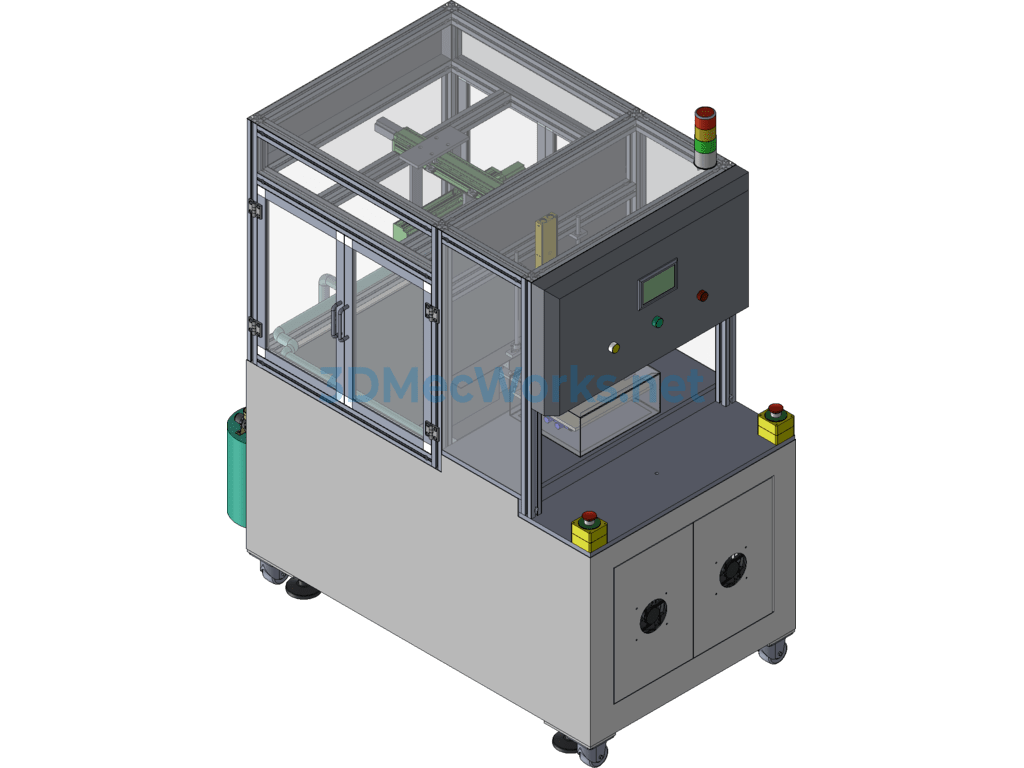

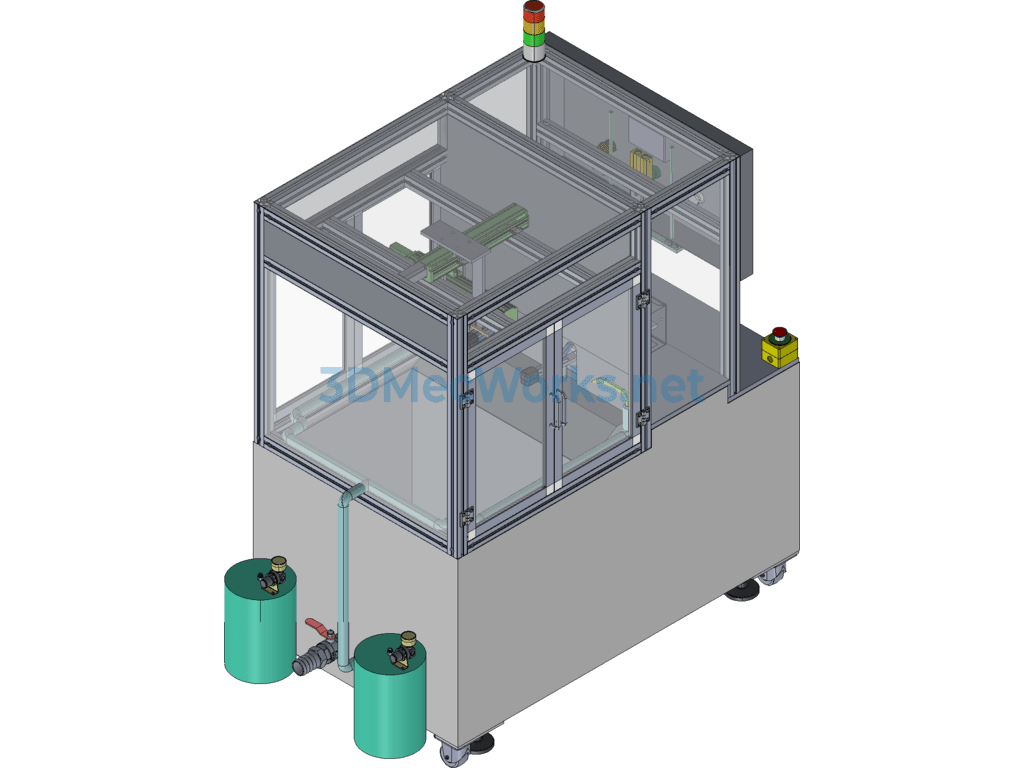

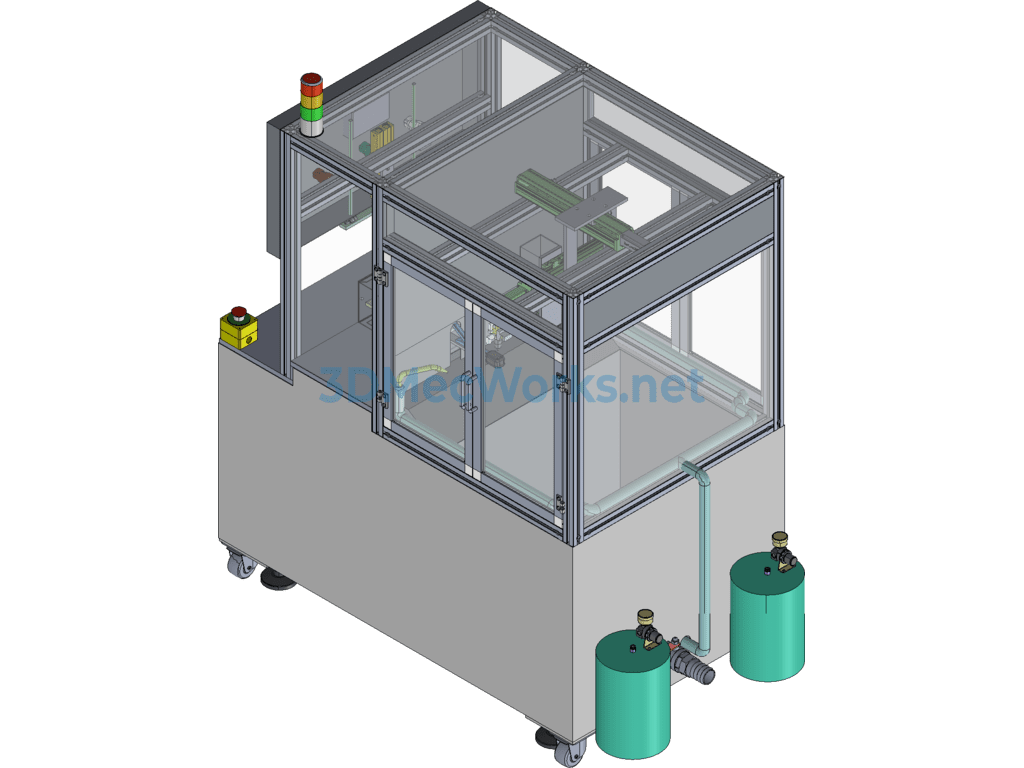

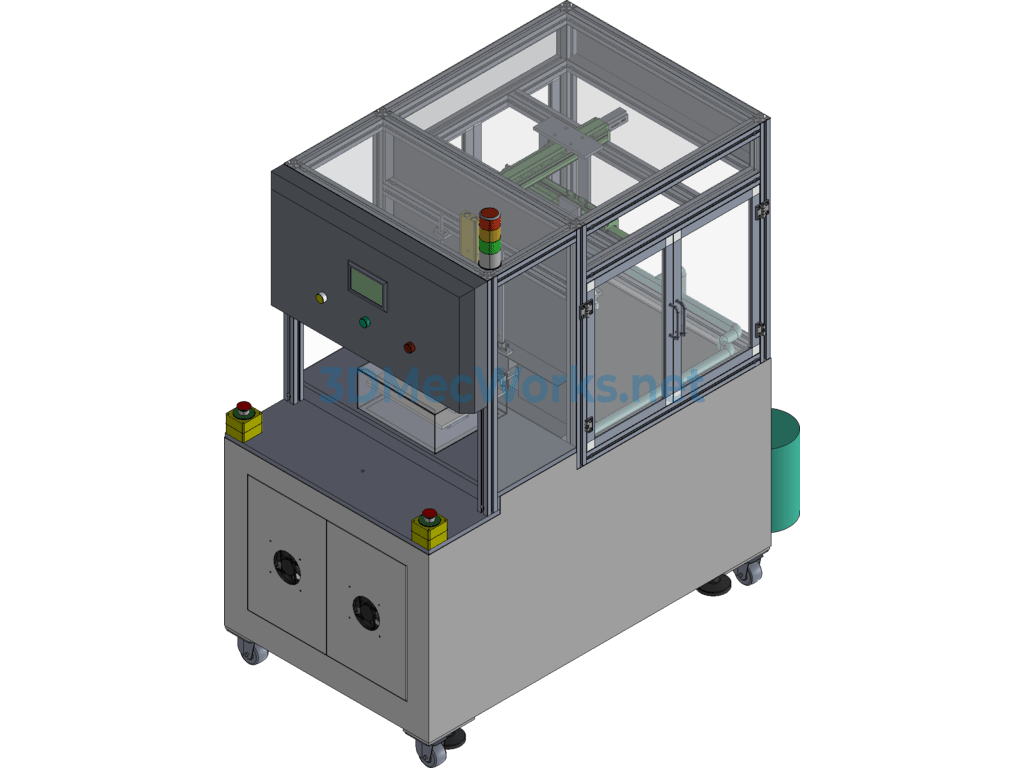

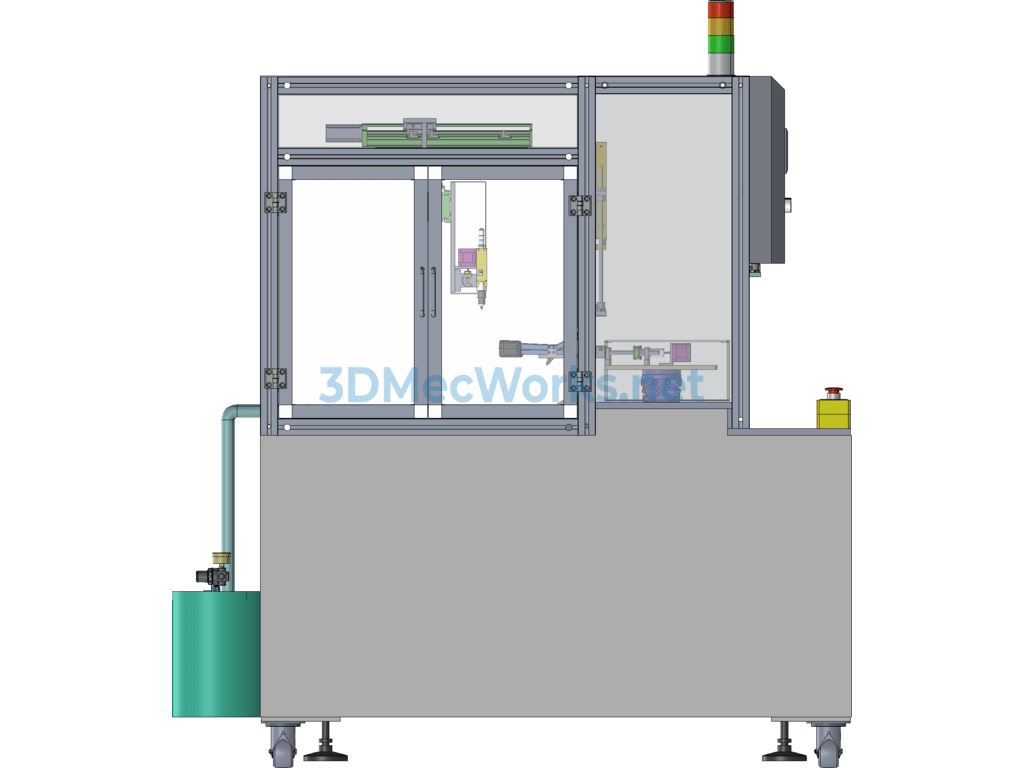

Automatic inkjet machine, suitable for the toy industry. After toys are molded, they undergo surface spraying to make their appearance uniformly colored and aesthetically pleasing. The workflow is as follows: 1. The cylinder opens the clamp, an operator places the mold, and presses the start button; 2. The clamp rotates 180 degrees to the spraying area, the motion module controls the inkjet valve for spraying, and both heads work simultaneously to improve production efficiency; 3. There is a dedicated cleaning mechanism below the spraying mechanism; 4. Motion control is managed by a PLC.

Specification: Automatic Inkjet Machine

|

User Reviews

Be the first to review “Automatic Inkjet Machine”

You must be logged in to post a review.

There are no reviews yet.