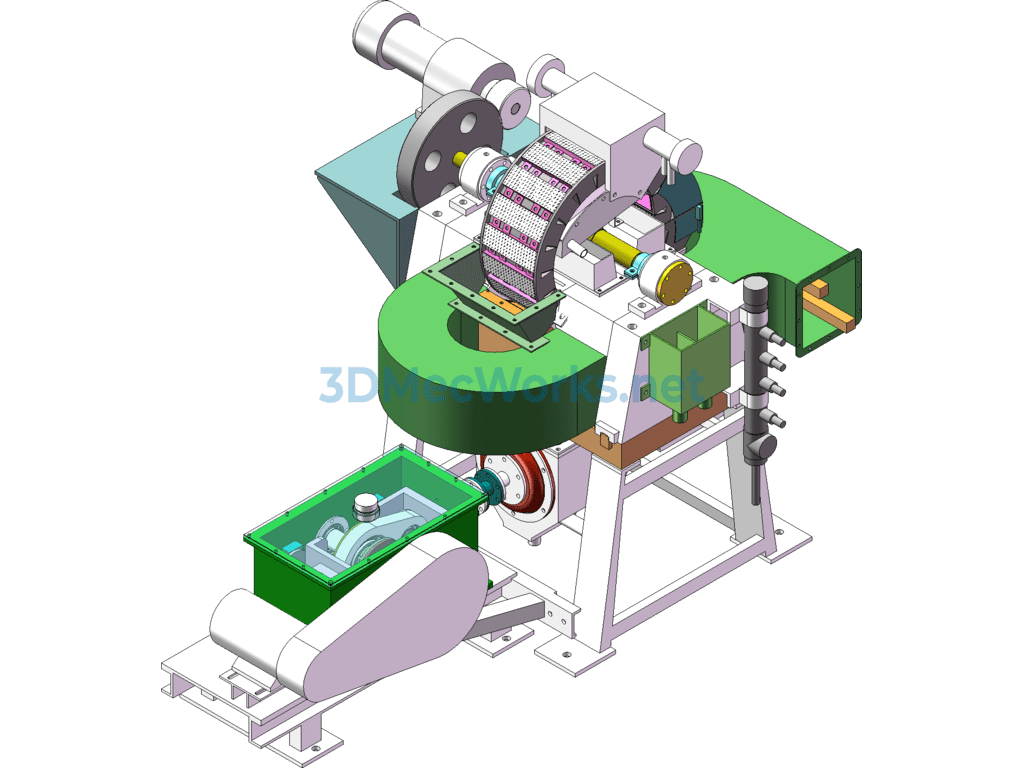

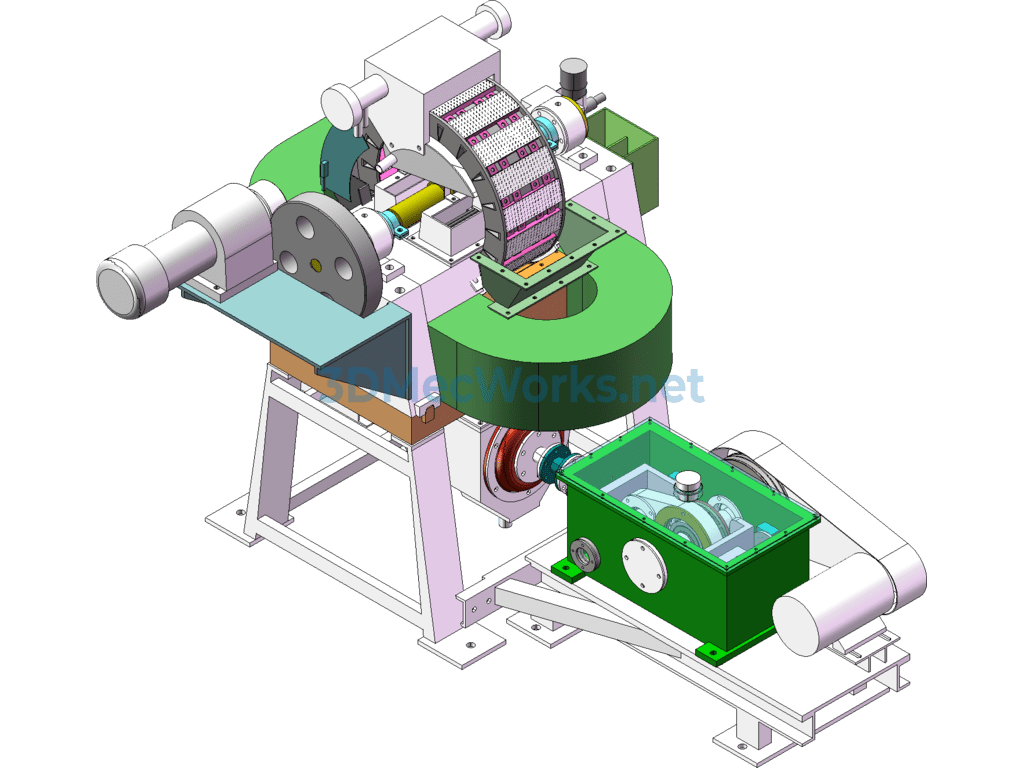

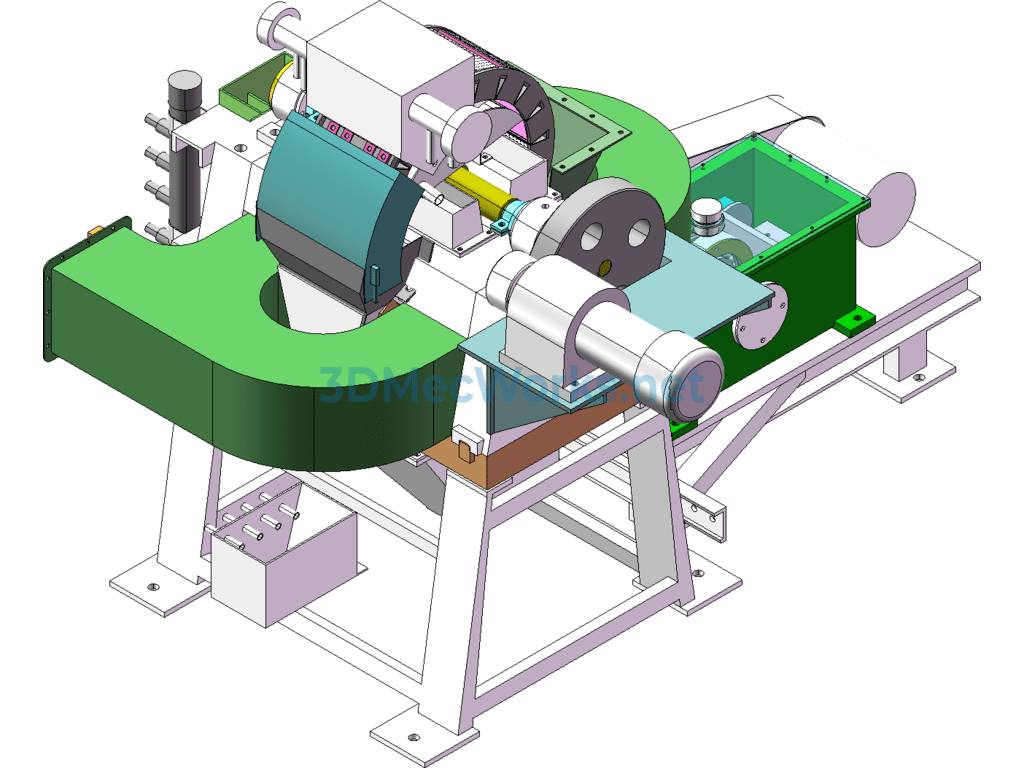

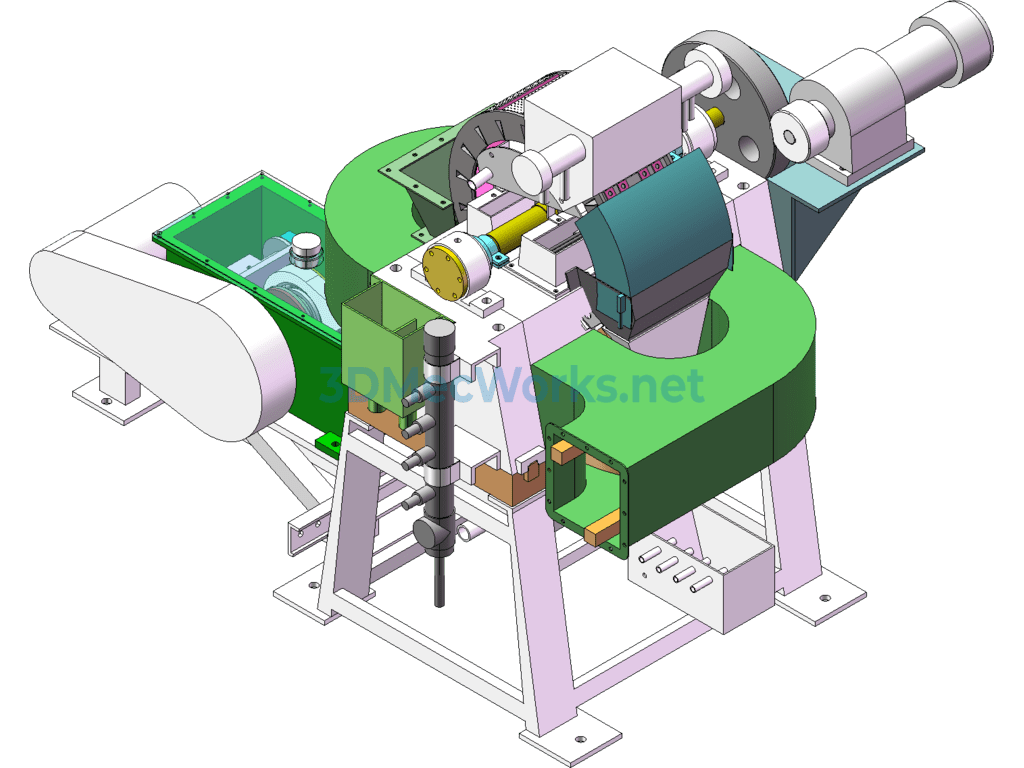

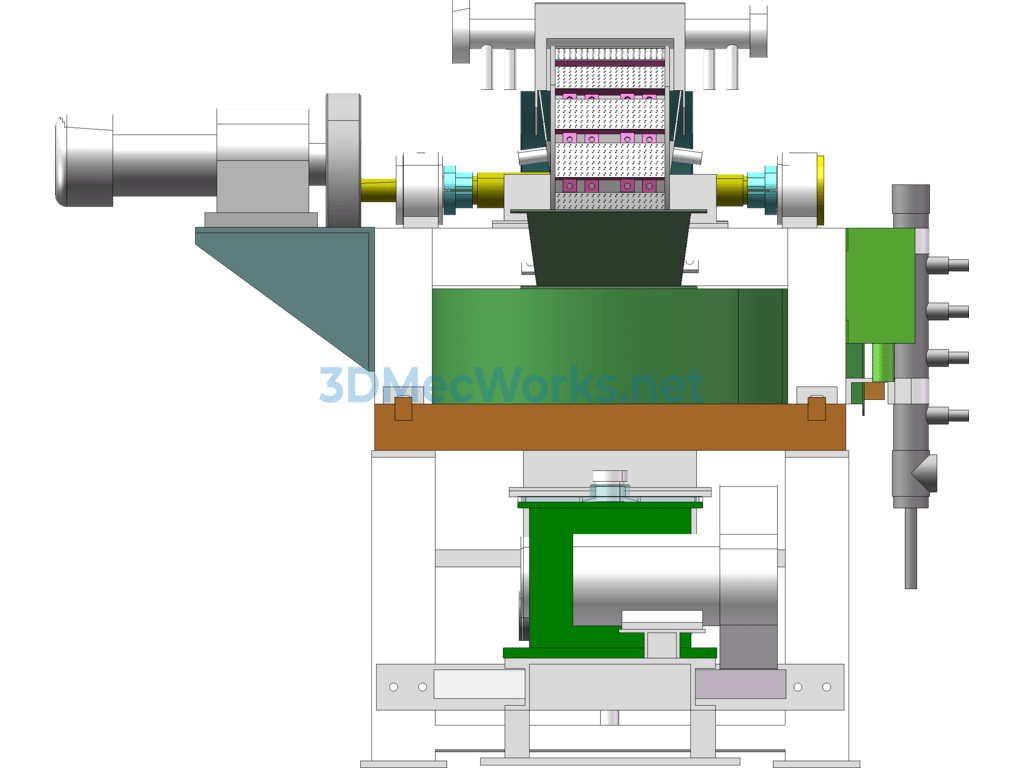

The magnetic separator is a sorting device used for removing iron powder from powdery particles for recycling. After the slurry flows into the tank through the ore feeding box, under the action of the water flow from the ore feeding water pipe, the ore particles enter the ore feeding area of the tank in a loose state. Under the influence of the magnetic field, magnetic ore particles form “magnetic flocs” or “magnetic chains,” which are then moved towards the magnetic poles due to the magnetic force, and are adsorbed onto the drum. Since the polarity of the magnetic poles alternates along the drum’s rotation direction and remains stationary during operation, “magnetic flocs” or “magnetic chains” are subject to magnetic stirring because of the alternating magnetic poles as the drum rotates. The gangue and other non-magnetic minerals mixed in the “magnetic flocs” or “magnetic chains” fall off during the stirring. Finally, the “magnetic flocs” or “magnetic chains” adsorbed on the drum’s surface are the concentrate.

Specification: High Gradient Magnetic Separator

|

User Reviews

Be the first to review “High Gradient Magnetic Separator”

You must be logged in to post a review.

There are no reviews yet.