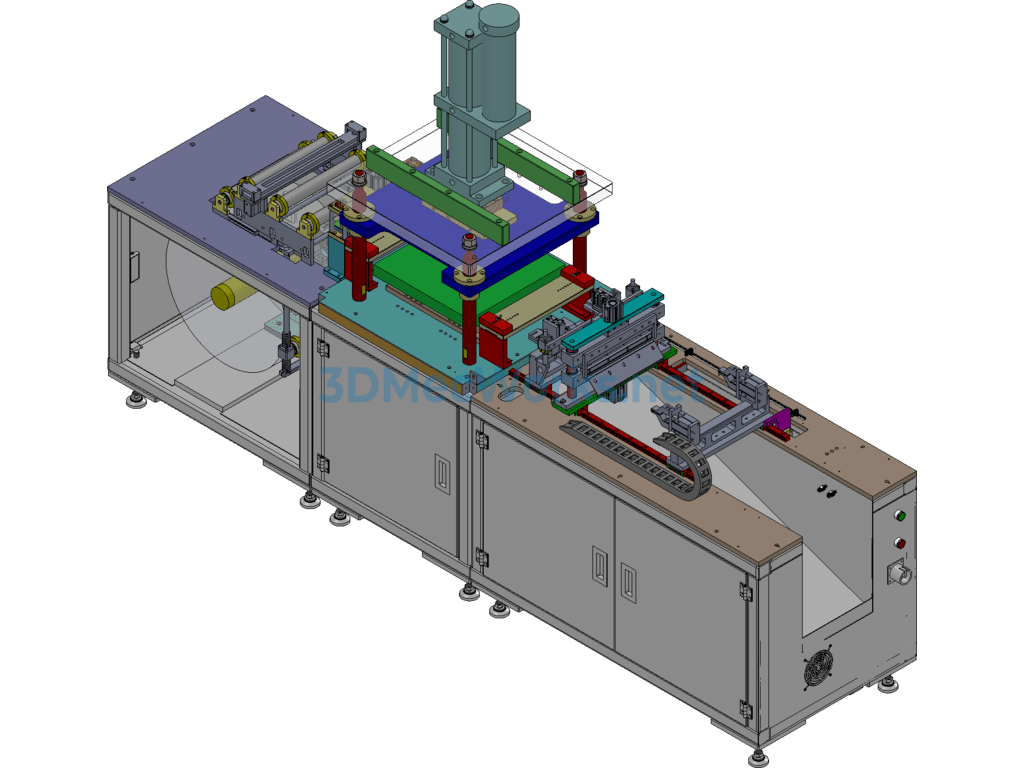

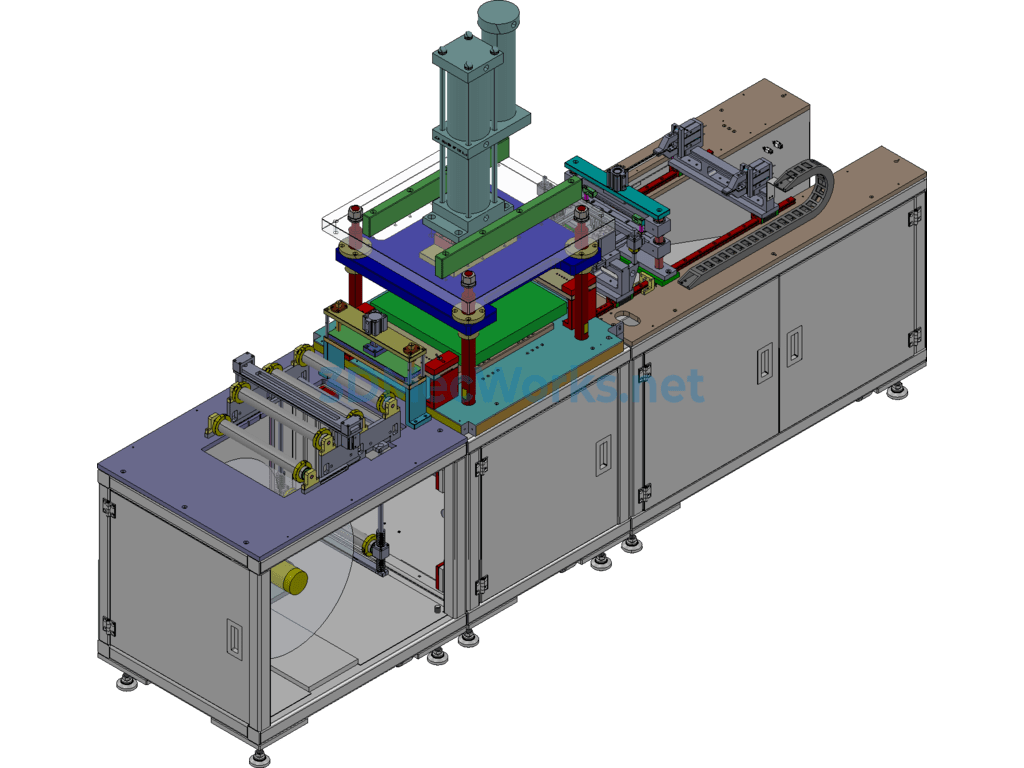

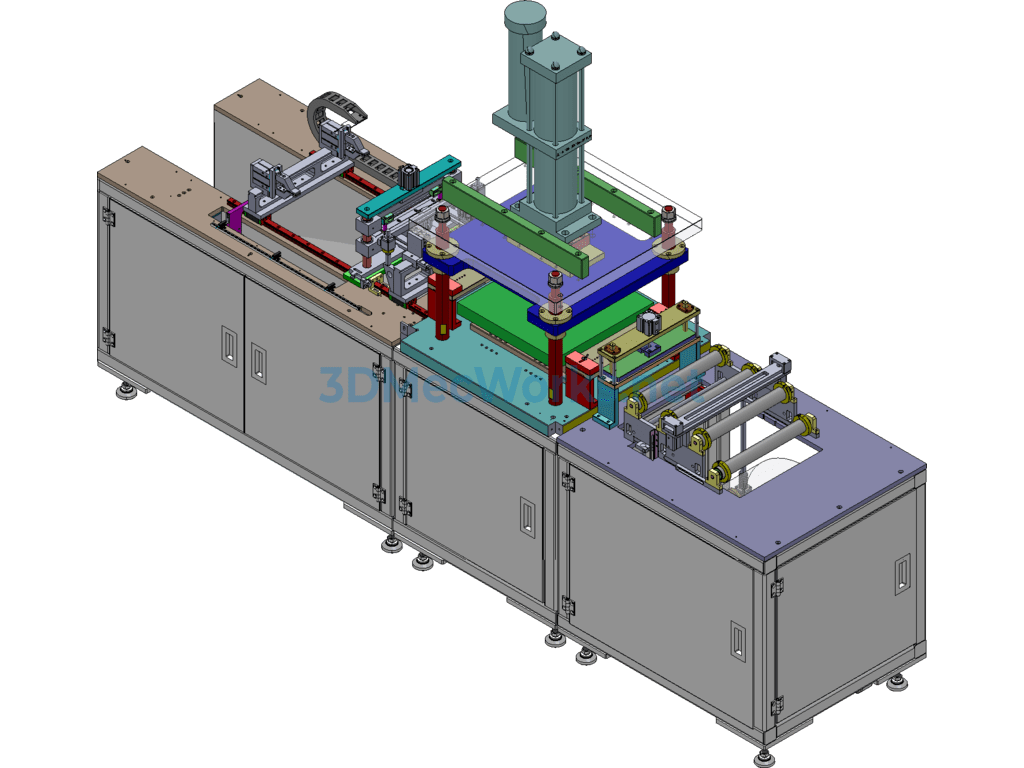

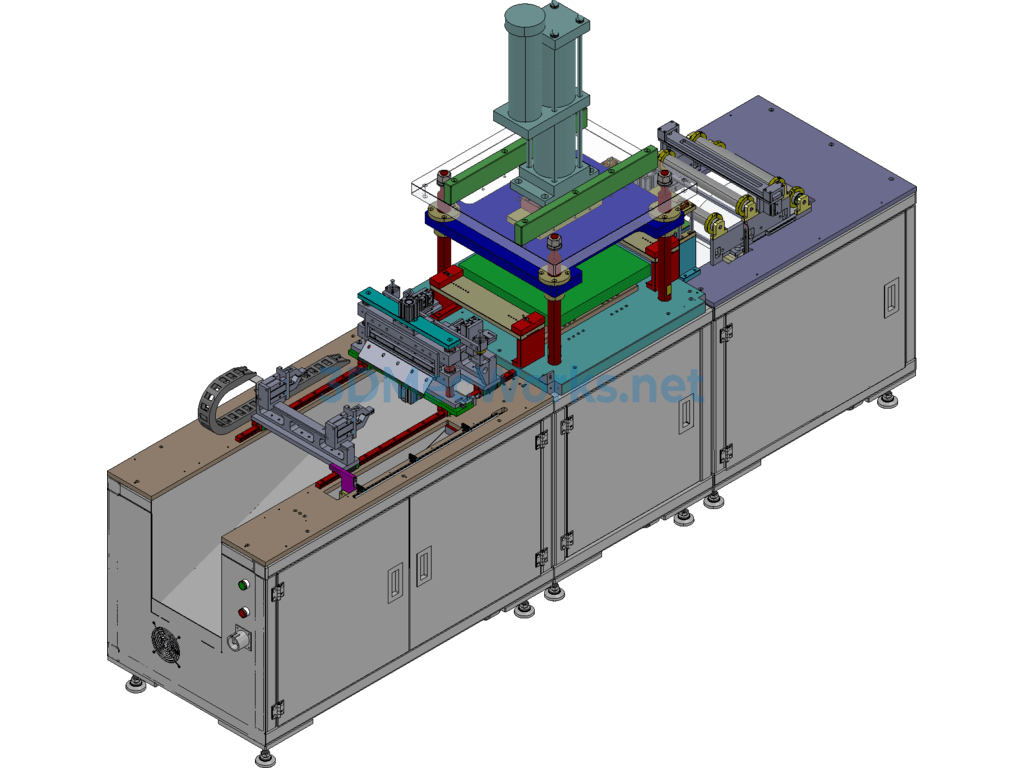

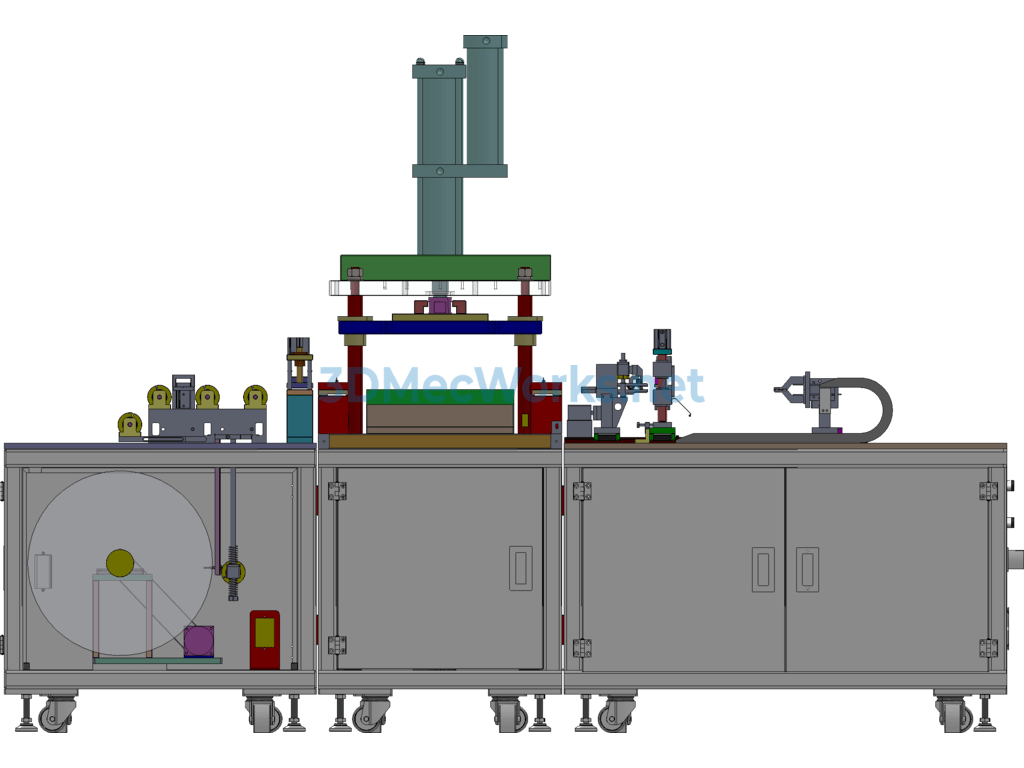

A set of fully automatic film punching machines, die-cutting membrane machines, and battery aluminum-plastic film forming machine equipment are mainly used for the forming and length-fixed cutting of aluminum-plastic films for soft-pack liquid lithium-ion batteries. The process includes: automatic feeding → tension control → servo stamping forming → servo automatic pulling → length-fixed cutting → manual collection. The equipment process flow is as follows: 1. Manually load the material roll (aluminum-plastic film) onto the unwinding mechanism. 