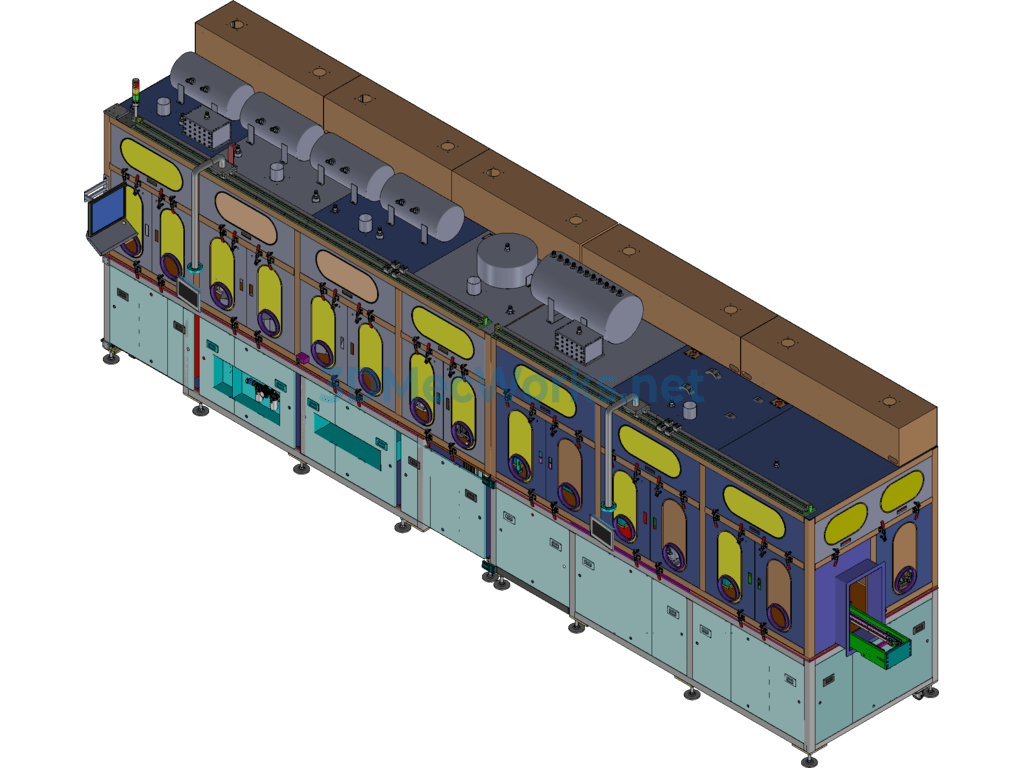

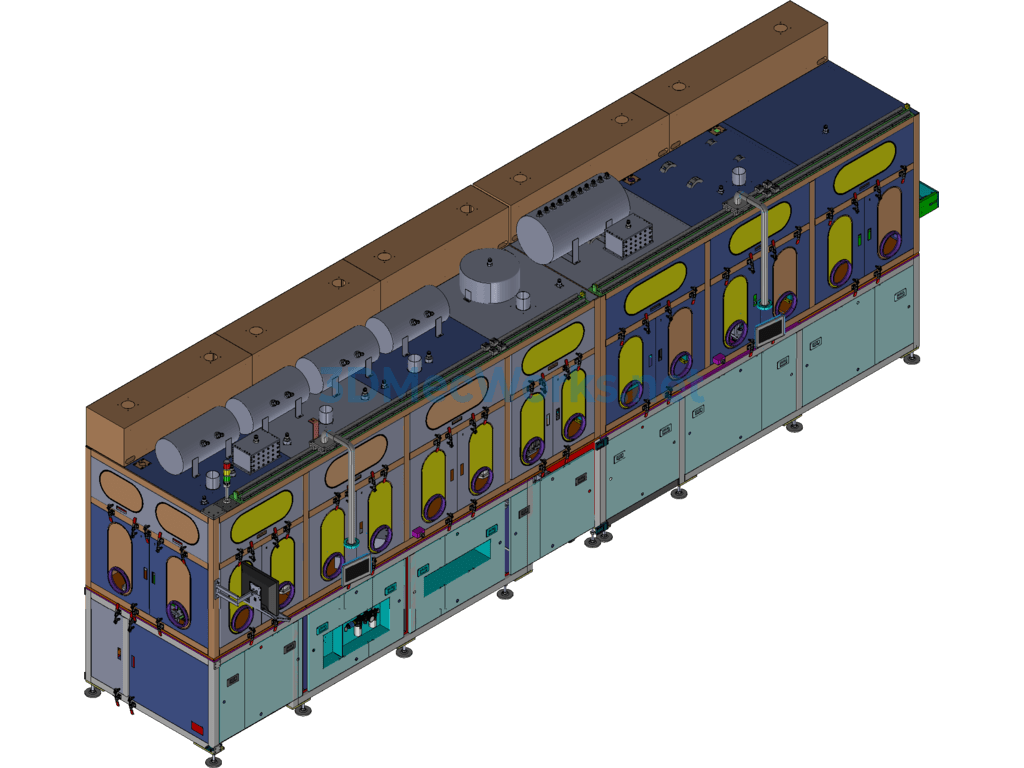

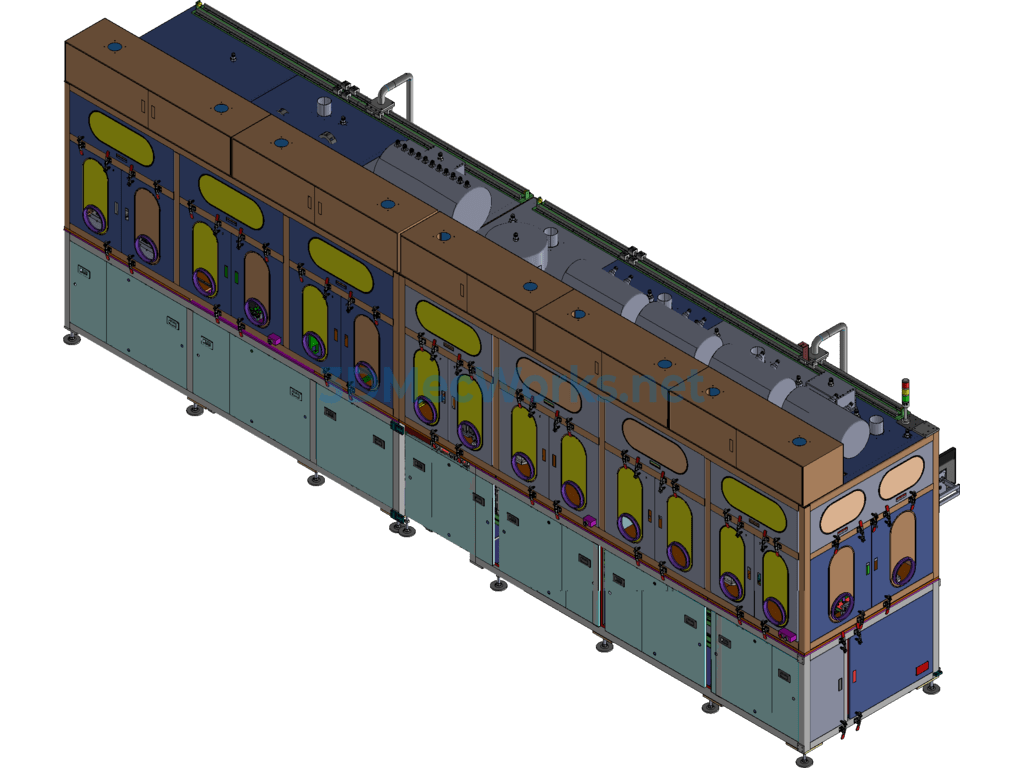

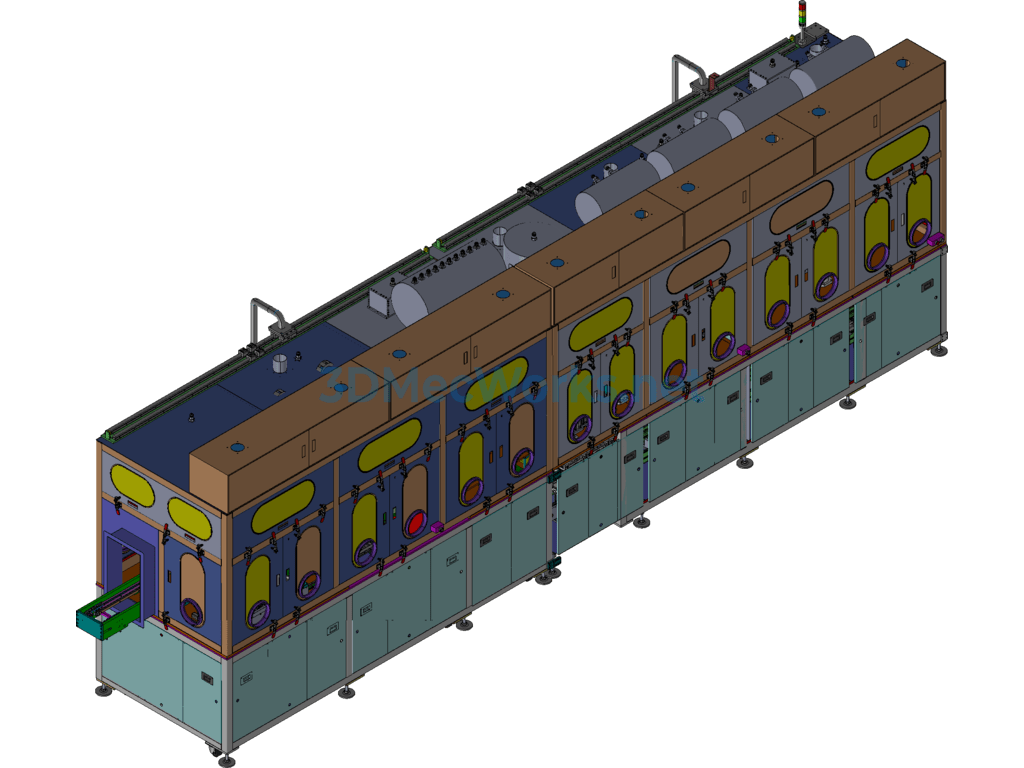

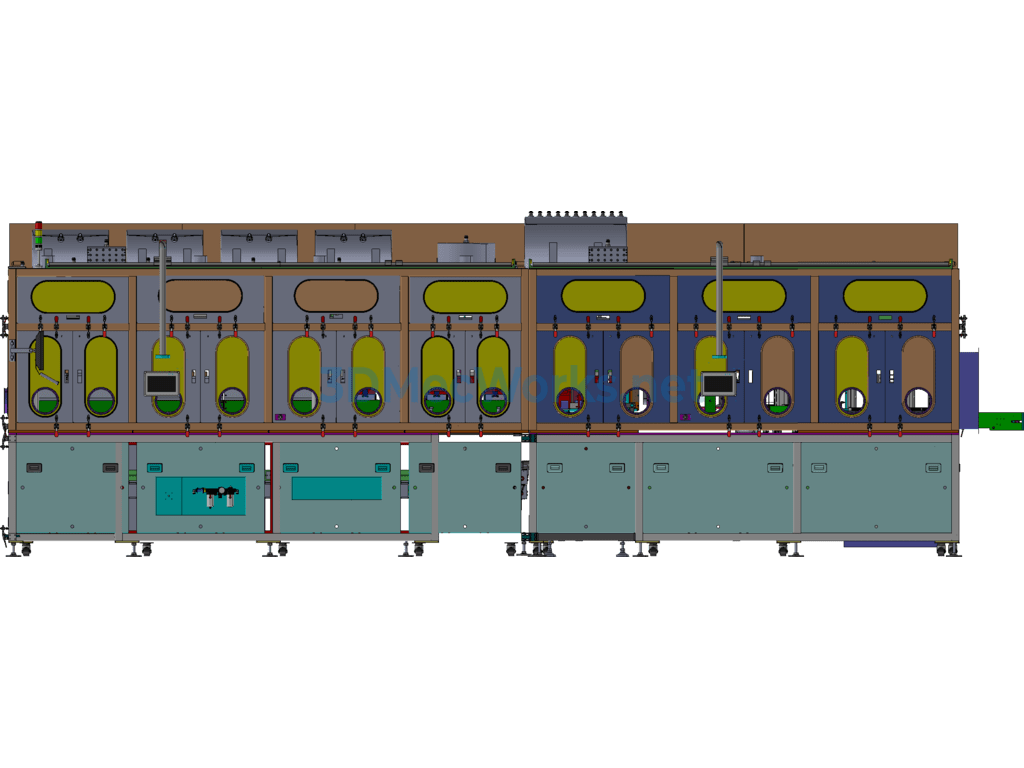

The device is mainly used for automatic filling machines for both mobile phone pouch lithium-ion batteries and power batteries, with key processes including automatic feeding and sealing. It achieves functions such as pre-filling weighing for pouch batteries, automatic filling, automatic resting, automatic vacuum sealing, post-filling automatic heating and packaging, automatic sorting of defective filling products, and automatic discharge. This device is one of the more efficient vacuum filling machines for pouch lithium batteries, designed with a 1-to-6 structure. It features precision and flexibility, with all processes from automatic feeding, defective scanning and ejection, vacuum filling, three-step resting, vacuum hot-press sealing, to