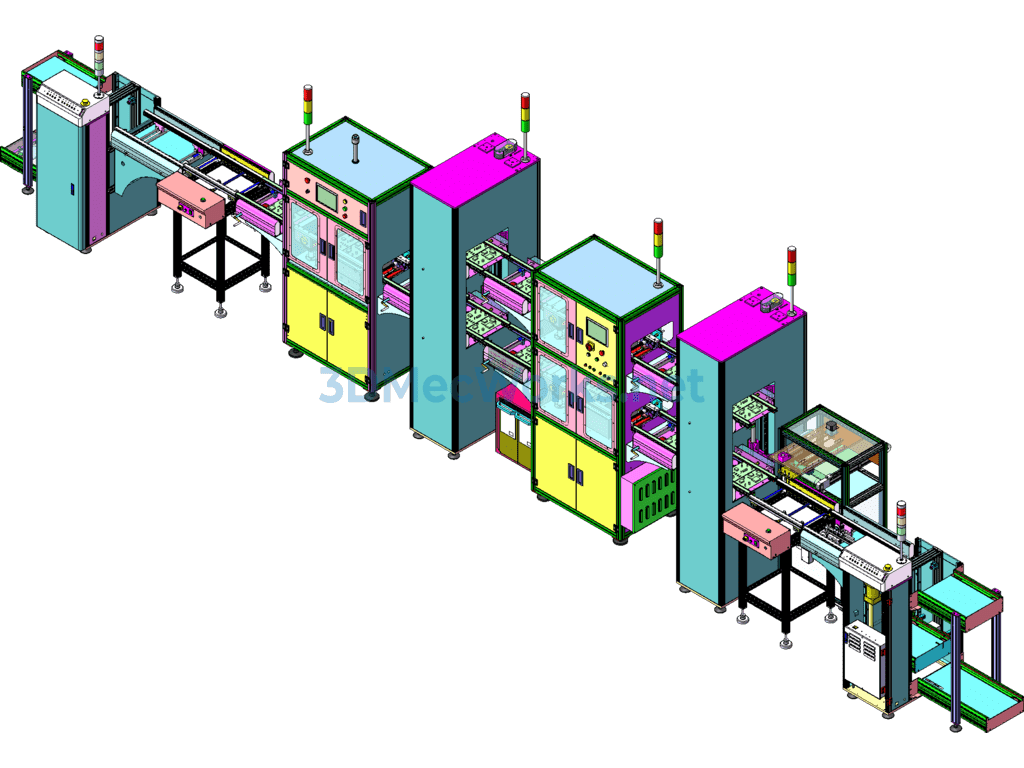

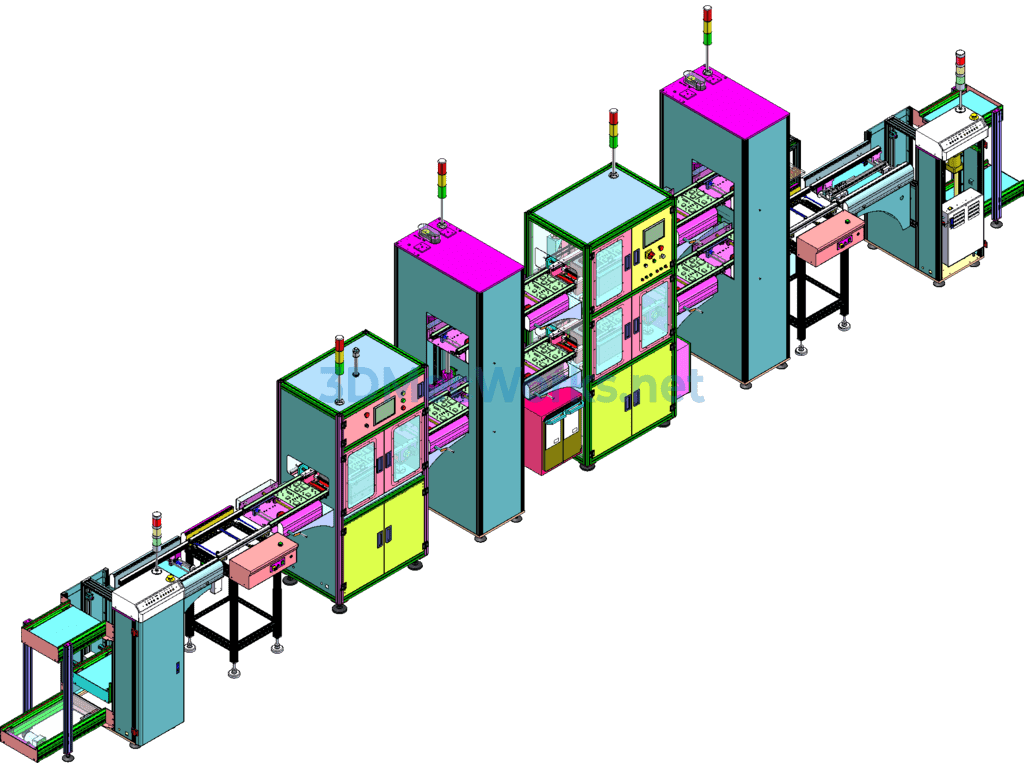

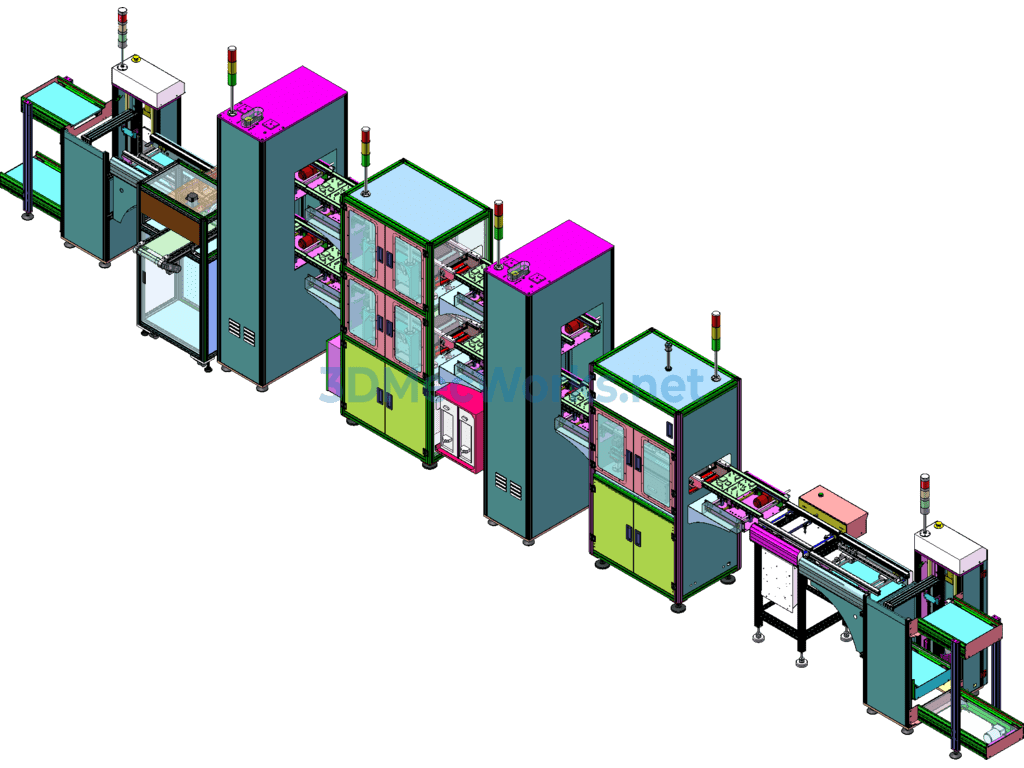

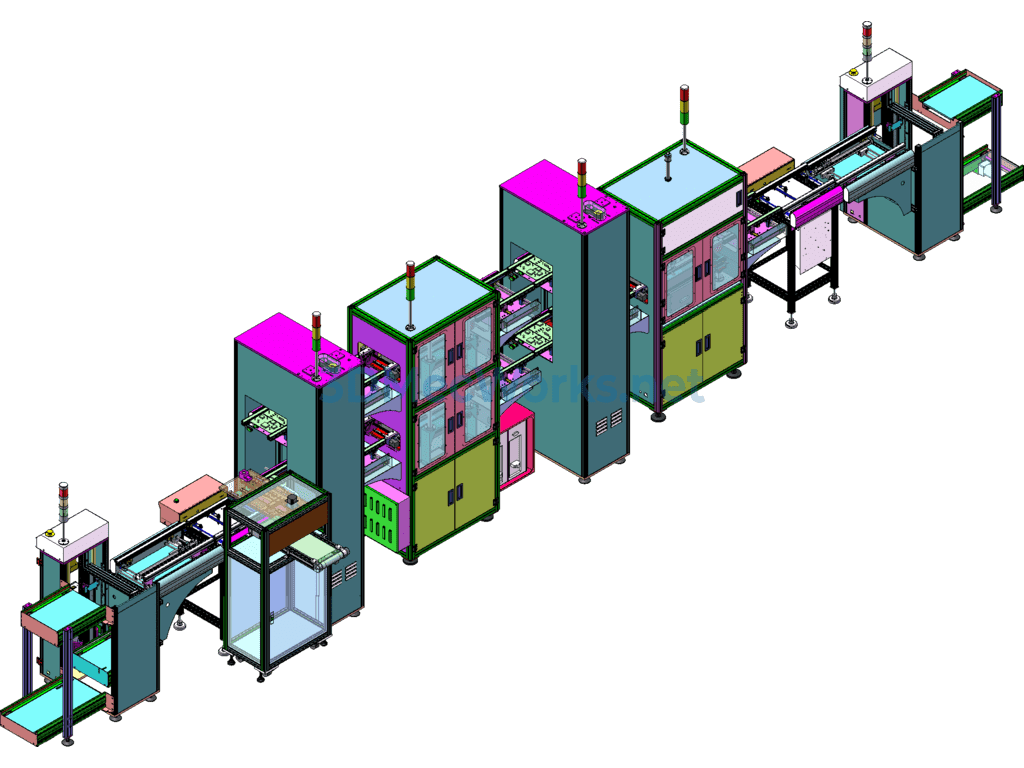

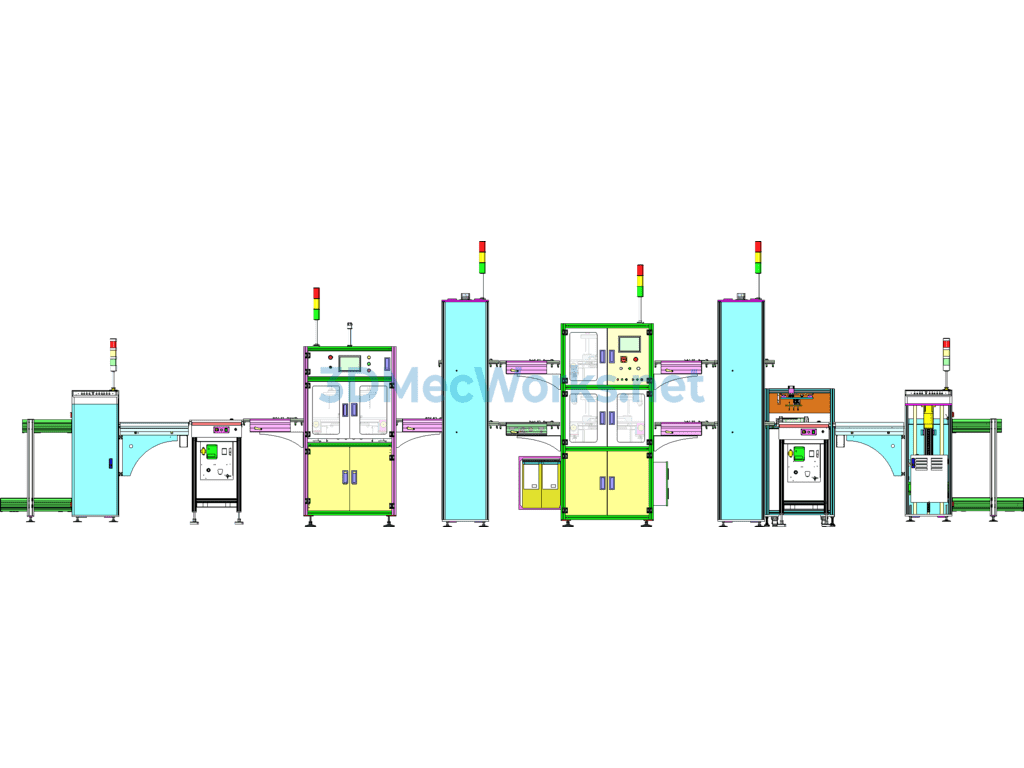

The PCB circuit board FCT functional test automation line is an automated unmanned production line testing and inspection machine in an electronics factory. This unmanned automatic testing line can be used universally for all PCB boards and various functional tests in an electronics factory. The equipment is approximately 10 meters long, comprising over 50 ordinary motors, more than 30 cylinders, over 10 stepper motors, and dozens of sets of screw rod slide rails, making the line body structure relatively complex. Other functions include ICT and FCT defect testing of PCB circuits, short circuit faults of circuit boards, and some high-voltage tests of capacitors and inductors. The line body consists of four sections: from the PCB loading machine