2. The motor controls the air-expanding shaft for automatic feeding. 3. The unwinding motor cooperates with the rear pulling servo to automatically adjust the tension. 4. The servo control pulls out the aluminum-plastic film to a fixed length. 5. The feeding tension mechanism works together to ensure smooth feeding of the aluminum-plastic film. 6. The rapid booster cylinder and servo motor cooperate to complete constant force stamping forming. 7. The length-fixed aluminum-plastic film is cut. 8. Manual collection, Automatic film punching machine battery aluminum-plastic film forming machine main technical parameters: 1. Equipment efficiency: ≥10ppm (specifically related to pulling length and parameter settings) 2. Aluminum-plastic film forming depth accuracy: ±0.1mm 3. Product qualification rate: ≥98% 4. Equipment utilization rate: 95% 5. Pulling method: Servo pulling post-cutting 6. Forming method: Servo motor constant force forming 7. Edge cutting accuracy: ±0.2mm 8. Effective width of cutting knife: 350mm 9. Maximum size of mold appearance: 400 (L) X 400 (W) 10. Maximum output of booster cylinder: 10T

Specification: Fully Automatic Film Punching Machine, Liquid Lithium-Ion Battery Aluminum-Plastic Film Forming and Cutting Machine

|

User Reviews

Be the first to review “Fully Automatic Film Punching Machine, Liquid Lithium-Ion Battery Aluminum-Plastic Film Forming and Cutting Machine”

You must be logged in to post a review.

There are no reviews yet.