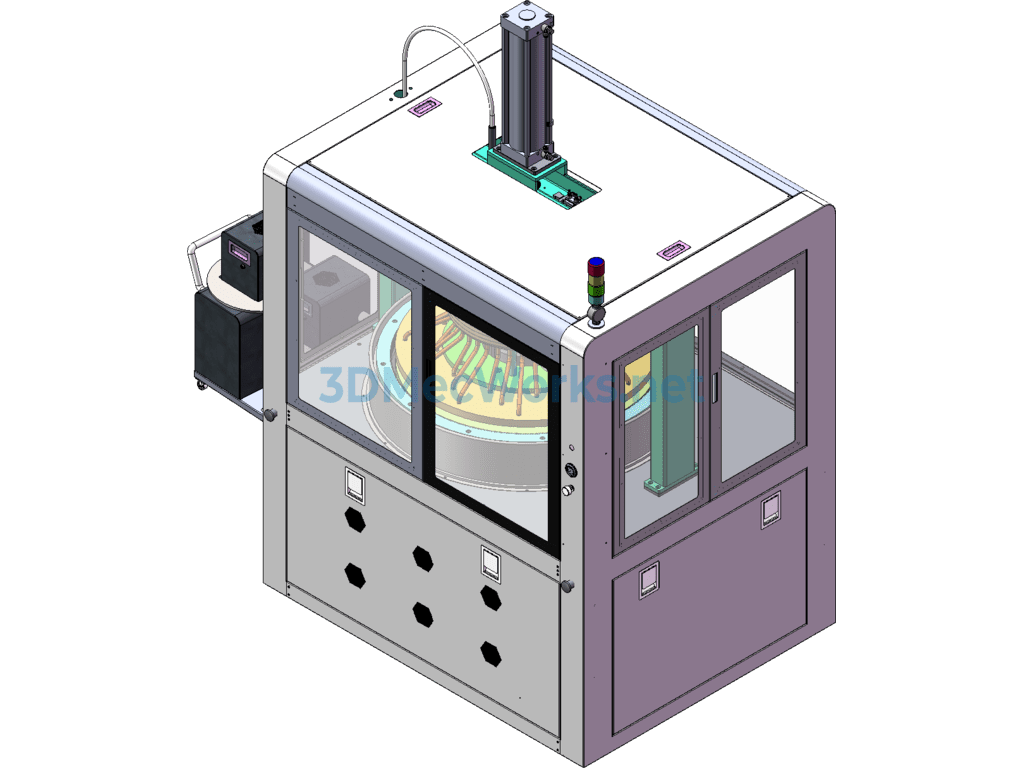

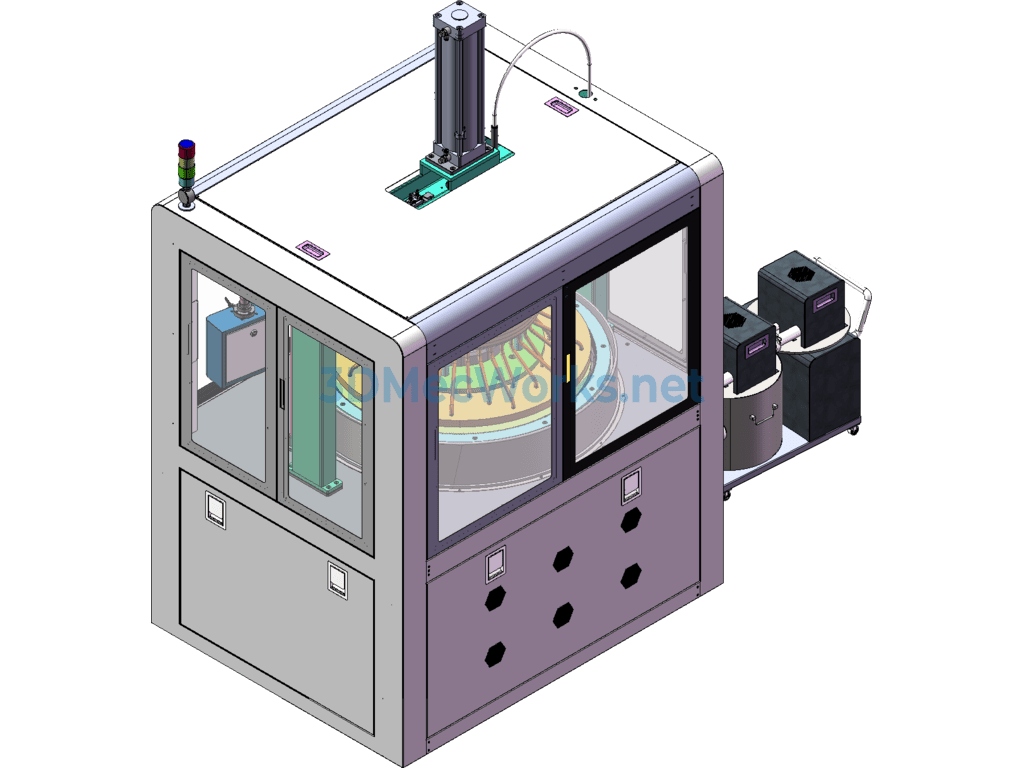

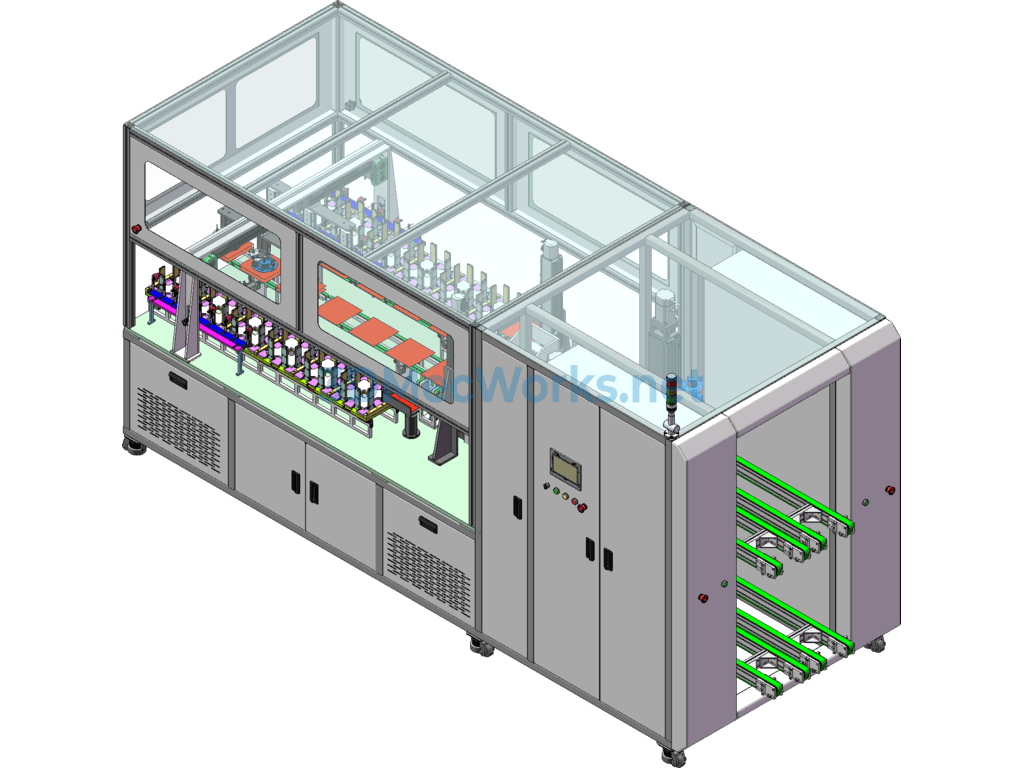

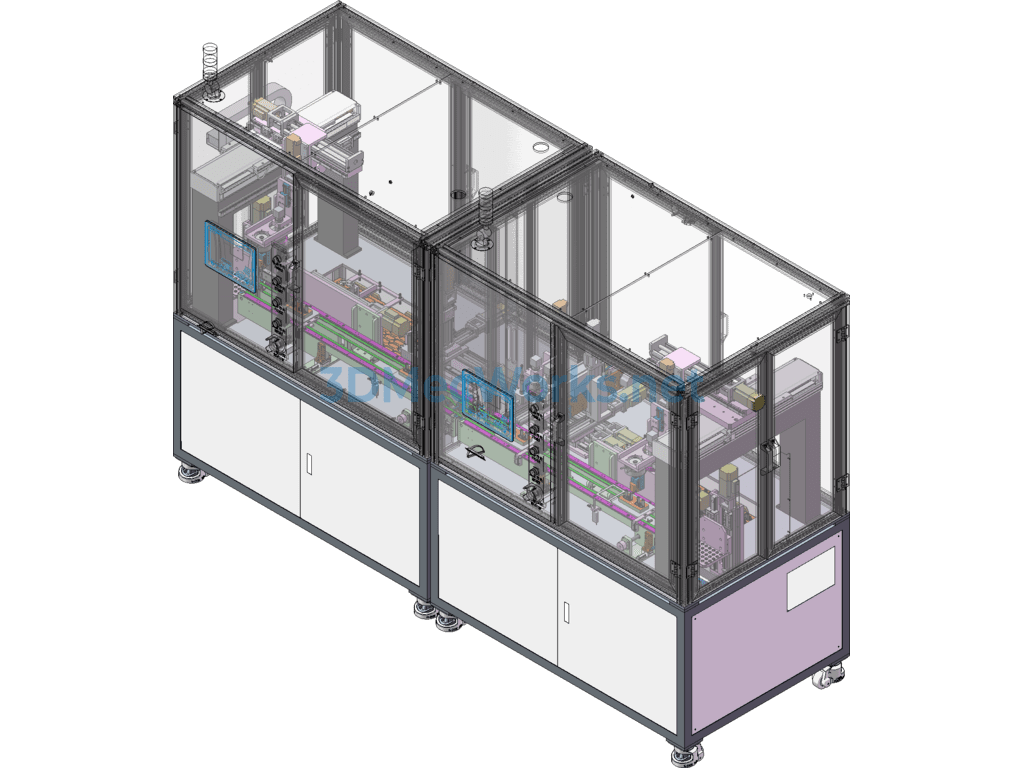

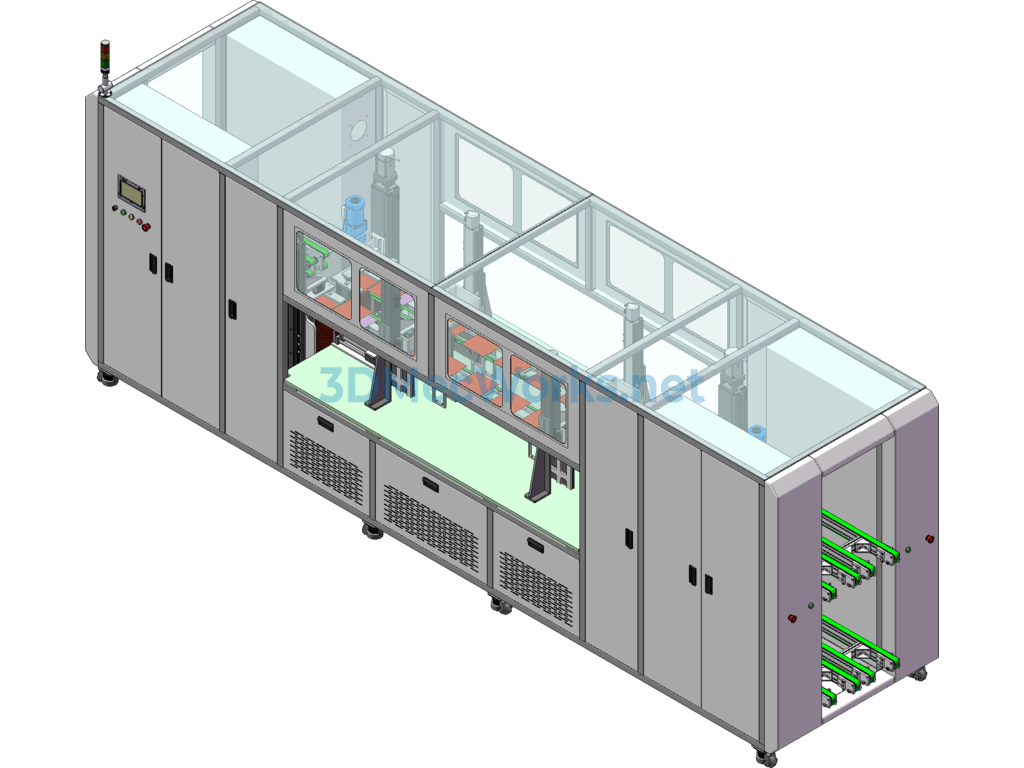

Non-standard High-Precision Automated Glass Polishing Machine (3D+2D+CAD Engineering Drawing+BOM List Details)

I. Main Uses

Mainly used for high-precision double-sided grinding/polishing of sapphire, blue glass, ceramic pieces, crystals, semiconductors, and other hard and brittle materials. It is particularly advantageous for processing ultra-thin workpieces.

II. Main Features

1. Precise Pressure Control: The use of PLC + PT + electrical proportional valve + low friction cylinder achieves high precision pressure closed-loop control;

2. Upper Disc Shock Absorption Device: A vibration-damping elastic connection method applicable both statically and dynamically;

