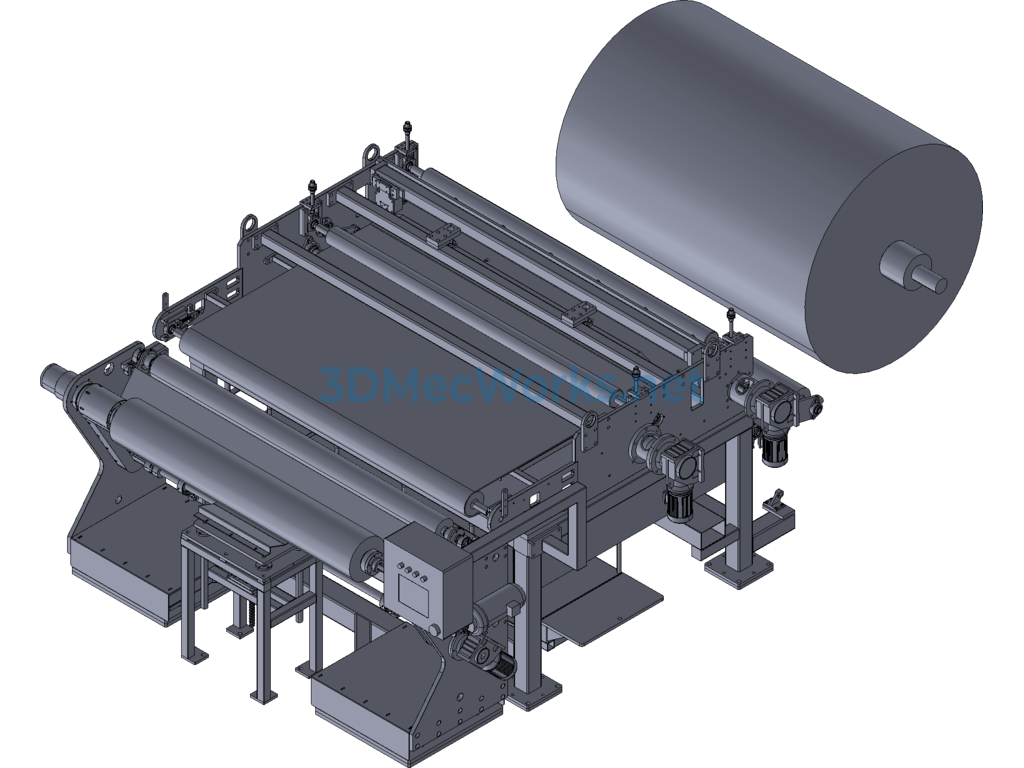

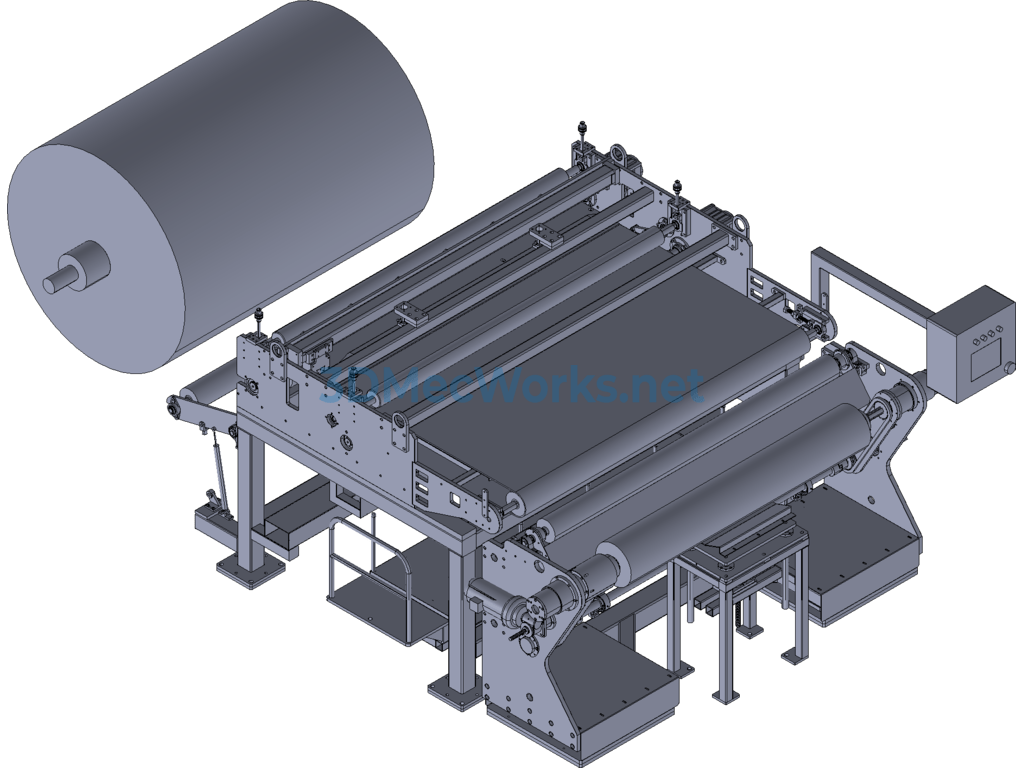

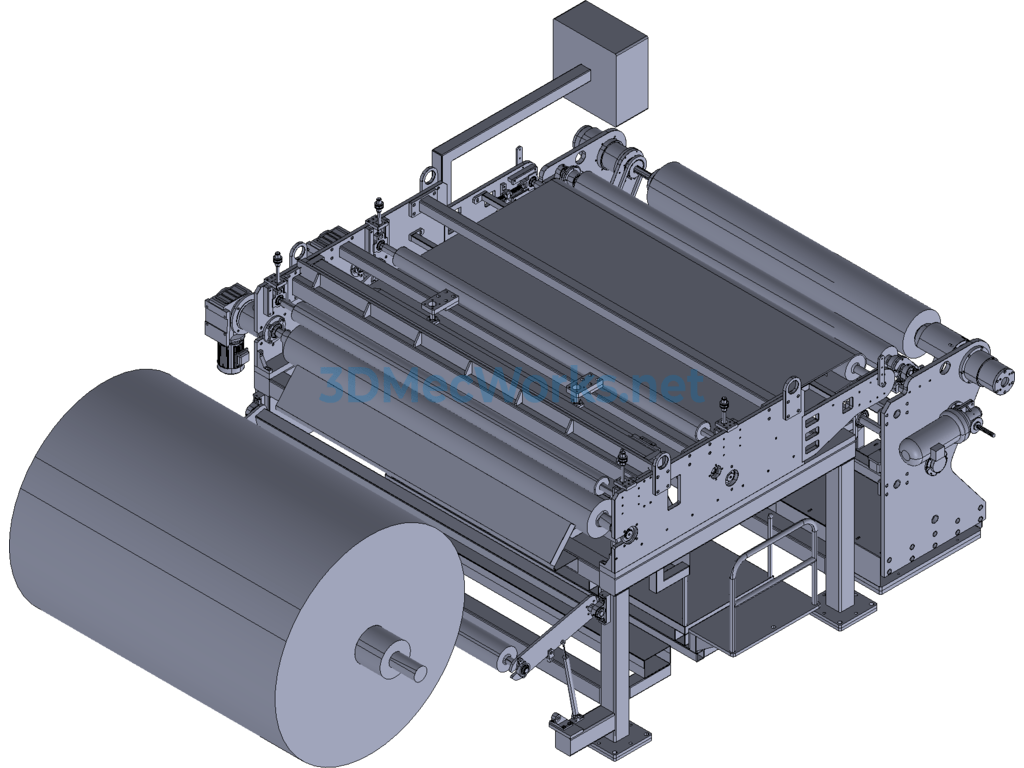

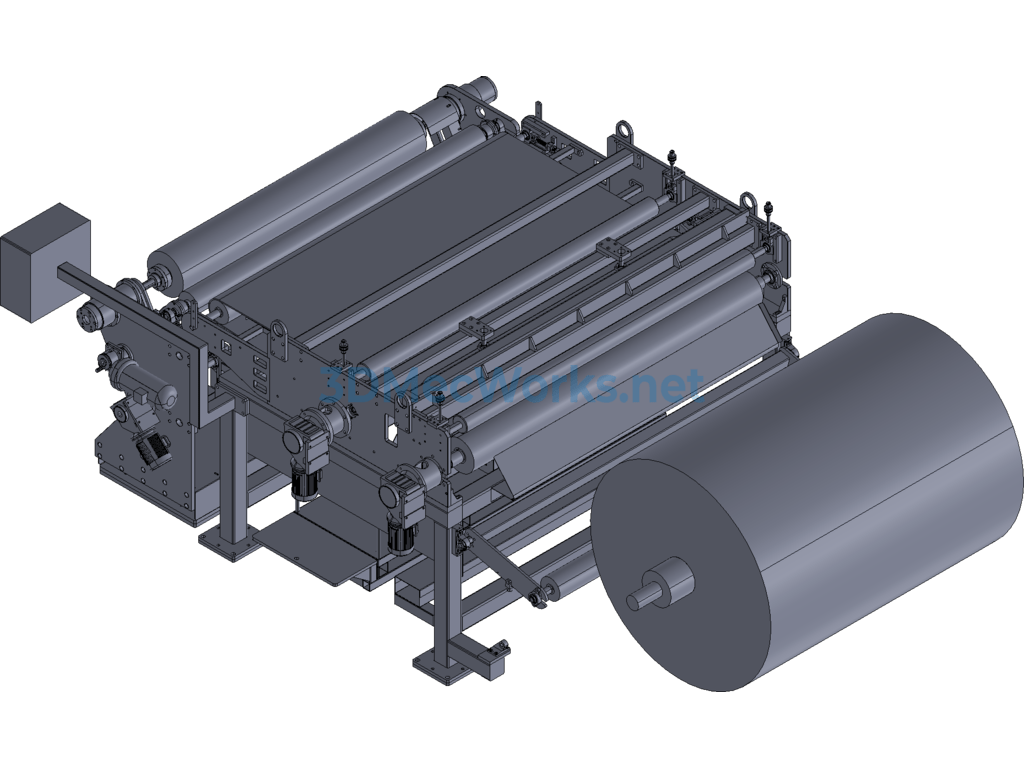

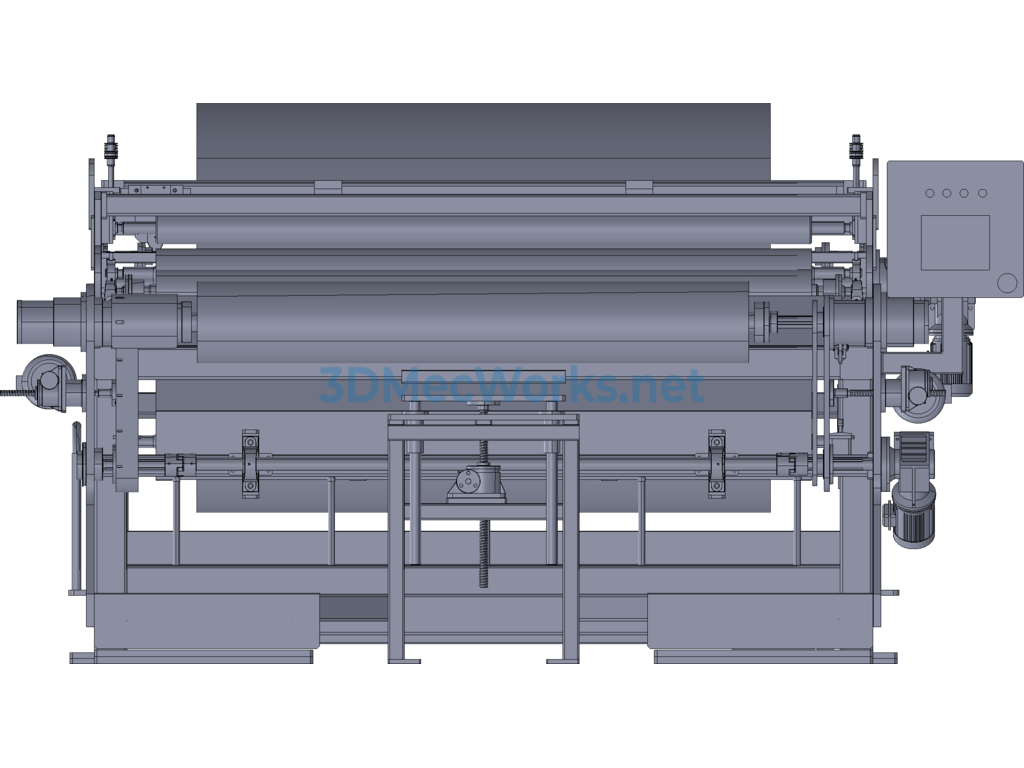

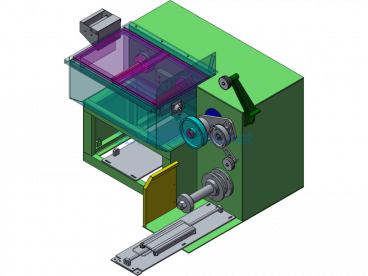

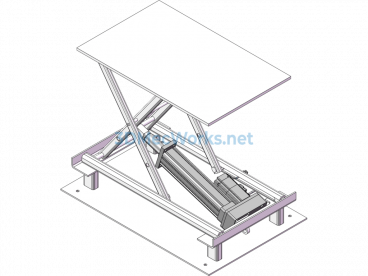

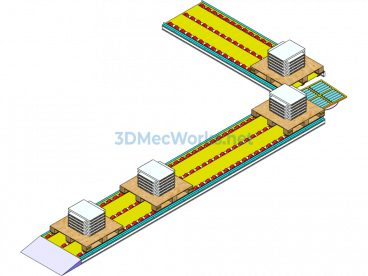

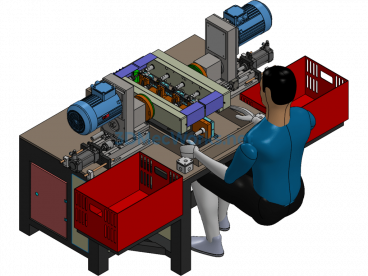

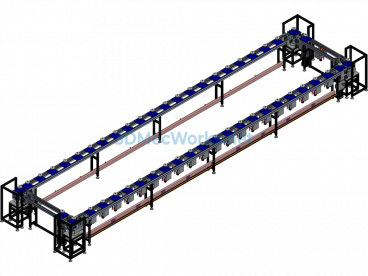

PVC flooring paper slitting equipment, mainly used for slitting PVC flooring paper. It divides the large roll of PVC flooring paper produced into several different small rolls according to customer demand and transportation requirements, thus facilitating transport and handling. Includes frame, wind-up machine, turning arm, front traction fixing roller, front tension roller, front pressure roller, front slide rail, front pressure cylinder, rodless cylinder, cutting knife, and cutting beam, with a pressure beam on the frame behind the cutting beam. The pressure beam has a pressure cylinder and a pressure body. The frame directly below the pressure body has a support plate, and the frame behind the support plate has a driving pulley roller. The end of the frame has a driven pulley roller, and a transmission belt is connected between the driven pulley roller and the driving pulley roller. The frame has a pulley motor and a front traction motor. This utility model achieves tensioning of PVC flooring paper through the front tension roller, cutting through the rodless cylinder, featuring a simple structure. The pressure plate helps ensure surface tension of PVC during cutting, making the cut more uniform. The transmission belt facilitates threading of PVC flooring paper, offering higher safety and enabling automated control.

There are no reviews yet.