discharging being automated. Starting from the front-end feeding, cycle fixtures, to the filling station, three-step resting, vacuum sealing, and discharging, the structure is complete. The frame is welded with square tubes and protected with aluminum profiles. From the diagram, it’s clear that the internal structure is complex once the outer cover is concealed. The battery cell grabbing and handling robot, together with the design of the battery cell feeding conveyed with tooling jigs, is very valuable for learning. First, before filling, the battery cavity inside needs to be evacuated to a high vacuum of -96 to -100kPa; secondly, during filling, it maintains a differential pressure laminar flow filling to avoid spraying, misting of the filling nozzle, and after filling, multiple vacuum evacuation and pressurization cycles are set. Among these, to prevent excessive evaporation of the electrolyte, the extraction pressure is set at -65 to -76kPa. Since a high vacuum needs to be drawn before filling and a low vacuum during the post-filling pressurization cycle, to enhance the stability of the equipment, four sets of vacuum systems are added, with three vacuum pumps and four gas storage tanks. One vacuum system is dedicated to high vacuum tasks using a TRP24 vacuum pump; another vacuum system is driven by two TRP48 vacuum pumps, and it uses internationally advanced vacuum differential pressure filling technology to ensure filling precision, production stability, and complete penetration of the battery electrolyte, while also considering clean production and the ease of equipment maintenance.

Specification: Soft Pack Power Lithium Battery High-Efficiency Vacuum Liquid Injection and Sealing Machine

|

User Reviews

Be the first to review “Soft Pack Power Lithium Battery High-Efficiency Vacuum Liquid Injection and Sealing Machine”

You must be logged in to post a review.

There are no reviews yet.