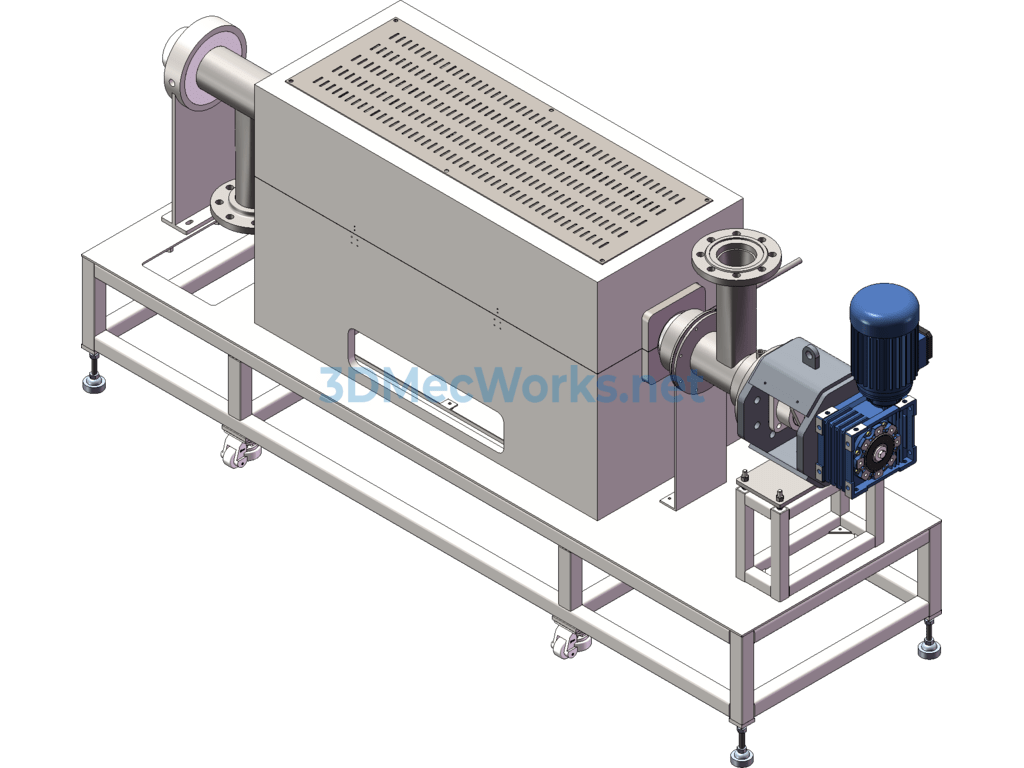

3. Precision Transmission System: High-precision full-gear transmission with small backlash;

4. Lower Disc Support: High-precision plane fluid bearing support with a large load capacity, stable operation, and maintenance-free;

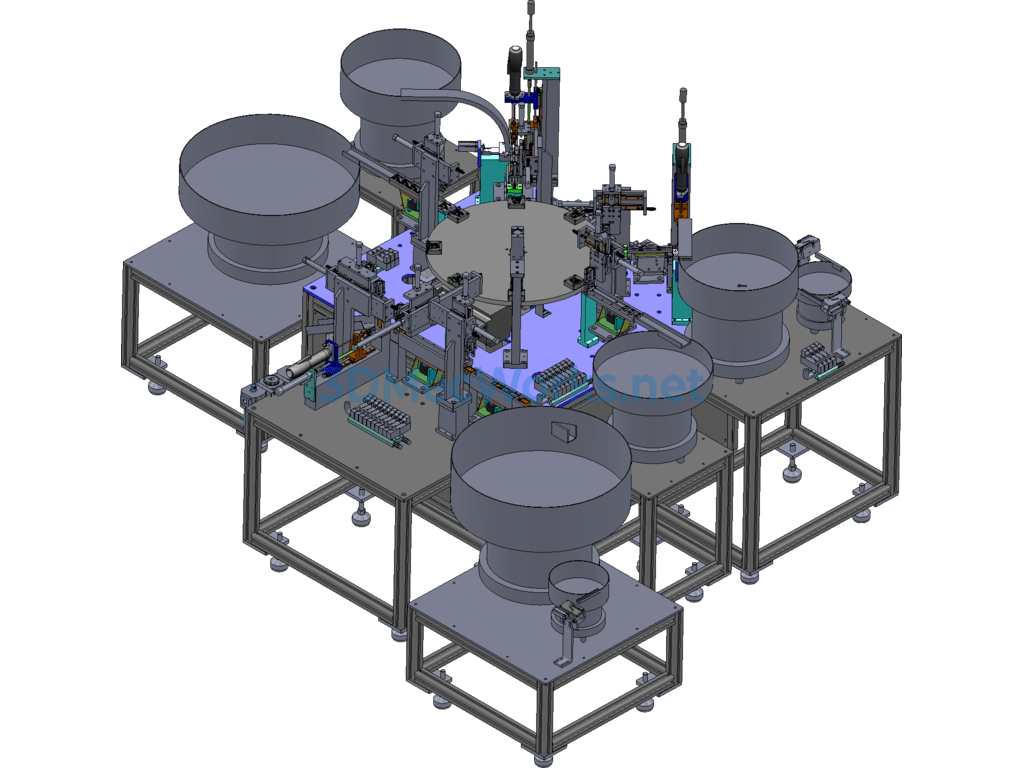

5. Pinion Gear Drive: The use of pinion gear drive in internal and external gears extends carrier lifespan, offers easy maintenance, and can also use involute gear drive;

6. Transmission System: Three-motor synchronous drive, the speeds of the upper disc, lower disc, ring gear, and sun gear (can rotate forward or reverse) can be set arbitrarily with a formula function.

Specification: Automated High-Precision Glass Polishing Machine (3D + 2D + CAD Drawings + BOM Details)

|

User Reviews

Be the first to review “Automated High-Precision Glass Polishing Machine (3D + 2D + CAD Drawings + BOM Details)”

There are no reviews yet.