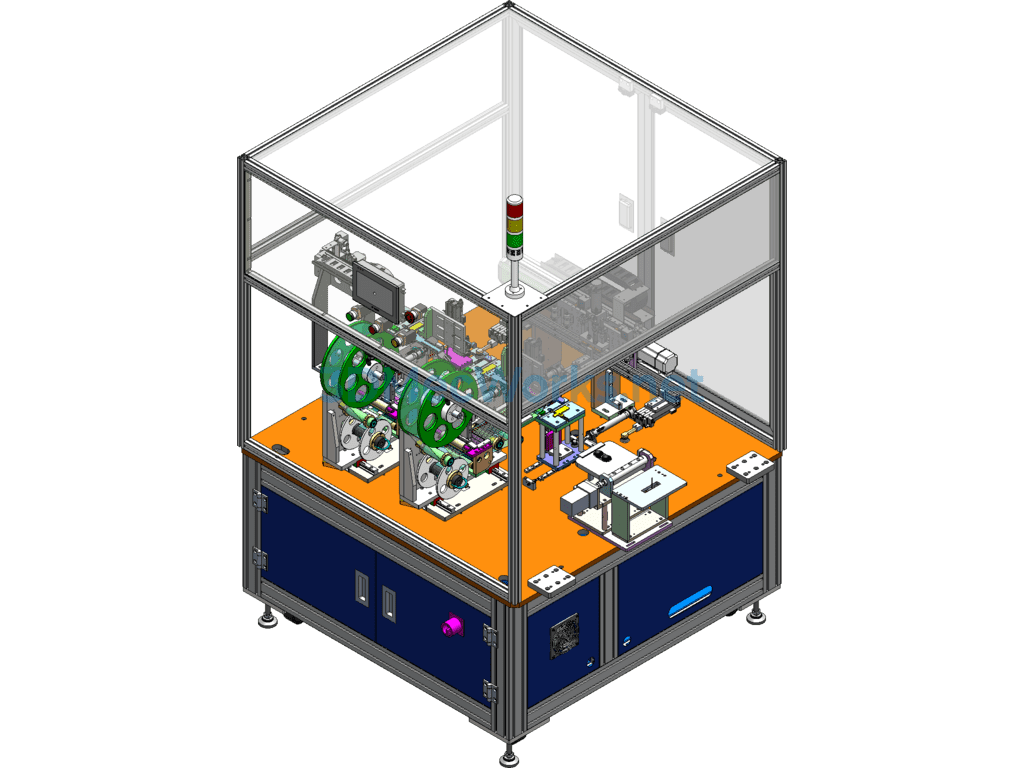

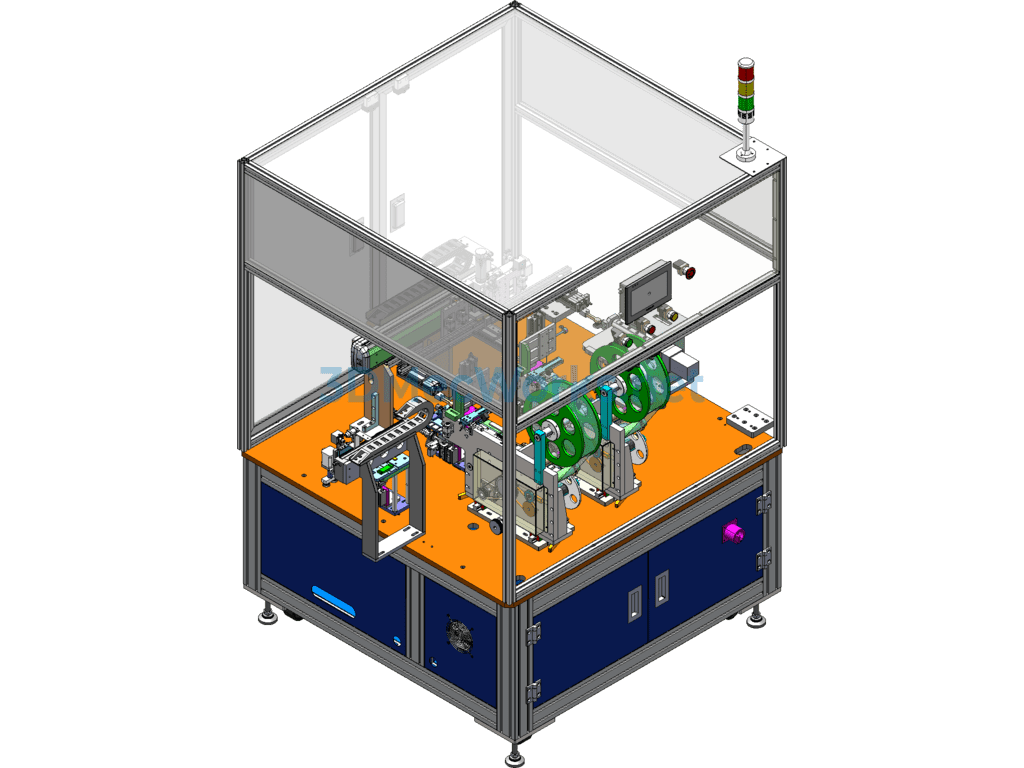

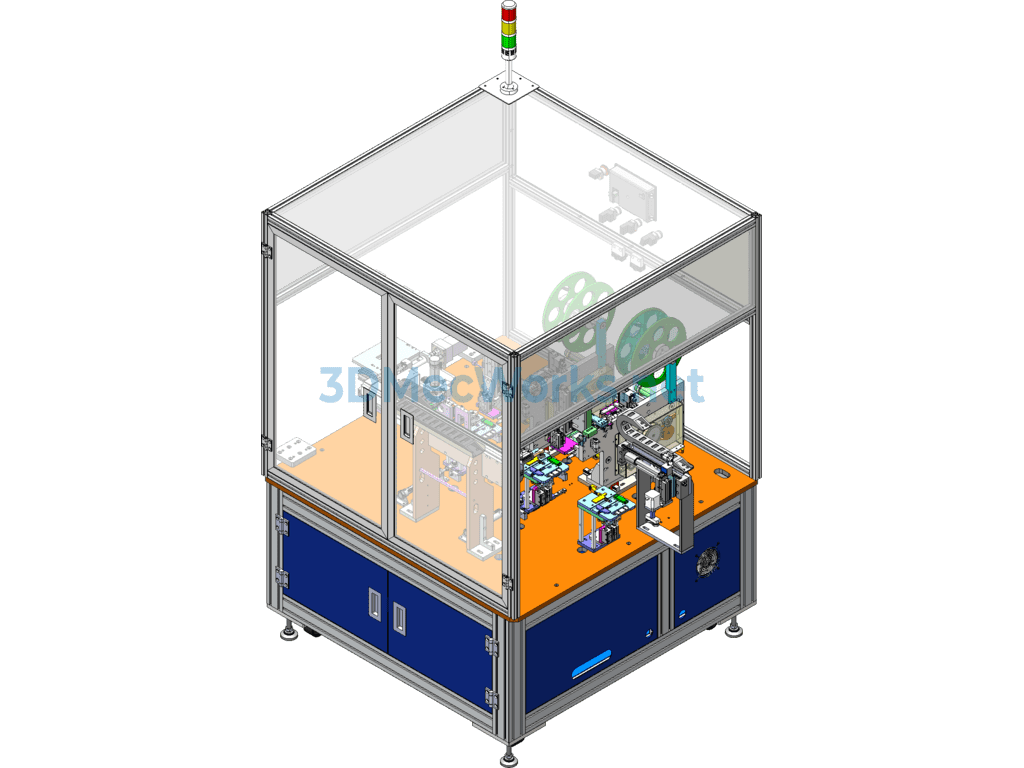

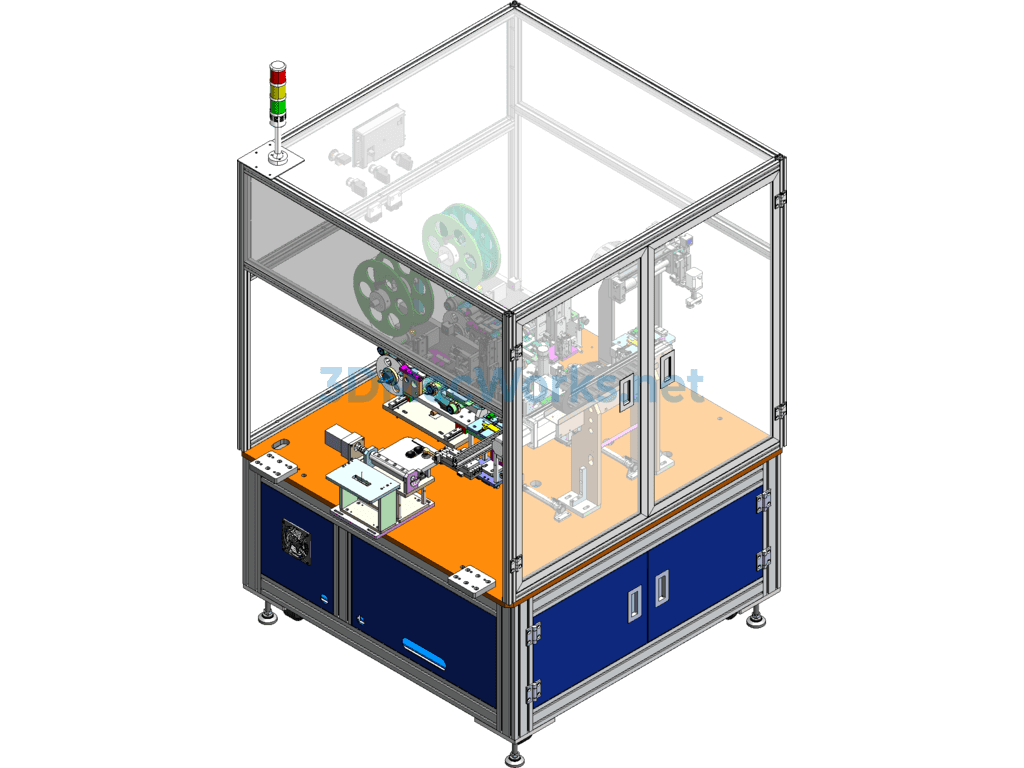

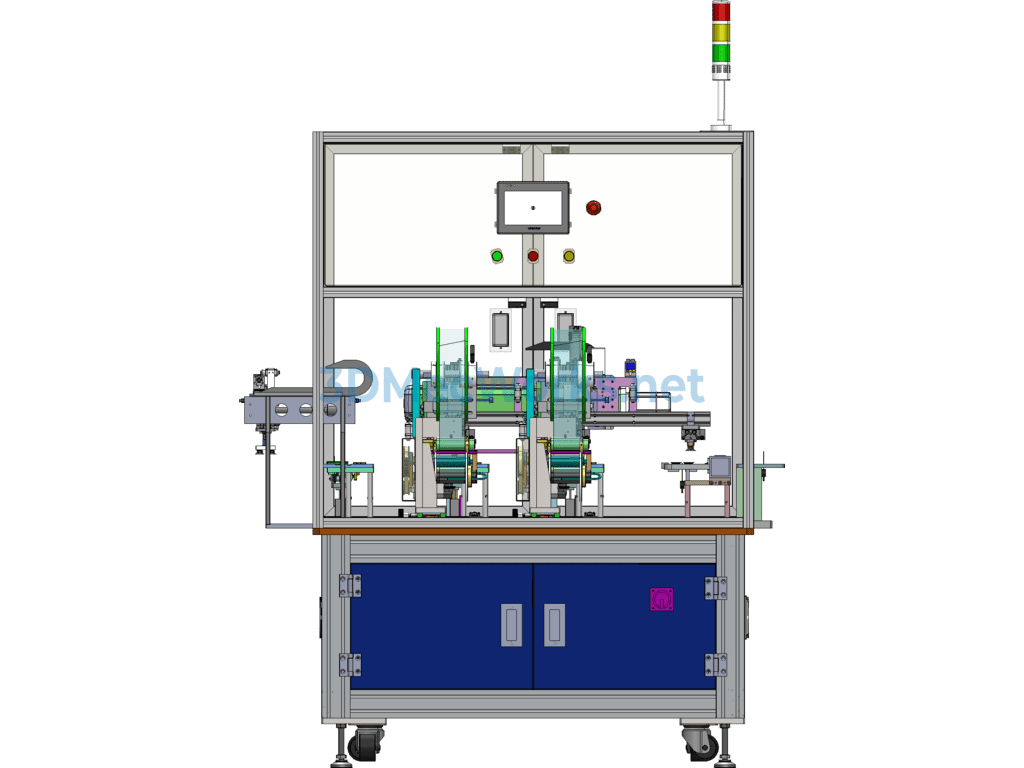

The double-sided adhesive tape applicator for cell backs is used for applying adhesive tape to the head of mobile phone batteries. Before the battery is fully formed, some insulating adhesive tape needs to be applied to the positive and negative connection points. This equipment consists of two labeling mechanisms capable of simultaneously applying two types of labels or two types of insulating adhesive tapes. Currently, it is more common to apply very small insulating adhesive tapes because the space at the electrode tab positions is small, making it quite challenging to apply such small insulating tapes. The automatic battery labeler and insulating tape applicator differ from traditional labelers in that this is a universal device capable of applying both labels and adhesive tapes, requiring only a modification of the label suction head. This device can achieve online testing and automatic labeling through changing the feeding method, or it can operate in a standalone mode. The robotic arm shown in the diagram is used for transporting products to the labeling position. When the sensor detects material, the peeling and labeling process begins. After the first labeling machine finishes applying one label, the second labeling machine can apply another label or an insulating tape. Essentially, two types of labels or insulating tapes can be handled by this single machine, which is highly efficient and stable, suitable for mass production. This equipment is ideal for the mobile phone industry, lithium battery industry, and food packaging industry. The labeling machine for mobile phone batteries and the adhesive tape machine are general-purpose models. This model was built using SolidWorks 2012, is parameterized, and editable.

Specification: Battery Cell Back Adhesive Tape Machine/battery Automatic Labeling Machine Tape Adhesive Insulation Tape Machine

|

User Reviews

Be the first to review “Battery Cell Back Adhesive Tape Machine/battery Automatic Labeling Machine Tape Adhesive Insulation Tape Machine”

You must be logged in to post a review.

There are no reviews yet.