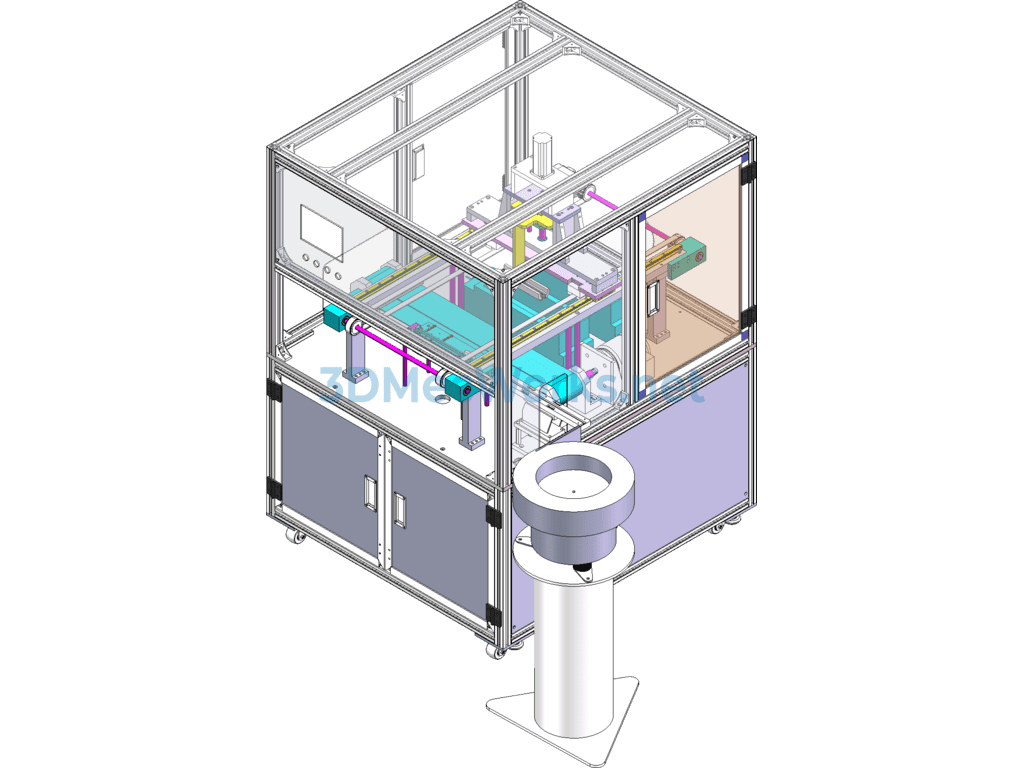

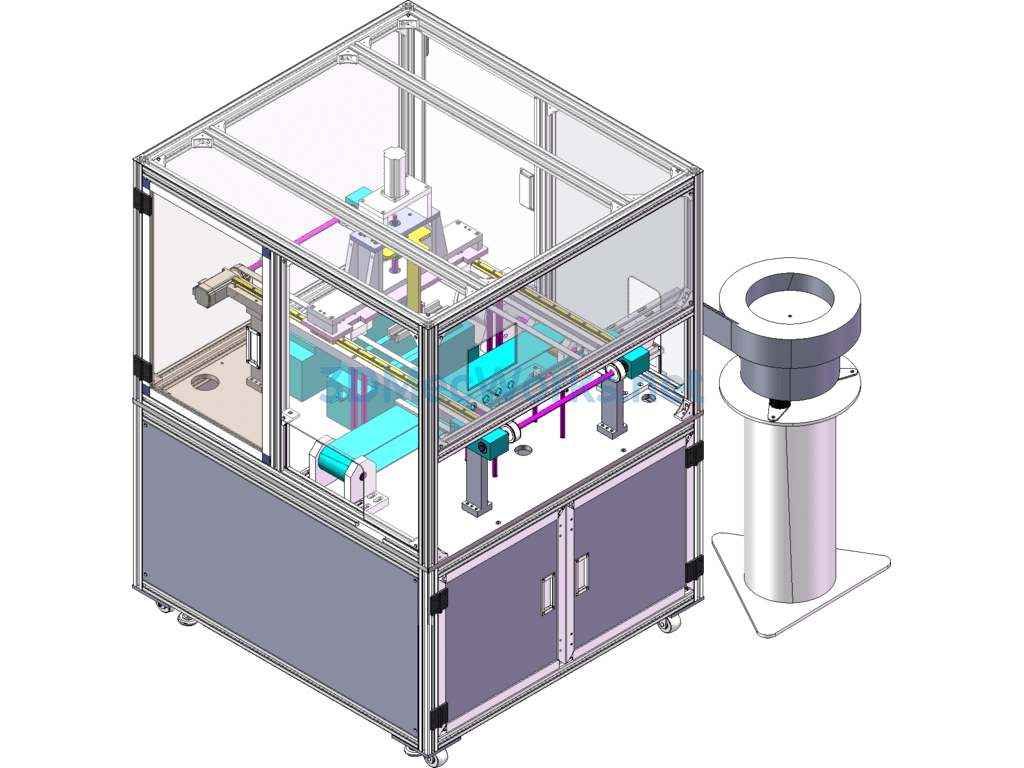

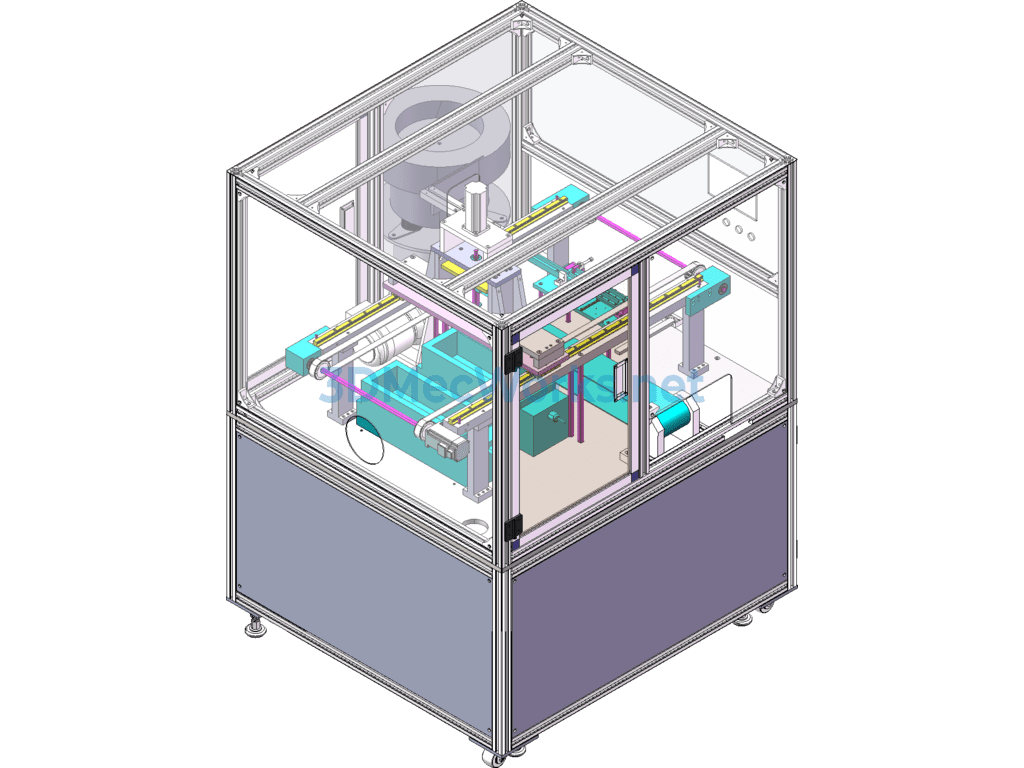

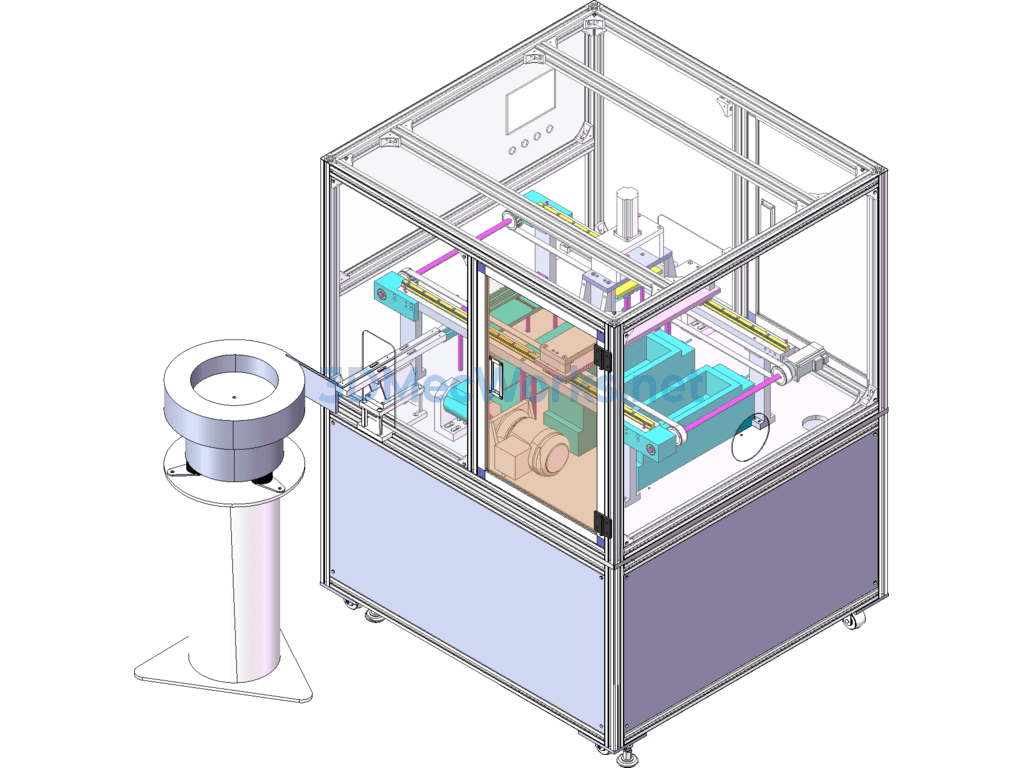

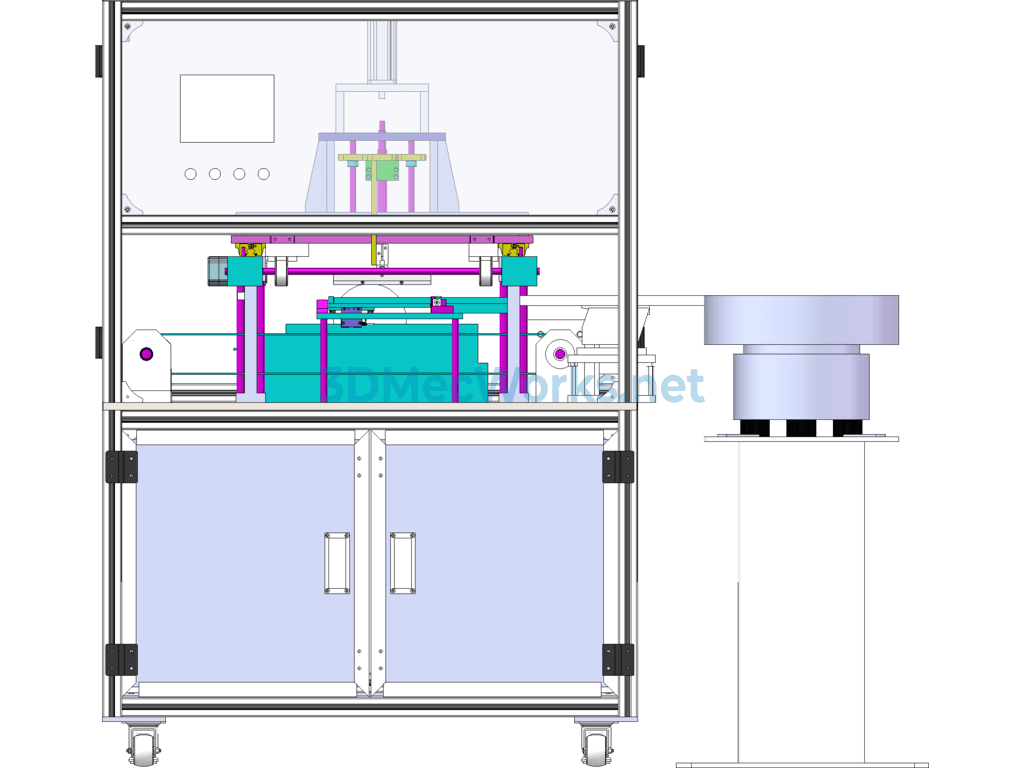

This device, after completing inductor winding, is a piece of equipment developed for solder tin dipping on the lead angle. There is a vibrating feeder for loading, followed by a gantry pick-and-place mechanism that clamps the inductor, first dipping it in flux, then dipping it in the tin furnace, cooling it, and finally placing the product on the production line for release.

Specification: Plug-In Inductor Vibration Feeding Soldering Machine

|

User Reviews

Be the first to review “Plug-In Inductor Vibration Feeding Soldering Machine”

You must be logged in to post a review.

There are no reviews yet.