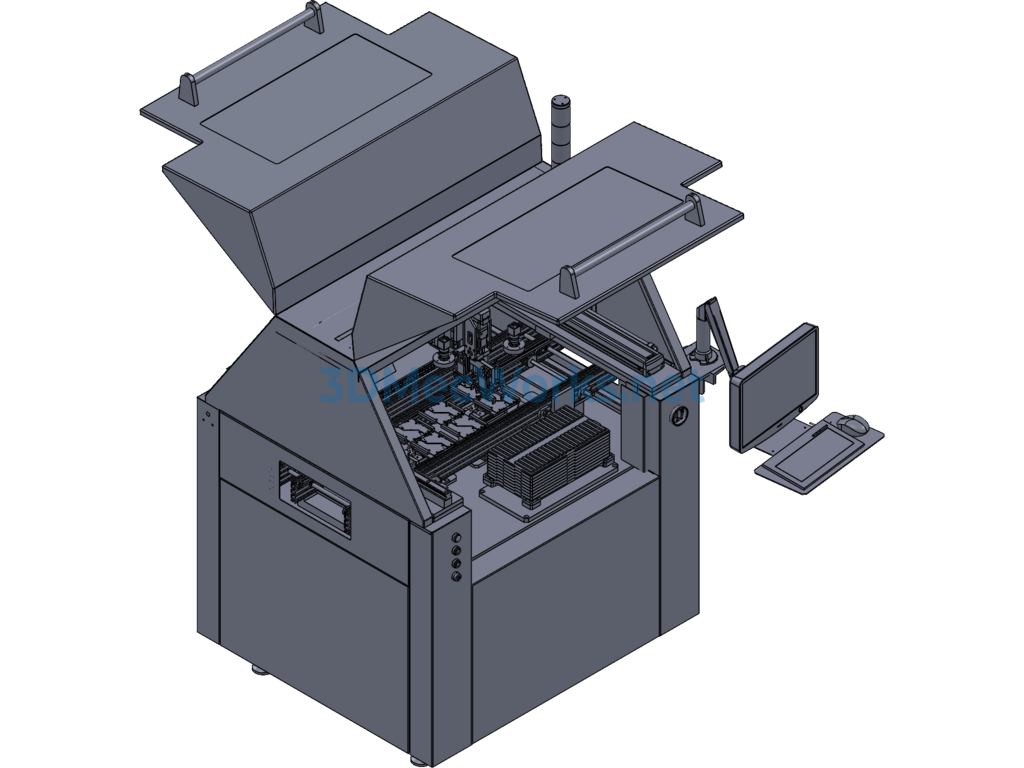

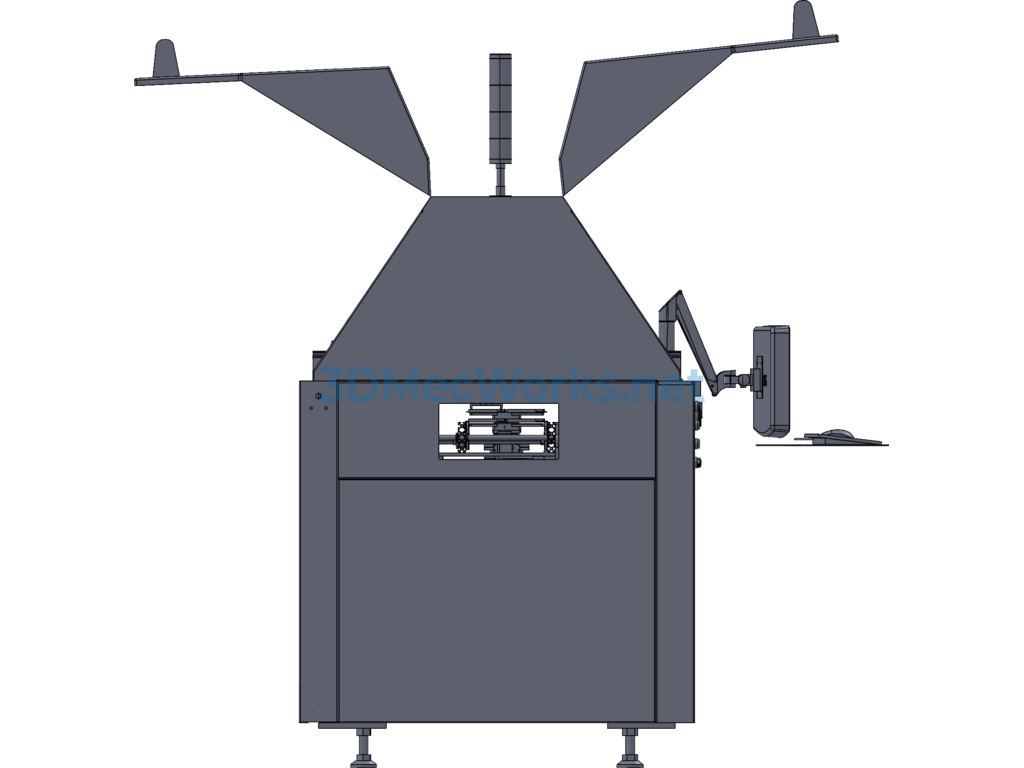

Non-standard Plug-in Machine Equipment

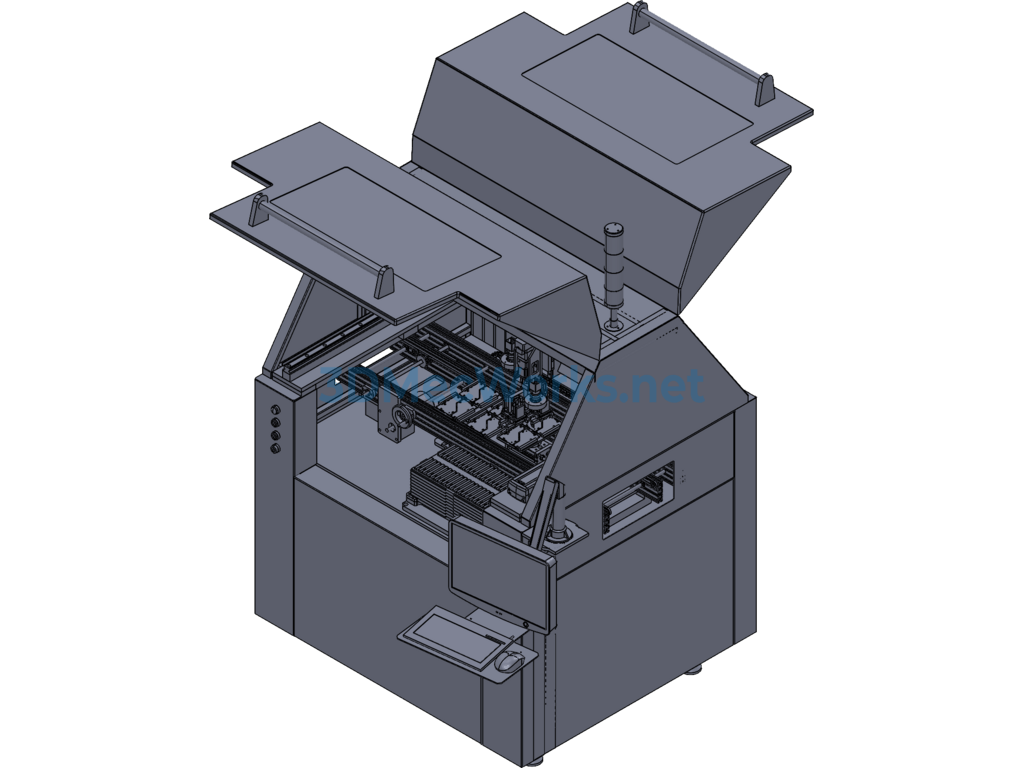

The automatic connector insertion machine design model includes a machine platform, wire supply unit, wire straightening unit, cutting unit, grooving unit, fixing unit, molds, cylinder power unit, and automatic feeding unit. It features low cost, easy maintenance, precise operation, and automatic feeding and unloading.

The characteristics include:

