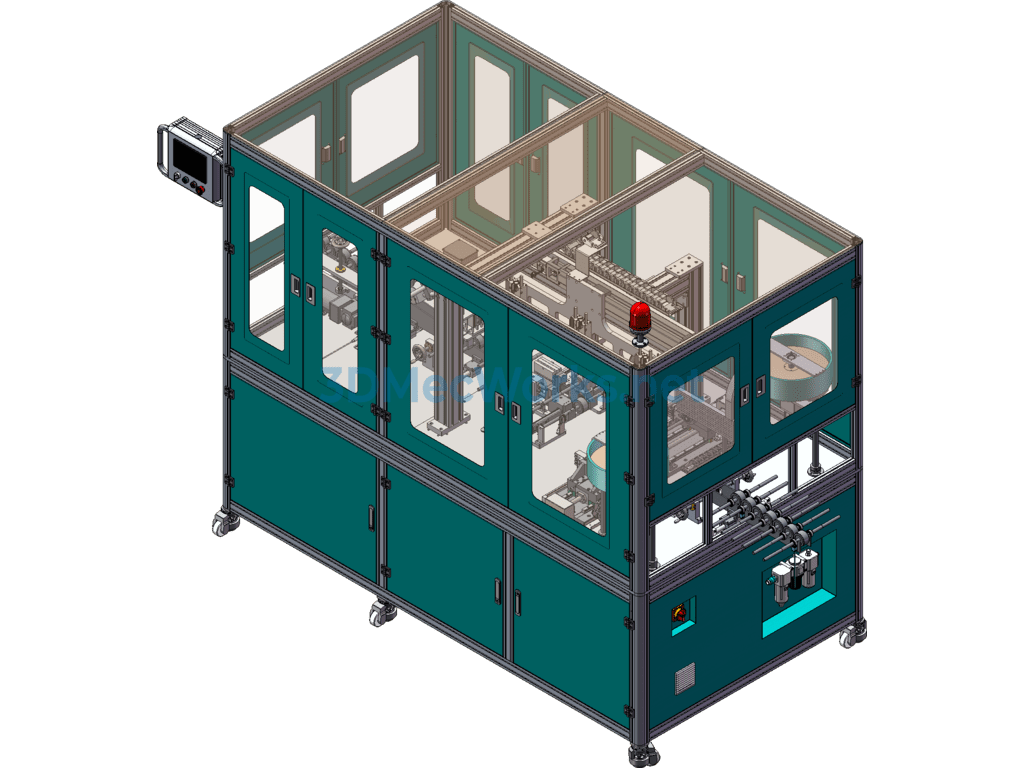

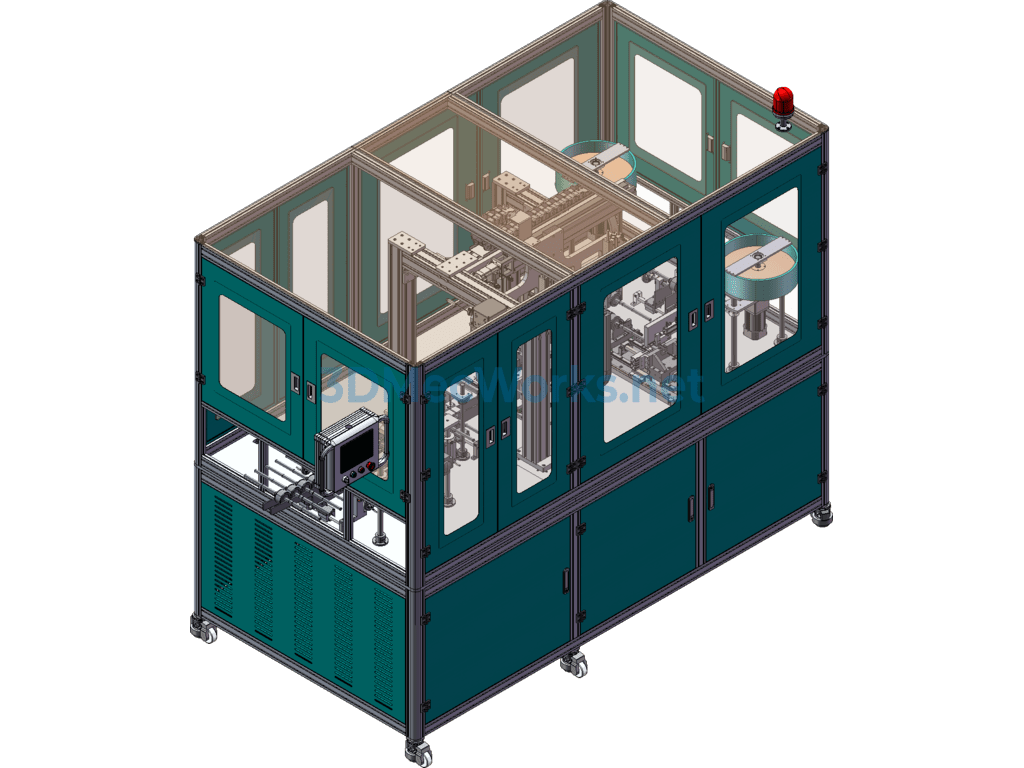

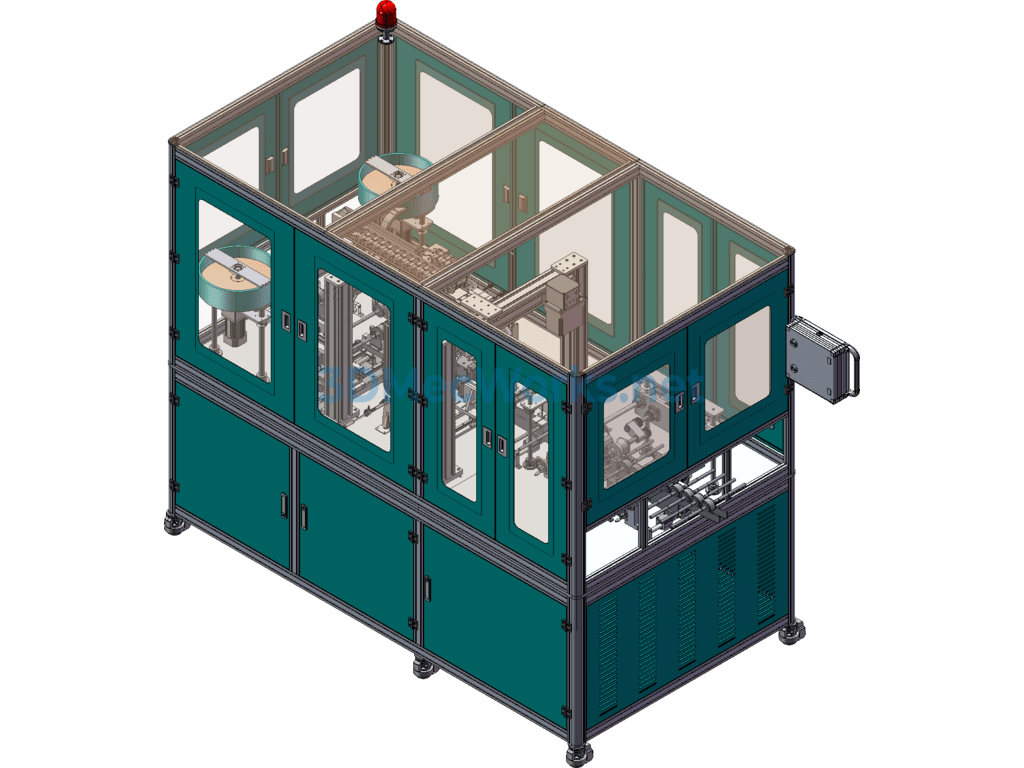

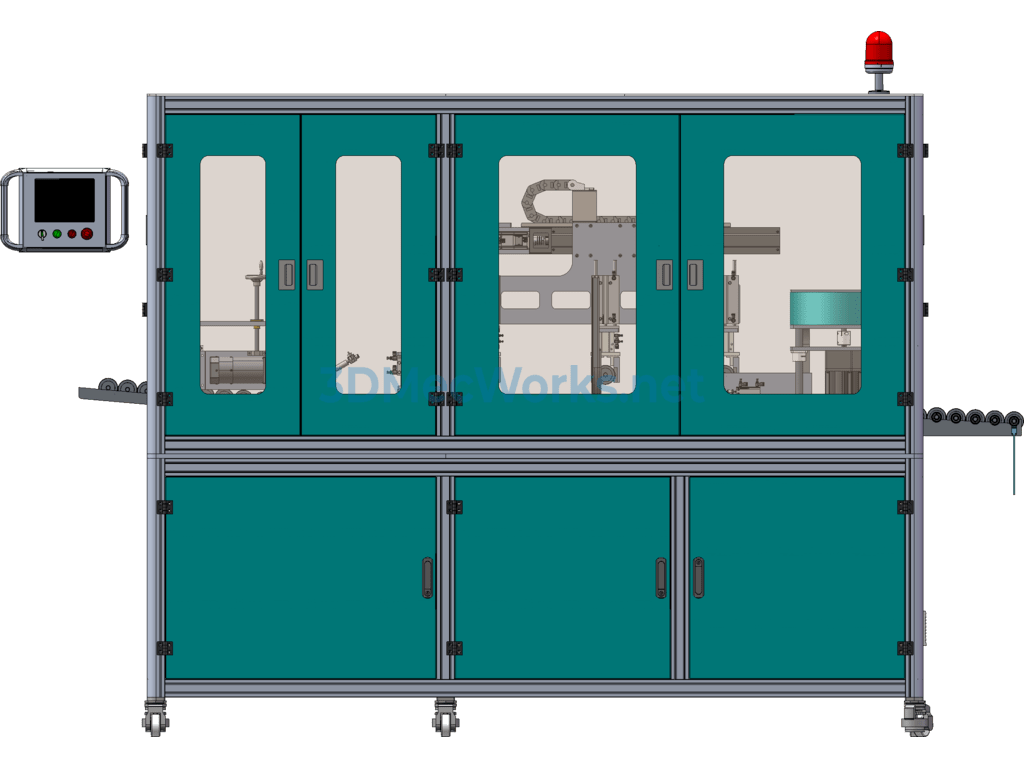

This set of models is for a dual-bearing rotor assembly equipment for duct motors, including rotor oiling, rotor bearing position circlip installation (circlip detection), and servo bearing pressing. The rotor enters the machine through the feeding chute, where the proximity switch fork mechanism is triggered. The lifting mechanism then elevates the rotor to the oiling roller for oil application. Afterward, it moves to the circlip station via the discharge chute. The transfer mechanism feeds the rotor to the circlip fixture, and after circlip assembly, it moves to the pressing mechanism. Bearings are fed using a disc feeder. After the bearing pressing is completed, the rotor enters the discharge chute. The file also includes formats such as step/x_t/igs/easm for easy download and use.

Specification: Double-Axial Extension Rotor Assembly Machine, Air Duct Motor Double Bearing Rotor Assembly Machine

|

User Reviews

Be the first to review “Double-Axial Extension Rotor Assembly Machine, Air Duct Motor Double Bearing Rotor Assembly Machine”

You must be logged in to post a review.

There are no reviews yet.