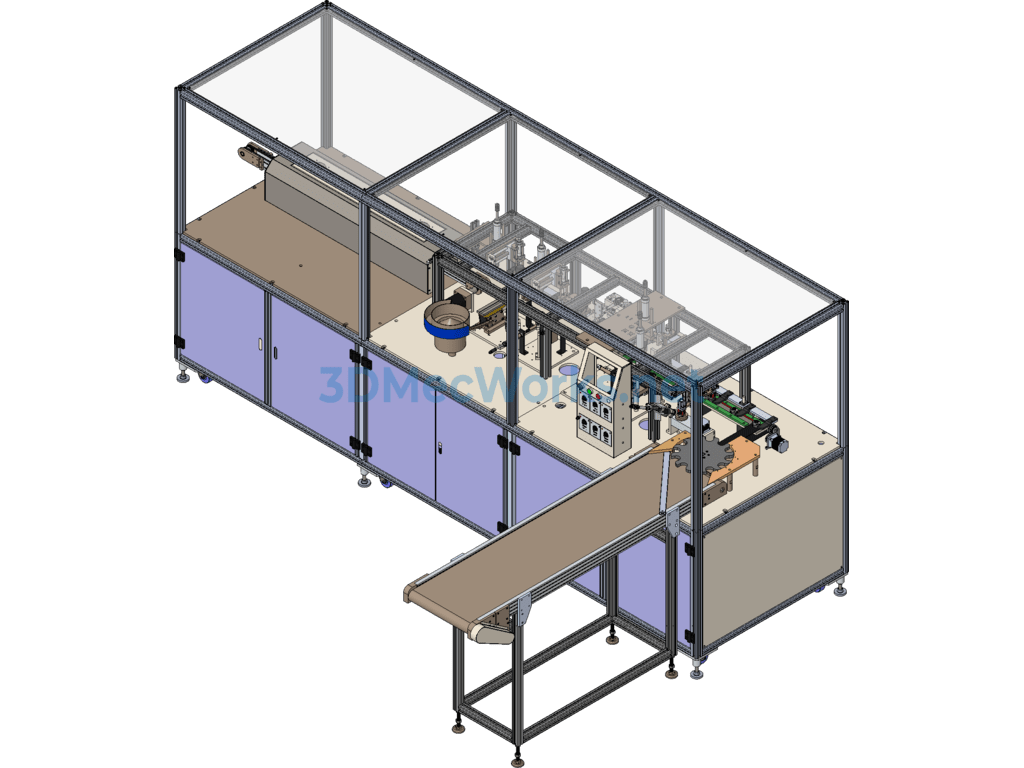

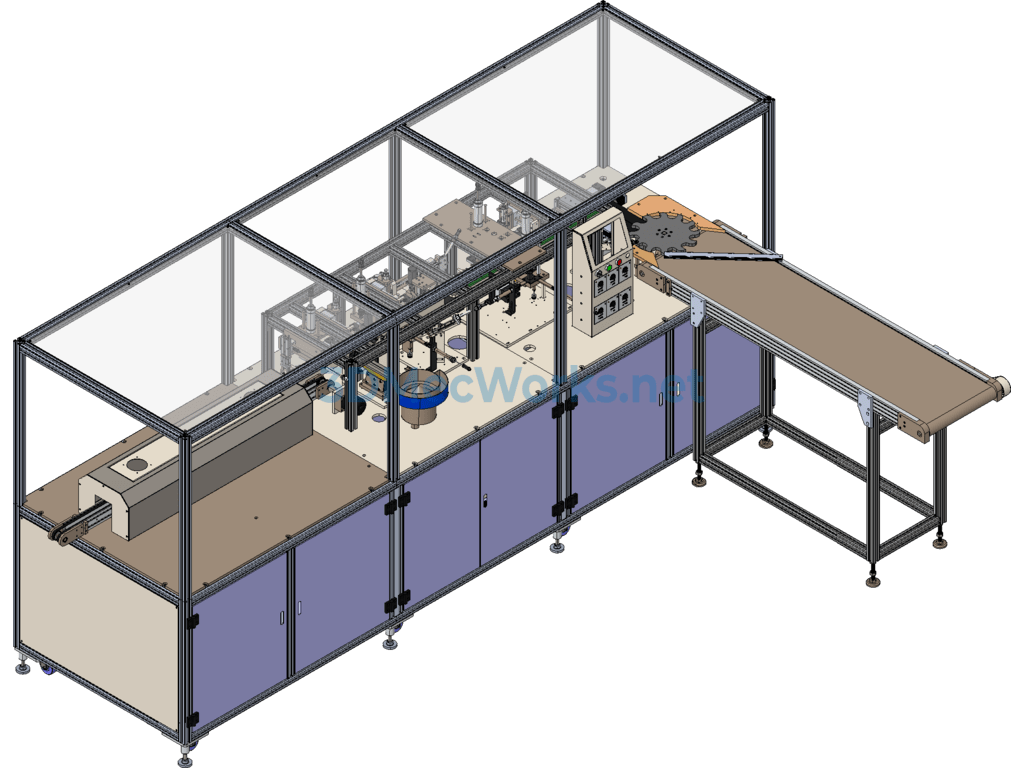

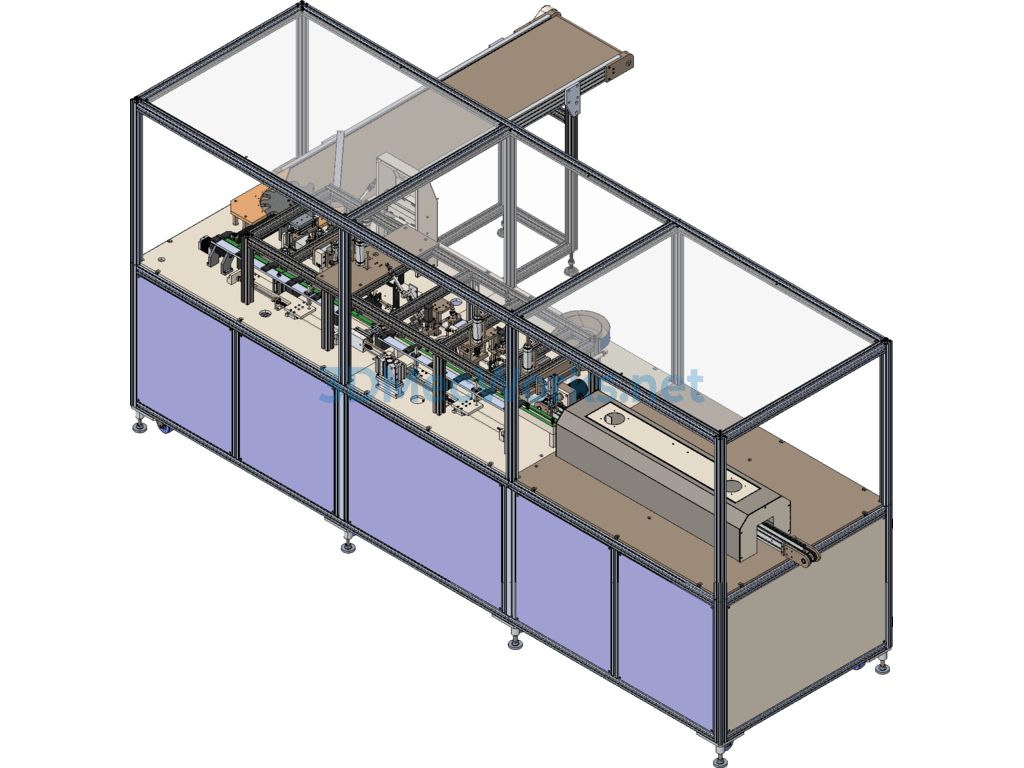

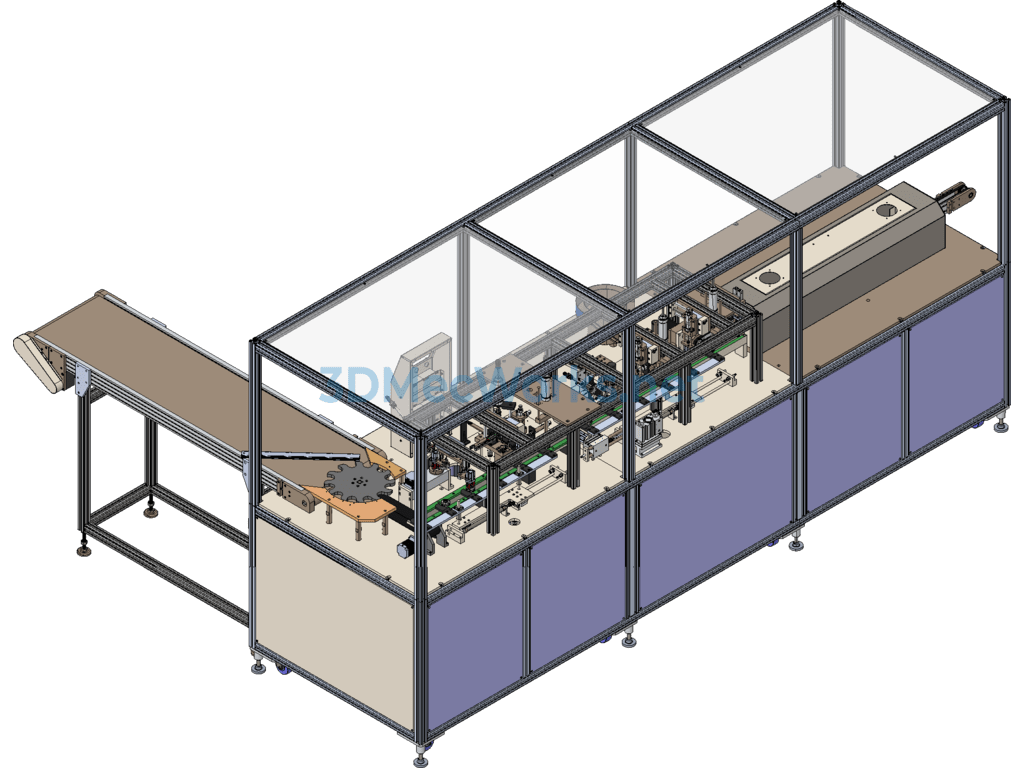

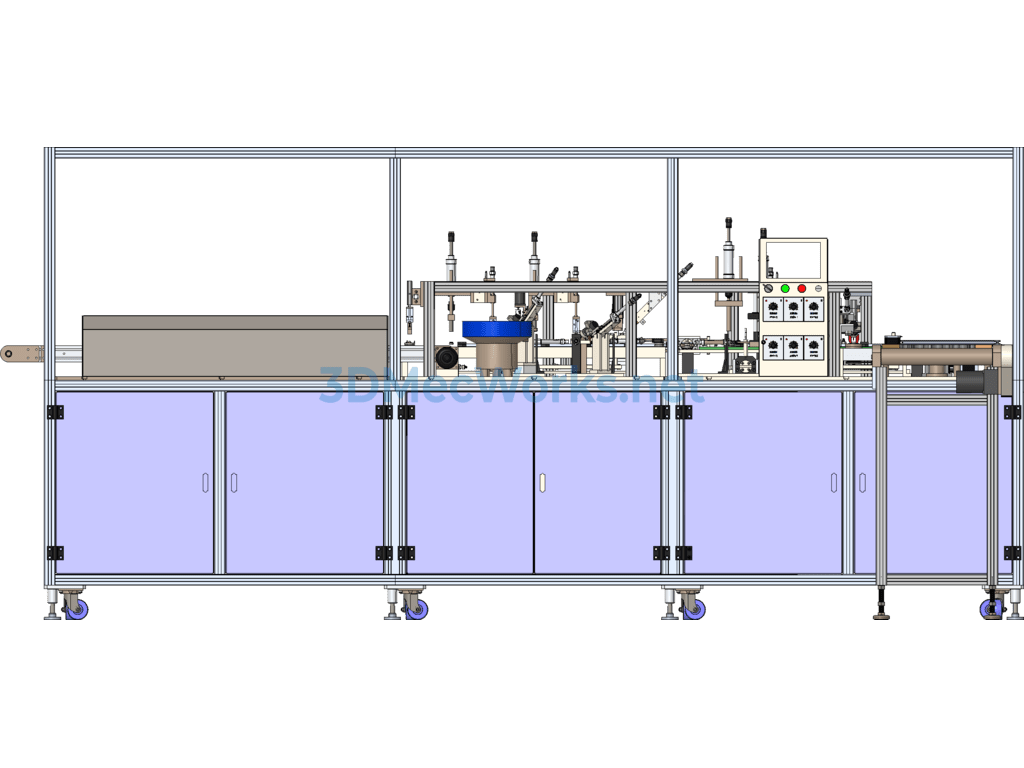

A detailed encoder automated assembly equipment design, designed with SolidWorks2014, includes detailed 3D models and keyshot rendering files, containing features that can be edited and modified. It has a complex mechanism with a decompressed size of nearly 1000 MB, consisting of over 472 components in total.

1. Component Orientation, Conveyance, and Escapement System: This system automatically arranges disordered components into machine-processable spatial orientations for smooth conveyance to subsequent escapement mechanisms, preparing for subsequent robotic arm gripping.

2. Gripping-Shift-Placement Mechanism: This mechanism grips or vacuum-holds the components precisely positioned by the escapement system and then moves them to another position (usually the assembly working position).

3. Assembly Working Mechanism: This refers to the mechanism that performs the main assembly actions such as pressing, clamping, fastening, snapping, bonding, welding, riveting, bonding, and welding with the previous component.

4. Inspection Mechanism: This mechanism is used to inspect the completed parts from the previous assembly step or the product of the last working step, such as missing component detection, dimension inspection, defect detection, function detection, and cleaning detection.

5. Component Extraction Mechanism: This mechanism sorts and removes qualified and non-qualified assembled components from the machine.

Specification: Encoder Automated Assembly Equipment Detailed Design + Keyshot Rendering

|

User Reviews

Be the first to review “Encoder Automated Assembly Equipment Detailed Design + Keyshot Rendering”

You must be logged in to post a review.

There are no reviews yet.