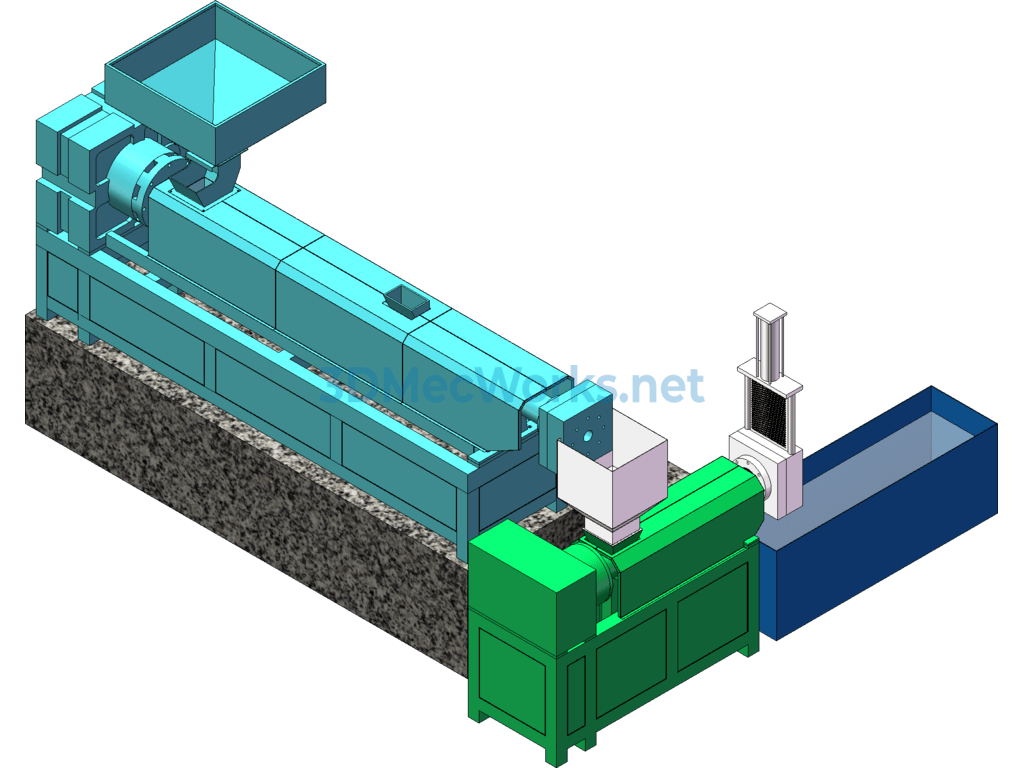

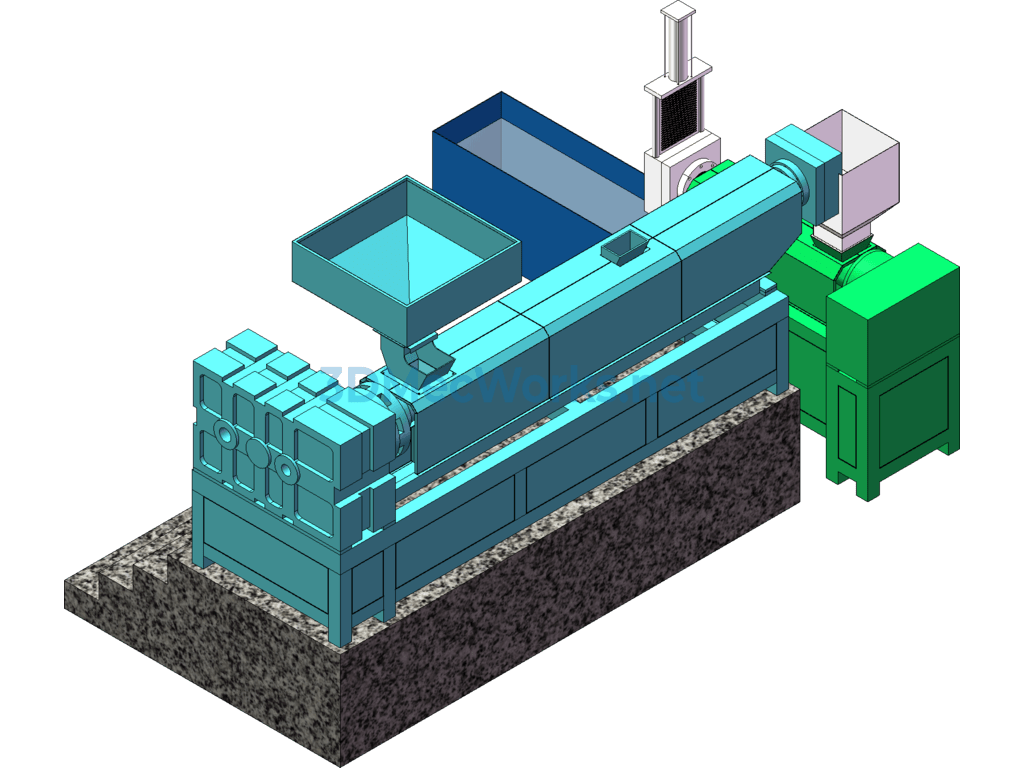

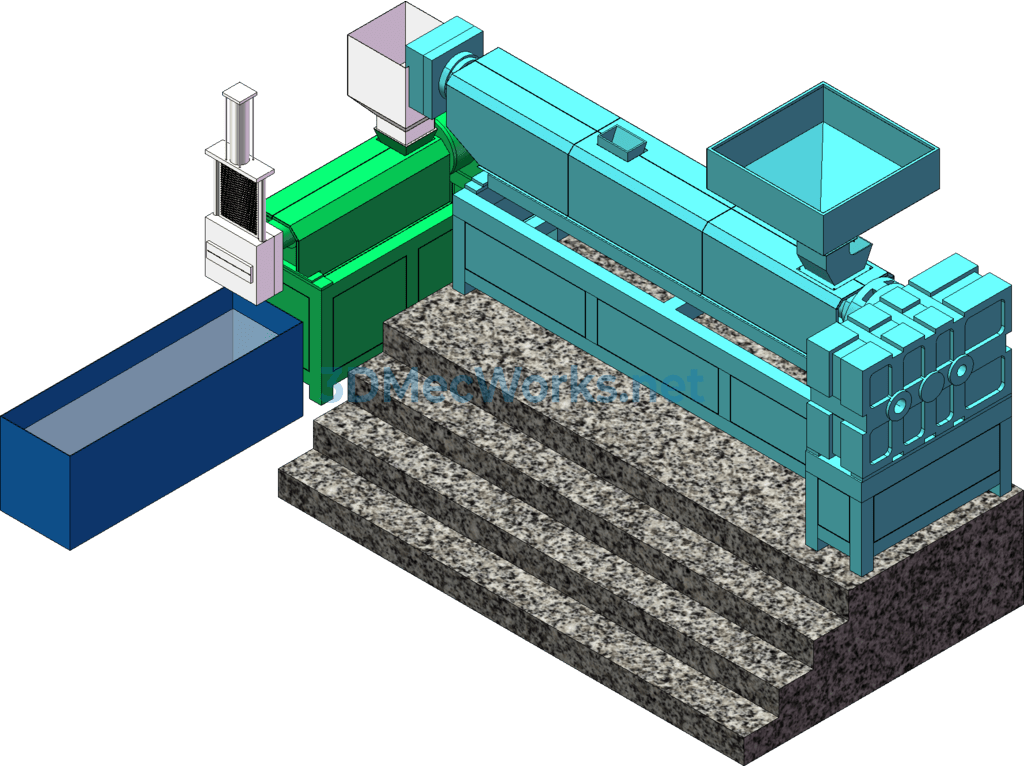

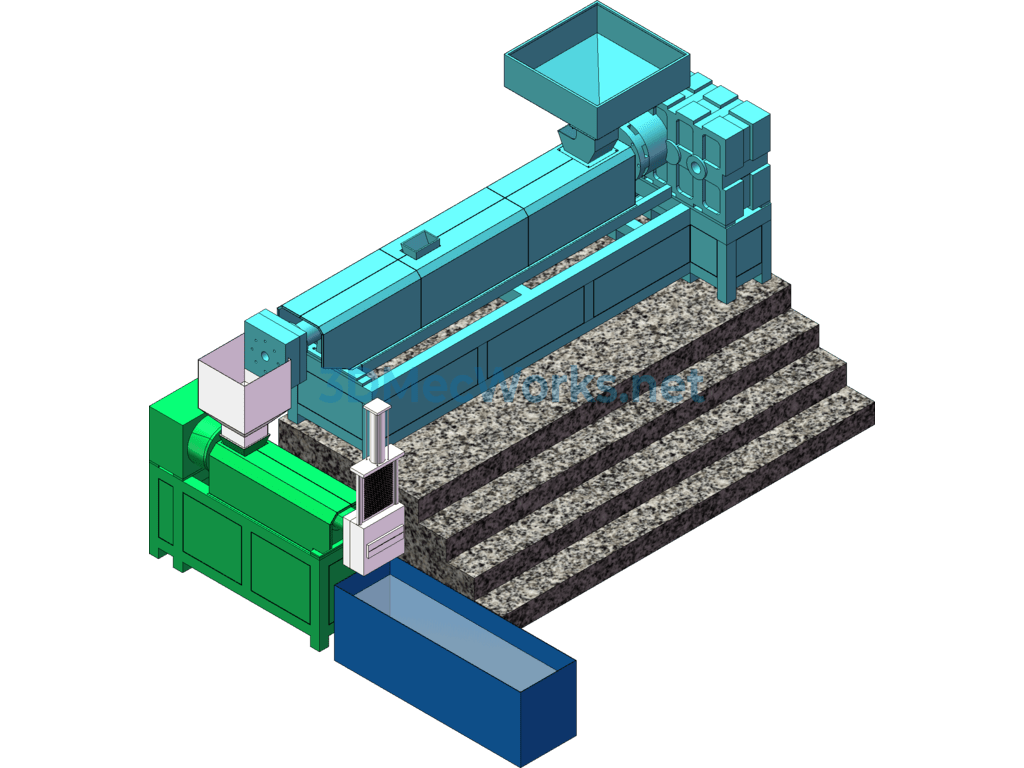

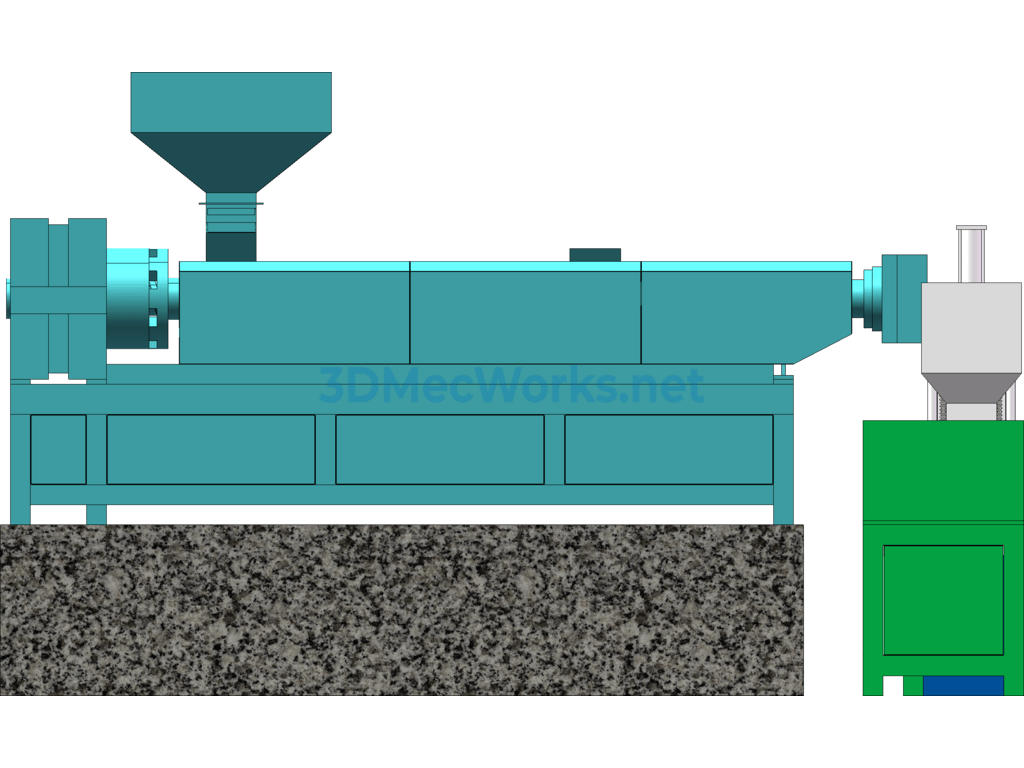

Working principle of dual-die pelletizing unit. Raw materials are placed into the hopper, smoothly dropping onto the screw from the hopper. The screw catches the materials and forces them forward as it rotates. Meanwhile, under the effect of the heater and the compression and stirring motion of the plastic itself, external and internal forces generate heat, causing the plastic’s temperature to rise rapidly and melt into a liquid state. It is then evenly extruded from the barrel before entering the auxiliary machine for stirring and pressing. Due to resistance from the network splitter and machine head, the material experiences strong compressive force during the process, compressing it tightly. This allows the plastic to be evenly extruded as strips through the mesh, then dropped into a water tank for cooling, and finally into a pelletizer to be cut into granular form. This model only demonstrates the main auxiliary machine model; please search for a generic model pelletizer yourself.

Specification: Dual Die Pelletizing Unit

|

User Reviews

Be the first to review “Dual Die Pelletizing Unit”

You must be logged in to post a review.

There are no reviews yet.