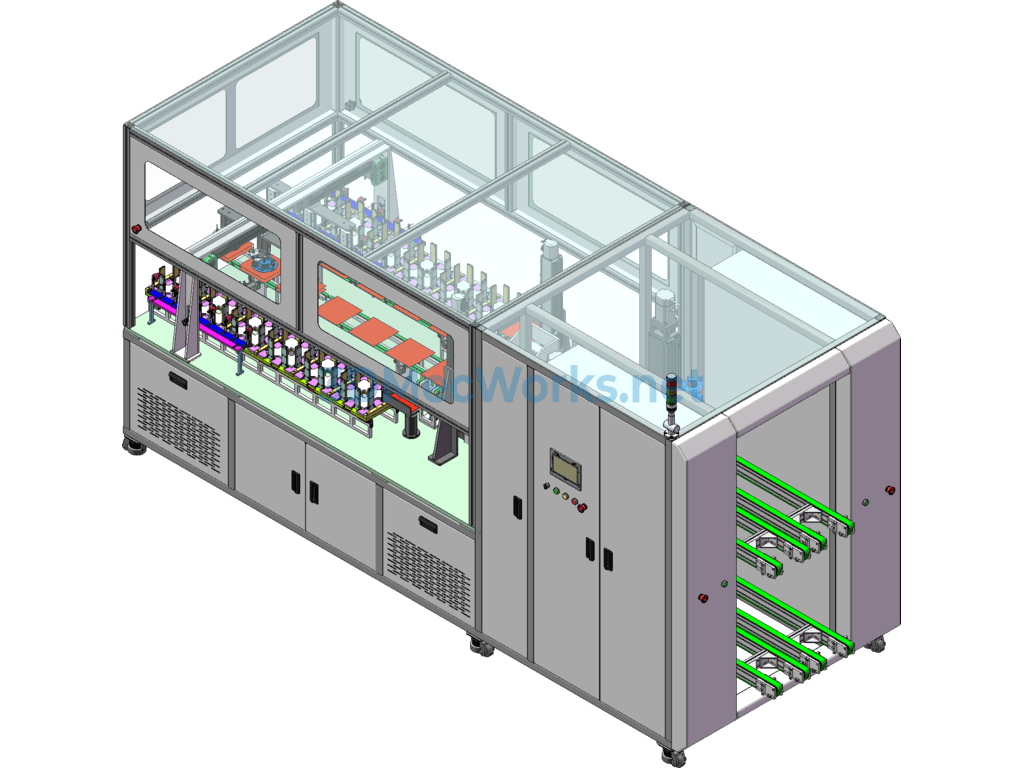

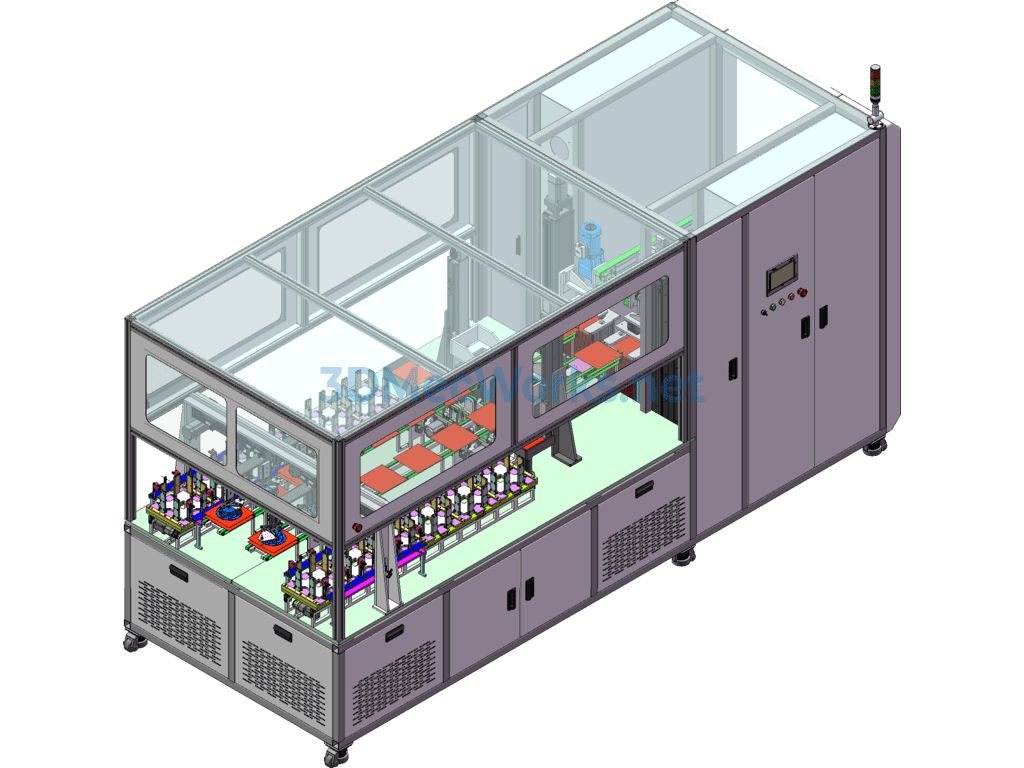

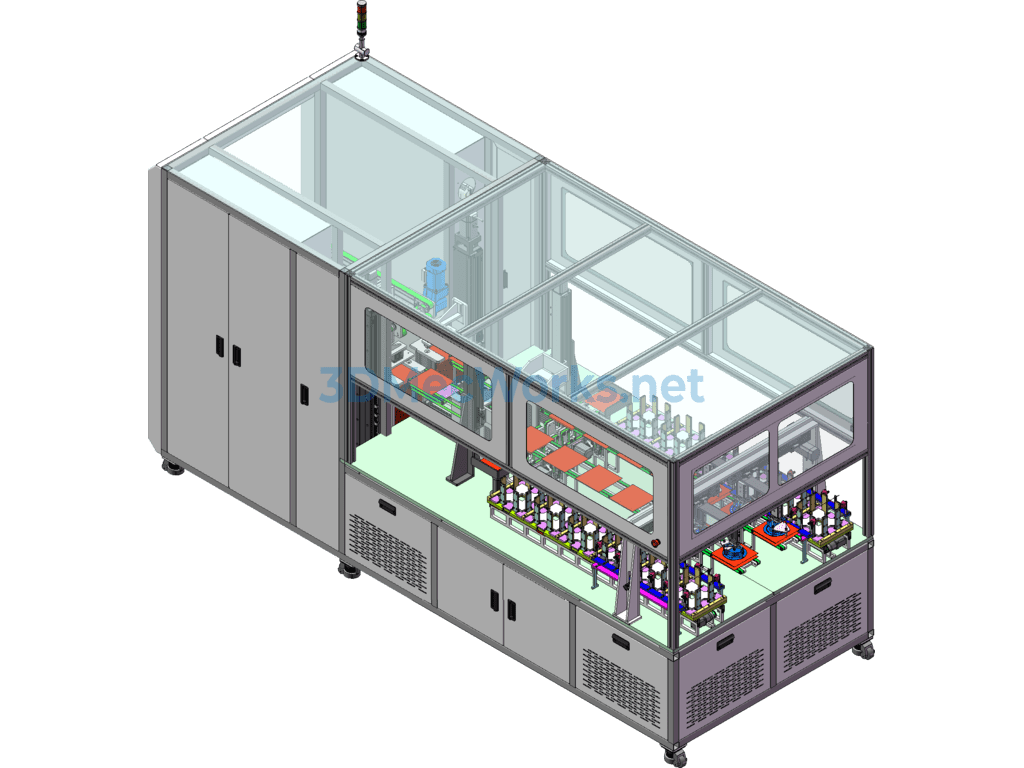

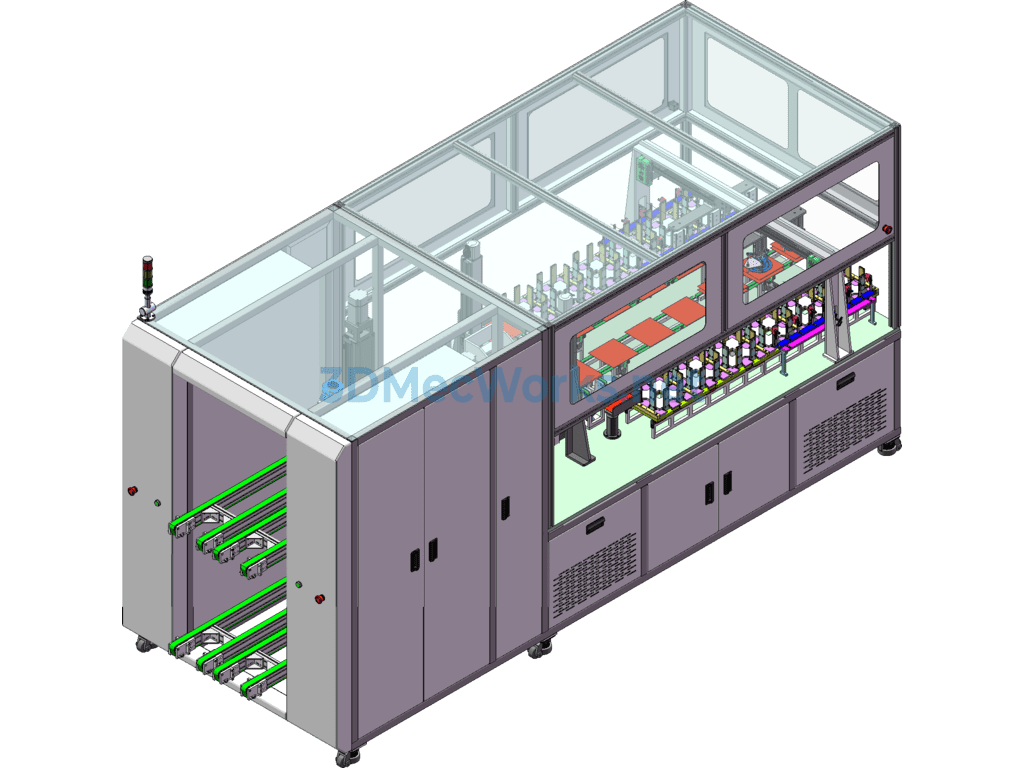

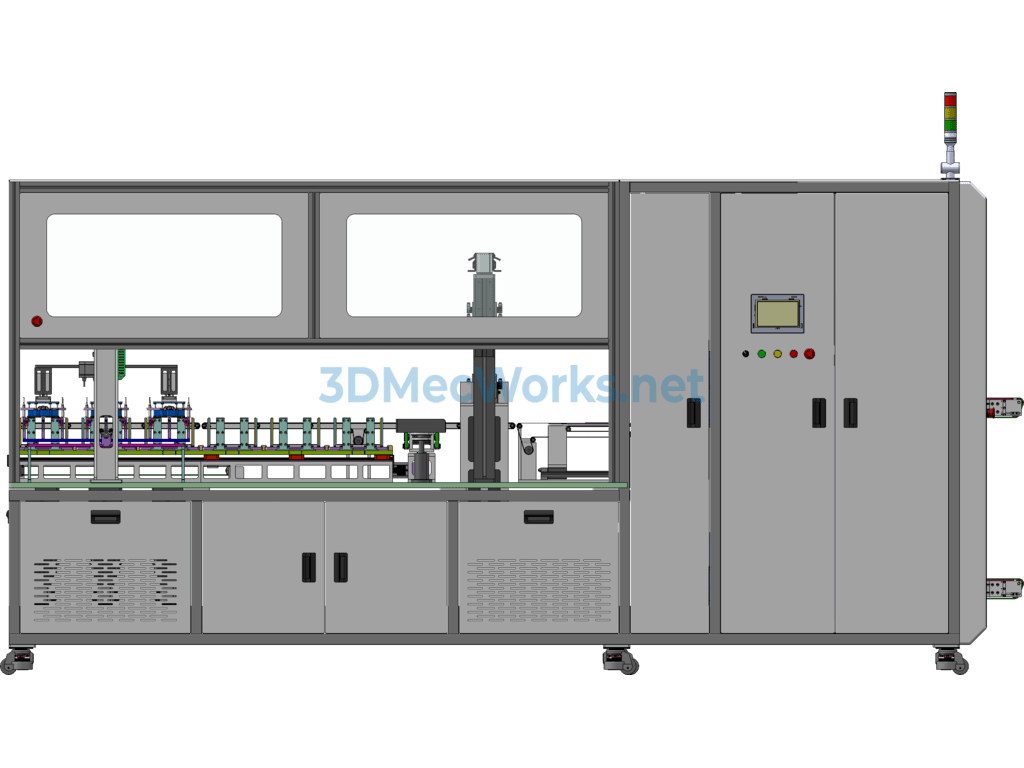

1. Production Process

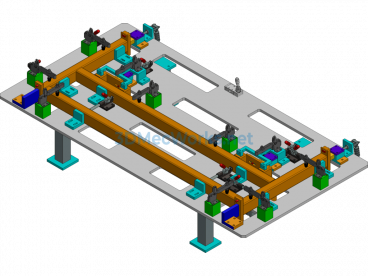

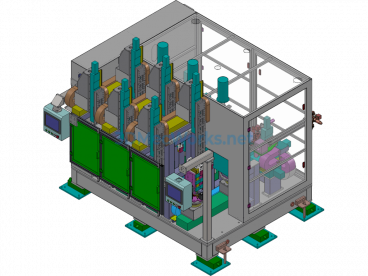

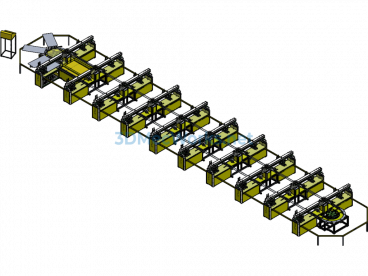

