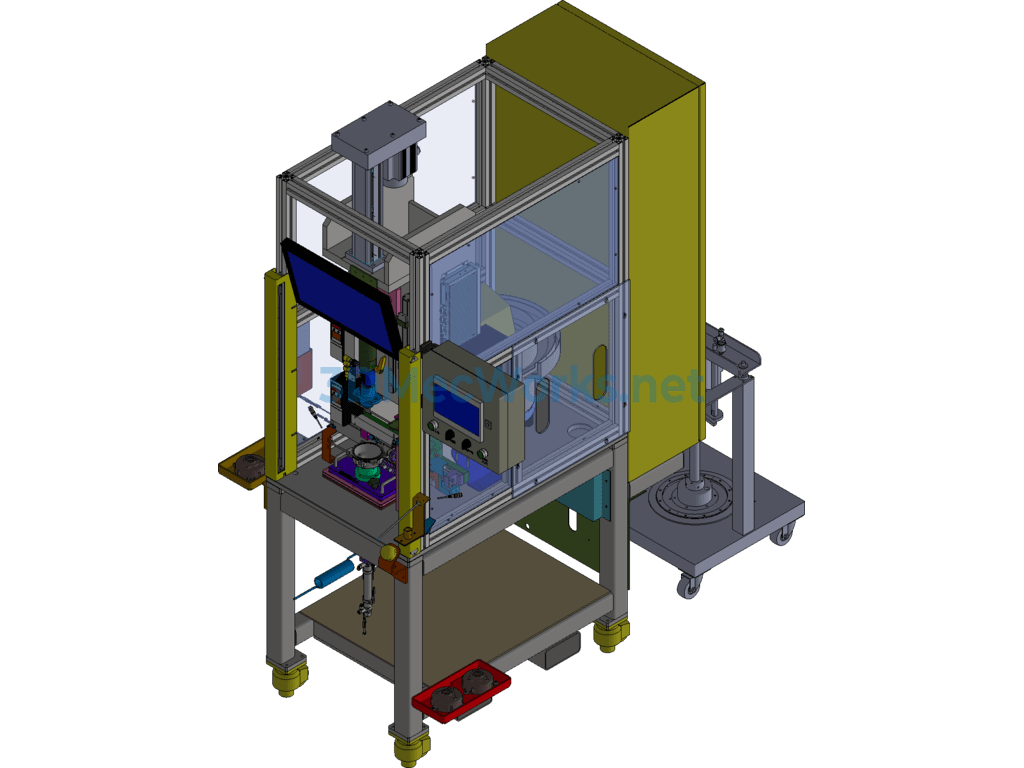

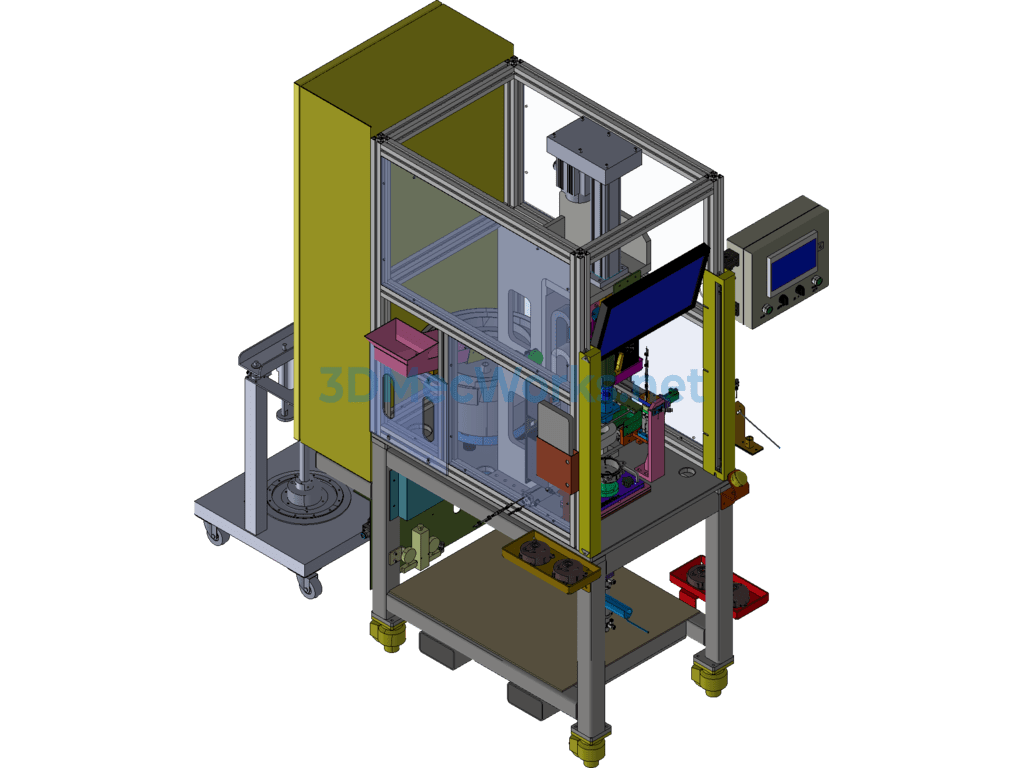

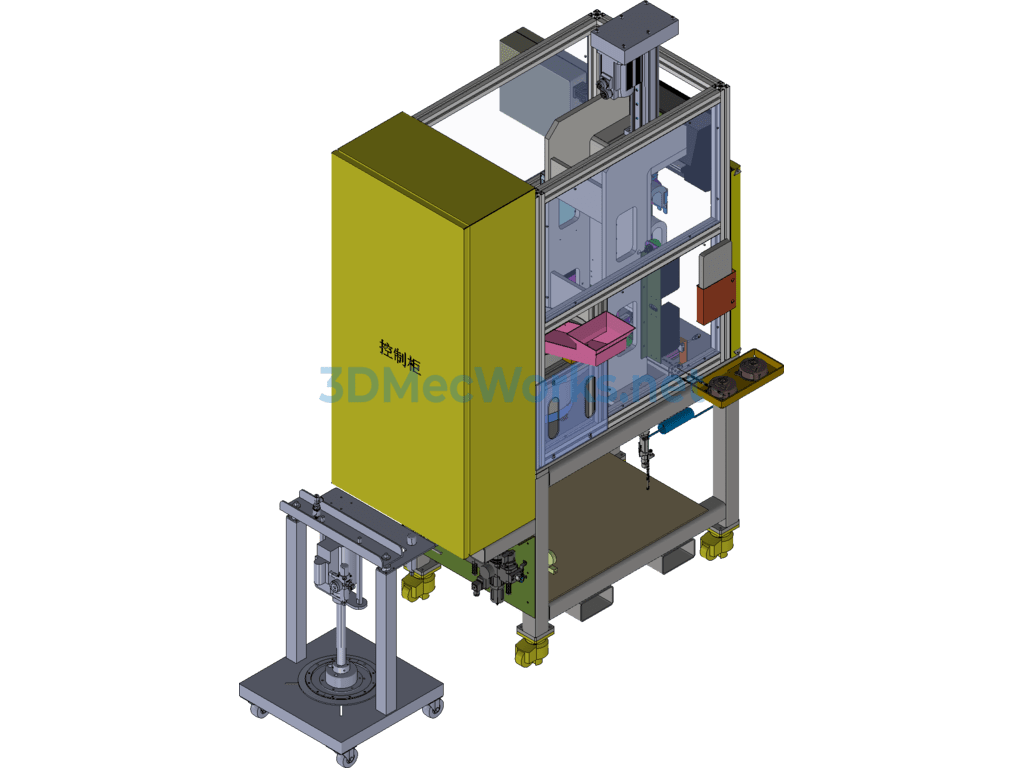

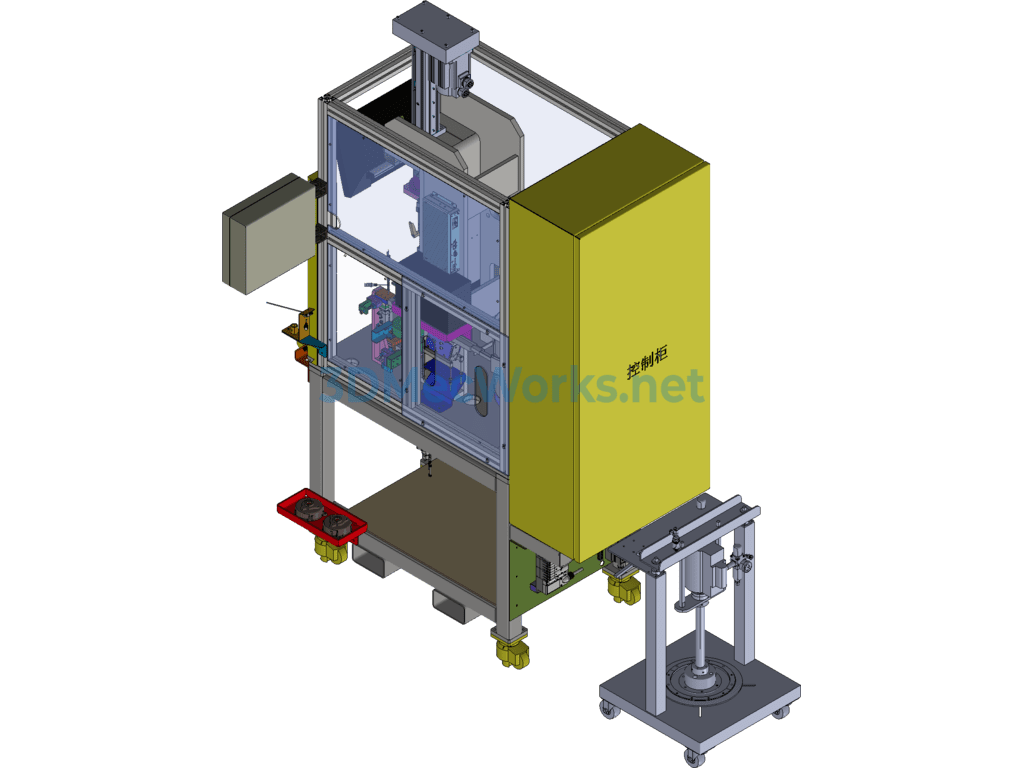

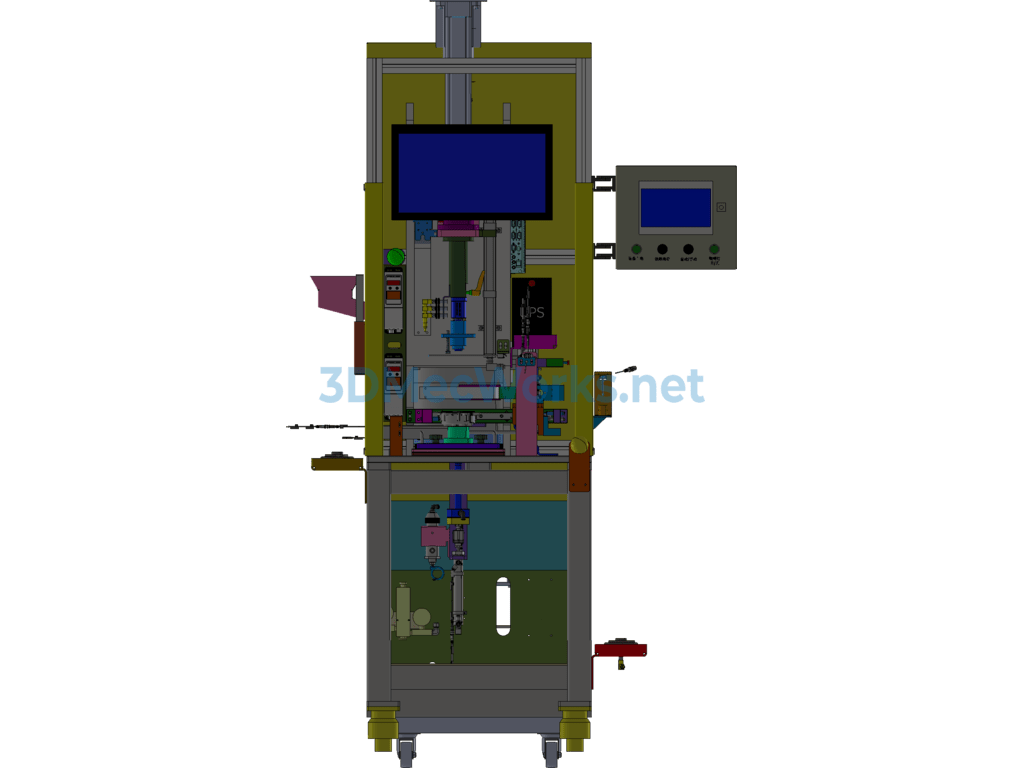

OP210 Upper Casing Bushing Press Installation

1. Purpose: Lubricate the upper casing and press the bushing into the upper casing;

2. Equipment specifications: 1000mm(W)x1400mm(L)x2000mm(Aluminum Profile H).

3. Equipment Technical Parameters

3.1 Equipment Power: 5kw;

3.2 Air Source: ≥ 0.5Mpa clean compressed air without oil or water. Air consumption: 5 liters/min.

