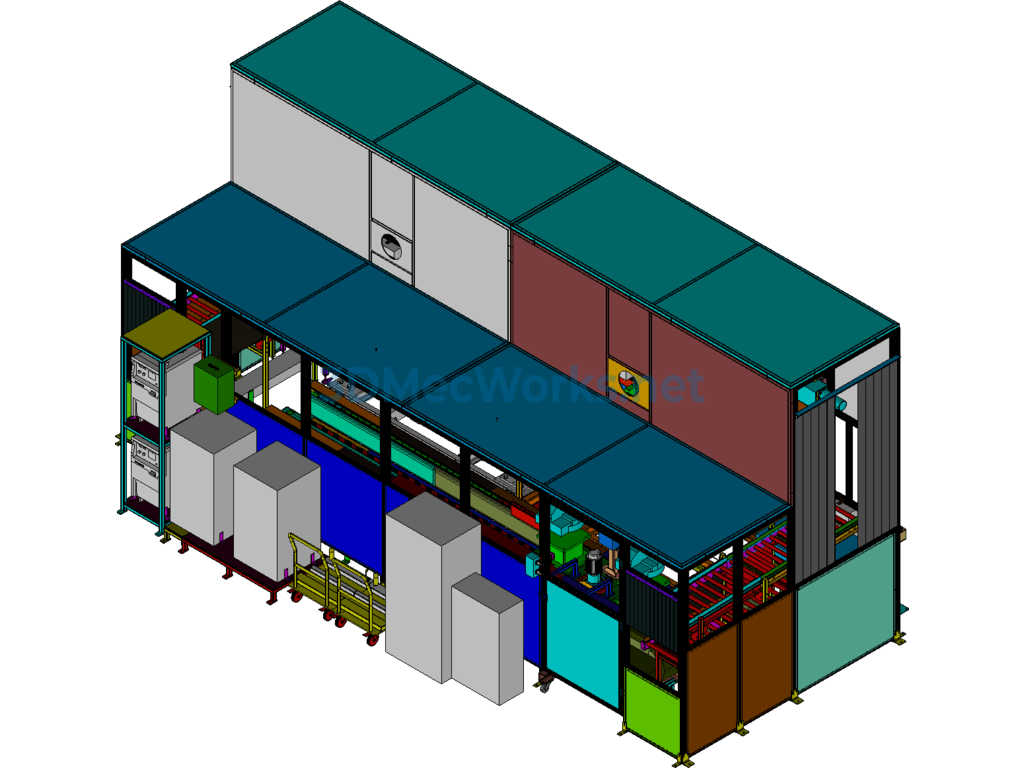

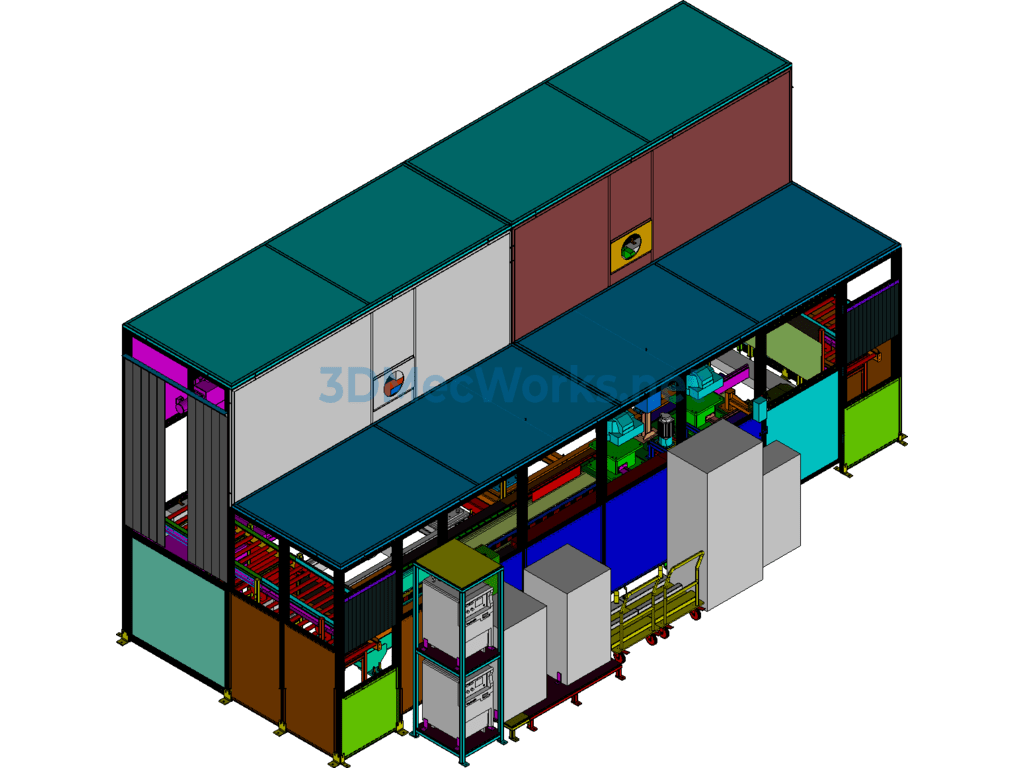

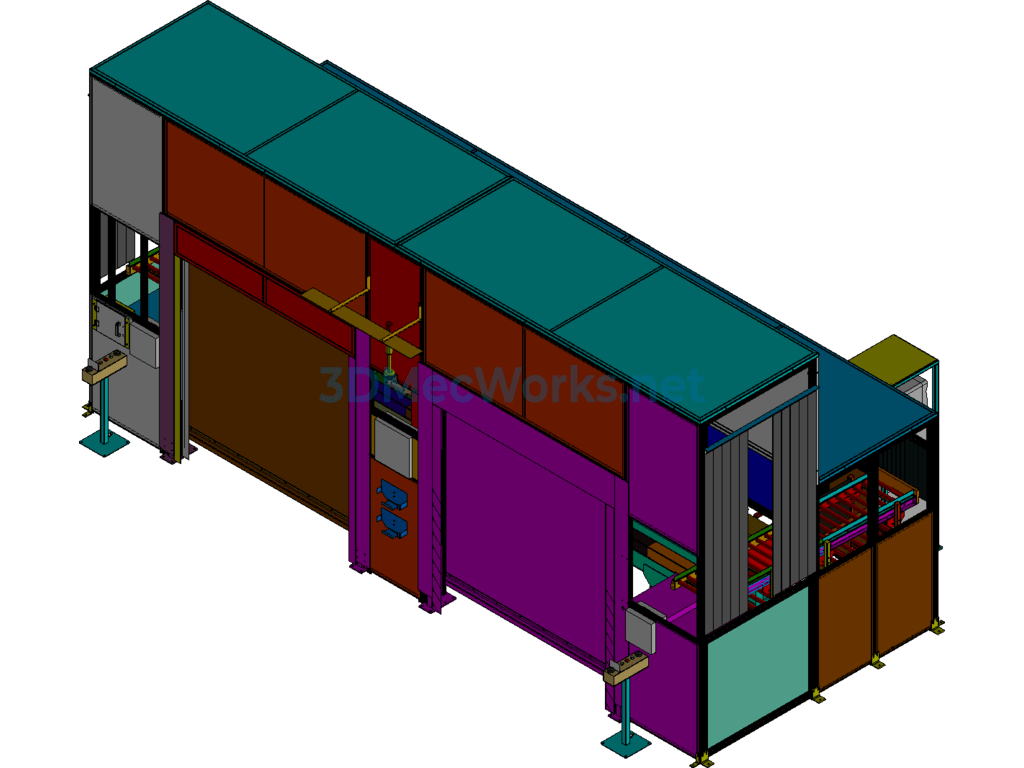

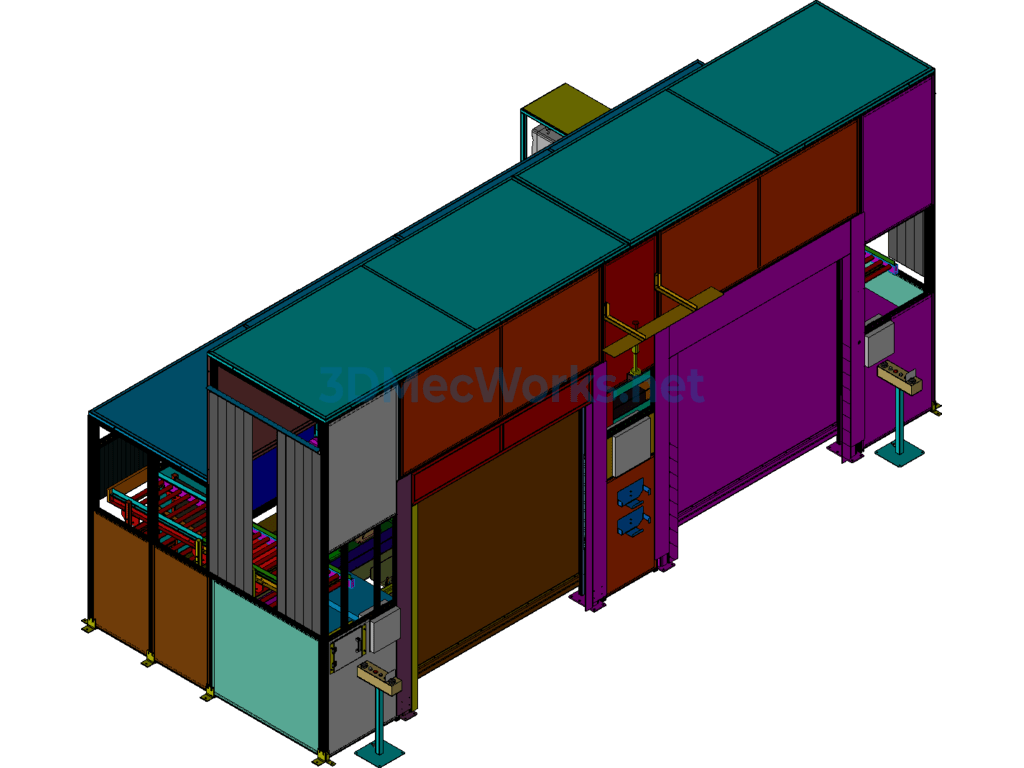

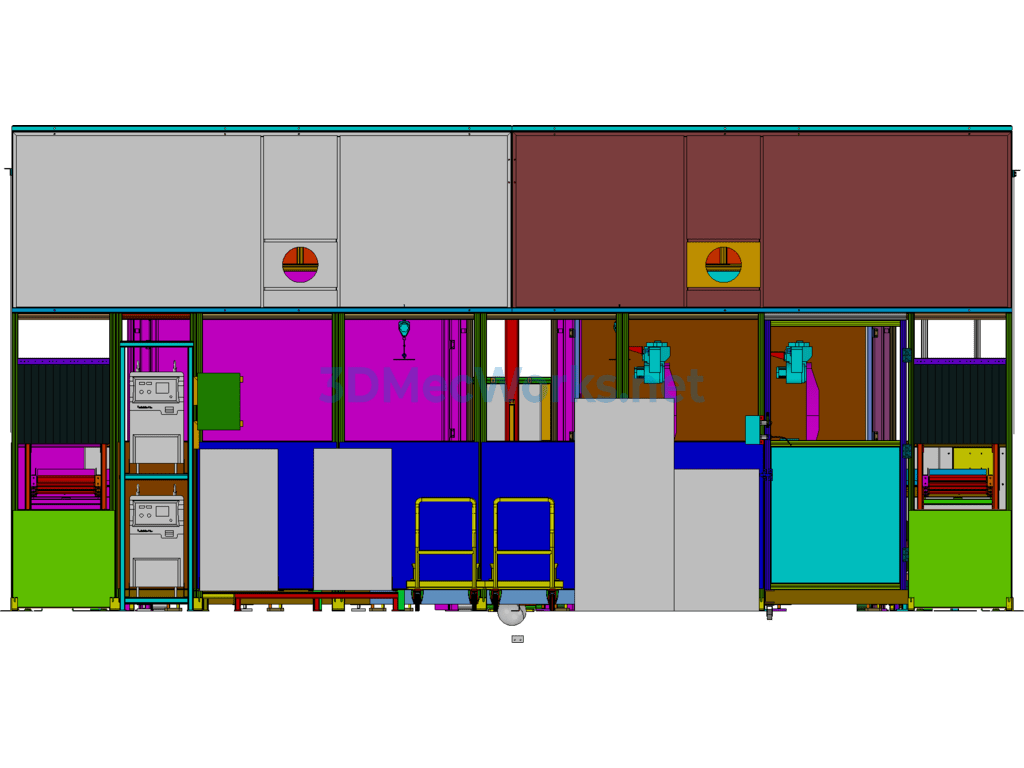

Dual-robot dual-fixture arc welding workstation assembly design includes CATIA-modeled parts and assembly drawings, as well as STP files and BIP rendering image files. The dual-robot dual-fixture arc welding workstation assembly design (stp+CATIA+keyshot, size: 1.7 GB) operates with two workstations in an alternating manner, ensuring that the robot welding time is synchronized with the loading and unloading time of workpieces. This method can save the rotation time of the positioner. The dual-fixture sliding rail type welding robot system takes advantage of two sets of sliding rails to alternately supply materials to the welding robot. The fixture is repositioned by the positioner to enable welding by the robot gun in different positions.

Specification: Dual Robot Dual Fixture Arc Welding Workstation Assembly Design

|

User Reviews

Be the first to review “Dual Robot Dual Fixture Arc Welding Workstation Assembly Design”

You must be logged in to post a review.

There are no reviews yet.