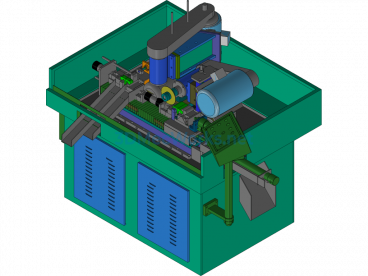

The equipment loads silicon wafers from stacked cassettes into wet baskets used by the texturing machine. The equipment’s functional modules include: cassette stack component, cassette replacement component, wafer transfer component, top wafer component, air-blow component, buffer component, dual and multiple wafer detection and removal component, elastic belt conveying component, telescopic wafer placement component, lifting wafer placement component, basket conveying component, and so on.

2. Tooling

Silicon wafer cassette: 400 pieces (compatible with 166-182)

Silicon wafer basket: 100 pieces

Spacing: 4.76mm/120 pieces 4.12mm

3. Applicable Wafers

Dimensions: 156-182

Thickness: 0.16-0.24MM

4. Capacity: 6000-8000pcs/h

5. Breakage Rate per Machine: ≦0.02% (excluding original fragments)

6. Mono and Polycrystalline: Compatible with both

7. Number of Channels: 2 channels

8. Basket Temporary Storage: 8 units

9. Equipment Dimensions: 3820*1450*1850 (L*W*H in mm)

10. Power Supply: 220V 50-60Hz

11. Compressed Air: 0.5-0.7MPa

12. Power: 3.2kw

There are no reviews yet.