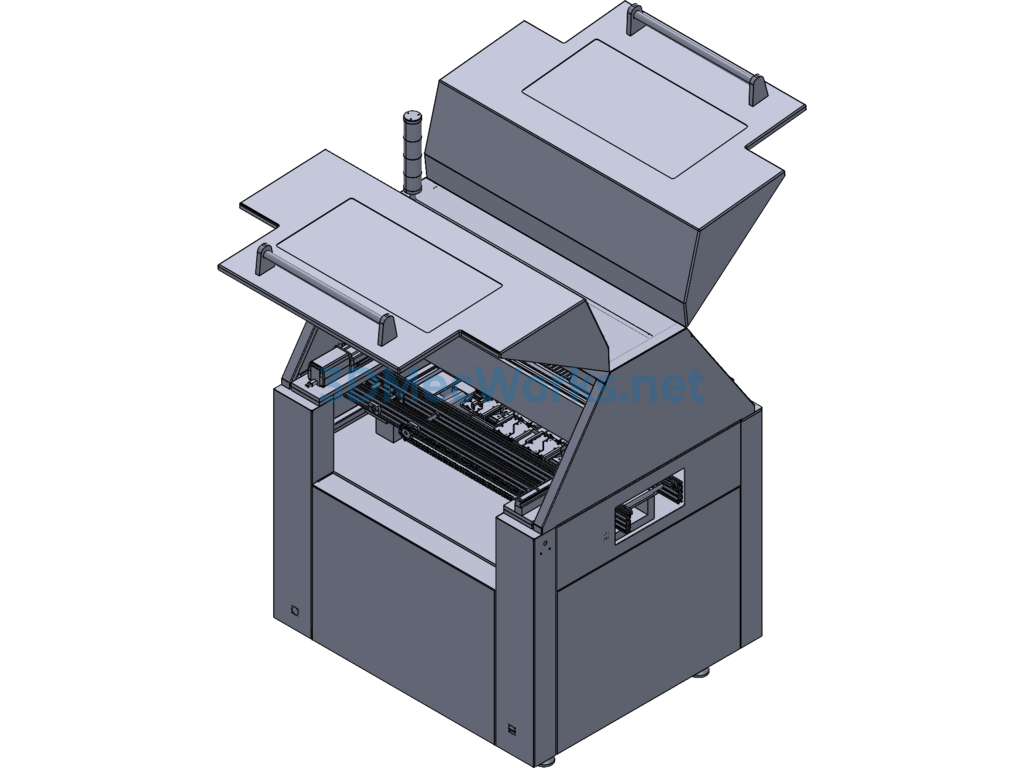

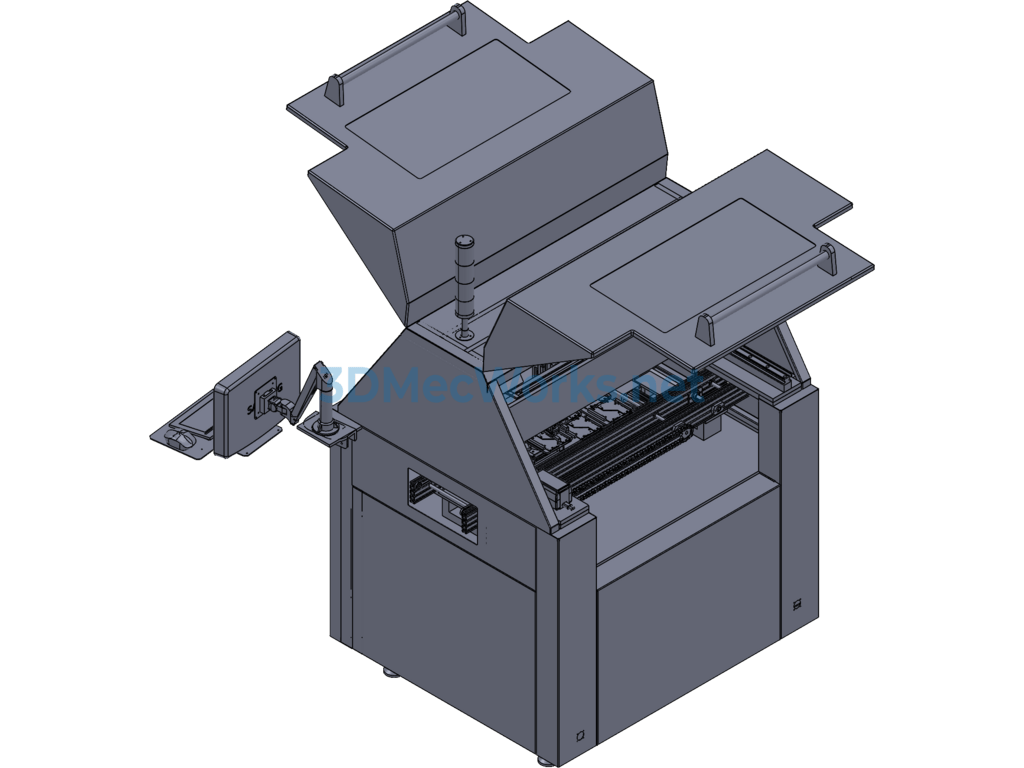

– A machine platform, comprising a fixed frame, a cylinder unit mounted on the fixed frame, and a sliding frame that moves with the piston rod of the cylinder unit;

– A wire supply unit, located at the top of the fixed frame and equipped with at least one metal wire spool;

– A wire straightening unit, positioned below the wire supply unit, used to straighten the bent metal wire from the spool into straight metal wire;

– A grooving unit, with a pair of clamping elements pivotally mounted on the sliding frame and located below the wire straightening unit, which consistently grip the straight metal wire;

– A mold with a guide slot that accommodates a workpiece, removably installed on the machine platform. When the cylinder unit is activated, the sliding frame and the grooving unit move downward with the piston rod of the cylinder unit, inserting the metal wire into the through-hole of the workpiece on the mold;

– A cutting unit, mounted on the fixed frame and situated between the grooving unit and the mold, which can be driven to cut the metal wire;

– A cylinder power unit, installed on the fixed frame to drive the cylinder unit, enabling the cylinder unit to guide the sliding frame to insert the metal wire into the workpiece’s through-hole, and cut the metal wire via the cutting unit.

This setup does not include parameters but can be edited. It can be opened with SOLIDWORKS 2010 and serves as excellent learning material.

Specification: Automatic Connector Insertion Machine, Non-Standard Equipment

|

User Reviews

Be the first to review “Automatic Connector Insertion Machine, Non-Standard Equipment”

You must be logged in to post a review.

There are no reviews yet.