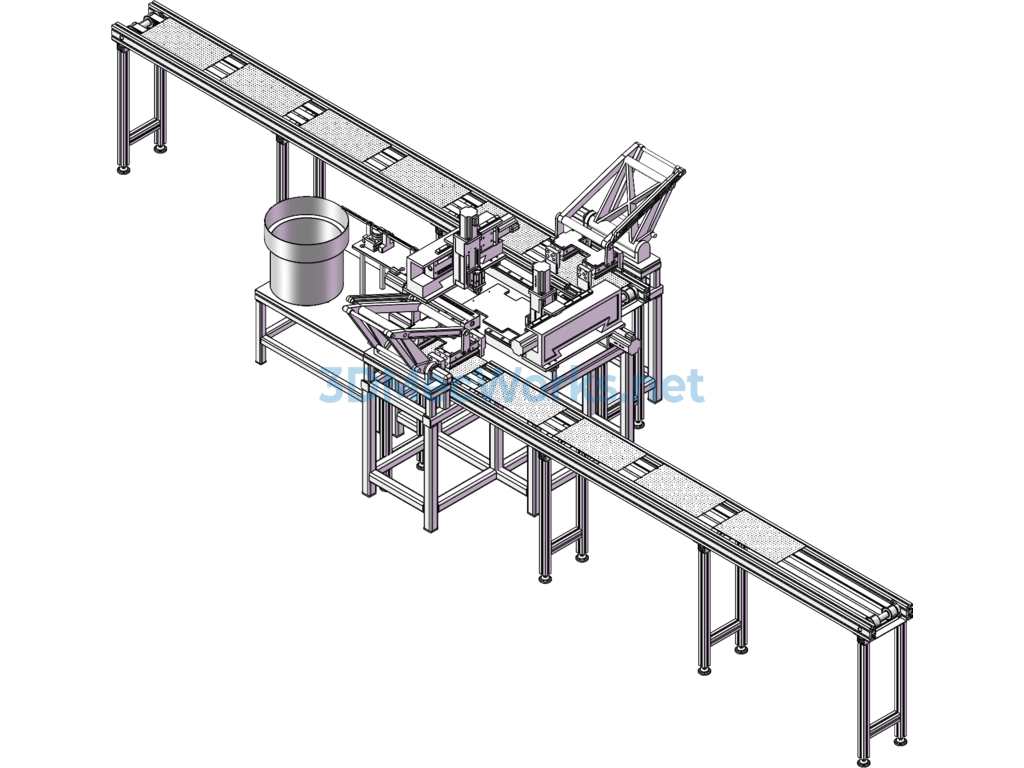

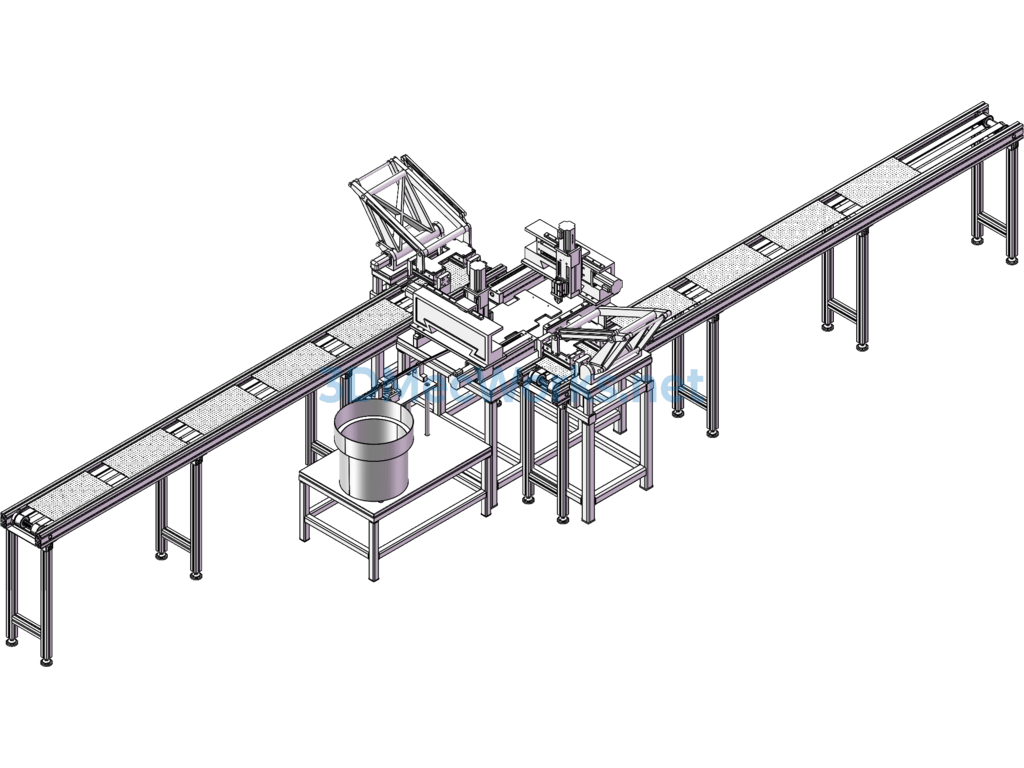

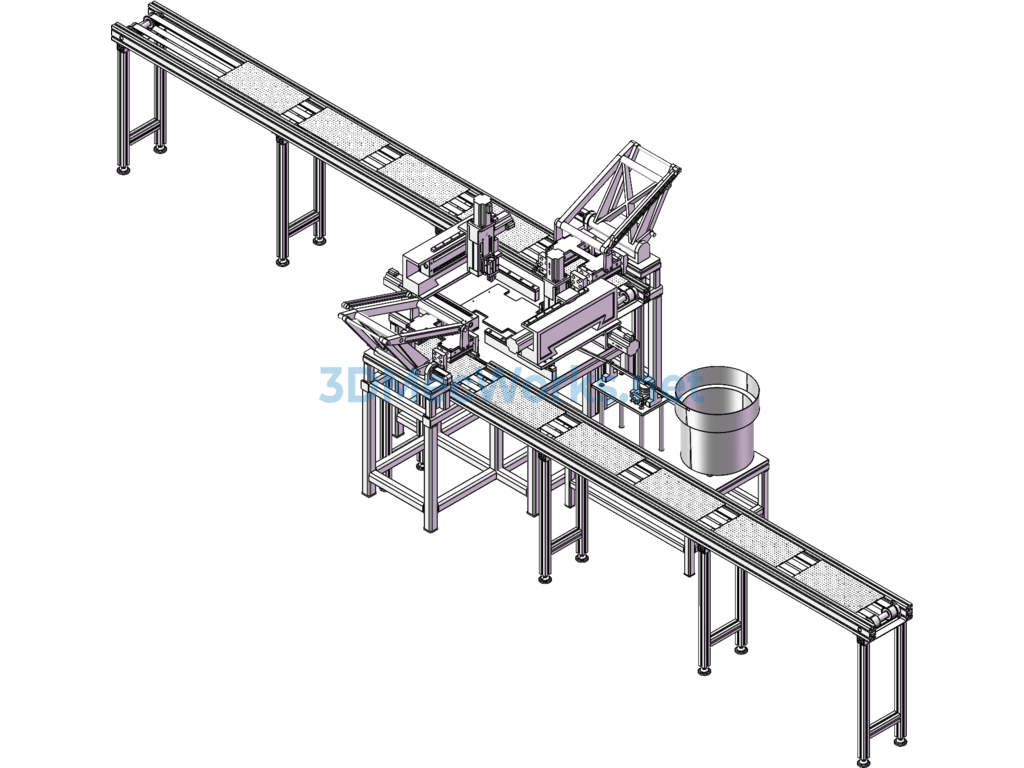

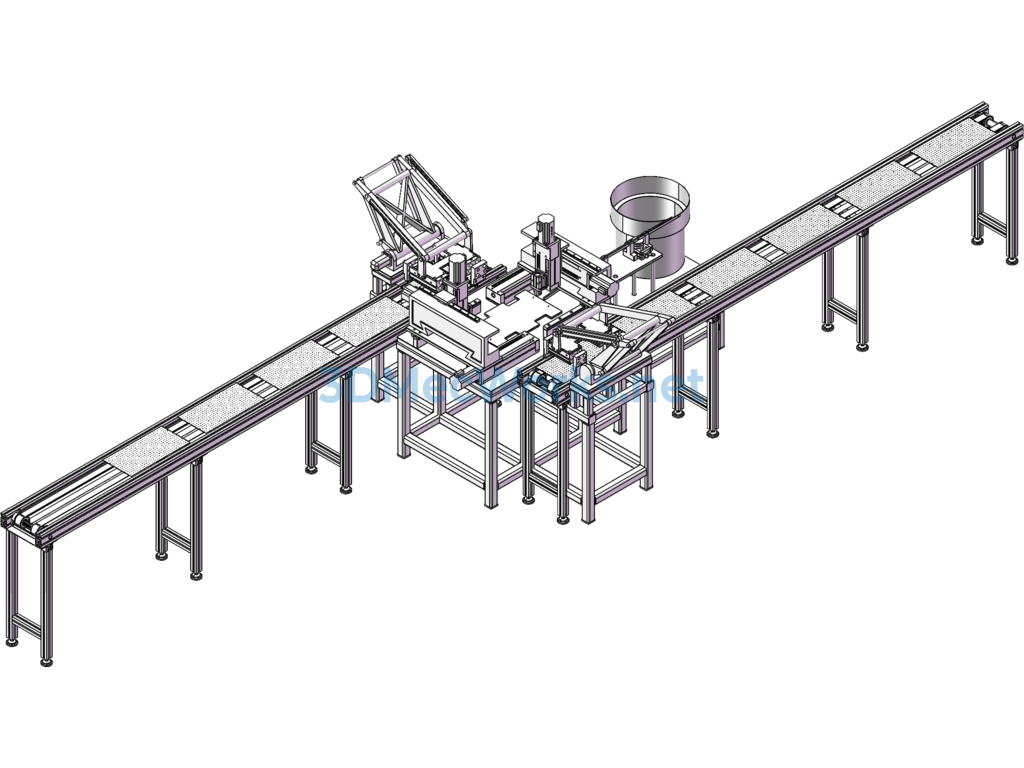

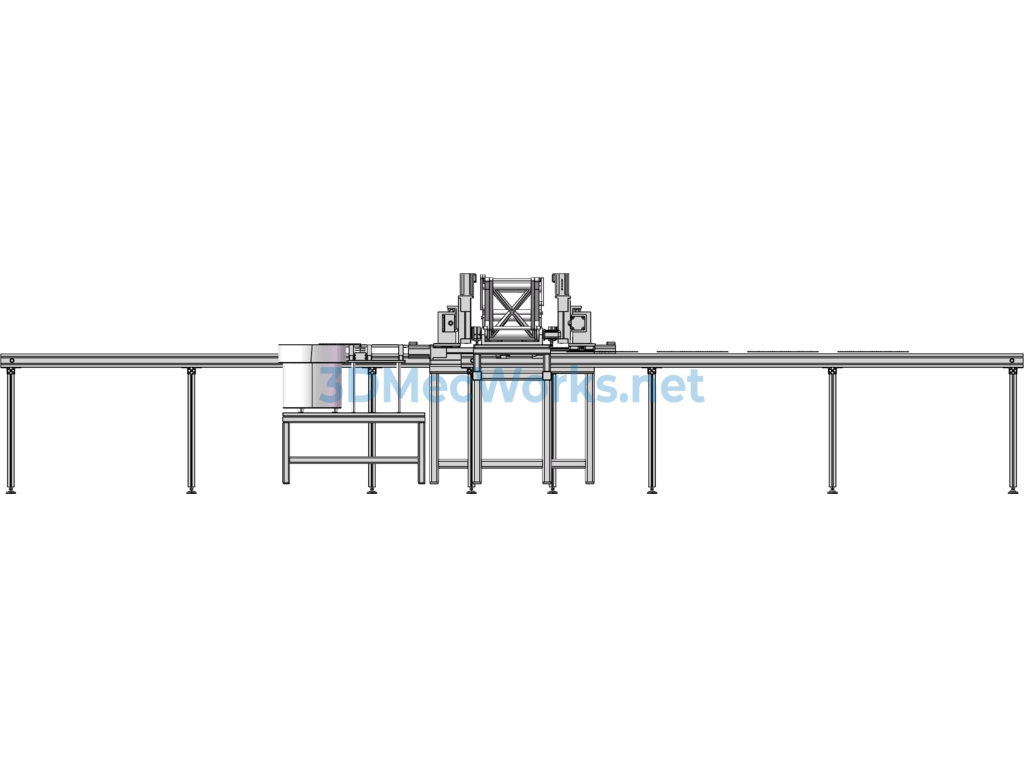

LED Insertion Machine SW Design 3D Model

LED lighting fixtures generally include a circuit board and multiple LEDs inserted into the circuit board. Since the positive and negative leads of the LED (corresponding to the longer and shorter leads, respectively) must be precisely aligned with the positive and negative holes on the circuit board to be properly inserted, manual alignment is still required after insertion to proceed to the next assembly step. If the positive and negative leads of the LED are not accurately aligned with the positive and negative holes on the circuit board during the insertion assembly, it is easy for the LED leads to become compressed against the circuit board, causing severe deformation of the leads. This significantly increases the defect rate of LED lighting assembly, and in severe cases, it may even damage production equipment, affecting normal production.

Existing LED fixtures usually rely on manually distinguishing the positive and negative leads of each LED. The excess length on the LED leads is cut in a lead cutting machine, after which the LEDs are either manually inserted one by one into the corresponding positive and negative holes on the circuit board.

Specification: Led Insertion Machine

|

There are no reviews yet.