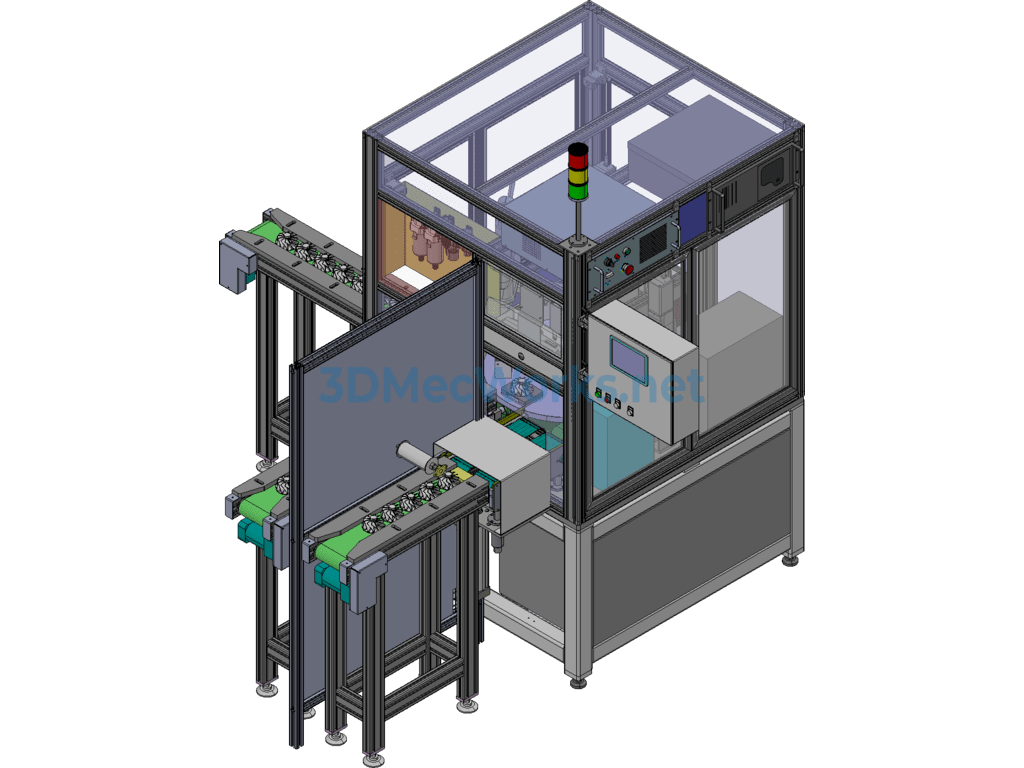

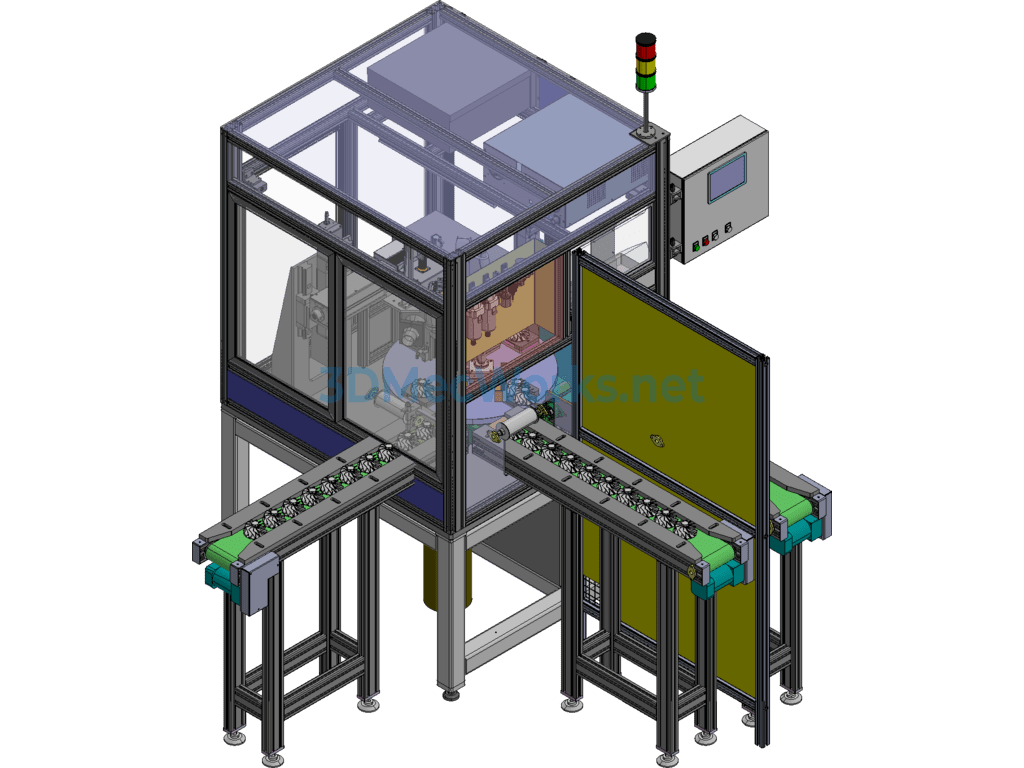

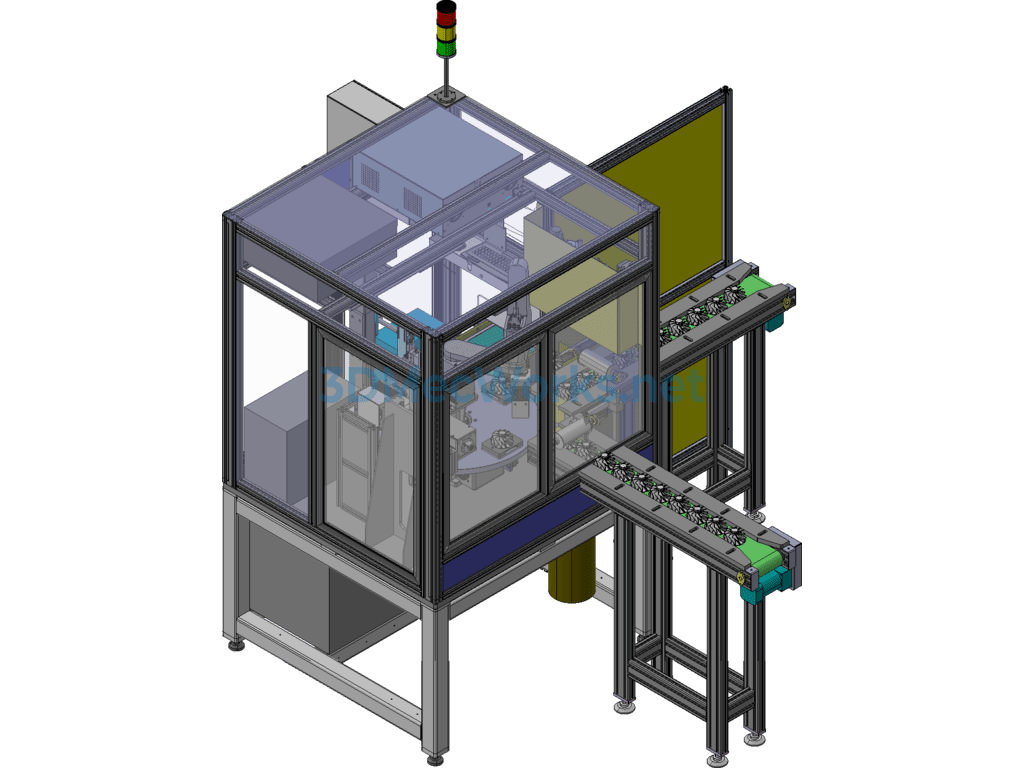

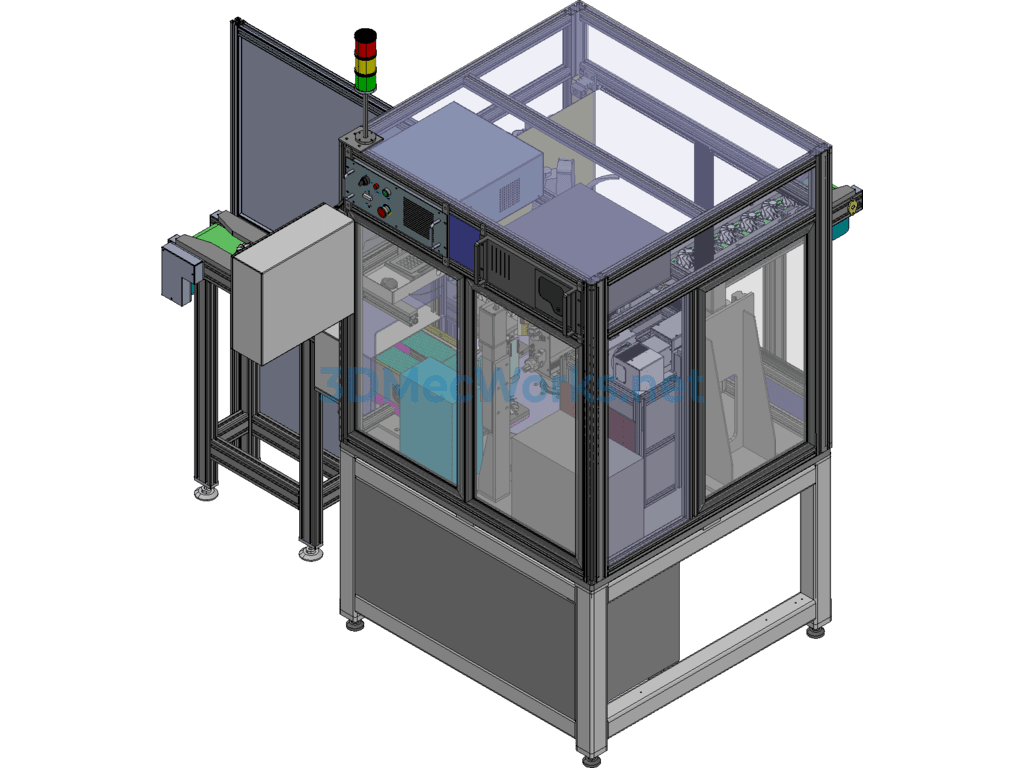

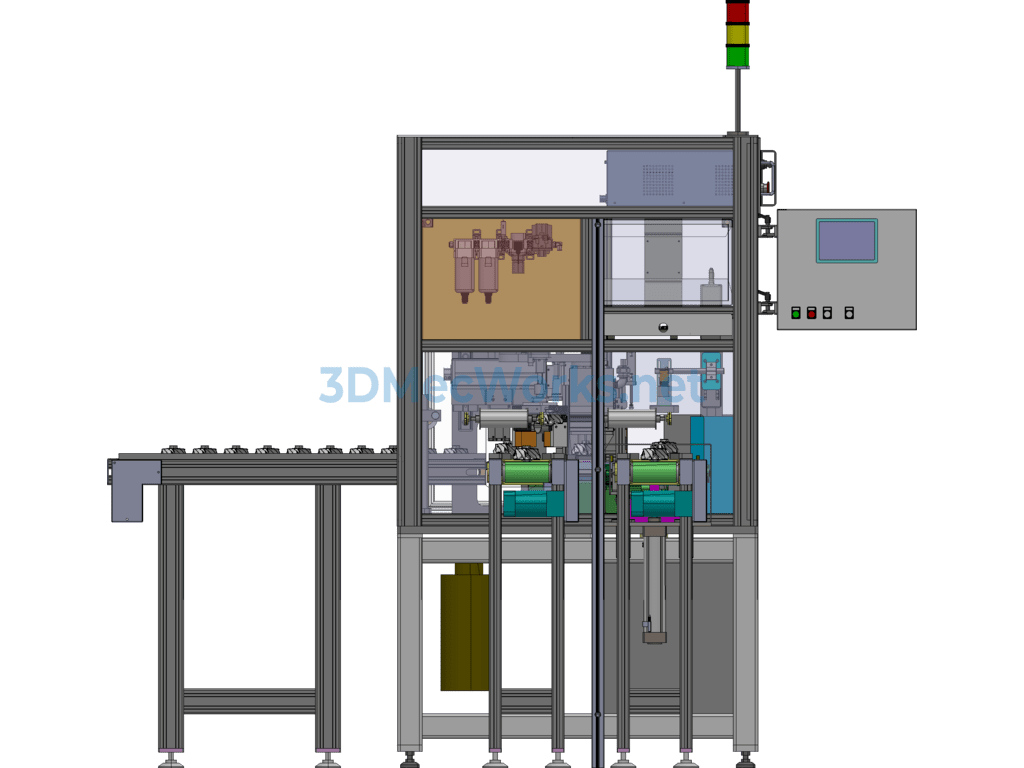

The overall style of the non-standard automation marking and inspection machine is in the form of a four-station turntable, including:

Automatic feeding station

Laser marking station

Barcode scanning inspection station

Inkjet marking station

Employees, according to production needs, select tooling that matches the model of the workpiece, manually adjust the gap between the nylon guide bars on the feeding line, input the product model and batch number, and after confirmation, the electric cylinder operates, adjusting the marking machine and QR code inspection camera to the corresponding height. Subsequently, the workpiece is placed on the feeding conveyor line; after the workpiece is in position, the robot grabs the workpiece, moves it above the bottom surface inspection camera to hover, performs defect detection, and if the inspection is qualified, it automatically feeds to the turntable tooling. If the inspection is not qualified, it is directly placed in the defective product buffer zone.

Specification: Automatic Marking and Inspection Machine Platform

|

User Reviews

Be the first to review “Automatic Marking and Inspection Machine Platform”

You must be logged in to post a review.

There are no reviews yet.