to the transfer table board, to the line body tester, to the unloading transfer table, and finally to the unloading machine. The main introduction is the tester, as the tester is double-layered with only the bottom layer operational. To use the upper layer, the front and rear transfer tables need to be replaced with elevators to achieve simultaneous upper and lower operations. In addition, the ICT equipment’s conveyor belt is driven by a cylinder, making the entire belt line and PCB descend to the bottom test pin board, allowing all the solder points of the PCB to touch the probes for testing. Meanwhile, the cylinder above the PCB board also descends, pressing the board into position for testing. After a few seconds, the test is completed, and the cylinder drives the conveyor belt back to its original position, indicating that the test is complete and the PCB board starts flowing into the next station for FCT testing for high voltage resistance and other parameters. The elevator transfers the circuit board to the FCT tester, which runs tests on both the upper and lower layers simultaneously with considerable efficiency. The total height of the automatic elevators at both ends is more than 2 meters, mainly for the cyclical transportation and elevation of PCB boards at both ends of the tester. After passing the test, products flow out of the line into the receiving machine. The entire set of equipment is structurally stable and cost-effective. After downloading the complete set of schematics of this assembly line, you can directly view and edit content modifications, including the ICT automatic tester BOM.xls. Anyone interested is welcome to download and learn from it.

Specification: Pcb Circuit Board Ict/fct Function Test Automation Line

|

User Reviews

Be the first to review “Pcb Circuit Board Ict/fct Function Test Automation Line”

You must be logged in to post a review.

There are no reviews yet.