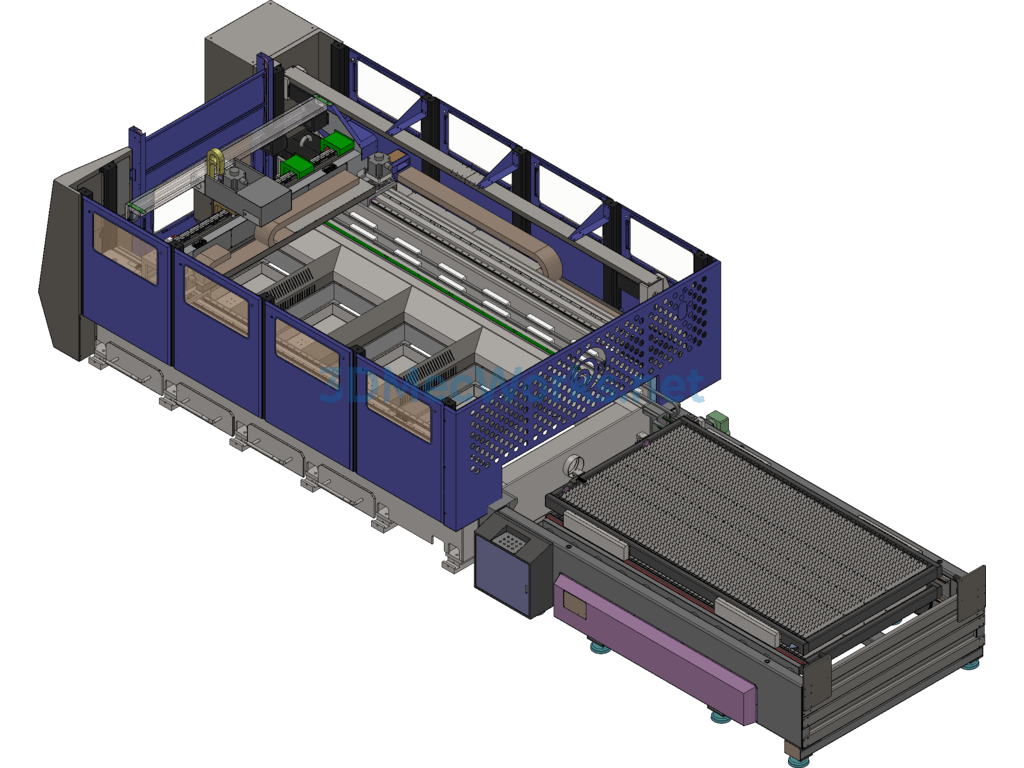

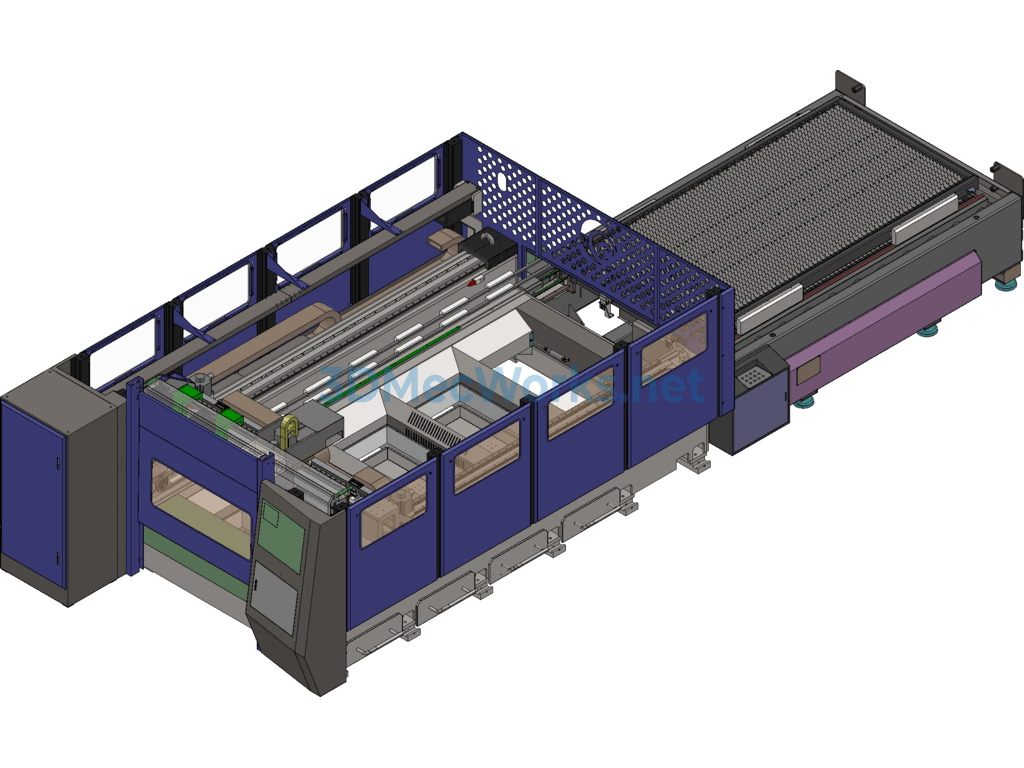

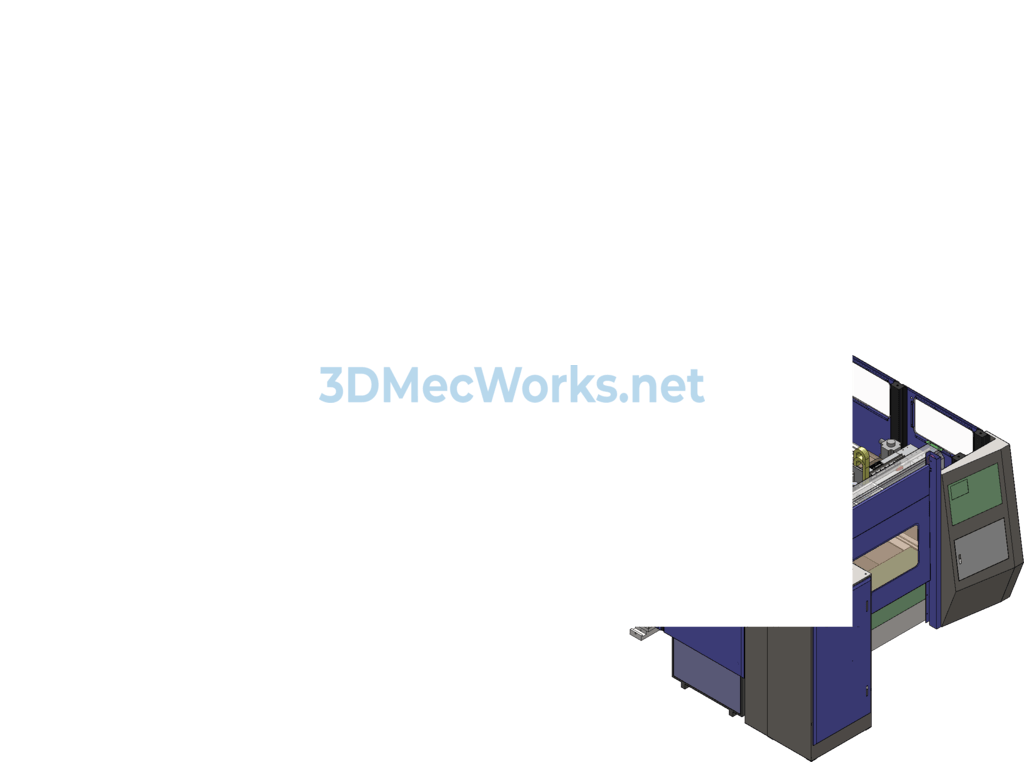

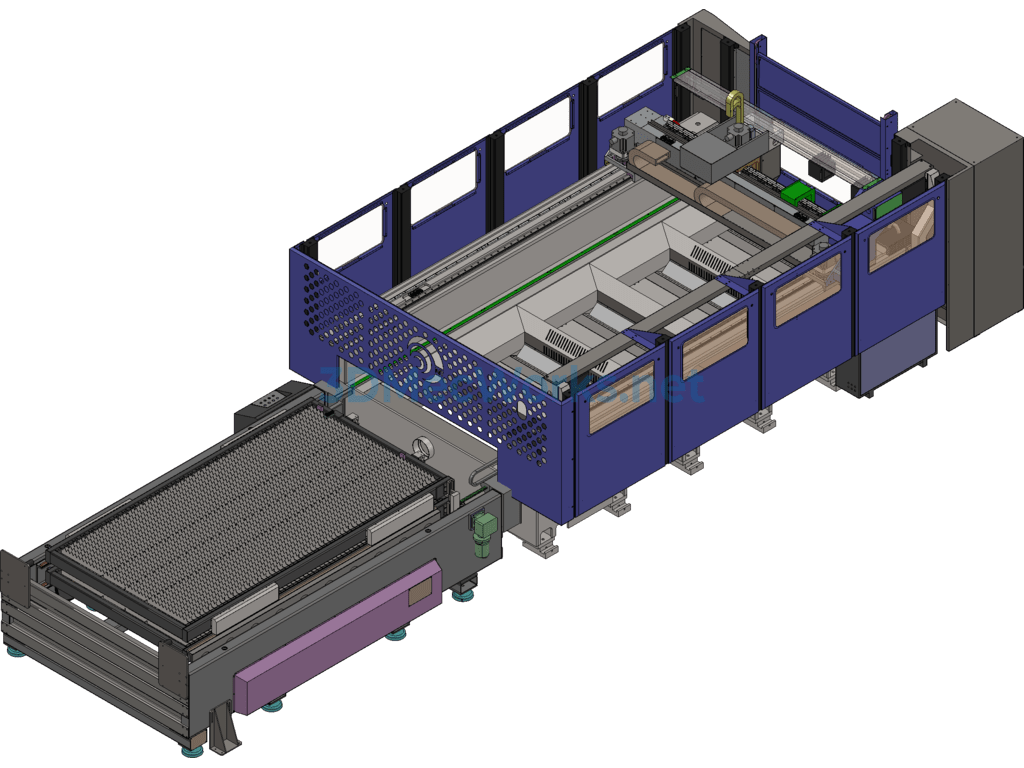

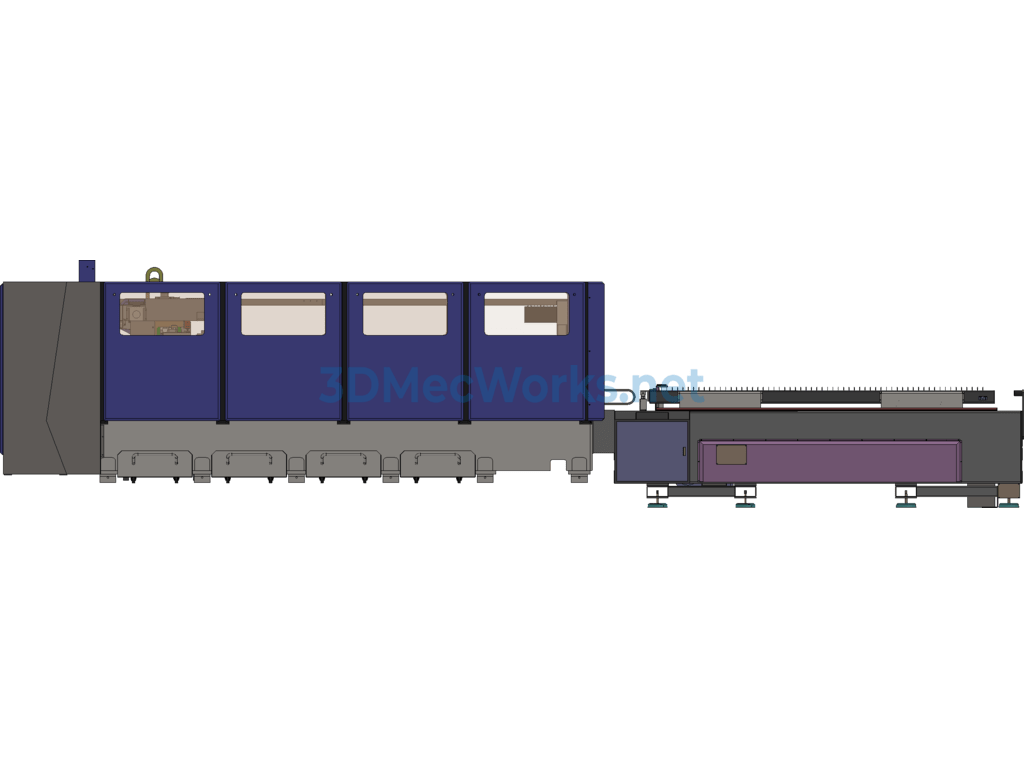

CNC Laser Cutting Machine SHC3015 Fiber Laser Cutting Machine is the mainstream mid-to-high-end fiber laser cutting machine on the market. A laser cutting machine emits a laser from the laser source, which is focused into a high-power density laser beam through an optical path system. Laser cutting processing uses an invisible beam to replace the traditional mechanical knife, offering high precision, rapid cutting, no restriction on cutting patterns, automatic nesting to save materials, smooth cut edges, low processing cost, and other features, gradually improving or replacing traditional metal cutting process equipment. The laser beam irradiates the surface of the workpiece, bringing it to the melting or boiling point, while high-pressure gas coaxial with the beam blows away the molten or vaporized metal. As the relative position of the beam and the workpiece moves, the material ultimately forms a slit, thus achieving the purpose of cutting. Laser cutting processing uses an invisible beam to replace the traditional mechanical knife, offering high precision, rapid cutting, no restriction on cutting patterns, automatic nesting to save materials, smooth cut edges, low processing cost, and other features, gradually improving or replacing traditional metal cutting process equipment. There is no mechanical stress or shearing burr on the slit; the processing precision is high, repeatability is good, and the material surface is not damaged; CNC programming can process any plane drawing, enables cutting of very large boards without requiring mold opening, economical and time-saving.

Specification: Fiber Optic Cnc Laser Cutting Machine

|

User Reviews

Be the first to review “Fiber Optic Cnc Laser Cutting Machine”

You must be logged in to post a review.

There are no reviews yet.