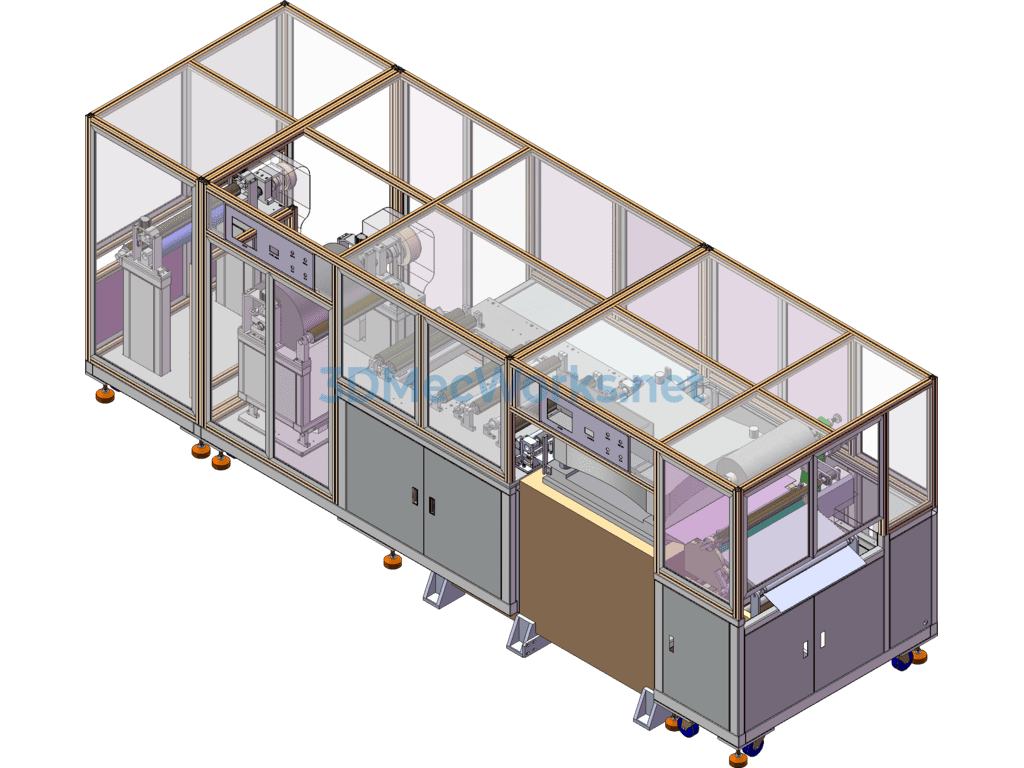

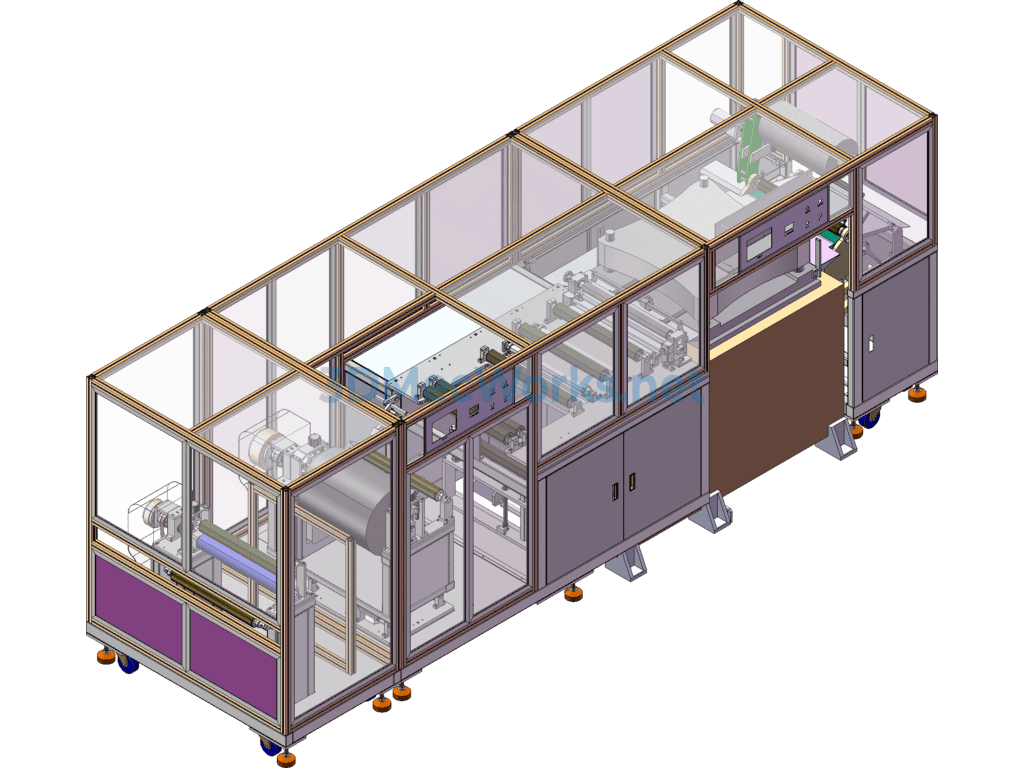

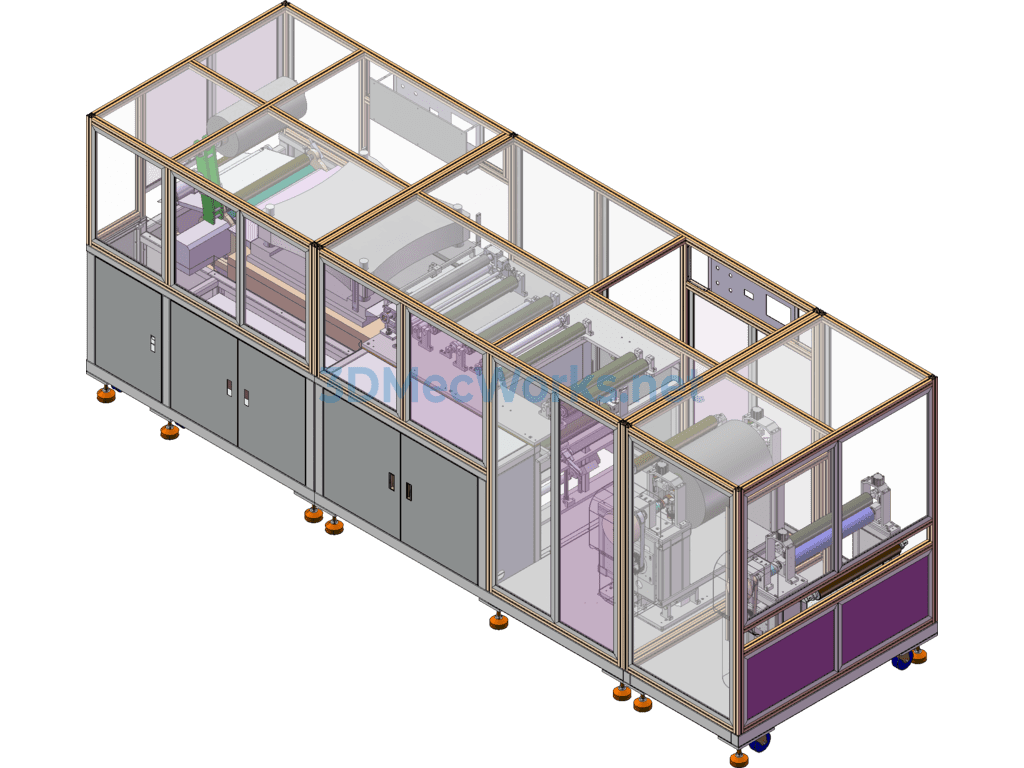

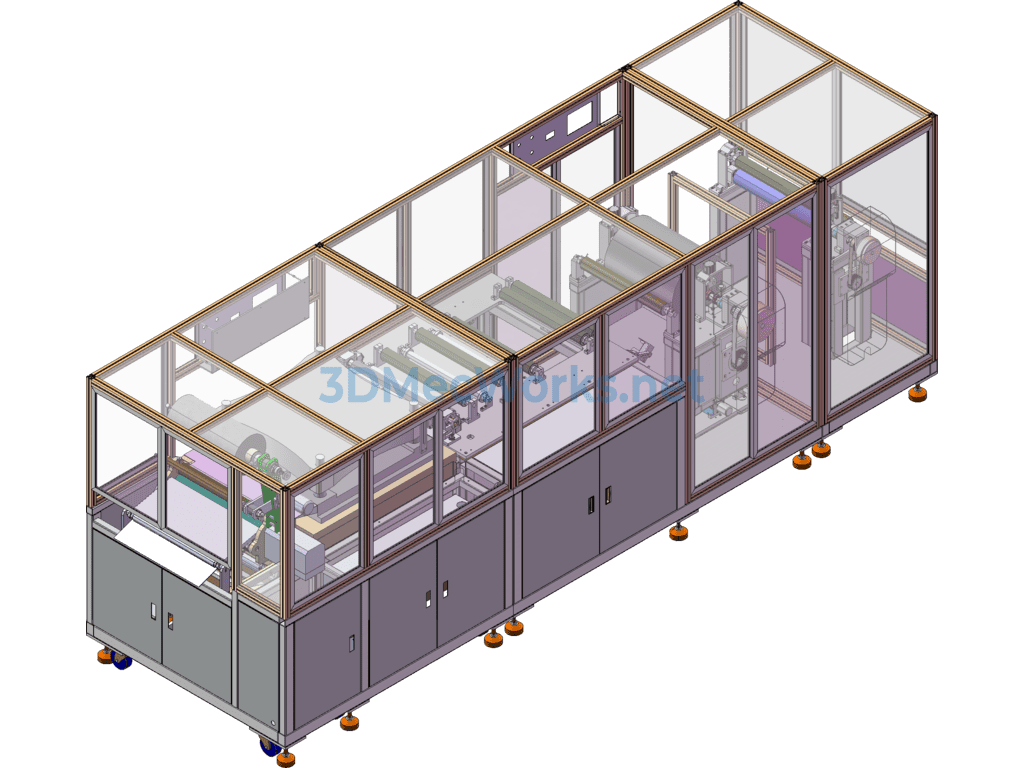

1. Applicable to the automatic sheet forming of coating and rolling the pole pieces in the gaps of lithium batteries.

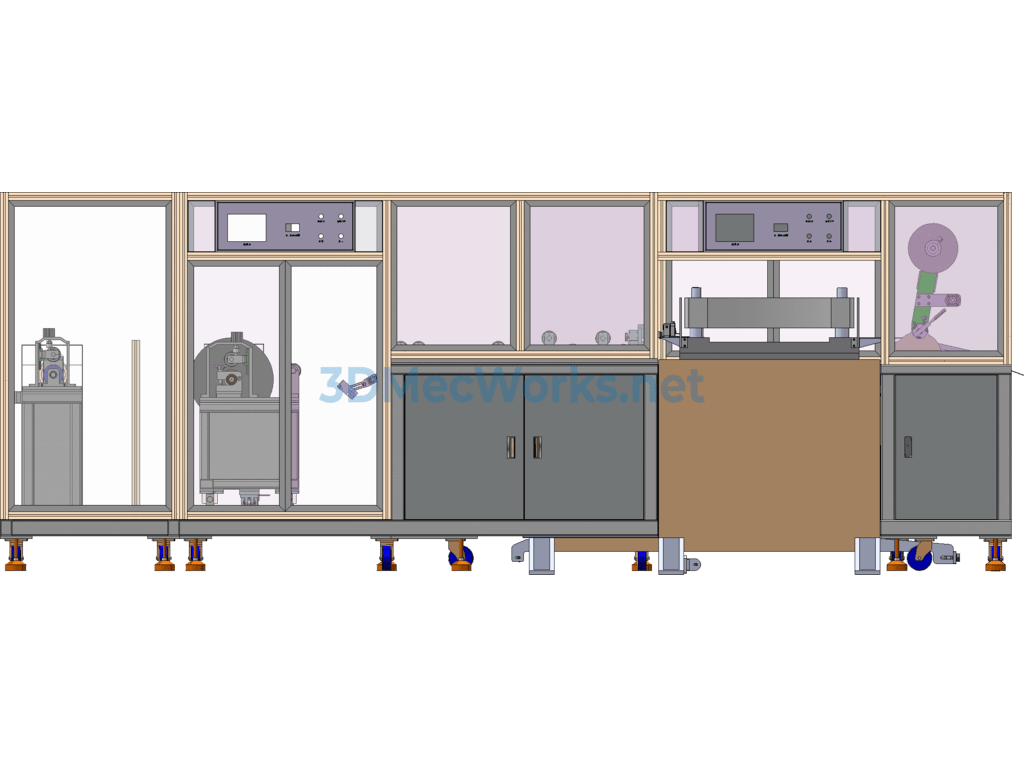

2. The roll material of pole pieces is actively unwound and corrected for deflection through the unwinding mechanism. It goes through the tension section, aligns with the cyclic carrier belt, and is fed into the die cutting mechanism by a servo-driven traction roller. The die cutting mechanism uses a laser knife mold to cut and form the incoming pole pieces. The carrier belt sends the formed pieces to the collection platform, and edge waste is automatically rolled up. Manual collection of pole pieces is required.

3. The unwinding device adopts magnetic powder tension adjustment, allowing for free and convenient adjustment of unwinding tension.

4. The feeding side uses an imported electric eye for deflection tracking, achieving a deflection correction accuracy of ±0.15mm.

5. For the carrier belt feeding, synchronous control is achieved with an input and traction servo motor to ensure the accuracy and stability of each feeding length.

6. The carrier belt can work in a cycle to reduce material consumption (Note: the working life of the carrier belt is approximately 10,000 cuts).

7. The die cutting uses electromagnetic force to transmit power, without using compressed air, saving air source consumption and reducing noise in the working environment, particularly suitable for cleanroom environmental requirements.

8. The main cutting machine adopts a mature machine base, stable and reliable.

There are no reviews yet.