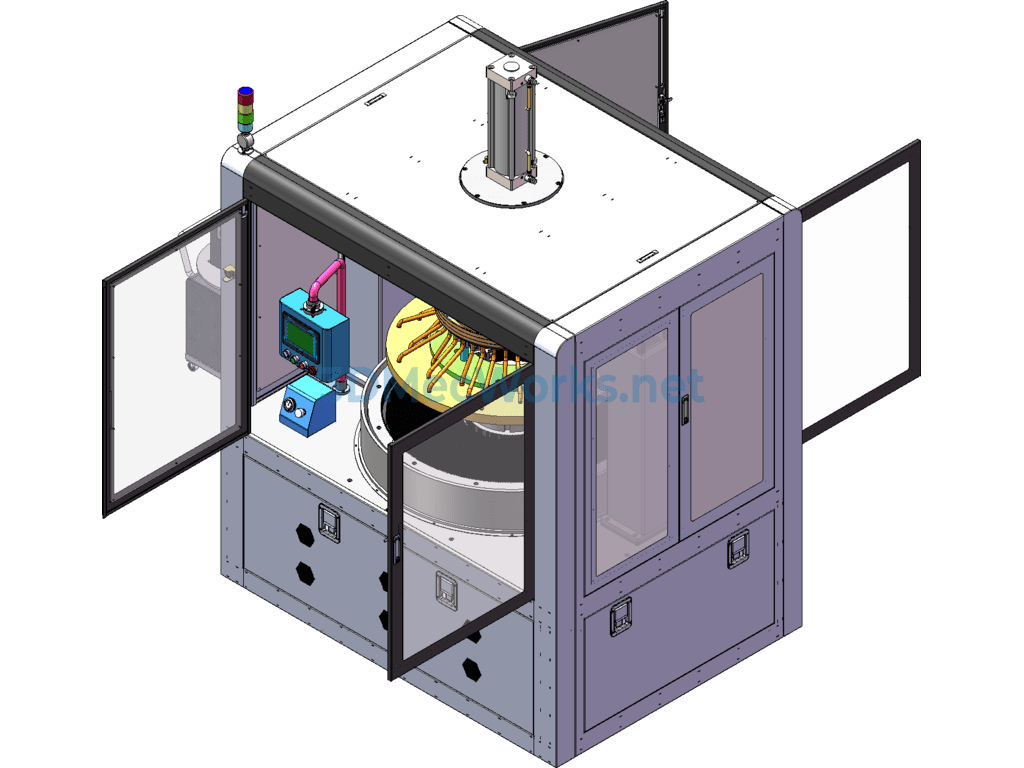

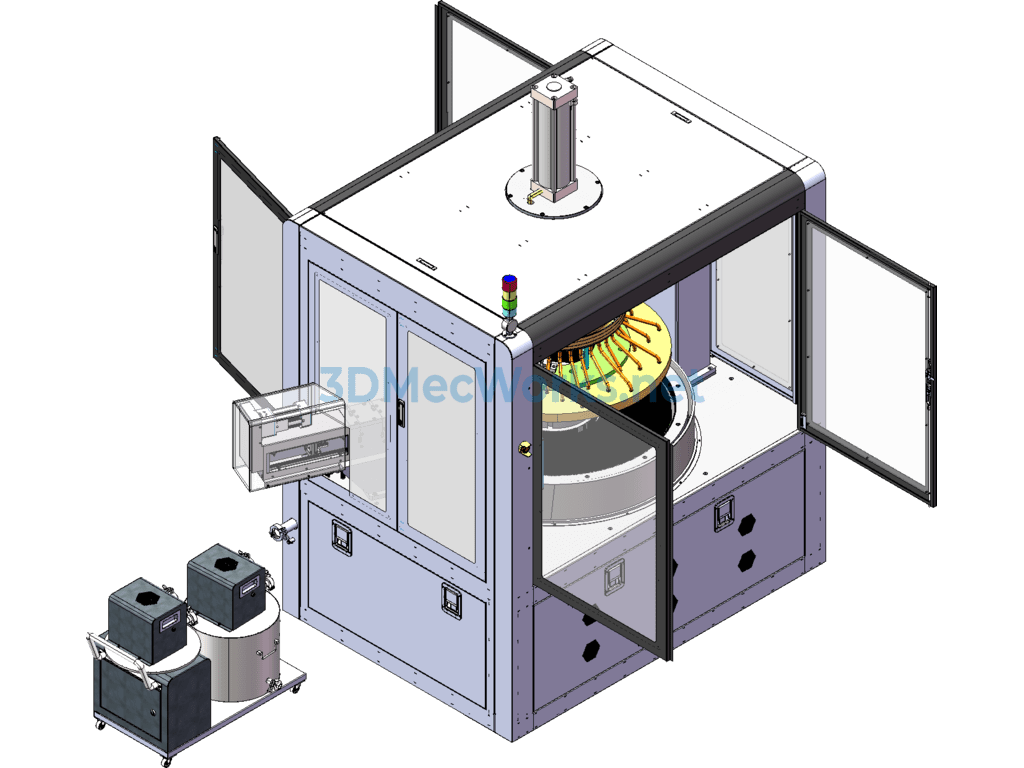

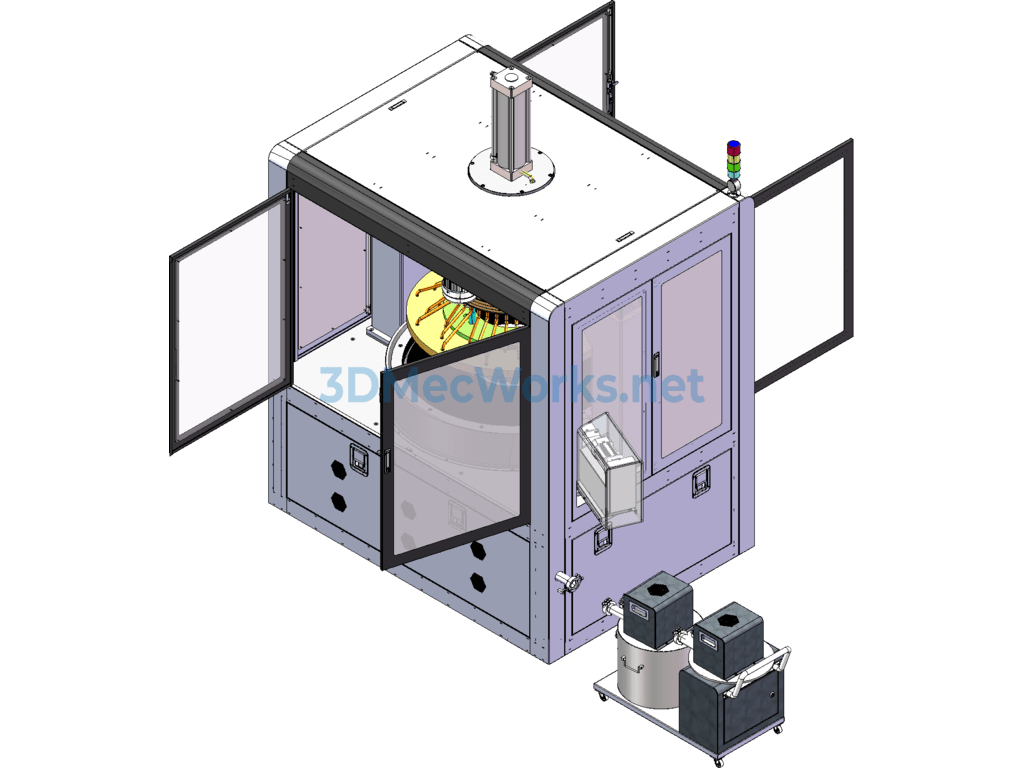

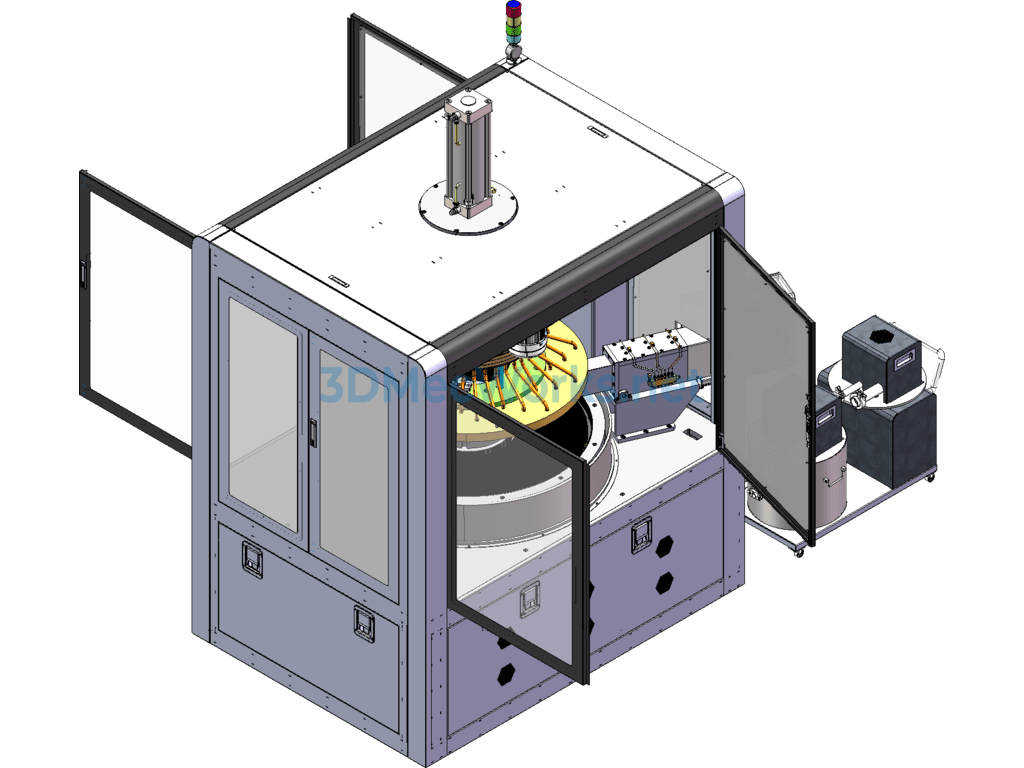

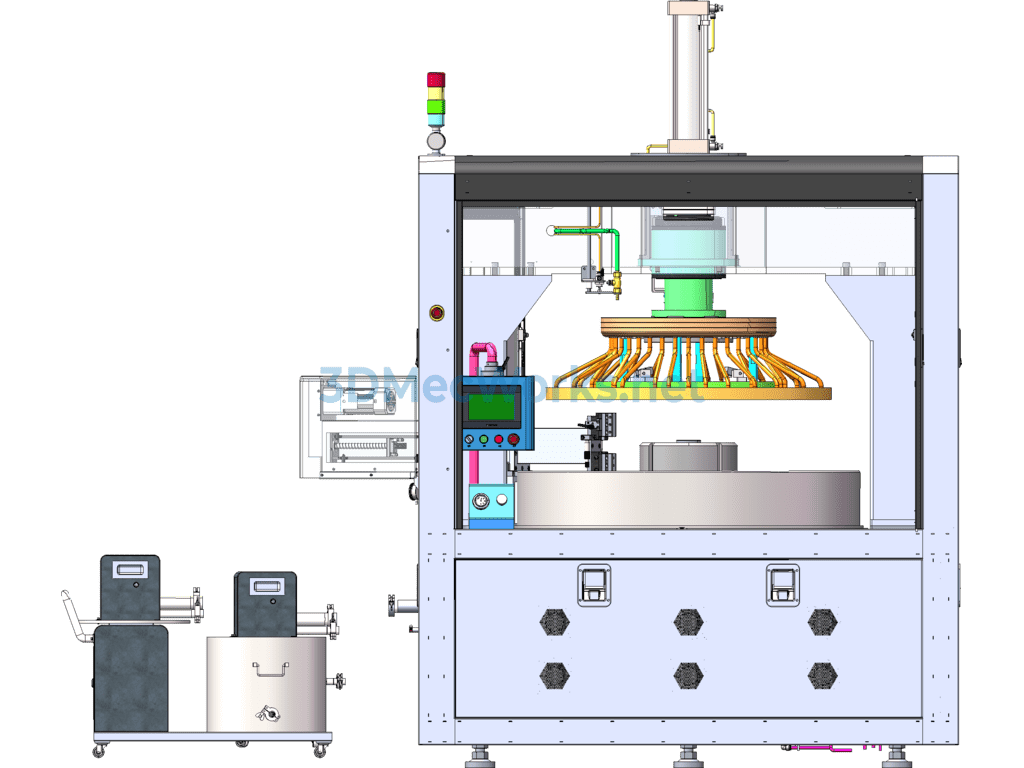

Double-Sided Grinding Machine

1. Main Purpose

Primarily used for high-precision double-sided grinding/polishing of sapphires, blue glass, ceramic wafers, crystals, semiconductors, and other hard and brittle materials, with distinct advantages in processing ultra-thin workpieces.

2. Main Features

1. Precision Pressure Control: PLC+PT+electric proportional valve+low-friction cylinder achieve high-precision pressure closed-loop control;

2. Upper Plate Vibration Damping Device: suitable for both dynamic and static elastic vibration damping connection method;

3. Precision Transmission System: high-precision, low-backlash full gear transmission;

4. Lower Plate Support: high-precision plane fluid bearing support, high load capacity, smooth operation, maintenance-free;

5. Pin Gear Transmission: internal and external teeth use pin gear transmission to extend carrier lifespan, easy maintenance, and involute gear transmission can also be used;

6. Transmission System: three-motor synchronous drive, with adjustable rotational speed of upper plate, lower plate, gear ring, and sun wheel (capable of forward and reverse rotation), featuring a recipe function.

Specification: Double-Sided Glass Grinding Machine

|

User Reviews

Be the first to review “Double-Sided Glass Grinding Machine”

You must be logged in to post a review.

There are no reviews yet.