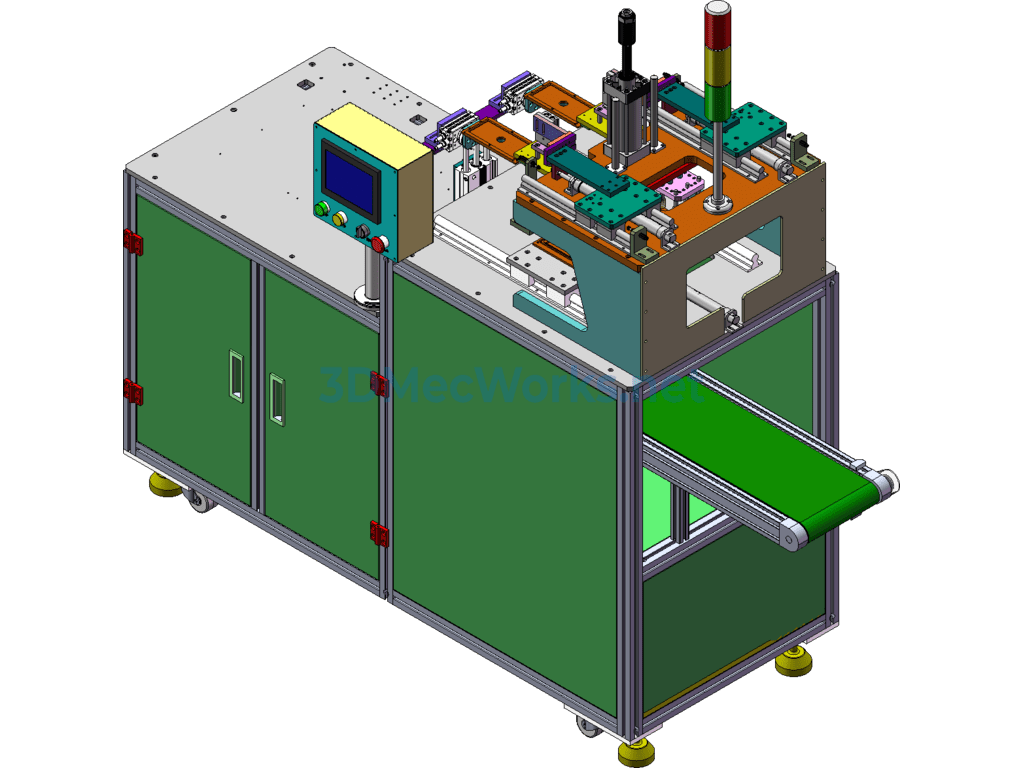

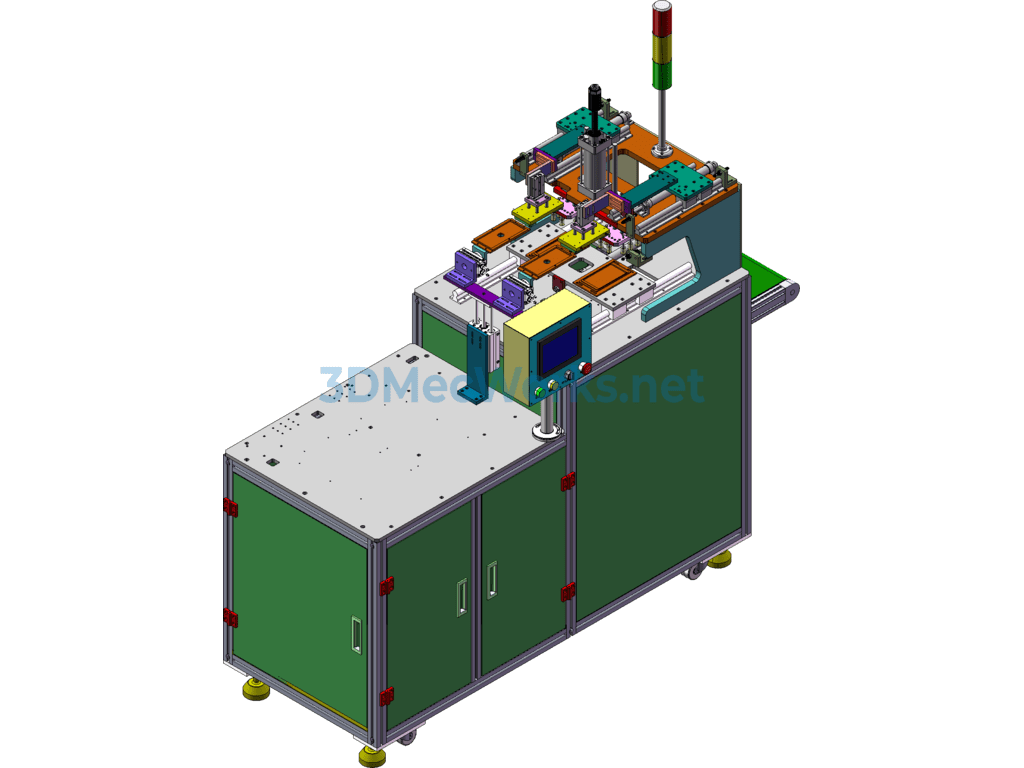

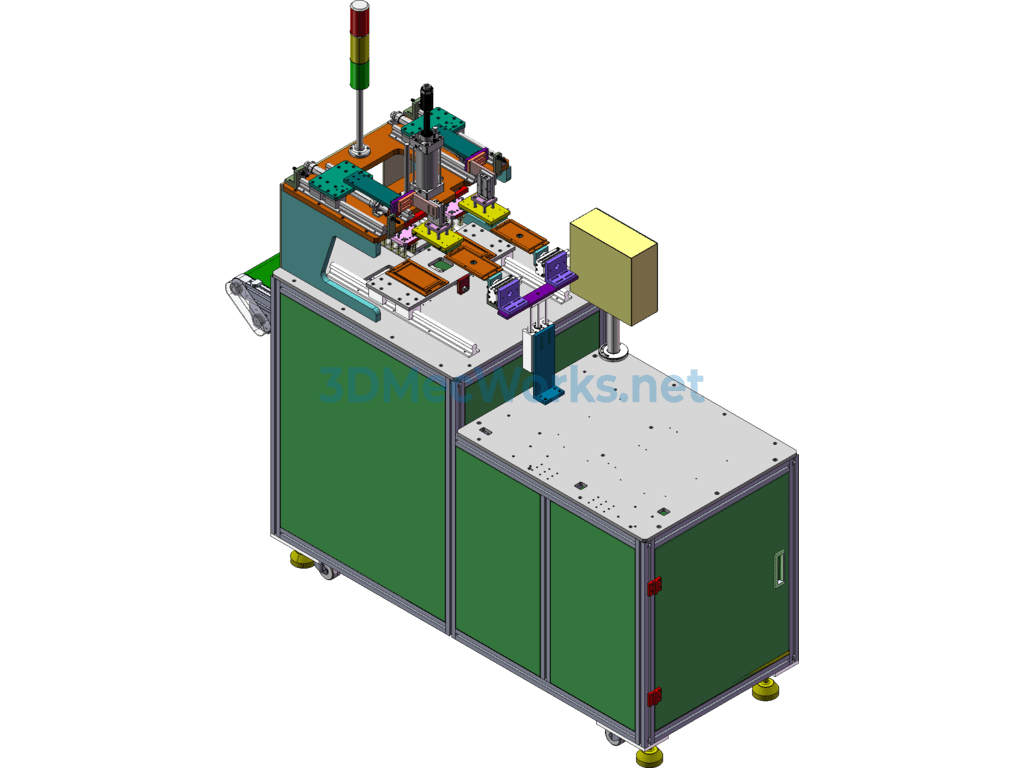

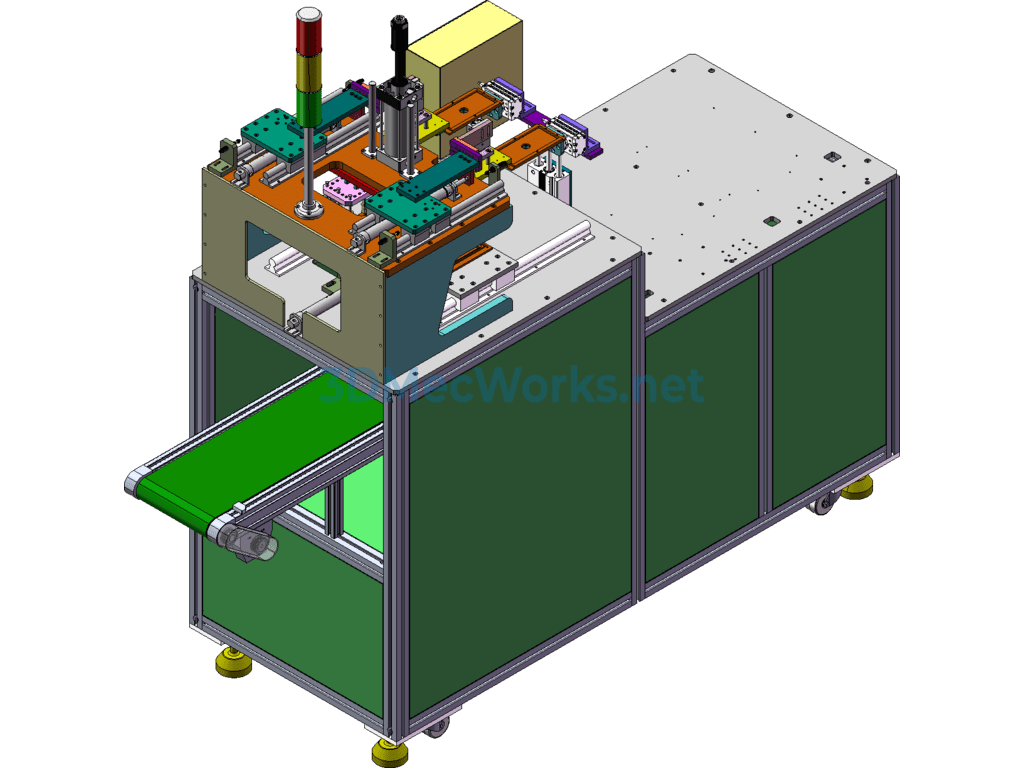

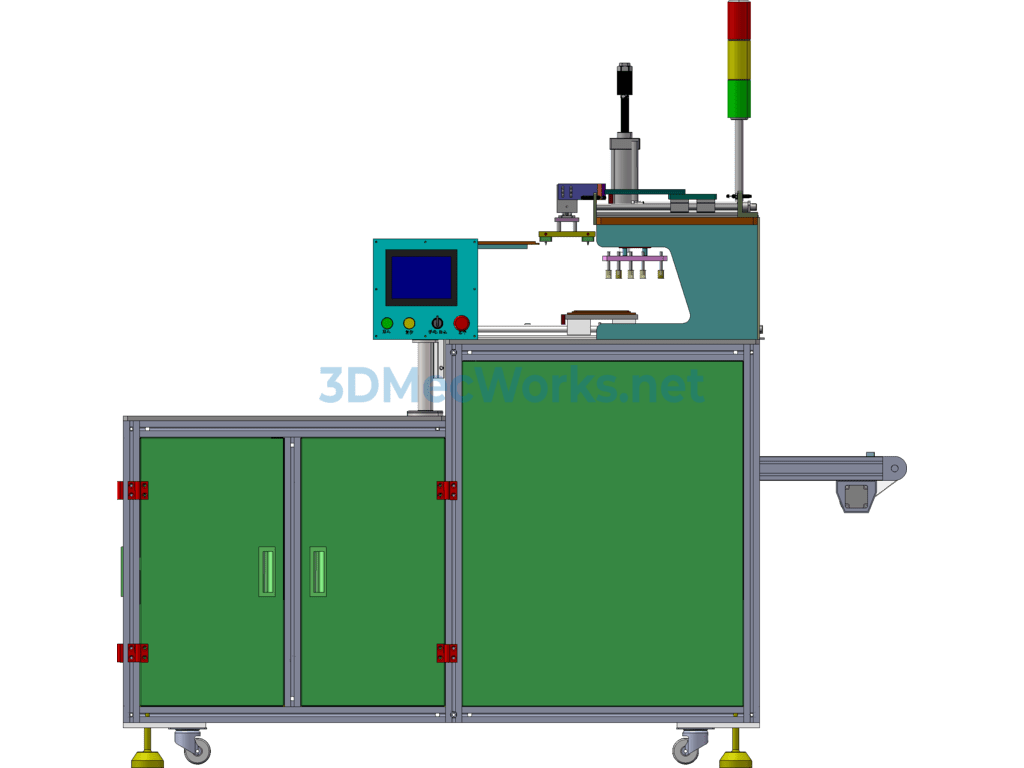

Fully Automatic Robotic Arm Loading Hot Press Forming Equipment A fully automatic robotic arm loading hot press forming equipment, first, let’s introduce the major modules of the equipment. This equipment is composed of six major modules: 1. Loading Bin Module, 2. Lifting Machine Elevation Module, 3. Material Handling Robotic Arm Module, 4. Rotating Hot Press Module, 5. Forming and Discharging Module, 6. Discharge Conveyor Belt Module. Below is the introduction of the functional action principles of the equipment: The main function of the loading bin is for the switching and storage of products. This material frame can stack 200 products. The bin automatically switches material suction when empty with two groups. In the bin, products are lifted by the lifting machine module. The robotic arm picks one sheet and the lifting machine ejects another. After the robotic arm picks up the product, it is placed for secondary positioning in a fixture, and then placed into the hot press fixture. The hot press structure performs a hot press for 3 seconds and then retracts. After hot pressing, the product is rotated by the rotary cylinder and placed into the bottom forming fixture. The product slides into the forming structure for shaping, with a forming time of 2 minutes. Once forming is complete, the product is extracted and the slide table slides out. The product is placed onto the discharge conveyor belt for unloading. The above is the entire structural principle and functional description of this mobile phone steel sheet loading hot press forming equipment. The equipment structure is mature and stable.

Specification: Non-Standard Fully Automatic Hot Press Shaping Machine With Robotic Arm Loading

|

User Reviews

Be the first to review “Non-Standard Fully Automatic Hot Press Shaping Machine With Robotic Arm Loading”

You must be logged in to post a review.

There are no reviews yet.