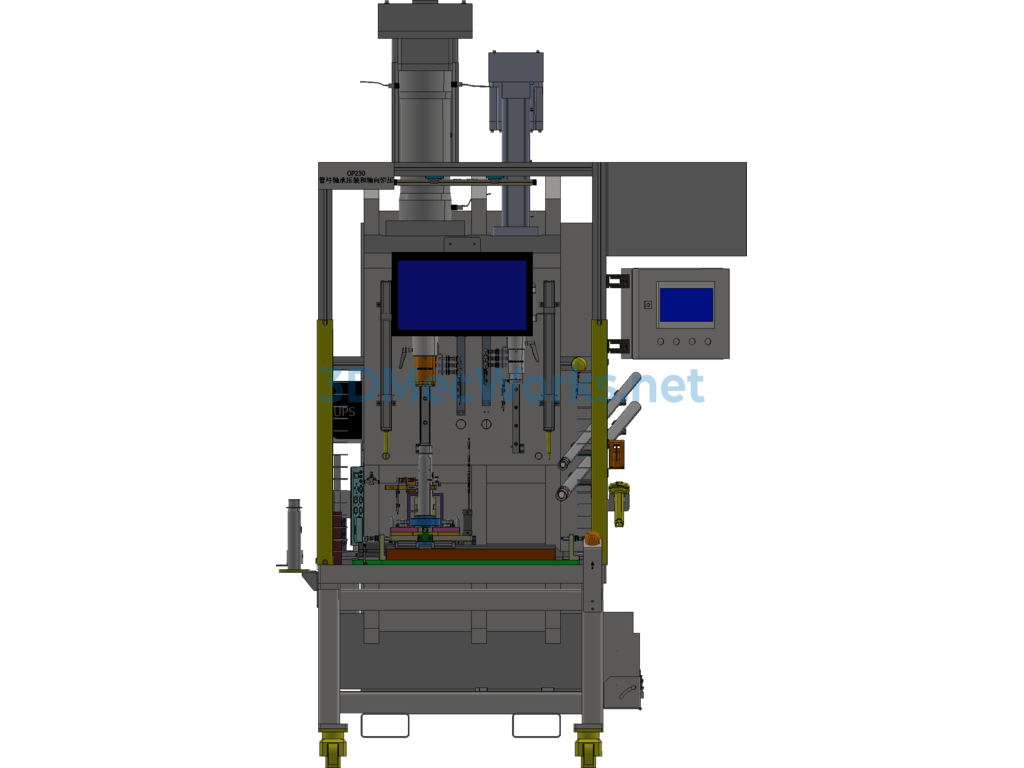

OP180A Tubular Bearing Press-Fitting and Axial Riveting

1. Purpose: To press-fit the bearing into the upper tubular, and to perform multi-point axial riveting on the tubular cylinder;

2. Equipment Operation Process:

1) Take the upper tubular cylinder, perform a visual inspection, and if it passes, place it in the lower positioning fixture, sensor detects it in position (manual 3s)

2) Take the bearing, perform a visual inspection, and if it passes, place it in the upper press head, sensor detects it in position (manual 3s)

3) Press the start button (manual 1s)

4) The servo press drives the press head downwards (automatic 7s)

5) Press-fitting completed, press head automatically retracts (automatic 3s)

6) Transfer cylinder moves the product horizontally to the riveting station (automatic 2s)

7) The servo press drives the riveting head downwards (automatic 7s)

8) Press-fitting completed, press head automatically retracts (automatic 3s)

9) Horizontal transfer cylinder resets (automatic 2s)

10) Manually remove the completed part, ensure the bearing rotates smoothly without sticking, transfer to temporary storage position (in case of defect, alarm sounds, manually remove defective parts, place in NG box, trigger NG photoelectric, and reset system) (manual 2s)

Production Cycle: ≤33s

3. Compatible Products: XK507C, SP232C

Specification: Op180a Column Bearing Press-Fitting and Axial Riveting

|

User Reviews

Be the first to review “Op180a Column Bearing Press-Fitting and Axial Riveting”

You must be logged in to post a review.

There are no reviews yet.