3.3 Equipment Operation Mode: Product loading/unloading done by operator (manual), bushing automatic loading, pressing operation completed by equipment (automatic).

3.4 Press Force Monitoring: Pressure sensor range 10KN, precision 0.3%FS, with self-calibration function, sectional monitoring curve available.

3.5 Press Displacement Monitoring: Stroke 300mm, precision ±0.02mm, full stroke monitoring.

3.6 Press Assembly Judgment: Whether pressure and displacement are within qualified range.

3.7 Position Accuracy: Coaxiality of the pressing head positioning center hole and the fixture positioning installation hole is less than 0.05mm, verticality of pressing head to the workbench surface is 0.05mm.

3.8 Equipment Requirements: Pressing head adopts floatable mechanism while ensuring rigidity; pressing head and fixture equipped with identifiable sensors, equipment can identify automatically.

3.9 Model Change: Fixtures to be replaced are placed below the equipment, with a special placement tray manufactured.

3.10 Equipment CPK value ≥1.33; precision of pressed parts and pressing precision to be verified according to drawing requirements.

4. Compatible Products: XK507C, JLFC3C, SP232C

Specification: Op210 Upper Housing Bushing Press-Fit

|

User Reviews

Be the first to review “Op210 Upper Housing Bushing Press-Fit”

You must be logged in to post a review.

There are no reviews yet.